Professional Documents

Culture Documents

Inspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00

Uploaded by

Akhilesh KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00

Uploaded by

Akhilesh KumarCopyright:

Available Formats

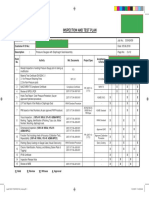

DOCUMENT NO:

GSCC-ZS-PV-ITP-005-2014

REV.01

ITEM DESCRIPTION

PRESSURE VESSELS

ITEM NO / DRAWING NO:

PED-0246 & 0242 REV.1

PROJECT

RABIGH II REFINIG & PETROCHEMICALS

(CP3 & CP4)

JOB NO: GSCC-MD-2014-356

INSPECTION TEST PLAN (ITP) REV.00

Revised to incorporate client and PIM comments

QA/QC ENGG

GSCC

QA/QC

MANAGER

GSCC

ZS

AI

GS E&C

SA

For Approval

QA/QC ENGG

GSCC

QA/QC

MANAGER

GSCC

ZS

AI

GS E&C

SA

ISSUENCE

PREPARED By

REVIEWED

By

ACCEPTED

By

ACCEPTED

By

REV:

DATE:

DOC.NO. OPR08-01

REV. No: 00

PAGE 1

APPROVED BY CLIENT

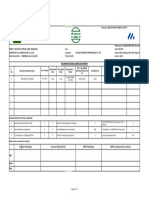

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

DATE: 29/10/2014

DRAWING No: PED-0242-05-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

ITE

WORK PROCESESS

M

ACTIVITY

No:

Pre-Inspection Meeting

DOCUMENTS

1.1

Weld Map, WPS, PQR,

Weld Repair Procedure,

Welding Control &

Consumable Procedure

1.2

Welder Qualification

Record Review

1.3

NDE Personnel

Qualification and Procedure

Review

Receiving Inspection

CHARECTERISTIC

TO BE CHECKED

Review of Weld Map, WPS,

Fabrication Drawings, & Applicable

Codes & Specifications

Review of Welder Qualification Records

Review of NDE (RT, UT, MT,

PT) Procedures & Codes &

Spec.

EQUIPMENT NAME : BYPRO OIL DRUM

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

2.1

Review of MTC/ Material Specification

DOC No: OPR08-01

GSCC

ZS

CLIENT

AI

GS E&C

Res Sign Res Sign Res Sign Res

H

SA

Sign Res

Approved GSCC

WPS & PQR and

& Approved

Procedures

As per ASME Sec. IX

Approved 3rd Party

WQT Records

AMES Sec. V

Approved 3rd Party

Procedures

Mill Test

Certificates

As per Drawings

ASME Sec. VIII

Div.1

ASME Sec. II Part A

Identification Marking Heat Number

against MTC / Material

Specification

INSPECTION STAGES

INSPECTION

FORM &

RECORD

Approved Fabrication

Drawings,

ASME Sec. IX,

ASME Sec. VIII. Div 1

Visual Inspection, Dimension Checking

As Per Specification

Shell, Dishes, Forgings,

Pipe & Fittings, Nozzles

VESEEL TAG No: P 210-D-1126

MTC & Material

Specification

Incoming Material

Inspection Report,

Doc. No:

OPR08-40

REV.NO: 02

PAGE 2

Sign

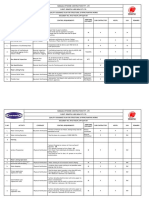

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

DATE: 29/10/2014

DRAWING No: PED-0242-05-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

ITE

WORK PROCESESS

M

ACTIVITY

No:

2.2

Welding Consumables

Material Traceability

of Pressure Parts,

Attachment to

Pressure Parts

4.1

CHARECTERISTIC

TO BE CHECKED

VESEEL TAG No: P 210-D-1126

EQUIPMENT NAME : BYPRO OIL DRUM

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

Verification against the Requirement

of the Consumable MTC

As per ASME Sec. II

Part C

INSPECTION STAGES

INSPECTION

FORM &

RECORD

GSCC

ZS

AI

CLIENT

GS E&C

Res Sign Res Sign Res Sign Res

SA

Sign Res

Raw Material

Inspection

Report.Doc. OPR08-04

Traceability Verification As per MTC

And approved Fabrication Drawings.

Drawings, marking

on Plates & Pipes

ASME Sec. VIII

Div.1

Approved

Fabrication

Drawings,

Incoming Material

Inspection Reports

Doc.OPR08-40

Fit-Up Alignment check, Tack Welds,

Surveillance of welding parameters

against the applicable WPS

Fabrication Drawings,

applicable WPS and

Weld Map

Inspection Report, DOC.

OPR08-64

WFirst,

RRest

IW

IW

PT on back gouged Surface

ASME Sec. V

3rd PARTY Procedure

AIS QP-7.5.1D

Visual Inspection of welds 100%

ASME Sec. VIII

Div. 1

Inspection Report, DCO.OPR08H

07

In-Process Inspection

Long Seam & Cir.

Seam Fit-Up,

Welding to the Shell

to Head

Carry out MT (100%)

Carry out RT

(Head to Shell Circular Seam-Full

RT, Shell Long Seam-Spot RT )

DOC. No: OPR08-01

ASME Sec. V &

ASME Sec

VIII,Div.1

3rd PARTY,

AIS QP-7.5.1C

ASME Sec. V &

ASME Sec

3rd PARTY,

AIS QP-7.5.1A

VIII,Div.1

REV.NO: 02

PAGE 3

Sign

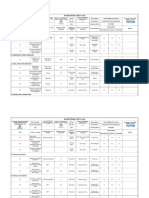

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

DATE: 29/10/2014

DRAWING No: PED-0242-05-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

4.2

Rolled Nozzle Neck

4.3

4.4

4.5

Nozzle layout

Marking on shell and head

EQUIPMENT NAME : BYPRO OIL DRUM

INSPECTION STAGES

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

INSPECTION

FORM &

RECORD

Fit-up alignment check, Tack Welds,

Surveillance of welding

p a r a m e t e r s against the applicable

WPS.

Fabrication Drawings,

applicable WPS & ASME

Sec VIII. Div.1

Inspection Reports,

DOC. OPR08-64

PT on the back gouged surfaces

& 100% Visual Inspection, 100 % RT for

Nozzle butt welds, 100 % MT

ASME Sec .V

3rd Party Procedure

AIS QP-7.5.1A AIS-QP 7.5 1C

Nozzle Orientation conformity and

As Per Fabrication

Inspection Reports,

Drawings.

DOC. OPR08-67

Fit-Up Tack weld visual

check, Surveillance of

welding parameters

against applicable

WPS, weld Visual 100%

Applicable WPS/ Weld

Map,

Reports

Inspection Report

OPR08-64 OPR08-07

H

Verify fit-up tolerance,100 % PT & Full

RT

ASME Sec .V

3rd Party Procedure

AIS QP-7.5.1A AIS-QP 7.5 1D

Fit-Up Tack weld visual

check, Surveillance of

welding parameters

against applicable

WPS

Applicable WPS/ Weld

Map,

Reports

Inspection Report

OPR08-64 OPR08-07

H

ITE

WORK PROCESESS

M

ACTIVITY

No:

Nozzle Fabrication

VESEEL TAG No: P 210-D-1126

CHARECTERISTIC

TO BE CHECKED

verification of weld edge

preparation

10" above joints pipe to

pipe, pipe to elbow, pipe to

flange, pipe to Tee etc..

10" below joints pipe to

pipe, pipe to elbow, pipe to

flange, pipe to Tee etc.

Verify fit-up tolerance,100 % Weld visual

& PT

DOC. No:

ASME Sec .V

GSCC

ZS

AI

CLIENT

GS E&C

Res Sign Res Sign Res Sign Res

Sign Res

3rd Party Procedure

AIS QP-7.5.1A AIS-QP 7.5 1D

REV.NO: 00

SA

PAGE 4

Sign

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

DATE: 29/10/2014

DRAWING No: PED-0242-05-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

Nozzle Neck to shell &

head fit-up & welding

Fit-Up Tack weld visual check,

Surveillance of welding parameters

against applicable WPS, weld Visual

100%

Applicable WPS / Weld

Main Drawings ASME

Sec V

Inspection Reports Doc.

OPR08-64

WFirst,

RRest

IW /S

IW

PT on back gouged Surface

ASME Sec V

3rd PARTY,

AIS QP-7.5.1D

UT on Nozzle Neck to head & shell weld

ASME Sec VIII Div-1,

PED-246-UT

PED -QC-07,Rev-0

MT on Nozzle Neck to shell and head

weld

ASME Sec V

3rd PARTY,

AIS QP-7.5.1C

Inspection Report

DOC. OPR08-07

IW/S

External attachment

Fit-Up & Welding on

the vessels including

leg support and Lifting lugs MT on Leg supports to Shell

Attachment welds

MT on all External attachment welds &

temporary support removed area & Arc

strikes removed area.

4.8

All the Internal

Fit-Up and Welding

on the Vessel

INSPECTION STAGES

INSPECTION

FORM &

RECORD

CHARECTERISTIC

TO BE CHECKED

Welding parameters, surveillance

against applicable WPS, Verification of

location Inspection of weld

4.7

EQUIPMENT NAME : BYPRO OIL DRUM

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

ITE

WORK PROCESESS

M

ACTIVITY

No:

4.6

VESEEL TAG No: P 210-D-1126

Fit-Up Tack weld visual check,

Surveillance of welding parameters

against applicable WPS, weld

Visual

100%

Verify Fit-Up tolerance

DOC .No:

Fabrication

Drawings,

Applicable WPS.

3rd Party MT Procedure

AIS-7.5.1C

3rd PARTY,

AIS QP-7.5.1C

3rd Party MT Procedure

AIS-7.5.1C

3rd PARTY,

AIS QP-7.5.1C

Applicable WPS/

Approved Drawings.

Inspection Reports.

Inspection Report

WPS, DOC.

OPR08-07

REV.NO: 00

GSCC

ZS

AI

CLIENT

GS E&C

SA

Res Sign Res Sign Res Sign Res

Sign Res

PAGE 5

Sign

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

DATE: 29/10/2014

DRAWING No: PED-0242-05-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

ITE

WORK PROCESESS

M

ACTIVITY

No:

4.9

4.10

4.11

4.12

4.13

Internal Inspection of

Vessel (Before

closing the Head)

Final Dimension &

Visual checking of Vessel

RF Pads leak Test

CHARECTERISTIC

TO BE CHECKED

VESEEL TAG No: P 210-D-1126

EQUIPMENT NAME : BYPRO OIL DRUM

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

INSPECTION STAGES

INSPECTION

FORM &

RECORD

ASME Sec. VIII. Div.1

Approved Drawings,

MT on Internal attachment welds

ASME Sec .V

3rd PARTY

AIS QP-7.5.1C

Fabrication Drawings,

Inspection Reports.

APPROVED DWG,

Inspection Reports. DOC.

Fabrication Tolerance

OPR08-08

Approved Procedures

QP PPT-08 Rev.0

Pneumatic Test of Pads at 5 PSIG

Certification of Equipment Applicable ASME Certification Mark in

& PDR

Equipment with PART STAMP

Documents Review and

Equipment Release

Dossier Review (IRB)

DOC.No:

ZS

AI

CLIENT

GS E&C

Res Sign Res Sign Res Sign Res

Visual Inspection of Internal surface

and verification of nozzle internal sharp

corners rounding off.

Verification of dimension (Over all

dimensions, Nozzles and

attachments) and Final Visual

Inspection

GSCC

Inspection Report

DOC. OPR08-07,

SA

Sign Res

Inspection Report OPR08-12

Drawings

Certification rub off / Photo

ASME Sec. VIII , Div.1

Approved Formats

REV.NO: 00

PAGE 6

Sign

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

DATE: 29/10/2014

DRAWING No: PED-0242-05-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

ITE

WORK PROCESESS

M

ACTIVITY

No:

LEGEND:

DOC.No:

CHARECTERISTIC

TO BE CHECKED

VESEEL TAG No: P 210-D-1126

EQUIPMENT NAME : BYPRO OIL DRUM

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

INSPECTION STAGES

INSPECTION

FORM &

RECORD

GSCC

ZS

CLIENT

AI

GS E&C

Res Sign Res Sign Res Sign Res

Sign Res

IW- Initial Witness , H- Hold Points , W- Witness Points , S- Surveillance , R- Review of Records

REV.NO: 00

PAGE 7

SA

Sign

You might also like

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNo ratings yet

- Itp Non AsmeDocument7 pagesItp Non AsmeAkhilesh Kumar100% (1)

- Inspection and Test Plan For Fin Tube Heat ExchangerDocument4 pagesInspection and Test Plan For Fin Tube Heat ExchangerSenthil Kumar100% (2)

- Method Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Document4 pagesMethod Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Nigin Parambath50% (2)

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Quality Assurance Protocol: Raw MaterialDocument2 pagesQuality Assurance Protocol: Raw MaterialShah Newaz KabirNo ratings yet

- Fabrication of Steel Structure and Steel Equipment (Itp)Document4 pagesFabrication of Steel Structure and Steel Equipment (Itp)Javed MANo ratings yet

- ITP For Steel Structure1Document3 pagesITP For Steel Structure1吴兴泊No ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- Inspection and Test Plan For Steel StrucDocument6 pagesInspection and Test Plan For Steel Strucwawan gunawan100% (1)

- ITPDocument1 pageITPVenkatesh PethurajNo ratings yet

- Fabrication Division QMDDocument11 pagesFabrication Division QMDRakesh RanjanNo ratings yet

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- General Format For Girder Fabrication Check ListDocument4 pagesGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryNo ratings yet

- ITP For REPAIR - MODIFY OF STEEL STRUCTUREDocument8 pagesITP For REPAIR - MODIFY OF STEEL STRUCTUREShewale PravinNo ratings yet

- Welding Procedure Specification (WPS) FormDocument2 pagesWelding Procedure Specification (WPS) FormEarl Harbert0% (2)

- Swiss International LLCDocument4 pagesSwiss International LLCBurning TrainNo ratings yet

- 3.2 Standard1Document1 page3.2 Standard1Thi PhamNo ratings yet

- Weld RepairDocument2 pagesWeld RepairAnurag YadavNo ratings yet

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocument4 pagesRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksAjoy Prasad75% (4)

- Inspection and Test Plan Steel Structure: 1. Document ReviewDocument2 pagesInspection and Test Plan Steel Structure: 1. Document ReviewMikiRoniWijaya100% (1)

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- Itp For Fabrication Steel Structure of Warehouse and WorkshopDocument6 pagesItp For Fabrication Steel Structure of Warehouse and WorkshopPhong Do100% (1)

- Standard QAPDocument9 pagesStandard QAPsivaNo ratings yet

- Approved Welding Procedures List RegioDocument2 pagesApproved Welding Procedures List Regiogabriel__regio100% (1)

- Field ITP Civil Rev-8after Lump-Sump.Document17 pagesField ITP Civil Rev-8after Lump-Sump.Echik Kici100% (3)

- Welding Visual Inspection FormatDocument2 pagesWelding Visual Inspection Formatgst ajah100% (3)

- Larsen & Toubro Limited: Ecc DivisionDocument4 pagesLarsen & Toubro Limited: Ecc Divisionmanu_gite100% (2)

- QAP For Painting WorksDocument3 pagesQAP For Painting WorksRanjan KumarNo ratings yet

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- ITP For Electric HeatersDocument5 pagesITP For Electric Heatersakram husseinNo ratings yet

- ITP For Fabrication & Erection of TanksDocument20 pagesITP For Fabrication & Erection of TanksosersNo ratings yet

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocument1 pageReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNo ratings yet

- Itp PipingDocument4 pagesItp PipingkennethNo ratings yet

- Condensate Tank WELDING LOGDocument6 pagesCondensate Tank WELDING LOGhasan shahriarNo ratings yet

- ITP Steel Structure Rev.01Document2 pagesITP Steel Structure Rev.01Imam SyarifudinNo ratings yet

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- Revised IMIR ReportDocument2 pagesRevised IMIR ReportSimbu ArasanNo ratings yet

- Pressure Vessel Itp PDFDocument4 pagesPressure Vessel Itp PDFkorbelNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Welding Procedure Specification: Neo StructoDocument2 pagesWelding Procedure Specification: Neo Structohareesh13hNo ratings yet

- Plate Inspection ReportDocument1 pagePlate Inspection ReportlalitaliNo ratings yet

- QAP For PQR'S - For Impact TestingDocument3 pagesQAP For PQR'S - For Impact TestingDries VandezandeNo ratings yet

- ITP For Steel StructureDocument3 pagesITP For Steel Structuretrey100% (4)

- Daily Progres 22 AprilDocument2 pagesDaily Progres 22 AprilIqbal Nurrasa Bakti100% (3)

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocument5 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariNo ratings yet

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Hydrotesting Procedure Rev 4Document6 pagesHydrotesting Procedure Rev 4Rajesh K PillaiNo ratings yet

- ITP For Process PipingDocument4 pagesITP For Process PipingSebastian RajeshNo ratings yet

- Contractor Quality Control Plan For Storage Tank ErectionDocument2 pagesContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (4)

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Welding Consumables Control RegisterDocument5 pagesWelding Consumables Control RegisterAli Mhaskar100% (2)

- Welding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotDocument3 pagesWelding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotRicardo LourençoNo ratings yet

- Precision Storage Vessels PVT LTD: Pressure Test ReportDocument2 pagesPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocument2 pagesWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNo ratings yet

- Inspection and Test Plan For Line PipeDocument4 pagesInspection and Test Plan For Line Pipesachinumarye100% (1)

- Itp PipingDocument4 pagesItp Pipingerdemlix100% (2)

- ITP Format For New PVDocument8 pagesITP Format For New PVDavid LambertNo ratings yet

- False CeilingDocument48 pagesFalse CeilingAkhilesh KumarNo ratings yet

- Api 571Document8 pagesApi 571Akhilesh KumarNo ratings yet

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDDocument14 pagesProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarNo ratings yet

- PaintingDocument6 pagesPaintingAkhilesh KumarNo ratings yet

- FlooringDocument10 pagesFlooringAkhilesh KumarNo ratings yet

- PlasteringDocument56 pagesPlasteringAkhilesh KumarNo ratings yet

- WaterproofingDocument5 pagesWaterproofingAkhilesh KumarNo ratings yet

- Chainlink FencingDocument56 pagesChainlink FencingAkhilesh KumarNo ratings yet

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDDocument16 pagesProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarNo ratings yet

- Back FillingDocument70 pagesBack FillingAkhilesh KumarNo ratings yet

- Brick MasonaryDocument80 pagesBrick MasonaryAkhilesh KumarNo ratings yet

- Procedure For Fencing WorksDocument3 pagesProcedure For Fencing WorksAkhilesh KumarNo ratings yet

- ConcretingDocument28 pagesConcretingAkhilesh KumarNo ratings yet

- Anti TermiteDocument30 pagesAnti TermiteAkhilesh KumarNo ratings yet

- Procedure For PVC DoorsDocument3 pagesProcedure For PVC DoorsAkhilesh KumarNo ratings yet

- 12 Form WorkDocument7 pages12 Form WorkAkhilesh KumarNo ratings yet

- 15 ConcretingDocument22 pages15 ConcretingAkhilesh KumarNo ratings yet

- Procedure For Road WorkDocument5 pagesProcedure For Road WorkAkhilesh KumarNo ratings yet

- Procedure For Roof Water ProofingDocument4 pagesProcedure For Roof Water ProofingAkhilesh KumarNo ratings yet

- 06-Earthwork in ExcavationDocument7 pages06-Earthwork in ExcavationAkhilesh KumarNo ratings yet

- Procedure For Plumbing Sanitary WorkDocument5 pagesProcedure For Plumbing Sanitary WorkAkhilesh Kumar100% (1)

- Procedure For Horticulture WorksDocument4 pagesProcedure For Horticulture WorksAkhilesh KumarNo ratings yet

- Procedure For Flooring WorksDocument4 pagesProcedure For Flooring WorksAkhilesh Kumar0% (1)

- 11-Backfiling at Station NoDocument7 pages11-Backfiling at Station NoAkhilesh KumarNo ratings yet

- Procedure For RCCDocument3 pagesProcedure For RCCAkhilesh KumarNo ratings yet

- Procedure For Antitermite TreatmentDocument4 pagesProcedure For Antitermite TreatmentAkhilesh KumarNo ratings yet

- Procedure For Area Grading and Development WorksDocument3 pagesProcedure For Area Grading and Development WorksAkhilesh KumarNo ratings yet

- False Ceiling Proc.Document4 pagesFalse Ceiling Proc.Akhilesh KumarNo ratings yet

- Procedure For Aluminum Door Window and VentilatorsDocument3 pagesProcedure For Aluminum Door Window and VentilatorsAkhilesh KumarNo ratings yet

- Materials Concrete Mix TestingDocument5 pagesMaterials Concrete Mix TestingAkhilesh KumarNo ratings yet

- RIT Pipe Labeling Painting and Valve Tag Standard 03 01 2013 PDFDocument3 pagesRIT Pipe Labeling Painting and Valve Tag Standard 03 01 2013 PDFThaiminh Vo100% (1)

- Science 10 - Week 28Document4 pagesScience 10 - Week 28Mira VeranoNo ratings yet

- Cri PumpsDocument10 pagesCri PumpsManoj MallakuntlaNo ratings yet

- Hyundai/Kia A6GF1, A6LF1/2/3, A6MF1/2: Click On Part Numbers For Product Details or VisitDocument1 pageHyundai/Kia A6GF1, A6LF1/2/3, A6MF1/2: Click On Part Numbers For Product Details or Visitserhei umrukhinNo ratings yet

- Boundary Layer SuctionDocument2 pagesBoundary Layer Suctionengineer bilalNo ratings yet

- Hydraulic Analysis of Ductile Iron PipeDocument8 pagesHydraulic Analysis of Ductile Iron PipemartjnNo ratings yet

- Installation, Operation, Repair and Parts Manual: Series 9300 Hydraulically-Driven Centrifugal PumpsDocument28 pagesInstallation, Operation, Repair and Parts Manual: Series 9300 Hydraulically-Driven Centrifugal PumpsvandoNo ratings yet

- 07 Surface Christmas TreeDocument27 pages07 Surface Christmas Treeام فاطمة البطاط100% (3)

- The FAS Is Oseco's Problem-Solving Rupture Disc: Forward Acting ScoredDocument3 pagesThe FAS Is Oseco's Problem-Solving Rupture Disc: Forward Acting ScoredCarlos RinconNo ratings yet

- Esp Calculation Table (Ranjith)Document6 pagesEsp Calculation Table (Ranjith)RanjithNo ratings yet

- MSS SP45 Bypass and Drain ConnectionsDocument12 pagesMSS SP45 Bypass and Drain ConnectionsChotiwan Rattanasatien100% (1)

- ABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesDocument69 pagesABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesBhaiJan59100% (4)

- Marley Product Catalogue Brochure DigitalDocument34 pagesMarley Product Catalogue Brochure DigitalTsako ManganyeNo ratings yet

- SAES-L-410 PDF Download - Design of PipelinesDocument4 pagesSAES-L-410 PDF Download - Design of PipelinesZahidRafiqueNo ratings yet

- Multi V S BrochureDocument13 pagesMulti V S BrochureEliya MbwanjiNo ratings yet

- Homemade Hydraulic Ram Pump For Livestock WaterDocument19 pagesHomemade Hydraulic Ram Pump For Livestock WaterHartoyo Gondomulia100% (1)

- Air Compressed PlantDocument22 pagesAir Compressed PlantMicgale StephenNo ratings yet

- Fan Curves 2 PDFDocument5 pagesFan Curves 2 PDFdasmechNo ratings yet

- Water SystemDocument9 pagesWater SystemArun GuptaNo ratings yet

- Parameter Deviation Causes Consequences ActionDocument4 pagesParameter Deviation Causes Consequences ActionAlumni Affairs Secretary VNITNo ratings yet

- ESP Calculation - Ventilation4uDocument4 pagesESP Calculation - Ventilation4uKaide Johar BohraNo ratings yet

- Hampdon Wind Tunnel H 6910 12 CDLDocument41 pagesHampdon Wind Tunnel H 6910 12 CDLardiantio887No ratings yet

- Electropneumatically Operated Valves Series 3 and 4Document18 pagesElectropneumatically Operated Valves Series 3 and 4Diana DrutaNo ratings yet

- T2pg94 102 PDFDocument9 pagesT2pg94 102 PDFakamalapuri388No ratings yet

- Pumps & Pumping Systems-GeneralDocument349 pagesPumps & Pumping Systems-GeneralKondala RaoNo ratings yet

- MM Pressure Regulator Catalogue - E (1) 015-PCV-588Document32 pagesMM Pressure Regulator Catalogue - E (1) 015-PCV-588Do PhanNo ratings yet

- 42 Inch Flare Hot TappingDocument4 pages42 Inch Flare Hot Tappingavi07me4uNo ratings yet

- Atx 060Document2 pagesAtx 060TimmyJuriNo ratings yet

- Preaction System Design GuideDocument15 pagesPreaction System Design GuideMarkNo ratings yet

- Turbulence Notes Fluent-V6.3.06 PDFDocument49 pagesTurbulence Notes Fluent-V6.3.06 PDFthanakorn vichiensamuthNo ratings yet