Professional Documents

Culture Documents

Heat Extraction From Gradient Layer Using External Heat Exchangers To Enhance The Overall Efficiency of Solar Ponds

Uploaded by

Raghvendra DeshpandeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Extraction From Gradient Layer Using External Heat Exchangers To Enhance The Overall Efficiency of Solar Ponds

Uploaded by

Raghvendra DeshpandeCopyright:

Available Formats

2011

IEEE First Conference on Clean Energy and Technology CET

Heat Extraction from Gradient Layer using External

Heat Exchangers to Enhance the Overall Efficiency

of Solar Ponds

Yusli Yaakob\ Abhijit Date2, Aliakbar Akbarzadeh3

Energy Conservation and Renewable Energy Group

School of Aerospace, Mechanical and Manufacturing Engineering

RMIT University

P.O Box 71, Bundoora, Victoria, 3083, Australia

lyusli.yaakob@rmit.edu.au

2abhijit.date@rmit.edu.au

3aliakbar.akbarzadeh@rmit.edu.au

Abstract- A salinity gradient solar pond is a combined

generation of electricity specifically at remote area locations.

It holds the promise of providing an alternative to Diesel

generation of electricity specifically at remote area locations.

solar collector and thermal energy storage system, and in

past heat has been successfully extracted from the lower

convective zone (LCZ) in working ponds.

discusses possibility

of

This paper

heat extraction from the

non

Figure 1 and 2 shows a typical experimental solar pond

which consists of three regions (surface zone, gradient and

lower zone). The surface or upper convective zone (UCZ) is a

homogeneous layer of low salinity brine or fresh water. The

gradient layer or non-convective zone (NCZ) constitutes a

thermally insulating layer that contains a salinity gradient to

suppress convection currents. The lower zone (LCZ) is a

thermally convective zone with a homogeneous salt

concentration and the brine in this region is much hotter than

that in the surface zone.

convective zone (NCZ) using an external heat exchanger.

Here, two methods of heat extraction from different levels

within

the

NCZ

using

external

heat

exchanger

are

presented. The first method uses thermosyphon effect to

transfer the heat from different levels in NCZ to the

binary fluid.

The second method uses pumps (forced

convection)

for

theoretical

modeling

thermosyphon

heat

based

extraction.

This

paper

and

experimental

heat

extraction

presents

results

method.

for

Later

theoretical predictions and experimental results have been

compared. This investigation shows good prospects for

...

'C.c

application of this system for heat extraction from NCZ of

5-10% salinity

cBl

0<1)

Q.I

large solar ponds. By extracting heat from the NCZ the

efficiency of a solar pond could be increased up to 30%.

Dai average ambient temperature

UCZ

Keywords- Salinity-gradient solar pond; heat extraction;

thermosyphon; heat exchangers.

I.

NCZ

00

INTRODUCTION

A solar pond is a low-cost solar collector with long term

thermal storage capability. It utilizes a large body of salted

water with a density gradient from to bottom that absorb solar

radiation and stores the thermal energy [1]. The solar pond

technology has been used in Israel [2] and USA [3,4] for

power generation and low-temperature process heat

applications respectively. Solar pond is a simple and low cost

solar energy system for a relatively longer period of time. It

holds the promise of providing an alternative to Diesel

978-1-4577-1354-5/11/$ 26.002011 IEEE

LCZ

00

50

1 00

15

30 Salintly ( % by wt.)

Temperature (DC)

Fig. I The schematic of salinity gradient solar pond

23

2011

IEEE First Conference on Clean Energy and Technology CET

experimental study were found to be localised, further

experimental studies using an external heat exchanger (which

would be more practical for medium- to large-scale solar

ponds) needed to be conducted. The similar study has been

conducted by[15] both numerically and experimentally for the

0.64 m2 mini solar pond. The result showed the improvement

of the solar pond performance.

The current study proposes an alternative method of heat

extraction from the NCZ, by drawing the brine through

external heat exchangers using small pumps and re-injection

at difference levels (Figure 3). This study is also looking at the

possibility of circulating the water in the heat exchanger

without using pumps. This paper presents theoretical

modeling and experimental results for thermosyphon based

heat extraction system. The experimental results will then

used for validation of the theoretical modeling.

Fig. 2 A 50m2 experimental salinity gradient solar pond at RMIT University

Conventionally heat has been extracted from solar ponds

solely from the LCZ by two common methods. The first

method is by withdrawing the hot brine through an external

heat exchanger as experimented in EI Paso, Texas [4], Kutch

in India [5], Beith Ha'arava in Israel [2] and Singapore [6].

The second method is by using an in-pond heat exchanger,

where the cold water is used as heat transfer fluid as

demonstrated at Pyramid Hill, Victoria [7] and Marshad in

Iran [8] . Tabor [9] has discussed both of these methods in his

review of solar pond technology, and stressed that both

method have convenient practical merit.

Heat

Temperature

sensors

-t;;;:;:;;-',--,

Hot

pump

NCZ

______

The main concerns with solar ponds is the thermal

performance to store and deliver the heat which is in average

of 15-20% [10]. Many researchers have studied ways of

improving the thermal performance of solar ponds. This could

be done by improving the water clarity to allow better

penetration of sunlight to the storage zone [11], putting a

reflector to reflect additional solar radiation into solar pond

[12] and by improving the method of heat extraction from

LCZ [13].

Temperature

! d'e!.1 !..

}; a

'.

-----

__________________

;.

j.

;..

Pump

-C

...... ____

;.

;.

!

;.

Fig. 3 Proposed heat extraction system from NCZ

II.

THEORETICAL MODELLING OF THERMOSIPHON HEAT

EXCHANGER

An alternative method of extracting heat from solar pond

was investigated theoretically by Andrews and Akbarzadeh

[14] with the aim of increasing the overall energy efficiency

of collecting solar radiation, storing and delivering heat. In

this method, heat is extracted from the NCZ as well as, or

instead of, from the LCZ. The theoretical analysis showed that,

heat extraction from the gradient layer has the potential to

significantly reduce heat losses to the surface and

consequently increase the overall energy efficiency of the

solar pond by up to 50%. Leblanc et al. [7] have carried out an

experimental study of the heat extraction process proposed by

[14] at RMIT University, Bundoora East, Victoria, Australia

for a period of two months by using an in-pond heat

exchanger made of polyethylene pipe. Results indicate that

heat extraction from the gradient layer increases the overall

efficiency of the solar pond by up to 55% compared with the

conventional method of extraction from the LCZ. Leblanc et

al. [7] concluded that although convection currents in the

978-1-4577-1354-5/11/$ 26.00 2011 CO IEEE

c::::::>

c::::::>

24

Thermosiphon refers to a passive heat exchanger based on a

temperature differential with gravity causing the liquids to

circulate by density variations without the need for a

mechanical pump. Tundee et al.[16] and Singh et al. [17] have

applied the similar concept of gravity assisted heat exchanger

in their experiments to remove the heat from solar pond and

potentially produce the electricity by combining it with

thermoelectric modules.

The modelling consists of 15 equations with 15 of the

following unknowns were solved using a Visual Basic-Excel

computer program.

(U,

V, h i' h o,Tco,Tho,Ts, M,;; ,/2,ReI ,Re2,Red

Nu ,Nu

i

o

'

2011

IEEE First Conference on Clean Energy and Technology CET

[p.g.p(L -IXThi -Tho)]

+ [PogoPoLc(Th' _ ( Tho; Th, ))]

fz Ts

Re2 Red

Copper

M'

coil

' ]+[/,( pv' ]

pu

H

H

+ [ pu2 ] + [ pu2 ]

(5)

[r.( 2L;Lc

ki

ko

(6)

Where, the friction factors in fully developed flow in the

thermosiphon and coil are given by equations (7) and (8).

J;

12

Fig. 4 Thermosiphon heat exchanger system schematic diagram

The following mathematical model of the system was

derived to determine the performance of the heat exchanger,

based on the thermosiphon heat exchanger system as shown in

figure 4.

Cp(Tco -TcJ u4 2 Cp(Thi -ThJ

,,;, Cp(]Co - ) mllho [( Th, 1ho ) -T, ]

ff

1c,

(0.79lnRel-1.64(

3000 < ReI < 5xl06

(7)

(0.79lnRez -1.64tZ

3000 < Rez < 5xl06

(8)

The Reynolds numbers for the flow in thermosiphon and

through the circular coil are given by equations (9) and (10).

The energy balance in the system is defined through equation

(1), considering the heat flow into the cooling coil and the

heat taken away by the cooling water by equation (2) and the

heat transfer rate due to forced convection between the hot

water outside the coil wall and inside the coil by equation (3).

me

puD

ReI

=--

Rez

(9)

Jl

pVDc

(10)

Jl

The Nusselt number due to convection heat transfer from the

coil waH and inside the copper tube are given by equations (11)

and (12)

(1)

Nuo

0.913Re618Pr1/3

(2)

(11)

(12)

where, the Reynolds number inside the copper tube is;

(13)

The difference of velocity due to the restriction by cooling

coil in the system is given by;

The convection coefficient heat transfer inside and outside of

the copper tube are expressed by equation (14) and (15)

respectively.

(4)

Nu hid

Nu hoLe

I

The available pressure due to buoyancy and the pressure loss

using Darcy's pressure drop correlation in the system are

expressed by equations (5) and (6).

978-1-4577-1354-5/11/$ 26.00 2011 IEEE

25

(14)

(15)

2011

IEEE First Conference on Clean Energy and Technology CET

III. EXPERIMENTAL STUDY

An experimental study was conducted to measure the actual

performance of a thermosiphon heat exchanger. The

arrangement is shown in Figure 5. The water will rise to fill

the U-shape siphon as the vacuum pump is turned on. The

vacuum pump is shut off when the water reached the desired

level, where the pressure is approximately -10 kPa. The data

acquisition system is switched on for five minutes to check the

stability of all the temperatures before the heater is turned on.

After five minutes, the cold water valve is opened to allow tap

water to flow through the heat exchanger coil and the flow

rate in is measured. As the tank water gets hotter, it starts to

rise due to the natural convection process, and as it flows

through the heat exchanger, it will lose some heat making it

colder. Therefore it will fall back to the tank, and the cycle is

repeated. The outcome from this process is that the

temperature of the cold water outlet will rise to create a

temperature difference between inlet and outlet.

(b)

Fig. 5 (al Schematic diagram of thermosiphon heat exchanger (bl

Thermosiphon H=heat exchanger experimental set-up

A monitoring system using a DataTaker (DT800) data

acquisition system was used to allow continuous temperature

measurements for six different locations. Thermocouples were

placed at the inlet and outlet of the cold water; inlet and outlet

of the hot water on the siphon; in the tank; and next to the rig

to measure the ambient temperature.

A flow visualisation technique, adopted from [18], was

used to measure the velocity of the hot water in the U-shaped

thermosiphon by injecting dye into the system. The dye is

injected, while the water is circulating in the system, to the

siphon pipe through a small tube. A Canon digital camera was

used to capture the movement of the dye in the video mode. A

stopwatch was used to record the time as the dye travel passed

by the marked scale with 0.1 m interval on the clear pipe

section. By analysing the series of video obtained, the distance

travelled by the dye during a particular time was calculated in

order to determine the flow velocity in thermosiphon.

Heated water

outlet

Visualisation

IV. RESULTS AND DISCUSSION

Copper coil

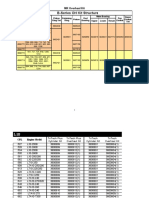

Theoretically the system is initiated with input values of the

physical geometry, the water properties with relevant

coefficient of loss factor and the temperature of hot water and

cooling water. The system has been modelled with the effect

of cooling water mass flow rate through the heat exchanger

coil of 0.033 Lis, 0.04 Lis, 0.05 Lis, 0.067 Lis and 0.1 Lis.

The experiments have been carried out accordingly applying

the same mass flow rates. As a result, the input temperatures

of hot and cold water were obtained as the system is reaching

the steady states as shown in table 1. These temperatures

becomes an input values to the theoretical modelling.

Immersion Heater

TABLE!

EXPERIMETALS TEMPERATURES OUTCOMES

(a)

me

(Lis)

0.033

0.04

0.05

0.067

0.1

978-1-4577-1354-5/11/$ 26.00 2011 CO IEEE

26

Thi, oc

40.11

38.28

36.66

34.05

32.34

Tci, oC

17.06

16.6

16.89

16.72

16.55

2011

IEEE First Conference on Clean Energy and Technology CET

The obtained results from theoretical and experimental

were compared and are shown in figure 6 to 8.

Theoretically the velocity of hot water shows a slight

decreased of velocity between minimum and maximum of the

cooling water flow rates as shown by the values in figure 7.

The similar phenomenon occurs in experimental, where the

velocity is decreased with the increased of the cooling water

mass flow rates from 0.0581 m/s at 0.033 Lis to 0.0538 mls at

0.1 Lis. The effect of buoyancy dominantly has driven the

velocity of the hot water due to the temperature difference,

where the larger temperature difference will cause more heat

loss from hot water and make the water less dense and flow

with high velocity.

45.00

40.00

35.00

30.00

f!

.'l 25.00

.,

0- 20.00

()

15.00

10.00

5.00

2600

-fr-Thi

-o-Tha Thea

....... Tci

...... Tea Thea

....... Teo Exp

-o-Tha Exp

0.00 +----------j

0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 0.11

Cooling water mass flow rates (Lis)

...

"

l:

Fig. 6 Temperature difference of cooling water and hot water

Figure 6 shows the temperature differences of cold and hot

water for theoretical and experimental respectively.

Temperature difference of cold water are getting decreased

with the increased of the cooling water mass flow rates,

approximately 16 aC for flow rate of 0.033L1s and reduced to

around 5 DC at flow rate of 0.1 Lis theoretically. This

phenomenon clearly due to the effect of the mass flow rates,

where the lower the flow rates will caused more heat to be

absorbed by the cooling water inside the coil and vice versa.

The results from experiments shows slightly higher

temperature on the output, but it curve proved the similar

phenomenon is achieved. The hot water temperature

difference is remains constant approximately of 1.2 DC with

the variations of cooling water mass flow rates, for both

experimental and theoretical. This condition is due to the

effect of the constant hot water temperature in the tank, where

the return hot water will gradually gain the heat again before it

re-enter the thermosiphon heat exchanger.

....... Qe Thea

...... Qe Exp

-0- Qh Exp

-+- Qh Thea

The amount of heat extracted by the cooling water and the

heat removed from the hot water theoretically and from

experiment is shown in figure 8. Apparently, the theoretical

results show the balance of the heat transfer phenomenon with

heat which has been extracted by the sooling water and heat

that had been removed from the hot water. This is to proved

the validity of the modelled equations for this thermosiphon

system. But, the experimental result shows a larger difference

between heat extracted by cooling water and the heat removed

from the hot water, approximately 8%-12% compared to

theoretical result. The results are proportional to the obtained

velocities as discussed previously. This is understandable, as

velocity is one of the parameters to determine the quantity of

the energy produced. Theoretically, 1644 w of energy can be

produced and 2283 w of energy has been extracted from this

thermosiphon system.

0.0550

Collectively, all results in figure 6, 7 and 8 show a good

agreement between theoretical and experiments. The

sensitivity of velocity of hot water, u though with small

changes may lead to large discrepancy on the heat extracted

by cooling water and heat removed from the hot water. As an

example, with the difference of 0.0003 mls of hot water

velocity between mass flow rate of 0.033 Lis and 0.04 Lis has

resulted a difference of 304.46 W of heat removed from the

hot water as shown in figure 8.

0.0500

Exp

0.0450 +---------j

0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 0.11

Cooling water mass flow rate (Lis)

Fig. 7 Variation of hot water velocity, u inside the thermosiphon

978-1-4577-1354-5/11/$ 26.00 2011 IEEE

1600

Fig. 8 Energy Extracted from variation of cooling water mass flow rate

...... u hot

1800

Cooling water mass flow rate (Lis)

-0- u hot Thea

2000

1000 +------,---------"

0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1 0.11

2116

1200

iii 0.0600

Qi

>

2283

2200

1400

0.0650 ,------,

2400

27

2011

V.

IEEE First Conference on Clean Energy and Technology CET

CONCLUSIONS

h

s

new method of extracting heat from the NCZ of a solar

pond using thermosiphon heat exchanger has been studied

theoretically and experimentally. Both theoretical and

experiment work has been carried out to realised the concept

of this heat extraction system. The theoretical modelling show

valid results and encouraged a further study. A prototype

thermosiphon system with a coiled heat exchanger has been

manufactured and tested in laboratory. The preliminary test

results obtained from it showed a good agreement at the

variations of cooling water mass flow rates from 0.033 Lis to

0.1 Lis. The 2283 W of heat has been extracted from this

experiments has provide a positive motivation of

implementing this system to the improved the overall

efficiency of heat extraction from solar ponds. Further study

to observe the thermosiphon heat exchanger performance in

solar pond is necessary in order to prove the concept of this

initial result.

A

d

C

T

REFERENCES

[I]

[2]

[3]

[4]

Proceeding of the3rd International Conference on Progress in

[7]

The authors would like to express their appreciation to the

School of Graduate Research, RMIT University for providing

financial support for attending 8th SEE conference.

[8]

NOMENCLATURE

[11]

!1

Dynamic viscosity (N.s/m2)

g

LJP

f

Re

Nu

A

D

d

L

I

u

Th

Tc

h

Exp

Theo

[12]

Density (kg/m3)

Thermal expansion (K'I)

Prandtl number

Pr

[9]

[10]

Mass flow rate of cooling water (kg S'I)

Specific heat (J/kg.C)

fJ

[13]

[14]

Thermal conductivity (W/m. C)I Losses

gravity (m2/s)

Pressure difference caC)

[15]

Losses due to friction

Reynolds number

Nusselt number

Area (m2)

Diameter of thermosiphon pipe (m)

Diameter of copper tube (m)

Height (m)

Length of copper tube (m)

Velocity surrounding heat exchanger (m/s)

Velocity in Siphon (m/s)

Temperature of hot water (0C)

[16]

[17]

[18]

Temperature of cold water (0C)

Convection heat transfer coefficient (W/m2 0C)

Experiment

Theoretical

Subscripts

I

2

a

thermosiphon

circular heat exchanger coil

inlet

outlet

978-1-4577-1354-5/11/$ 26.00 2011 CO IEEE

1993.

A. Kumar and V. V. N. Kishore, "Construction and Operational

Experience of A 6000 m2 Solar Pond at Kutch, India, " Solar

Energy, vol. 65, pp. 237-249, 1999.

T. H. Kho, et al., "Design and Performance Evaluation of a Solar

Pond for Industrial Process Heating, " Int. J Sustainable Energy,

vol. 10, pp. 83-101, 1991.

1. Leblanc, et al., "Heat Extraction methods from salinity gradient

solar ponds and introduction system of heat extraction for

improved efficiency, " Solar Energy, in Press, 2010.

M. R. Jaefarzadeh, "Heat extraction from a salinity-gradient solar

pond using in pond heat exchanger, " Applied Thermal Engineering,

vol. 26, pp. 1858-1865, 2006.

H. Tabor, "Solar Ponds, " Solar Energy, vol. 27, pp. 181-194, 1981.

Y. F. Wang and A. Akbarzadeh, "A study on the transient

behaviour of solar ponds, " Energy, vol. 7, pp. 1005-1017, 1982.

Y. F. Wang and Yagoobi, "Effect of water turbidity on thermal

performance of salt gradient solar pond, " Solar Energy, vol. 54, pp.

301-308, 1995.

S. Aboul-Enein, et al., "Parametric study of a shallow solar-pond

under the batch mode of heat extraction, " Applied Energy, vol. 78,

pp. 159-177, 2004.

A. Akbarzadeh, et al., "Solar Pond Technologies: A review and

Future Directions, " in Advances in Solar Energy. vol. 16, ed:

Earthscan, UK, 2005, pp. 233-294.

1. Andrews and A. Akbarzadeh, "Enhancing the thermal efficiency

of solar ponds by extracting heat from the gradient layer, " Solar

Energy, vol. 78, pp. 704-716, 2005.

M. M. Ould Dah, et aI., "The influence of the heat extraction mode

on the performance and stability of a mini solar pond, " Applied

Energy, vol. 87, pp. 3005-3010, 2010.

S. Tundee, et aI., "Heat extraction from salinity-gradient solar

ponds using heat pipe heat exchangers, " Solar Energy, vol. 84, pp.

1706-1716, 2010.

R. Singh, et aI., "Electric power generation from solar ponds using

combined thermosyphon and thermoelectric modules, " Solar

Energy, vol. 85, pp. 371-378, 2011.

T. T. Lim, "Flow Visualisation : Techniques and examples, " pp.

43-72, 2000.

Solar Ponds,

[5]

ACKNOWLEDGMENT

me

N. D. Kaushika, "Solar ponds: A review, " Energy Conversion and

vol. 24, pp. 353-376, 1984.

H. Z. Tabor and B. Doron, "The Beith Ha'arava 5MW(e) Solar

Pond Power Plant (SPPP) - Progress Report, " Solar Energy, vol.

45, pp. 247-253, 1990.

A. H. P. Swift, et aI., "Operational Result for 3355 m2 Solar Pond

in EI Paso, Texas, " presented at the Solar Engineering, 1987.

H. Xu, et al., "operating experience with the EI Paso Solar Pond, "

Management,

[6]

Cp

cold

hot

heat exchanger coil surface

copper tube

heat exchanger coil

thermosiphon pipe

28

You might also like

- Eligible Candidates List of PH.D/M.SC (Engg) by Research Degree For 18Th Vtu Annual ConvocationDocument42 pagesEligible Candidates List of PH.D/M.SC (Engg) by Research Degree For 18Th Vtu Annual ConvocationRaghvendra DeshpandeNo ratings yet

- M.tech SyllabusDocument4 pagesM.tech SyllabusRaghvendra DeshpandeNo ratings yet

- Brochure WS1Document2 pagesBrochure WS1Raghvendra DeshpandeNo ratings yet

- Probabilistic Techniques For Three-PhaseDocument6 pagesProbabilistic Techniques For Three-PhaseRaghvendra DeshpandeNo ratings yet

- Servo MotorsDocument24 pagesServo MotorsRaghvendra DeshpandeNo ratings yet

- EEE++MTech+ 2016Document47 pagesEEE++MTech+ 2016Raghvendra Deshpande100% (1)

- Preface: The National Institute of Engineering, MysuruDocument78 pagesPreface: The National Institute of Engineering, MysuruRaghvendra DeshpandeNo ratings yet

- Probabilistic Techniques For Three-PhaseDocument6 pagesProbabilistic Techniques For Three-PhaseRaghvendra DeshpandeNo ratings yet

- B. R. Ambedkar: Important FactsDocument9 pagesB. R. Ambedkar: Important FactsRaghvendra DeshpandeNo ratings yet

- Probabilistic Techniques For Three-PhaseDocument2 pagesProbabilistic Techniques For Three-PhaseRaghvendra DeshpandeNo ratings yet

- Servo MotorsDocument24 pagesServo MotorsRaghvendra DeshpandeNo ratings yet

- A 93.7% Peak Efficiency DC-DC Buck Converter With All-Pass Network Based Passive Level Shifter in 55 NM CMOSDocument4 pagesA 93.7% Peak Efficiency DC-DC Buck Converter With All-Pass Network Based Passive Level Shifter in 55 NM CMOSRaghvendra DeshpandeNo ratings yet

- Planning and Optimization of Hybrid Renewable Energy SystemsDocument21 pagesPlanning and Optimization of Hybrid Renewable Energy SystemsRaghvendra DeshpandeNo ratings yet

- Missing Abstract and List of Figures in Wind Turbine PaperDocument1 pageMissing Abstract and List of Figures in Wind Turbine PaperRaghvendra DeshpandeNo ratings yet

- Understanding Power Quality IssuesDocument5 pagesUnderstanding Power Quality IssuesKumar Surender0% (1)

- A Novel Approach in Modeling and Analysis of Vector Controlled Symmetrical Two-Phase Induction Machine For Smart Grid ApplicationsDocument24 pagesA Novel Approach in Modeling and Analysis of Vector Controlled Symmetrical Two-Phase Induction Machine For Smart Grid ApplicationsRaghvendra DeshpandeNo ratings yet

- Understanding Power Quality IssuesDocument5 pagesUnderstanding Power Quality IssuesKumar Surender0% (1)

- Renewable Energy: S. Rajanna, R.P. SainiDocument20 pagesRenewable Energy: S. Rajanna, R.P. SainiRaghvendra DeshpandeNo ratings yet

- Presentation 1Document2 pagesPresentation 1Raghvendra DeshpandeNo ratings yet

- Raj Anna 2016Document15 pagesRaj Anna 2016Raghvendra DeshpandeNo ratings yet

- Conference BrochureDocument2 pagesConference BrochureRaghvendra DeshpandeNo ratings yet

- Renewable Energy: S. Rajanna, R.P. SainiDocument13 pagesRenewable Energy: S. Rajanna, R.P. SainiRaghvendra DeshpandeNo ratings yet

- Visvesvaraya Technological University: "Jnana Sangama", Belagavi - , Karnataka StateDocument1 pageVisvesvaraya Technological University: "Jnana Sangama", Belagavi - , Karnataka StateRaghvendra DeshpandeNo ratings yet

- Dept. of ECE: Invited TalksDocument4 pagesDept. of ECE: Invited TalksRaghvendra DeshpandeNo ratings yet

- Classification of Disturbances in Hybrid Power System Using Modular PNN and SVMsDocument14 pagesClassification of Disturbances in Hybrid Power System Using Modular PNN and SVMsRaghvendra DeshpandeNo ratings yet

- BrochureDocument2 pagesBrochureRaghvendra DeshpandeNo ratings yet

- Two Applications For Power Quality Analysis Using The Matlab Wavelet ToolboxDocument5 pagesTwo Applications For Power Quality Analysis Using The Matlab Wavelet ToolboxRaghvendra DeshpandeNo ratings yet

- BrochureDocument2 pagesBrochureRaghvendra DeshpandeNo ratings yet

- SBES Workshop 1 ReportDocument26 pagesSBES Workshop 1 ReportRaghvendra DeshpandeNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tetra Pak CIP Unit PDocument2 pagesTetra Pak CIP Unit PNaglaa FathyNo ratings yet

- YHZS75 Mobile Concrete Mixing Plant - (220V-60HZ)Document5 pagesYHZS75 Mobile Concrete Mixing Plant - (220V-60HZ)DelioNo ratings yet

- 1 - NDT Basics Ut, MT.,PT, RiDocument20 pages1 - NDT Basics Ut, MT.,PT, RiGMNo ratings yet

- Ec T30 PDFDocument1,500 pagesEc T30 PDFNorman Valle Sáenz100% (1)

- DSS Site Visit ReportDocument13 pagesDSS Site Visit Report39 - Deep MandokarNo ratings yet

- Experiment 4 (Physics For Eng)Document9 pagesExperiment 4 (Physics For Eng)RESI-AURIN, JK L.No ratings yet

- AVK Dams - Reservoirs - HydroPower BrochureDocument15 pagesAVK Dams - Reservoirs - HydroPower Brochureindra putraNo ratings yet

- Allouzi 2018Document36 pagesAllouzi 2018arti sahuNo ratings yet

- Technical Data Sheet FFBDocument4 pagesTechnical Data Sheet FFBvenkiram88No ratings yet

- GRE Pipe InstallationDocument32 pagesGRE Pipe Installationelkhatri100% (3)

- The Manual of Fastening EN 8100 PDFDocument106 pagesThe Manual of Fastening EN 8100 PDFOleh SmolovyiNo ratings yet

- Instructions:: Gujarat Technological UniversityDocument2 pagesInstructions:: Gujarat Technological UniversityKislay ChoudharyNo ratings yet

- 2000 BMW Z3 - M Roadster - Z3 - M Coupe Electrical Troubleshooting ManualDocument382 pages2000 BMW Z3 - M Roadster - Z3 - M Coupe Electrical Troubleshooting ManualShelli Godfrey100% (1)

- Fluids and Buoyancy QuizDocument2 pagesFluids and Buoyancy QuizWaleed El ShirbeenyNo ratings yet

- Esab Tech Tips: Quick Guide Aristo U8 Control PanelDocument16 pagesEsab Tech Tips: Quick Guide Aristo U8 Control Panelthom0% (1)

- Experiment No. 4 - Load Test On Impulse Water TurbineDocument4 pagesExperiment No. 4 - Load Test On Impulse Water TurbinerrameshsmitNo ratings yet

- Technology of Heat Treating-Straightening of Long Shafts With Low RigidityDocument8 pagesTechnology of Heat Treating-Straightening of Long Shafts With Low RigidityShariq KhanNo ratings yet

- SD 14 eDocument12 pagesSD 14 eseaqu3stNo ratings yet

- Determination of The Tensile Strength of An OCF Canister FoamDocument3 pagesDetermination of The Tensile Strength of An OCF Canister Foamemre sönmezNo ratings yet

- ASTM A106 GR.B Steel Tube PDFDocument2 pagesASTM A106 GR.B Steel Tube PDFKader KaderNo ratings yet

- Tech-Doc Fabius GSDocument77 pagesTech-Doc Fabius GSJoseNo ratings yet

- ExDocument2 pagesExSinggih KurniawanNo ratings yet

- Climate Control PDFDocument80 pagesClimate Control PDFArivup PavalanNo ratings yet

- 87 s10Document12 pages87 s10carlosestayNo ratings yet

- Forces and Motion: Basics: Not For Sale, Exclusive For Gordon College OnlyDocument5 pagesForces and Motion: Basics: Not For Sale, Exclusive For Gordon College OnlyAlyssa FrancoNo ratings yet

- CPL Cross Reference - Overhaul KitsDocument13 pagesCPL Cross Reference - Overhaul KitsAugusto NuñezNo ratings yet

- Analysis of Water Hammering in Pipeline and Its CFD SimulationDocument6 pagesAnalysis of Water Hammering in Pipeline and Its CFD SimulationDuzzysNo ratings yet

- Weld Defect Code Acceptance CriteriaDocument17 pagesWeld Defect Code Acceptance CriteriaNavanitheeshwaran Sivasubramaniyam100% (3)

- PUMP IN SERIES and PARRALEL FM51Document4 pagesPUMP IN SERIES and PARRALEL FM51Abenezer TasewNo ratings yet

- B&J Fuel InjectionDocument24 pagesB&J Fuel InjectionZeeshan Ahmad100% (1)