Professional Documents

Culture Documents

Mountain View Community Centre Tender

Uploaded by

Dean KoortzenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mountain View Community Centre Tender

Uploaded by

Dean KoortzenCopyright:

Available Formats

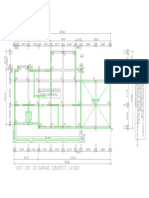

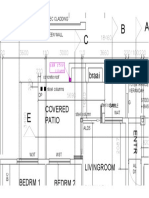

KOUKAMMA MUNICIPALITY MOUNTAIN VIEW MULTIPURPOSE COMMUNITY CENTRE

ITEM No.

PAY

REF

DESCRIPTION

PRICING DATA

UNIT

QTY

RATE

AMOUNT

SECTION F : BUILDING WORKS

NOTE: Section F : Building have been measured in

accordance with the "Standard System of Measuring

Builders Work 1999 (Sixth Edition - Revised)" as issued

by the Association of South African Quantity Surveyors

F1

PSBA

BRICKWORK

F1.1

Brickwork of NFP bricks (7 MPa nominal compressive

strength) in class II mortar including all ties:

F1.1.1

Half brick walls with 75 mm wide brick reinforcement every

fourth course

m2

100

One brick walls with 150 mm wide brick reinforcement every

fourth course

m2

80

245 mm Hollow walls of two one brick skins with expansion

joints between skins

m2

50

270 mm Hollow walls of two one brick skins with expansion

joints between skins

m2

650

405 mm Hollow walls of one half brick skin and one one brick

wall with expansion joints between skins

m2

100

F1.1.2

F1.1.3

B2.2

F1.1.4

B2.2.1

F1.1.5

F2.1

BRICKWORK SUNDRIES

F2.1.1

Splayed mortar fillet one course high in cavity

530

F2.1.2

Closing cavity of hollow wall vertically with brickwork half

brick

wide

200

Closing cavity of hollow wall horizontally with brickwork half

brick wide

245

Expansion joints with "Sondor Jointex" between vertical

brickwork surface:

45

F2.1.3

F2.1.4

F2.2

Prestressed fabricated lintels:

F2.2.1

110 x 70 mm Lintels in lengths exceeding 3 m

16

F2.2.2

110 x 170 mm Lintels in lengths not exceeding 3 m

275

F2.3

Brickwork reinforcement:

F2.3.1

75 mm Wide reinforcement built in horizontally

12 550

F2.3.2

150 mm Wide reinforcement built in horizontally

1 240

F2.4

Galvanised hoop iron cramps, ties, etc:

F2.4.1

30 x 1.6 mm Wall tie 500 mm long with one end built into

brickwork and the other shot fired to concrete support

No

30

30 x 1.6 mm Roof tie 750 mm long with one end fixed to

timber and other end built into brickwork

No

120

No

20

F2.4.2

F2.5

Air bricks etc:

F2.5.1

230 x 160 Clay vermin proof air bricks

Carried forward /

TENDER NO. 09/2013

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

m2

875

m2

265

Brought forward /

F3

FACE BRICKWORK

"Corobrick Firelight Travertine" face bricks pointed with

recessed horizontal and vertical joints:

F3.1

Extra over brickwork for face brickwork

F4

DAMPROOFING OF WALLS AND FLOORS

F4.1

One layer 375 micron "Consol plastics brickgrip DPC

embossed damp proof course in walls

F5

JOINT SEALANTS ETC

Clear Neutral silicone sealant:

F5.1

F6

In joint sealing and pointing all round external window and

door frames

365

ROOF COVERINGS ETC

PROFILED METAL SHEETING AND ACCESSORIES

0.47 mm "Safintra Klip-Lok" profiled galvanised sheet

steel with "Dune" finish on one side and a coat of off

white backer to the reverse; in single lengths fixed to

timber purlins; including all trims, flashings, closers and

the like with "Dune" finish on one side; all in accordance

with the manufacturers specification and instruction:

F6.1

Roof covering with pitch not exceeding 25 degrees

F6.2

EO for fixing in a vertical position; including all framework

F7

ROOF INSULATION

F7.1

"Alucushion" heavy grade bubblefoil insulation laid taut over

purlins and fixed concurrent with roof covering including

galvanised steel straining wires

F7.2

CARPENTRY AND JOINERY

SUPPLEMENTARY PREAMBLES

Fixing

Items described and "nailed" shall be deemed to be fixed

with hardened steel nails or shot pins to brickwork or

concrete

Sizes

The Contractor shall make allowance in his prices for minor

variances in stated finished sizes of timber doors, door

members, door frames, architraves, etc., which are to match

existing

Wrought timber

The specified sizes of wrought timbers are the nett finished

sizes as required and the Contractor is to make such

allowance for wrought faces as he deems necessary.

Carried forward /

m2

760

20

m2

780

m

RATE

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

Brought forward /

Prices:

Prices for all joinery work are to include for general framing,

housing and notching, arris rounded angles, gluing, blocking,

planting on, screwing, adhesives, dowels, pellets, cross

tounges, screws, hangers and nails and setting up complete

and also for all square cutting and waste. Tops shall be

secured with metal or hardwood buttons.

ROOFS, ETC

Sawn softwood:

F7.2.1

38 x 114 mm Wall plate

110

F7.2.2

50 x 75 mm Battens

805

F7.2.3

50 x 76 mm Cross bracing

155

F7.2.4

38 x 50 mm Splayed eaves beam

110

305

Wrought softwood:

F7.2.5

Rafters; including treatment to ends and dpc sock all as specifi

F8

ROOF TRUSSES

The pre-fabricated timber roof trusses shall be designed by a

registered professional engineer and shall be in accordance

with SABS 0160 and 0163

Plate nailed timber roof truss construction:

The following is applicable in respect of pre-fabricated timber

roof trusses:

Trusses are at a maximum of 1 200 mm centres

Ceilings are 6,5 mm gypsum board with plastered joints on 38

x 50 mm brandering at 400 mm centres in on direction

The roof truss prices must include for all temporary bracing as

required to ensure a stable construction

The dimensions in the descriptions of the trusses are

nominal and actual measurements are to be obtained from

the representative/agent and/or the site before design or

fabrication commences

Prices must include for manufacturing, transport, storage,

hoisting and complete fixing in position including all necessary

temporary timber stiffeners, steel supports, truss hangers, etc.

as well as cutting to accurate lengths at eaves, ridges, hips,

valleys, notching, etc (roof bracing and roof truss anchors

elsewhere), all executed in accordance with manufacturer's

installation specification

The span of the roof trusses are measured between external

edges of the wall plates

The roof overhang of the trusses are measured from the

external edge of the wall plate to the back of the fascias

Carried forward /

RATE

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

No

25

Hoist and fix into position mono pitched pre-fabricated roof

trusses spanning approximately 8 000 mm with a height of 1

300mm; as per drawings and specification; including all

fixings; bracing; hoop iron; hurricane clips; and the like

No

Hoist and fix into position mono pitched pre-fabricated roof

trusses spanning approximately 3 800 mm with a height of 1

200mm; as per drawings and specification; including all

fixings; bracing; hoop iron; hurricane clips; and the like

No

25

m2

65

135

220

220

No

No

No

No

Brought forward /

Wrought softwood pre-fabricated roof trusses as

described:

F8.1

F8.2

F8.3

Hoist and fix into position double pitched pre-fabricated roof

trusses spanning approximately 13 000 mm with a height of

2 700mm; as per drawings and specification; including all

fixings; bracing; hoop iron; hurricane clips; and the like

EAVES, VERGES, ETC.

Everite Nutec fibre cement:

Eaves soffit covering ne 600 mm wide of 4 mm thick sheets

fixed to existing brandering along edges and at 450 mm

centres across sheets; including all quadrants, half rounds

and the like

F8.3.1

F8.4

12 x 300 mm Fascias and barge boards including galvanised

steel H-profile jointing strips and three times countersunk

drilled at not exceeding 1 050 mm centres for and screwed to

fascia battens or rafters with brass screws

SKIRTINGS

Wrought meranti:

F8.4.1

19 x 69 mm Skirting plugged to

F8.4.2

brickwork 19 mm Quadrant fixed to

F9

skirting DOORS, ETC.

F9.1

"Swartland" 813 x 2032 x 40 mm Semi-solid SA Pine core

flush panel door with matching edging strips and standard

3.2 mm hardboard covering on both sides including all

ironmongery, furniture and finish; as per the schedule (D02)

F9.1.1

Ditto; but 813 x 1900 x 40 mm (D04)

F9.1.2

"Swartland" 900 x 2032 x 40 mm Solid SA Pine core flush

panel door with matching edging strips and standard 3.2 mm

hardboard covering on both sides including all ironmongery,

furniture and finish; as per the schedule (D03)

F9.1.3

"Swartland" Double door formed of two 807 x 2032 x 44 mm

Meranti FLBB door (SD20/1612) with 76 x 32 mm splayed

weatherboard including all ironmongery, glazing, furniture and

finish; as per the schedules (D05)

Carried forward /

RATE

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

No

No

m2

520

m2

120

Brought forward /

F9.1.4

F9.2

F9.2.1

F10

"Swartland" Double door formed of two 807 x 2032 x 44 mm

Meranti FLBB door with 44 x 108 mm top rail and styles, 22 x

108 mm braces twice screwed to boarding with countersunk

brass screws, 22 x 222 mm bottom rail and 22 x 70 mm T&G

V-jointed boarding including all ironmongery, furniture and

finish; as per the schedules (D01)

FRAMES, ETC

"Swartland" wrought meranti frames formed of 100 x 69 mm

frame with sill for door 1613 x 2032 mm high (D01 & D05)

CEILINGS AND PARTITIONS

NAILED UP CEILINGS

F10.1

40 mm Thick Isoboard high density polystyrene closed cell

insulation board with groove finish including 38 x 50 mm

sawn softwood brandering at 700 mm centres in one

direction fixed to underside of trusses with adhesive at 200

mm centres; edge fixed with concealed ceiling clips screwed

to brandering (ref 5.2)

Gypsum plasterboard with 63 mm wide strips of mesh

scrim nailed over joints and the whole finished with

gypsum skim plaster trowelled to a smooth polished

surface to the thickness recommended by the

manufacturer:

F10.2

F10.3

6,4 mm Ceilings including 38 x 50 mm sawn softwood

brandering at 400 mm centres in one direction nailed to

underside of timber roof rafters

Extra over ceiling for 600 x 600 mm trap door of 50 x 50 mm

wrought softwood rebated framing with one 38 x 38 mm

sawn softwood cross brander covered with ceiling board and

fitted flush in opening with 8 x 40 mm wrought meranti flat

strips fixed to ceiling timber all round

F10.4

Gypsum plasterboard cornices:

F10.4.1

70 mm Coved cornices (ref 4.1)

F10.4.2

22 x 44 mm COL timbers shadow line cornice fixed to wall (ref

4.2)

F11

FLOOR COVERINGS, WALL LININGS, ETC

F11.1

SUPPLEMENTARY PREAMBLES

All materials shall be in colours to be selected by the

representative or agent and, where applicable, laid to

approved patterns.

Carried forward /

No

160

150

RATE

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

m2

490

Brought forward /

MARMOLEUM FLOOR COVERING

2.5 X 2 mm wide Floorworx Forbo Marmoleum Fresco

Topshield supplied and installed in accordance with the

specification and by approved specialists:

F11.1.1

On floors in patterns

F11.1.2

EO for 2 tint

F11.1.3

EO for stairs

F11.1.4

F11.2

EO for Floorworx extruda MSN 120 stair nosings

IRONMONGERY

m2

100

3

m2

12

Note - All door ironmongery not specifically listed here is

deemed to be included in the door description

LETTERS, NAMEPLATES, ETC

F11.2.1

F11.2.2

150 x 150mm AL 5022 -E01 plate with electrical symbol

No

75 x 150mm AL 5022 -E10/E11 AS male or female symbol

No

F11.2.3

F11.2.4

F11.2.5

F11.2.6

38mm High plastic letter or numeral

No

No

1

10

No

10mm x 100mm High thick perspex plate with 8 engraved and

painted letters or numerals

F12

BATHROOM FITTINGS

F12.1

F12.2

W & B Hardware theft proof toilet roll holder code 2798

"Franke" stratos paper towel dispenser code STRX600

F12.3

"Franke" stratos soap dispenser code STRX618

F12.4

150 x 150mm AL 5022 -E02 plate with tea cup symbol

150 x 150mm AL 5022 -E14 with paraplegic symbol

"Franke" waste bin code STRX605

5

No

8

No

No

No

8

8

4

No

F12.5

F12.6

F12.7

"Charman Industries" code SR1 satin polished stainless steel

grabrail plugged

"Charman Industries" code DL3 stainless steel grabrail

plugged

No

No

450 x 600 x 1.6 mm Reflective polished stainless steel mirrors

8

No

Carried forward /

RATE

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

Frame for door size 813 x 2 032 mm high in 270 mm cavity

wall (D02&3)

No

10

Frame for door size 813 x 1 900 mm high in 110 mm wall

(D04)

No

Brought forward /

F13

METALWORK

GALVANISED PRESSED STEEL DOOR FRAME

1.6 mm Double rebated frames; including all hinges,

striking plate, rubber buffers, fixing lugs and the like; all

in accordance with the door schedule

F13.1

F13.2

F14

POWDER COATED ALUMINIUM WINDOWS

F14.1

3 300 x 2 125 mm NUKLIP window frame coupled with

approved butterfly gasket, wedge, packing piece, mullions as per manufacturers specifications; complete with all

ironmongery and glazing; all in accordance and as described

in the window schedule (Type W1)

No

F14.2

Ditto; but 2 500 x 390 mm (Type W2)

No

F14.3

Ditto; but 2 700 x 2 125 mm (Type W5)

No

F14.4

Ditto; but 300 x 2 125 mm (Type W7)

No

F14.5

1 230 x 1 060 mm TECHNAL window frame coupled with

approved butterfly gasket, mullions, wedge, packing piece as per manufacturers specifications; complete with all

ironmongery and glazing;all in accordance and as described

in the window schedule (Type W8)

No

590 x 590 mm BETCRETE polycrete window frame

complete with aluminium opening casement inserts coupled

with approved butterfly gasket, wedge, woolpile and finseal,

sill - as per manufactures specifications; complete with all

ironmongery and glazing; all in accordance and as described

in the window schedule (Type W3)

No

11

F14.7

Ditto; but 1 790 x 1 190 mm (Type W11)

No

F14.8

Ditto; but 1 790 x 590 mm (Type W6)

No

F14.9

800 x 800 x 300 mm WINBLOK concrete surround window

frame complete with aluminium opening casement inserts

coupled with approved butterfly gasket, wedge, woolpile and

finseal - as per manufactures specifications (code:

WB66/260) complete with all ironmongery and glazing; all in

accordance and as described in the window schedule (Type

W4)

No

38

F14.10

Ditto; but 400 x 400 x 300 mm (Type W9)

No

10

F14.11

Ditto; with fixed aluminium louver (Type W10)

No

F15

ROLLER SHUTTERS, ETC

F15.1

Allow the PC amount of R5 000 for a high security screen

door

Item

Allow the PC amount of R4 500 for kitchen hatch

Item

F14.6

F15.2

Carried forward /

RATE

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

m2

775

Brought forward /

F16

PLASTERING

INTERNAL PLASTER

Cement plaster on brickwork:

F16.1

On walls including narrow widths

EXTERNAL PLASTER

Cement plaster on brickwork:

F16.2

On walls including narrow widths

m2

290

F16.2

Splayed plaster; approximately 140 mm wide

50

F17

TILING

F17.1

FLOOR TILING

F17.1.1

300 x 300 x 5 mm First grade non-slip porcelain tiles (PC

amount R200/m2) fixed with tile adhesive; all as per

specification (ref 1.1)

F17.1.2

EO for 150 x 300 mm skirting (ref 2.2)

F17.2

WALL TILING

F17.2.1

300 x 300 x 5 mm First grade non-slip porcelain tiles (PC

amount R200/m2) fixed with tile adhesive; all as per

specification (ref 3.2 note)

F17.2.2

m2

m

m2

200 x 200 x 5 mm First grade white glazed ceramic tiles fixed

with tile adhesive; all as per specification (ref 3.2 note)

m2

F18

PAINTWORK

F18.1

ON INTERNAL PLASTERED SURFACES

F18.1.1

One coat Plascon plaster primer and two coats Plascon

superior low sheen paint (ref 3.1)

F18.1.2

One coat Plascon plaster primer and two coats Plascon

kitchen and bathroom paint (ref 3.2)

F18.2

ON EXTERNAL PLASTERED SURFACES

F18.2.1

One coat Plascon plaster primer and two coats Plascon

superior paint

F18.3

ON FIBRE CEMENT

50

85

17

15

775

m2

261

m2

235

m2

One coat Plascon plaster primer and two coats Plascon

superior low sheen paint (ref 3.1)

F18.3.1

On eaves soffits, etc

F18.3.2

On fascias and bargeboards

F18.4

ON METAL

F18.4.1

One coat SIGMA cover primer and 2 coats SIGMADUR

0

m2

m2

m2

Carried forward /

12

34

RATE

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

220

m2

50

145

m2

65

Brought forward /

F18.5

ON WOOD

Three coats Plascon woodcare interior waterbased varnish

F18.5.1

On skirtings (ref 2.1)

Three coats Plascon woodcare exterior waterbased varnish

F18.5.2

On doors and frames

One coat Plascon professional wood primer and two coats

Plascon professional super matt paint

F18.5.3

On cornices (ref 4.2)

One coat Plascon professional wood primer and two coats

Plascon Velvaglo paint

F18.5.1

On doors

F18.6

ON PLASTERBOARD

One coat Plascon plaster primer and two coats Plascon

Professional all purpose matt paint

F18.6.1

On ceilings (ref 5.1)

F18.6.2

On cornices (ref 4.1)

F18.7

ON POLYSTYRENE

m2

m

120

160

One coat Plascon all purpose thinned and two coats Plascon

Professional all purpose matt paint

F18.7.1

On ceilings (ref 5.2)

F19

PLUMBING AND DRAINAGE (PROVISIONAL)

RAINWATER DISPOSAL

m2

520

Alugutter charcoal grey

F19.1

150 x 150 mm Eaves gutters

F19.2

Extra over 150 x 150 mm eaves gutters for stopped ends

F19.3

Extra over for outlet for 100 x 100 mm downpipe

F19.4

100 x 100mm Rainwater pipes

F19.5

Extra over 110 x 110mm rainwater pipe for bend

F19.6

Extra over 110 x 110mm rainwater pipe for shoe

F19.7

Extra over 50 x 75 mm rainwater pipe for eaves or plinth offset

900 mm projection

m

No

Carried forward /

No

m

No

No

No

135

10

16

80

16

16

16

RATE

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

12

38

Brought forward /

F20

All the following items will be allocated to work group 146

Drainage

F20.1

SOIL DRAINAGE

uPVC pipes:

F20.1.1

110 mm Pipes vertically or ramped to cleaning eyes etc in and

including trenches not exceeding 1 m deep

F20.1.2

110 mm Pipes laid in and including trenches not exceeding 1

m deep including all excavations in earth, bedding cradle and

blanket fill of selected granular material, main fill compacting

in layers not exceeding 150 mm thick, adjust moisture

content to optimum and compact to a density of 90% Nod

AASHTO in drain trenches including carting off surplus

displaced material

F20.1.3

F20.2

160 mm Pipes laid in and including trenches not exceeding 1

m deep including all excavations in earth, bedding cradle and

blanket fill of selected granular material, main fill compacting

in layers not exceeding 150 mm thick, adjust moisture

content to optimum and compact to a density of 90% Nod

AASHTO in drain trenches including carting off surplus

displaced material

F20.2.1

Extra over uPVC pipe for fittings:

No

F20.2.2

110 mm Bend

No

No

160 mm Bend

F20.2.3

F20.2.4

110 mm Access bend

No

F20.2.5

160 mm Access bend

No

F20.2.6

110 mm Junction

No

F20.2.7

160 mm Junction

No

F20.2.8

110 mm Access junction

No

F20.3

160 mm Access junction

F20.3.1

Cast Iron:

No

F20.3.2

110 mm Rodding eye

No

F20.4

160 mm Rodding eye

F20.4.1

Sundries:

m3

F21

Unreinforced concrete (15MPa) bedding under pipes

F21.1

Manholes, gulley traps, etc:

No

F21.2

110 mm uPVC Gulley trap and hopper with grid not exceeding

1000 mm deep all set and encased in (20MPa) mass concrete

to form kerb, finished smooth with plaster

No

Stubstack complete with vent pipe

F22

Testing:

Testing of soil drainage system

Carried forward /

Item

RATE

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

550 x 400 mm "Springbok" code 7031 white glazed vitreous

china washhand basin with one taphole fixed with and

including semi concealed brackets

No

510 x 400 mm "Sola 510 Medical" code 703700 white

glazed vitreous china washhand basin with one taphole

fixed with and including semi concealed brackets

No

"Parktown" low level white glazed vitreous china floor

mounted WC suite comprising code 431600 pan with heavy

duty white plastic double flap toilet seat and 9 litre code

7109DP Hibiscus duct cistern

No

"Orchid" low level white glazed vitreous china wall mounted

paraplegic WC suite comprising code 439016 pan fixed on

and including floor bracket with Jazz thermoset seat code

8531Z0 and Gerbit Kombifix wall hung cistern with Gerbit

Delta15 flush actuator and the like, including fixing in

position

No

No

No

No

No

No

10

No

No

No

22

No

No

Brought forward /

All the following items will be allocated to work group 148

- Plumbing

F23

SANITARY FITTINGS

F23.1

"Vaal":

F23.2

F23.3

F23.4

F23.5

F24

"Flatback" code 705326 white glazed porcelain top inlet wall

urinal with 38 mm code 8787z0 chrome plated domical

grating, chrome plated code 8543Z0 top inlet spreader and

fixed with two code 8127Z0 hanger brackets with flushmaster

code FJ6000

Stainless Steel:

Stainless steel shall be grade 304 (18/10)

F24.1

F25

F25.1

F25.2

F26

F26.1

F26.2

"Frankie Quinline" double centre bowl drop in sink, size 1

235 x 435 mm wide fixed in position on joinery fitting

WASTE UNIONS, ETC.

32 mm "Cobra" code 301 CP or equal approved basin waste

union

32 mm "Cobra" code 316-40 CP sink waste

TRAPS, ETC.

uPVC:

40 mm Deep seal "P" or "S" trap

"Geberit" in wall trap code 151.110.11.1

Brass:

F27

40 mm "Cobra" code 345/40 CP or equal approved bottle trap

F28

F28.1

F28.1.1

F28.1.2

F28.1.3

TAPS, VALVES, ETC.

Cobra or equal approved:

15 mm Brass hose bib tap with hose union

15 mm "Melia" code ME-228-15 undertile stopcock

15 mm "Melia" Code ME-214-15 pillar tap

Carried forward /

RATE

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

Brought forward /

F28.1.4

15 mm Brass external tap

No

F28.1.5

15 mm "Medical" Code 503-21B medical raised nose elbow

action pillar tap

No

15 mm "Melia" code ME-266/041/10 CP sink mixer tap with

overarm swivel outlet code

No

F28.1.7

15 mm Urinal metering valve code KM6-000

No

F28.1.8

28 mm Brass gate valve

No

F28.1.9

22 mm Brass non-return valves

No

F28.1.10

28 mm Brass vacuum breaker

No

F28.1.11

22 mm Brass expansion release valve

No

F28.1.12

22 mm Combination brass temperature and pressure

regulating safety valve

No

F28.1.13

Cobra Masterbox I valve box

No

F29

SANITARY PLUMBING

F29.1

uPVC pipes:

F29.1.1

40 mm Pipes

F29.1.2

40 mm Pipes chased

60

F29.1.3

50 mm Pipes

F29.1.4

50 mm Pipes chased

F29.1.5

110 mm Pipes

15

F29.2

Extra over uPVC pipes for fittings:

F29.2.1

110 mm Pan connector

No

F29.2.2

40 mm Bend

No

10

F29.2.3

50 mm Bend

No

F29.2.4

110 mm Bend

No

16

F29.2.5

40 mm Junction

No

11

F29.2.6

50 mm Junction

No

F29.2.7

110 mm Junction

No

F29.2.8

110 x 40 mm Reducing junction

No

F29.2.9

40 mm Access bend

No

10

F29.2.10

50 mm Access bend

No

F29.2.11

110 mm Access bend

No

F29.2.12

40 mm Access junction

No

10

F29.2.13

50 mm Access junction

No

F29.2.14

110 mm Access junction

No

F28.1.6

Carried forward /

RATE

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

RATE

Brought forward /

F29.2.15

40 mm Two-way vent valve

No

F29.2.16

110 mm Two-way vent valve

No

F29.3

Testing:

F29.3.1

Testing of waste pipe system

Sum

F30

WATER SUPPLIES

F30.1

Below Ground:

50

No

15

No

Class 10 hdpe piping

F30.1.1

32 mm Water piping laid in ground or ground filling including

excavating with not less than 900 mm cover including bedding

cradle and blanket fill of selected granular material, main fill

compacting in layers not exceeding 150 mm thick, adjust

moisture content to optimum and compact to density of 90%

Mod AASHTO in trenches including carting off surplus

displaced material

Extra on piping for the following Class 10 fittings:

F30.1.2

32 mm Fittings

Sundries:

F30.1.3

F30.2

300 x 200 x 200 mm High precast concrete stopcock box

including precast concrete lid, all excavations, etc

Above Ground:

Class 0 copper pipes:

F30.2.1

15 mm Pipes chased

20

F30.2.2

22 mm Pipes chased

65

F30.2.3

28 mm Pipes chased

F30.2.4

35 mm Pipes chased

10

F30.2.5

42 mm Pipes chased

12

F30.3

Extra over class 0 copper pipes for capillary fittings:

F30.3.1

15 mm Fittings

No

20

F30.3.2

22 mm Fittings

No

40

F30.3.3

28 mm Fittings

No

F30.3.4

35 mm Fittings

No

F30.3.5

42 mm Fittings

No

F30.4

Polypropylene pipes with thermoplastic coupling:

F30.4.1

15 mm Pipes fixed to walls

11

F30.5

Extra over polypropylene pipes for thermostatic fittings:

F30.5.1

15 mm Fittings

No

Carried forward /

AMOUNT

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

RATE

AMOUNT

Brought forward /

F30.6

Testing:

F30.6.1

Testing water pipe system

F31

ELECTRIC WATER HEATERS

F31.1

100 Litre "Kwikot" 600 Kpa electric combination water heater

(EF100-2D) complete with pressure reducing valve, shut-off

valve, vacuum breakers and plastic overflow tray with 50 mm

outlet pipe to eaves all to comply with SANS 151; horizontal

mounted in ceiling space

Item

No

F32

FIRE APPLIANCES, ETC.

F32.1

Hose reel complete with 30 m rubber hose, chromium plated

stopcock, shut-off nozzle and wall bracket

No

4,5 kg Dry chemical fire extinguisher including 150 x 700 x

19 mm thick wrought hardwood backing plate with

chamfered edges fixed to wall

No

F32.2

F33

SUB CONTRACT AMOUNTS AND BUDGETARY

ALLOWANCES

F33.1

JOINERY FITTINGS

F33.1.1

Subcontract amount sum of R85,000.00 for joinery fittings

F33.1.2

Profit (

F33.1.3

General attendance

F33.1.4

Special attendance if required

F33.2

KITCHEN APPLIANCES

F33.2.1

Subcontract amount sum of R50,000.00 for kitchen

appliances

Provisional Sum

85 000.00

Provisional Sum

50 000.00

%)

F33.2.2

Contractor's overheads, charges and profit on Item F33.2.1

(State % and extend as an amount)

F33.3

BLINDS, CURTAINS

F33.3.1

Subcontract amount sum of R30 000.00 for blinds

F33.3.2

Profit (

F33.3.3

General attendance

F33.3.4

Special attendance if required

F33.4

RAINWATER TANKS

F33.4.1

Subcontract amount sum of R35,000.00 for water harvesting

tanks (4Nr)

R 50 000

Provisional Sum

30 000.00

Provisional Sum

35 000.00

%)

F33.4.2

Profit (

F33.4.3

General attendance

F33.4.4

Special attendance if required

%)

Carried forward /

ITEM No.

PAY

REF

DESCRIPTION

UNIT

QTY

RATE

AMOUNT

Brought forward /

F33.5

GASWORKS

F33.5.1

Subcontract amount sum of R30,000.00 for gas cylinder and

installation thereof complete with lockable gas cage

F33.5.2

Profit (

%)

F33.5.3

General attendance

F33.5.4

Special attendance if required

TOTAL SECTION F:

Carried to Summary

Provisional Sum

30 000.00

You might also like

- IESL EstimateDocument14 pagesIESL EstimateAnuranga SahampathNo ratings yet

- Repair and painting works of Swastik Alps CHSDocument25 pagesRepair and painting works of Swastik Alps CHSSandeep MauryaNo ratings yet

- BoQ For A 3-Classroom Block 2021-22Document78 pagesBoQ For A 3-Classroom Block 2021-22mukiibiNo ratings yet

- Bungalow at PutrajayaDocument2 pagesBungalow at PutrajayaHantu TuahNo ratings yet

- 3 Final Plates PDFDocument48 pages3 Final Plates PDFAriane Joyze BronzalNo ratings yet

- Muro Wall FormworkDocument10 pagesMuro Wall FormworkDaliform GroupNo ratings yet

- Minimizing Color Variations in Troweled ConcreteDocument1 pageMinimizing Color Variations in Troweled ConcretepipiNo ratings yet

- Technical Data Sheet For HIT-HY 170 Injectable Mortar For Anchor in Concrete Technical Information ASSET DOC 4398553Document31 pagesTechnical Data Sheet For HIT-HY 170 Injectable Mortar For Anchor in Concrete Technical Information ASSET DOC 4398553ing urban100% (2)

- Cement Concrete PavementDocument8 pagesCement Concrete Pavementgtarun22guptaNo ratings yet

- Shs60m Can Build A 3 Bedroomed House, A Look at The Cost Breakdown - Nile PostDocument7 pagesShs60m Can Build A 3 Bedroomed House, A Look at The Cost Breakdown - Nile PostSuufu Mkhitaryan KirumiraNo ratings yet

- Procedure For Slab To SlabDocument5 pagesProcedure For Slab To SlabKarthik Chalageri 7100% (1)

- St-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1Document1 pageSt-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1MØhãmmed ØwięsNo ratings yet

- Cost For Each Pile CapDocument4 pagesCost For Each Pile CapGeetashree PaulNo ratings yet

- Amount BHD SL No Description Qty Unit Rate BHDDocument3 pagesAmount BHD SL No Description Qty Unit Rate BHDmunnumma50% (2)

- 187 NanoGrout EGDocument2 pages187 NanoGrout EGTristan Irvin Asi100% (3)

- NTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Document18 pagesNTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Corrosion Factory100% (1)

- 12.7 7 Wire Strand Proprieties VSLDocument1 page12.7 7 Wire Strand Proprieties VSLAbu BiduNo ratings yet

- 2018 19 LOKRITE Ironmongery CatalogueDocument98 pages2018 19 LOKRITE Ironmongery CatalogueKho Song YuanNo ratings yet

- Master Emaco S5400Document2 pagesMaster Emaco S5400WahyudiBlueghostNo ratings yet

- BOQs For Plan #611087Document4 pagesBOQs For Plan #611087tony13touchNo ratings yet

- Gir Gai Trading Hot Rolled Steel Sections PDFDocument4 pagesGir Gai Trading Hot Rolled Steel Sections PDFtpop1707No ratings yet

- Keenagoda BOQ FinalDocument30 pagesKeenagoda BOQ FinalChamin Subhawickrama50% (2)

- Reinforcement beam slab updateDocument2 pagesReinforcement beam slab updateRigel NapaNo ratings yet

- Slip MembraneDocument1 pageSlip MembranescchungNo ratings yet

- Closed-cell bond breaker and back-up materialDocument2 pagesClosed-cell bond breaker and back-up materialpbodooNo ratings yet

- Civil SpecificationsDocument86 pagesCivil Specificationstiruyam@gmail.comNo ratings yet

- Concrete&baseplate PDFDocument18 pagesConcrete&baseplate PDFmitimas2003No ratings yet

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Document6 pagesType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheNo ratings yet

- Construction Method Statement For ApplicDocument5 pagesConstruction Method Statement For ApplicKhasan MustofaNo ratings yet

- Flamex Fire ProtectionDocument4 pagesFlamex Fire ProtectionTori SmallNo ratings yet

- Tender BOQ - Architectural & Structural Works - Building 1Document23 pagesTender BOQ - Architectural & Structural Works - Building 1Erwin ObenzaNo ratings yet

- 8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralDocument5 pages8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralAnshuman RathNo ratings yet

- Tie Bars and Straps for Bulging BrickworkDocument2 pagesTie Bars and Straps for Bulging BrickworkStaszek WoznyNo ratings yet

- PWD Staff QTR Estimate (2) NFNDocument315 pagesPWD Staff QTR Estimate (2) NFNjitender pal vermaNo ratings yet

- Doors, Windows, Security & PartitionsDocument9 pagesDoors, Windows, Security & PartitionsOtunba Adeyemi KingsleyNo ratings yet

- Qcs 2010 Section 13 Part 5 Masonry Laying PDFDocument11 pagesQcs 2010 Section 13 Part 5 Masonry Laying PDFbryanpastor106No ratings yet

- Bathrooms Waterproofing: Method StatementDocument3 pagesBathrooms Waterproofing: Method StatementsohanpmeharwadeNo ratings yet

- Early Thermal Cracking CalculationsDocument1 pageEarly Thermal Cracking Calculationsmassive85No ratings yet

- DIV 15 Mechanical Labor1Document49 pagesDIV 15 Mechanical Labor1Anila SadasivanNo ratings yet

- Joint SealantsDocument4 pagesJoint SealantsBudiawan BudtseNo ratings yet

- Reinforcing Bar CouplersDocument32 pagesReinforcing Bar CouplersSivadol VongmongkolNo ratings yet

- HCF PDFDocument68 pagesHCF PDFSushmit SharmaNo ratings yet

- Guidelines For Site Inspection - by Blas R. Cadalso1Document18 pagesGuidelines For Site Inspection - by Blas R. Cadalso1abstickleNo ratings yet

- Anti-Ram Bollards: Sales Office: 0870 600 2425Document4 pagesAnti-Ram Bollards: Sales Office: 0870 600 2425rajivr_ranjan_vermaNo ratings yet

- Acrow SpanDocument2 pagesAcrow SpangattaiahNo ratings yet

- Joints To Avoid CracksDocument8 pagesJoints To Avoid Cracksprakashcg123No ratings yet

- False Form WKDocument12 pagesFalse Form WKRonald Cario SeguinNo ratings yet

- Water Cascade MS - Pentens T-308+T-100Document5 pagesWater Cascade MS - Pentens T-308+T-100Huzz EllieyzaNo ratings yet

- All in RatesDocument7 pagesAll in Rateskian hongNo ratings yet

- Method Statement For CoringDocument4 pagesMethod Statement For CoringNasir Nagoor PitchaiNo ratings yet

- Package II Part II.5.2 BOQ 25 Users Pre-Fabricated Septic TankDocument2 pagesPackage II Part II.5.2 BOQ 25 Users Pre-Fabricated Septic Tankdox4useNo ratings yet

- Technical Data Sheet for Knauf Vidiwall Metal Stud PartitionsDocument12 pagesTechnical Data Sheet for Knauf Vidiwall Metal Stud PartitionsmatsiasNo ratings yet

- BOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFDocument2 pagesBOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFVeena NageshNo ratings yet

- SECTION 03490 Glass Fiber Reinforced Concrete (GFRC)Document17 pagesSECTION 03490 Glass Fiber Reinforced Concrete (GFRC)SunilNo ratings yet

- Preparation of Renovation WorksDocument41 pagesPreparation of Renovation WorksRonald KaakuNo ratings yet

- BOQ OF FURNISHING AND INTERIOR WORKSDocument16 pagesBOQ OF FURNISHING AND INTERIOR WORKSAbhishek SankerNo ratings yet

- Door and WindowDocument22 pagesDoor and WindowAsHasrinaNo ratings yet

- Boq FormatDocument79 pagesBoq FormatacroxmassNo ratings yet

- 0qmdXWcSQNCwdhgrhBBY ES1 CV Tips 1Document3 pages0qmdXWcSQNCwdhgrhBBY ES1 CV Tips 1Dean KoortzenNo ratings yet

- 26-03 - NationalGovernment Guideline Professional Fees Scope of Services and Tariff of Fees For Persons Registered in Terms ofDocument60 pages26-03 - NationalGovernment Guideline Professional Fees Scope of Services and Tariff of Fees For Persons Registered in Terms ofChris Mostert100% (1)

- Geotechnical Investigation 0Document22 pagesGeotechnical Investigation 0Dean KoortzenNo ratings yet

- Shape codes summary SANS 282 standardDocument1 pageShape codes summary SANS 282 standardSakthi KuppusamyNo ratings yet

- A.02 Section and ElevationsDocument1 pageA.02 Section and ElevationsDean KoortzenNo ratings yet

- ECSA Practice Note on Failed Concrete Raft FoundationDocument4 pagesECSA Practice Note on Failed Concrete Raft FoundationDean KoortzenNo ratings yet

- Ethics in Civil Engineering ProjectsDocument2 pagesEthics in Civil Engineering ProjectsDean KoortzenNo ratings yet

- SomethingDocument52 pagesSomethingRezhaNugrahaNo ratings yet

- Hip End Fixing DetailsDocument7 pagesHip End Fixing DetailsDean KoortzenNo ratings yet

- Sand Cement Floor Screeds 18092009Document12 pagesSand Cement Floor Screeds 18092009David PuenNo ratings yet

- Part C4 2.1 Report 1A Pages 1-35Document35 pagesPart C4 2.1 Report 1A Pages 1-35Dean KoortzenNo ratings yet

- Structural Topic PDFDocument1 pageStructural Topic PDFDean KoortzenNo ratings yet

- Technical Note #20: Clay Brick Vs Concrete: Movement of MasonryDocument6 pagesTechnical Note #20: Clay Brick Vs Concrete: Movement of MasonryDean KoortzenNo ratings yet

- Successful Plastering PDFDocument8 pagesSuccessful Plastering PDFDean KoortzenNo ratings yet

- Raft Foundation-TDDocument1 pageRaft Foundation-TDDean KoortzenNo ratings yet

- UNIT 17 TYPE 3D GARAGE-CONCRETE LAYOUT-Model PDFDocument1 pageUNIT 17 TYPE 3D GARAGE-CONCRETE LAYOUT-Model PDFDean KoortzenNo ratings yet

- Concrete Layout2Document1 pageConcrete Layout2Dean KoortzenNo ratings yet

- ECSA Practice Note on Failed Concrete Raft FoundationDocument4 pagesECSA Practice Note on Failed Concrete Raft FoundationDean KoortzenNo ratings yet

- Site: Description: Date:: Penetration Depth (MM) 3 1 2 4 5Document1 pageSite: Description: Date:: Penetration Depth (MM) 3 1 2 4 5Dean KoortzenNo ratings yet

- ECSA Practice Note on Failed Retaining WallDocument4 pagesECSA Practice Note on Failed Retaining WallDean KoortzenNo ratings yet

- WM Re Su 284 WD Con 3a 11vbhncv 05 18-ModelfdfgdgDocument1 pageWM Re Su 284 WD Con 3a 11vbhncv 05 18-ModelfdfgdgDean KoortzenNo ratings yet

- Technical Note #20: Clay Brick Vs Concrete: Movement of MasonryDocument6 pagesTechnical Note #20: Clay Brick Vs Concrete: Movement of MasonryDean KoortzenNo ratings yet

- Sand Cement Floor Screeds 18092009Document12 pagesSand Cement Floor Screeds 18092009David PuenNo ratings yet

- Chapter 8 PDFDocument20 pagesChapter 8 PDFDebendra Dev KhanalNo ratings yet

- 29 Guidelines For Site & House InspectionsadDocument1 page29 Guidelines For Site & House InspectionsadDean KoortzenNo ratings yet

- 04 - Clay Brick Technical Guide - Web PDFDocument6 pages04 - Clay Brick Technical Guide - Web PDFDean KoortzenNo ratings yet

- 6M Section Bending Schedule REV 01: ElevationDocument1 page6M Section Bending Schedule REV 01: ElevationDean KoortzenNo ratings yet

- Long Term Deflection of 7.5mmDocument1 pageLong Term Deflection of 7.5mmDean KoortzenNo ratings yet

- 04 - Clay Brick Technical Guide - Web PDFDocument6 pages04 - Clay Brick Technical Guide - Web PDFDean KoortzenNo ratings yet

- Tutorial Letter 101nDocument11 pagesTutorial Letter 101nDean KoortzenNo ratings yet

- Internshi P: Seiko Denki (M) SDN - BHDDocument19 pagesInternshi P: Seiko Denki (M) SDN - BHDAhmad FikriNo ratings yet

- Elec Emer Config Notes PDFDocument3 pagesElec Emer Config Notes PDFZORAWAR SINGH HAZURIA -No ratings yet

- Arctic Cat ATV Parts Discount Codes 606-678-9623Document2 pagesArctic Cat ATV Parts Discount Codes 606-678-9623VenkatNo ratings yet

- Yokogawa DCSDocument66 pagesYokogawa DCSsrikar_tpl100% (1)

- Technical Data Sheet for Heat Resistant Epoxy CoatingDocument5 pagesTechnical Data Sheet for Heat Resistant Epoxy CoatingJayaraman KamarajNo ratings yet

- Jay Holland DetailedDocument5 pagesJay Holland DetailedJay NovaNo ratings yet

- Pile Pull Out TestDocument6 pagesPile Pull Out TestHemandra KumarNo ratings yet

- Piaggio Beverly Tourer 400 I.E. (EN)Document301 pagesPiaggio Beverly Tourer 400 I.E. (EN)ManuallesNo ratings yet

- The National Authority For Egyptian RailwaysDocument5 pagesThe National Authority For Egyptian RailwaysMikel QaisiNo ratings yet

- Nellcor Bedside SpO2 Patient Monitor FeaturesDocument1 pageNellcor Bedside SpO2 Patient Monitor FeaturesPengadaan RSUDKNo ratings yet

- Library ClassificationDocument4 pagesLibrary ClassificationAngielu TorresNo ratings yet

- Introducing BACnetDocument70 pagesIntroducing BACnetquijote1381No ratings yet

- Eds 05 0001 132kv Grid and Primary Protection and Control Schemes PDFDocument17 pagesEds 05 0001 132kv Grid and Primary Protection and Control Schemes PDFlancenglotNo ratings yet

- Vivek Chachra's ResumeDocument3 pagesVivek Chachra's ResumevivekchachraNo ratings yet

- Hitendra Sarvaiya: PH No: +91 9428012434Document5 pagesHitendra Sarvaiya: PH No: +91 9428012434miss_jyoti_kapoorNo ratings yet

- P5002RIG01L1007Document2 pagesP5002RIG01L1007Franco Gaston (GR industrial S.R.L.)No ratings yet

- Owner's Manual For 1/6 HP Series SR Flexible Shaft Power ToolsDocument20 pagesOwner's Manual For 1/6 HP Series SR Flexible Shaft Power ToolsFazenda ItaNo ratings yet

- Rolling Center Cantilever Gate Systems and AccessoriesDocument18 pagesRolling Center Cantilever Gate Systems and AccessoriesnagtummalaNo ratings yet

- ISO 3506-2 - Mechanical PropertiesDocument2 pagesISO 3506-2 - Mechanical PropertiesPMartina100% (1)

- TDA8425 Hi-Fi Stereo Audio Processor Data SheetDocument24 pagesTDA8425 Hi-Fi Stereo Audio Processor Data SheetMuhammad IsmailNo ratings yet

- ETPDocument36 pagesETPSantiago RoseroNo ratings yet

- It Object Exercise 2Document14 pagesIt Object Exercise 2CpE LabNo ratings yet

- Manual T32 OhausDocument5 pagesManual T32 Ohauscristian celisNo ratings yet

- Pig Iron Production GuideDocument120 pagesPig Iron Production Guidesaurabh100% (1)

- CHSL Admit Card Henil PatelDocument3 pagesCHSL Admit Card Henil PatelHenil PatelNo ratings yet

- Case/Duct System (Automobile)Document7 pagesCase/Duct System (Automobile)Tran xuan ThuyNo ratings yet

- Rock Physics and Fluid Substitution ModelingDocument61 pagesRock Physics and Fluid Substitution ModelingArun Kumar Nagar100% (1)

- TL074Document12 pagesTL074Trisha JacksonNo ratings yet

- Conbraco - Safety Relief ValvesDocument52 pagesConbraco - Safety Relief ValvesEdbaac BANo ratings yet

- Construction Regulations 2014 PDFDocument64 pagesConstruction Regulations 2014 PDFBea Mok50% (2)