Professional Documents

Culture Documents

Us 20060212134

Uploaded by

luiscremaschiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 20060212134

Uploaded by

luiscremaschiCopyright:

Available Formats

US 20060212134A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2006/0212134 A1

(43) Pub. Date:

Dhawan

(54)

SMART-CONTROL PLC BASED TOUCH

SCREEN DRIVEN REMOTE CONTROL

PANEL FOR BOP CONTROL UNIT

(75) Inventor:

Samir Dhawan, Dehradun (IN)

Sep. 21, 2006

Publication Classi?cation

(51)

Int. Cl.

G05B 19/18

(52)

US. Cl. ................................................... ..700/3;700/7

(2006.01)

Correspondence Address:

LADAS & PARRY

26 WEST 61ST STREET

(57)

ABSTRACT

NEW YORK, NY 10023 (US)

The present invention relates to a device for controlling the

(73) Assignee: SARA SERVICES & ENGINEERS

(PVT) LTD.,

(21) Appl. No.:

11/359,764

(22) Filed:

Feb. 22, 2006

(30)

comprising: BOP control unit, master control panel con

nected to the BOP unit for acquisition of data and processing

the said data, comprising an input module, an output module

and analog 1/ P module; a plurality of slave panels connected

to master panel through the connecting means comprising

Foreign Application Priority Data

Feb. 24, 2005

BloW out preventer (BOP) used in Well drilling operations

(IN) ................................. .. 406/DEL/2005

input module, output module for controlling the BOP control

unit; Wherein the said slave panel is a programmable logic

controller (PLC) for controlling BOP control unit.

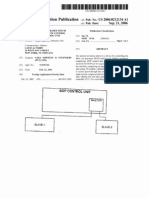

BOP CONTROL UNIT

_ MASTER

SLAVE-1

SLAVE-2 '

Patent Application Publication Sep. 21, 2006 Sheet 1 0f 3

US 2006/0212134 A1

' BOP CONTROL UNIT

MASTER

LII

1

SLAVE-1

SLAVE-2 '

Fig -1

BOP CONTROL UNIT

INPUT

OUTPUT

MASTER

Fig - 2(a)

INPUT/ OUTPUT DETAILS

INPUT

VALVE POSITION FROM

PROSIMITY

HYDROULIC PRESS.

FROM TRANSMITTER I

MASTER PANEL

PLC DETAIL

OPERATION OF VALVE

OUTPUT

THROUGH SOLENOID VALVE

PTR REG ULATER INCJDEC.

PTR INC. /DEC. THROUGH

SOLENOID VALVE

Fig. - 2(b)

Patent Application Publication Sep. 21, 2006 Sheet 2 0f 3

PowER

E] [J B SUPPLY

US 2006/0212134 A1

INPUT MODULE OUTPUT MODULE

Am'gg?gp

[:0

PRESS

AMPL'F'ER

WIRELESS

TRANSMITTER

A

Y

RADIo

'

LINKS

HYDRAuLIc

RELAYS

(I)-ACCUMULATOR

PRESS.

(ii)-MAN|FOLD

PRESS.

PRoxIMITY

(iii)-ANNULAR

PRESS.

SoLENoID

SELEcToR VALVE

AIR

CYLINDER

5- RS 485 PoRT / ETHERNET

FOR COMMUNICATION

WITH SLAVE PANEL

Fig. - 3

PowER SUPPLY SYSTEM WITH BATTERY

BACKUP FOR FOLLOWING DEvIcES

INPUT

AC-23OV

(a)- AMPLIFIER

(b)- RELAYS

(c)- SOLENOID VALVE

(d)- PRESS. TRANSMITTER

POWER

SUPPLY-24 VDC

E322) L'NKS

OUTPUT

24V DC

BATTEZER; IIIDAJDULE

Fig.- 4

Patent Application Publication Sep. 21, 2006 Sheet 3 0f 3

B C POWER

INPUT

Fr A 5 SUPPLY

US 2006/0212134 A1

OUTPUT

MODULE

MODULE

COMPUTER

CPU

PUSH

BUTTON

'

USEFHNPUT

TOUCH

scREEN

IE3-

UGHT

INDICATION

WIRELESS

|_>

RADIO

LINKS

A- Rs 232 PORT

8- Rs 485 PORT / ETHERNET

FOR COMMUNICATION

FOR COMMUNICATION

WITH PC

WITH MAsTER PANEL

Fig. -s

POWER SUPPLY SYSTEM WITH BATTERY

BACKUP FOR FOLLOWING DEVICES

(a)- COMPUTER CPU

INPUT

AC-23OV

(b)- TOUCH scREEN

'(c)- PUSH BUTTONS

- Ll

SUP'ZZV-EFWC

Dig/PD;

HT

RED'OISBI'SQTION

(n- no

BATTERY MODULE

24v 0c

Fig. - 6

Sep. 21, 2006

US 2006/0212134 A1

SMART-CONTROL PLC BASED TOUCH SCREEN

DRIVEN REMOTE CONTROL PANEL FOR BOP

CONTROL UNIT

FIELD OF THE INVENTION

input instructions in ladder logic program being debugged.

Thus, the emulator simulates the operation of the program

mable logic controller.

[0006]

These knoWn panels had some limitations, Which

Were as followszi

[0001] The present invention relates to a programmable

logic controller (PLC) based touch screen driven remote

[0007]

control panel for blowout preventer (BOP) control unit and

[0008] If an installed system needed an enhancement

fresh cables and hoses Were required.

more particular to a system for coupling a netWork of

Cable laying on offshore rigs Was too difficult.

programmable controller through an inter networking to a

monitoring and controlling bloWout prevention control unit

(BOP Control Unit)

BACKGROUND OF THE INVENTION

[0002] BOP Control units have been in existence for many

years, and are generally employed in the oil and gas industry

to control bloW out preventer. These are safety equipments.

These units are operated from the unit as Well as remote

[0009] Response time in air operated panel Was too

much ie the system actuated only after ?lling of air.

[0010]

The electrical system had a problem of interfer

ence and communication.

[0011] Fiber optics had a problem of ?eld maintenance.

[0012] Laying of cables in an offshore rig Was almost

next to impossible.

control panels. These panels alloW complete control and

pressure monitoring of the BOP control system from Drill

?oor or any other alternative place. These panels enable the

BOP control manifold to be placed in a safe area so that it

can remain operational in emergency condition. Presently

the panels systems being used are operated either by air or

arc electrical.

There Was no system of recording trends.

[0014] To overcome the limitations of the conventional

communication system a tWo-Way radio link (Wireless) or

tWo Wire system or ?ber optic communications link is often

necessary to permit a response to a communication initiated

from another location. A control system include a program

PRIOR ART

[0003]

[0013]

US. Pat. No. 4,295,529, WILLIAM N STRICK

LAND teaches a bloWout preventer for attachment to the

drill stem and being placed Within the drill casing during

Well operations provides a bottom seal assembly having an

attachment for slideably attaching the bottom seal assembly

mable logic controller (PLC) Which includes various ele

ments, that are often either sensors for providing inputs to

the PLC or relays for receiving output from the PLC each

under the control of an element controller and each con

nected to the PLC over a netWork for rapid execution.

[0015]

The PLC may be arranged in a master/slave net

Work. The master/Slave control system includes a master

peripherally to a section of drill stem With the bottom seal

(M) and a plurality of remote slave unit. The master (M)

assembly having at least one How opening alloWing oil, gas

and drilling ?uids to pass therearound. The upper portion of

including a master PLC, a data link, and an I/O module and

also controls I/O connection points using a program and a

communication parameter Which are set by a user, and also

the bottom seal assembly forms a valve Which cooperates

With a provided port-ring mounted above the bottom seal

assembly and having an outer diameter substantially equal to

the diameter of the casing.

[0004] US. Pat. No. 3,724,541, Curry B. David teaches

for use in a Well Where production is sustained through gas

lift methods, an apparatus Which shuts in the Well on

catastrophic failure. The apparatus includes a set of spaced,

slidably mounted pistons carried on the production tubing

string. Openings in the pistons permit gas ?oW doWn

through the pistons. When gas How is upWard in the annulus,

the loWer piston is lifted upWardly and contacts the centrally

located piston. The pair slide upWardly against the topmost

piston, Which is ?xedly mounted. When pressed together,

the openings through the pistons do not permit continued gas

How in the annulus. This closes the annulus to gas How.

[0005]

US. Pat. No. 5,276,811, C. Scott Zi?ferer teaches a

softWare package for developing ladder logic programs for

Programmable Logic Controllers (PLCs). This teaches a

method of troubleshooting ladder logic programs for a

programmable logic controller. The ladder logic program is

debugged using an emulator executing on a computer. The

emulator executes a second ladder logic program. The

second ladder logic program generates the inputs that drive

the ladder logic program being debugged. The second ladder

logic program is comprised of output instructions that drive

controls the respective I/O connection points for the remote

slave units.

[0016] The present invention provides neW features that

enhance and extend the capability of the conventional sys

tem.

OBJECTS & SUMMARY OF THE INVENTION

[0017] The present invention serves the needs of the prior

art enhancing and extending the capability of the PLC. It

also provides a method for communicating a programming

command to a controller, such as PLC by sending multiple

pages via the cellular netWork control system. The cellular

communications device can collect the data carried by the

?rst data page and issue an acknoWledgment receipt of the

data carried by that page.

[0018] The present invention further provides exclusive

marquee available at the time of reporting. It also gives

multicolored reporting graphically and digitally.

[0019] The present invention provides exclusive but

tons on touch screen for pressure setting/resetting/

customiZe/real time values etc.

[0020] The present invention also provides reading and

Writing facility for PLC register.

Sep. 21, 2006

US 2006/0212134 A1

[0021] The present invention also provides pressure

reading gauges (in KPa/Bar) With color for different

pressure setting.

[0022] The present invention has excellent feature that

is, if there is any poWer supply failure then automati

cally trend stores and user has no data loss.

[0037]

In case of valve operation ?rst We press push

button from any remote panel (Slave) that electrical signal

goes to PLC input module after processing in PLC CPU, the

Signal goes to master PLC. After reaching the signal in

master it Will generate the corresponding output to relay. As

relay Will operate the signal goes to solenoid it Will operate

[0023] The present invention also provides the safety

the air cylinder (Selector valve) When the valve operated

then its position feed back from proximity (Which is

feature for hardWare failure due to looping, purge,

communication or poWer supply.

mounted on selector valve open/close direction) comes in

master input module. The master send this feed back to slave

PLC it Will generate corresponding output and it Will be

[0024] The present invention also provides the GMT

time setting.

indicated by pilot light.

[0038]

0025

The p resent 1nvent1on

'

'

' a

a 1 so a 11 oWs re p orts 1n

graphical format.

[0026] According to the present invention there is pro

vided a device for controlling the BloW Out preventer (BOP)

used in Well drilling operations comprising:

[0027] BOP control unit master control panel connected

to the BOP Control unit for acquisition of data and

processing the said data, comprising an input module,

an output module and analog I/P module;

0028

A P lurali W of slave P anels connected to master

panel through the connecting means comprising input

module, output module for controlling the BOP control

unit;

Wherein the said slave panel is a programmable logic

controller (PLC) for controlling BOP control unit.

[0029] According to the present invention there is also

provided a slave panel, Which is rig ?oor master connected

With BOP control unit by proximity & pressure line (Input)

and airline (output) and remote panel (slave) With radio link

(Wire less) or tWo-Wire system or Fiber optic a device for

controlling the BloW out preventer

BRIEF DESCRIPTION OF THE DRAWINGS

[0030] FIG. 1. BOP Control unit having Master panel

connected With slave panels.

[0031] FIGS. 2(a) & (b). BOP Control unit illustrating the

Input/Output communication betWeen Master Panel and rest

Parts of BOP Control Unit.

[0032]

FIG. 3. Master Panel.

[0033] FIG. 4 PoWer Supply system With Battery Backup

for devices in Master Panel.

[0034]

FIG. 5. Slave Panel.

[0035] FIG. 6. PoWer Supply system With Battery Backup

for devices in Slave Panel.

General Working (Ref. FIG. 1-6)

In case the valve does not operate due to any reason

(valve stuck loW air pressure) master PLC Will generate

Alarm signal after 10 Seconds and send to slave PLC Where

this Will pop up on the screen With massage Function Fail

and Hooter Will sound and light blink Whenever alarm does

not acknoWledge.

Analog Processingzi

[0039] BOP control unit master panel has four Analog

input, three Hydraulic pressures (Annular pressure, Accu

mulator pres sure, and manifold pres sure) and one pneumatic

pressure (Rig air pressure) these all pressure comes in

transducers, the transducer convert these pressure in to 4-20

mA or 0-10 Volts electrical signal. This signal goes to master

analog module. Master PLC send this signal to slave PLC

Which Will read the signal and convert it in decimal format

and display on screen.

[0040]

We can set all four pressure on the screen ?rst enter

the set value of pressure that value goes to slave it Will send

this value With running pressure value if this running value

is less then to the set value then master PLC Will generate

alarm signal and sent to slave PLC Where this Will be popup

on the screen With massage pressure loW and Hooter Will

sound light blink Whenever alarm does not reset.

[0041] In case ?uid level in the tank has decreased from

the set valve, a signal goes to master PLC and is transferred

to slave PLC and accordingly alarm starts.

DETAILED DESCRIPTION

[0042] A BloWout Preventer (BOP) Control system is a

high pressure hydraulic poWer unit ?tted With directional

control valves to safely control kicks and prevent bloWouts

during drilling operations. BOP control unit/Accumulator

Unit/Accumulator unit assembly refers to the unitiZation of

the air and electric pump assemblies, hydraulic control

manifold and interface assembly onto the accumulator unit

module. The primary function of the accumulator unit

module is to provide the atmospheric ?uid supply for the

pumps and storage of the high pressure operating ?uid for

control of the BOP stack. It includes accumulators, reservoir,

imity & pressure line (input) and air line (output) and remote

panel With Radio link (Wire less) or tWo Wire system or ?ber

accumulator piping and a master skid for mounting of the air

operated pumps, electric motor driven pumps and the

hydraulic control manifold. Accumulator are ASME (Ameri

can Society of Mechanical Engineering) coded pressure

vessels for storage of high pressure ?uid. These accumula

tors are available in a variety of siZes, types, capacities and

pressure ratings. The tWo basic types are bladder and ?oat

Which are available in cylindrical styles. The Accumulators

can either be bottom or top loading. Top loading means the

optic.

bladder or ?oat can be removed from the top While it is still

[0036]

PLC Panel is a device Which can be used to operate

BOP Control Unit (accumulator unit). This panel has three

parts, one is master Which is mounted on BOP control unit

and tWo or more up to 247 slave panel (Remote panel) Which

is installed at tool pusher o?ice or the drillers site. And Rig

?oor master is connected With BOP control unit by prox

Sep. 21, 2006

US 2006/0212134 A1

off of control valve. When alarm conditions exist; the

mounted on the accumulator unit. Bottom loading accumu

lators must be removed from the accumulator unit to be

panel alerts the operator by activating the attached

serviced. Bladder and bouyant ?oat type accumulators can

alarm horn.

be repaired in the ?eld Without destroying their stamp of

approval.

[0059]

7 Pressure data can be presented in KPA or PSI.

Display of all pressures is through mimic pressure

[0043] With the concept of improvement it Was decided to

have an electronic system having Wireless modem.

[0044] The panel designed has the ability to collect, pro

cess, monitor and display the Rig air pressure, accumulator

gauges.

[0060] The remote control panel ?nally designed has

folloWing bene?tszi

[0061]

This panel has a digital touch screen display.

level, mains fail, loW accumulator pressure, loW manifold

pressure and loW rig air pressure, Rams operation and rams

position, Function test of rams and Ram operating time &

pressure loss.

[0062]

It has a cooler for High Temperature conditions.

[0063]

The unit status and logged alarms are noW

[0045] The BOP control unit has a master control panel

Which is a data acquisition and processing device from

[0064] It has air and battery backup.

pressure, annular pressure and manifold pressure, LoW ?uid

accumulator unit. Its functions are summariZed beloW.

[0046]

Receives and processes proximity sensor and

pressure transducer data and transmits this data to the

printable.

[0065] Minimum Rig up timeiNo air hosei6 core

electric cable/?ber optic cables.

[0066] Frequency Hopping radios are installed Which

communicate With a PLC.

driller and tool pusher control panel.

[0047] Receives and processes data entered by the

operator using the display touch screen at the driller

and tool pusher control panel.

[0048]

PoWers proximity sensor.

[0067] FIG. 1 illustrates that Master Panel in BOP control

unit connected to slave panels by a tWo-Way radio link

(Wireless) or tWo Wire system or ?ber optic communications

link to permit a response to a communication initiated from

another location.

[0068]

[0049] Transmits data to the driller and tool pusher

control panel. For historical data display and hard copy

printouts.

[0050] Con?gures the system and calibrates sensor,

When connected to a laptop.

[0051]

Proximity sensors are used to measure the position

of control valve of accumulator unit. They are poWered by

from the main PLC cabinet designed to be mounted through

the control valve nameplate. It is metal sensitive and pro

duces a signal pulse Whenever a metal (i.e disc detent offset

FIG. 2 (a) and FIG. 2 (b) illustrates Input to the

Master Panel are VALVE POSITION from Proximity and

Hydraulic Pressure from transmitter. Proximity senses the

position of valve from selector valve. There are basically

three types of Hydraulic Pressure i.e Accumulator Pressure,

Manifold Pressure and Annular Pressure.

[0069] FIG. 3 illustrates the systematic arrangement of

various parts of master panel in Block Diagram. Figure

shoWs Input Module is placed adjacent to CPU having

PoWer supply and Port A & B, Output Module is placed

adjacent to Input Module and Analog I/P Module is placed

adjacent to Output Module. HoWever, these elements are

of control valve) passes Within 10 mm of the sensor head.

internally connected to CPU. Port B, on CPU, for commu

[0052] Driller and tool pusher panels are intrinsically safe

nication With slave panels either Wired or Wireless, is pref

erably RS 485 type or Ethernet.

devices that display proximity sensor data, pressure trans

ducer data from the master control panel and control the

solenoid valves from the master control panel. The master

control panel poWers it. Consisting of:

[0053] 1 Wall mount style air purged (NEMA 4><)

stainless steel enclosure With graphic overlay.

[0070] FIG. 5 illustrates the systematic arrangement of

various parts of slave panel in Block Diagram. Figure shoWs

Input Module is placed adjacent to CPU having PoWer

supply and Port A & B, and Output Module is placed

adjacent to Input Module. HoWever, these elements are

internally connected to CPU. Port A on CPU for connecting

[0054] 2 Push button control stations With indicator

lights for BOP functions.

Computer CPU Which in turn connected to touch screen is

preferably RS 232 type. Port B on CPU for communication

With slave panel either Wired or Wireless is preferably RS

[0055] 3 Push button control station for bypass function

With indicator lights.

485 type or Ethernet.

[0071]

In one embodiment of Master Panel, proximity

[0056] 4 Alarm light With explosion proof horn for loW

sensor senses the position of valve from the selector valve

accumulator pressure, loW manifold pressure, loW rig

air pressure and loW ?uid level.

and passes signal to ampli?er. The Input Module processed

the signal received from ampli?er for processing, Which is

[0057] 5 Increase/decrease station to remotely control

annular regulated pressure.

further directed to CPU. Master Panel send the processed

signal to Slave Panels either via. ?ber optics or radio links

(Wireless). Slave PLC Will read the signal and convert it in

[0058] 6 It contains a touch screen that enables the

operator to vieW and set pressure and set alarm limits;

temporarily silence the alarm horn and functions on and

decimal format and display on screen.

[0072]

In another embodiment, BOP control unit master

panel has four Analog input three Hydraulic pressures

Sep. 21, 2006

US 2006/0212134 A1

(Annular pressure, Accumulator pressure, and manifold

pressure) and one pneumatic pressure (Rig air pressure) all

these pressure comes in transducers, the transducer convert

these pressure in to 4-20 mA or 0-10 Volts electrical signal.

This signal goes to master panel analog module. Master

panel send this signal to slave PLC Which Will read the

signal and convert it in decimal format and display on

screen.

[0073] We can set all the four pressure on the screen ?rst

enter the set value of pressure that value goes to slave it Will

send this value With running pressure value if this running

value is less then to the set value then master PLC Will

generate alarm signal and sent to slave PLC Where this Will

[0082] (b) The solving of the ladder logic to determine

each output.

[0083]

(c) The updating of the status of the output.

[0084] The term ladder is used as the expression of the

control logic is actually in the form a ladder, With each rung

of the ladder having an output i.e. a value for the required

state of a control element i.e. value corresponding to signals

from monitoring elements. Programmable Logic Controller

(PLCs) is relatively recent development in process control

technology.

[0085] A PLC is used to monitor input/output events and

conditions occurring in a controlled process. For example, a

be popup on the screen With massage pressure loW and

Hooter Will sound light blink Whenever alarm does not reset.

PLC can monitor such input conditions as pressure, How rate

and the like. A control program is stored in a memory Within

the PLC to instruct the PLC What actions to take upon

[0074] In case ?uid level in the tank has decreased from

the set valve, a signal goes to master panel and transferred

to slave PLC and accordingly alarm starts.

encountering particular input signals or conditions. In

response to these input signals provided by input reasons,

[0075]

In a preferred embodiment of slave panel, When the

user need to operate any function of BOP control unit like

valve open/close, Increase-decrease of annular pressure etc.

[0076]

In case of valve operation, ?rst the user press push

button from any remote panel (Slave) that electrical signal

goes to PLC input module after processing in PLC CPU, the

Signal goes to master panel via a radio link or ?ber optic.

After reaching the signal in master panel it Will generate the

corresponding output to relay. As relay Will operate the

signal goes to solenoid it Will operate the air cylinder

(Selector valve) When the valve operated then its position

feed back from proximity (Which is mounted on selector

valve open/close direction) comes in master panel input

module. The master panel send this feed back to slave PLC

it Will generate corresponding output and it Will indicate by

pilot light.

[0077]

In case of valve does not operate due to any reason

(valve stuck loW air pressure) master panel Will generate

the PLC drives and generates output signal Which are

transmitted via PLC output points to various output devices

such as hydraulic valves to control their operating pressure.

This approach to data transfer permits the netWork to rapidly

and ef?ciently handle large communications volumes With

out reducing transfer speed.

[0086] The Subject application is a mere statement of

invention, Where many alternations and modi?cation are

possible Without deviating from the scope of the invention.

The subject disclosure is for illustrative purposes only, hence

the same should not be construed to restrict the scope of the

invention.

1. A Device for controlling the BloW out preventer (BOP)

used in Well drilling operations comprising:

BOP control unit, master control panel connected to the

BOP unit for acquisition of data and processing the said

data, comprising an input module, an output module

and analog I/P module;

Alarm signal after 10 seconds and send to slave PLC Where

a plurality of slave panels connected to master panel

this Will be popup on the screen With massage Function

through the connecting means comprising input mod

ule, output module for controlling the BOP control unit;

Wherein the said slave panel is a programmable logic

controller (PLC) for controlling BOP control unit.

Fail and Hooter Will sound and light blink Whenever alarm

does not acknoWledge.

[0078]

FIG. 4 illustrates the poWer supply system in

Master Panel With battery backup for ampli?er, relays,

solenoid valve, pressure transmitter, radio links and PLC.

[0079] FIG. 6 illustrates the poWer supply system in slave

Panel With battery backup for computer CPU, touch screen,

push buttons, light indication, radio links and PLC.

[0080] AtWo-Way radio link (Wireless) or tWo Wire system

or ?ber optic communications link is often necessary to

permit a response to a communication initiated from another

location. A control system include a programmable logic

controller (PLC) Which includes various elements, that are

often either sensors for providing inputs to the PLC or relays

for receiving output from the PLC each under the control of

an element controller and each connected to the PLC over a

netWork for rapid execution by the three main steps executed

repeatedly by the

2. The device according to claim 1, Wherein the master

panel comprises an input module connected on one side to

a CPU While the other side is connected to an ampli?er for

amplifying and processing the received signal.

3. The device according to claim 2, Wherein said ampli?er

is triggered by a signal received through the proximity

connected to a selector valve.

4. The device according to claim 3, Wherein proximity is

a sensor.

5. The device according to claim 1, Wherein the output

module is connected to the relays for pneumatically con

trolling the opening and closing of the valve.

6. The device according to claim 1, Wherein analog I/P

Module placed adjacent to the output module is connected to

the pressure transmitter for transmitting hydraulic pressure

to the analog I/P Module for processing and transmitting the

input.

(a) The accruing of the status of each input to the

7. The device according to claim 6, Wherein said hydraulic

PLC needed to execute ladder logic for the process

pressure is accumulator pressure or manifold pressure or

annular pressure or combination thereof.

[0081]

being controlled.

Sep. 21, 2006

US 2006/0212134 A1

8. The device according to claim 1, Wherein the said slave

panel comprising an input module connected on one side to

CPU While the other side to a push button for placing the

user input.

9. The device according to claim 8, Wherein said slave

panel having output module placed adjacent to input module

for light indication in case of any failure notice.

10. The device as claimed in claim 1, Wherein the touch

screen is provided to display the data at the slave panel.

11. The device as claimed in claim 1, Wherein said

connected means is air link or ?ber optics.

12. The device according to claim 8, Wherein said slave

panel is rig ?oor master connected With BOP control unit by

proximity & pressure line (Input) and airline (output) and

remote panel (slave) With radio link (Wire less) or tWo-Wire

system or Fiber optic.

*

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Bid ProcessDocument85 pagesBid ProcessRobiatol Adawiah Mohammad ShamsidiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Mastercam Book 5 Axis Bai 1Document31 pagesMastercam Book 5 Axis Bai 1tuanvn76100% (3)

- mf8240 160824142620 PDFDocument698 pagesmf8240 160824142620 PDFArgopartsNo ratings yet

- DS350 1318 OperatorsDocument61 pagesDS350 1318 Operatorsluiscremaschi100% (1)

- Jib TextDocument36 pagesJib Textluiscremaschi100% (2)

- Comparisonofweldingeconomy Kehlnaht 12551752Document10 pagesComparisonofweldingeconomy Kehlnaht 12551752Asebaho BadrNo ratings yet

- WSH Manual Marine IndustriesDocument360 pagesWSH Manual Marine IndustriesluiscremaschiNo ratings yet

- F170a 23Document108 pagesF170a 23luiscremaschi100% (1)

- Controlling Pressure in Oil WellsDocument16 pagesControlling Pressure in Oil WellsluiscremaschiNo ratings yet

- EP0159813A2Document16 pagesEP0159813A2luiscremaschiNo ratings yet

- Us 4018276Document7 pagesUs 4018276luiscremaschiNo ratings yet

- Us 2749078Document12 pagesUs 2749078luiscremaschiNo ratings yet

- States Atent (191: (11) (45) (54) (75) (73) (21) (22) (51) (52) (53) Assignee: Koomey, Inc., Houston, TexDocument19 pagesStates Atent (191: (11) (45) (54) (75) (73) (21) (22) (51) (52) (53) Assignee: Koomey, Inc., Houston, TexluiscremaschiNo ratings yet

- Us 3015975Document9 pagesUs 3015975luiscremaschiNo ratings yet

- Us 20060212134Document9 pagesUs 20060212134luiscremaschiNo ratings yet

- USRE37167Document16 pagesUSRE37167luiscremaschiNo ratings yet

- Controlling Pressure in Oil WellsDocument16 pagesControlling Pressure in Oil WellsluiscremaschiNo ratings yet

- United States Patent (191: RandallDocument6 pagesUnited States Patent (191: RandallluiscremaschiNo ratings yet

- Us 4018276Document7 pagesUs 4018276luiscremaschiNo ratings yet

- Us 2749078Document12 pagesUs 2749078luiscremaschiNo ratings yet

- United States Patent (191: RandallDocument6 pagesUnited States Patent (191: RandallluiscremaschiNo ratings yet

- Us 3051273Document7 pagesUs 3051273luiscremaschiNo ratings yet

- Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1Document5 pagesJan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1luiscremaschiNo ratings yet

- States Atent (191: (11) (45) (54) (75) (73) (21) (22) (51) (52) (53) Assignee: Koomey, Inc., Houston, TexDocument19 pagesStates Atent (191: (11) (45) (54) (75) (73) (21) (22) (51) (52) (53) Assignee: Koomey, Inc., Houston, TexluiscremaschiNo ratings yet

- Crane 8012 LoadChartDocument12 pagesCrane 8012 LoadChartluiscremaschiNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- Us 3319746Document31 pagesUs 3319746luiscremaschi0% (1)

- Us 3311200Document10 pagesUs 3311200luiscremaschiNo ratings yet

- Principal Crane CapacityDocument12 pagesPrincipal Crane CapacityluiscremaschiNo ratings yet

- OhmDocument15 pagesOhmRhonnel Manatad Alburo88% (17)

- KTO12 Curriculum ExplainedDocument24 pagesKTO12 Curriculum ExplainedErnesto ViilavertNo ratings yet

- Non-Permanence Risk Report Template (Short Form) : Instructions For Completing TheDocument5 pagesNon-Permanence Risk Report Template (Short Form) : Instructions For Completing Theferrian prabowoNo ratings yet

- Dav Public School, Berhampur, Odisha Summer Holiday HomeworkDocument3 pagesDav Public School, Berhampur, Odisha Summer Holiday HomeworkOmNo ratings yet

- Porter's Five Forces: Submitted by Subham Chakraborty PGDMDocument5 pagesPorter's Five Forces: Submitted by Subham Chakraborty PGDMSubham ChakrabortyNo ratings yet

- Factors Affecting Drying Rates and MechanismsDocument4 pagesFactors Affecting Drying Rates and MechanismsMahesh VoraNo ratings yet

- IEC 60793-1-30-2001 Fibre Proof TestDocument12 pagesIEC 60793-1-30-2001 Fibre Proof TestAlfian Firdaus DarmawanNo ratings yet

- #1 Introduction To C LanguageDocument6 pages#1 Introduction To C LanguageAtul SharmaNo ratings yet

- Determination of The Molecular Weight of Polymers From Viscosity MeasurementsDocument10 pagesDetermination of The Molecular Weight of Polymers From Viscosity MeasurementsAbdullah MunawarNo ratings yet

- Air CasterDocument25 pagesAir CasterPrabir Kumar Pati100% (1)

- P - Issn: 2503-4413 E - Issn: 2654-5837, Hal 35 - 42: Jurnal Ekonomi Dan Bisnis, Vol. 11 No. 1 Juli 2022Document8 pagesP - Issn: 2503-4413 E - Issn: 2654-5837, Hal 35 - 42: Jurnal Ekonomi Dan Bisnis, Vol. 11 No. 1 Juli 2022Nova KartikaNo ratings yet

- Tuomo Summanen Michael Pollitt: Case Study: British Telecom: Searching For A Winning StrategyDocument34 pagesTuomo Summanen Michael Pollitt: Case Study: British Telecom: Searching For A Winning StrategyRanganath ChowdaryNo ratings yet

- Kamran Afzal ResumeDocument2 pagesKamran Afzal ResumeChelsea ElizabethNo ratings yet

- Emp Unit-1 Communication SkillsDocument14 pagesEmp Unit-1 Communication SkillsSaraswathi GopalNo ratings yet

- MMA Electrode ClassificationDocument3 pagesMMA Electrode ClassificationRathnakrajaNo ratings yet

- 3D Password Seminar ReportDocument7 pages3D Password Seminar ReportRukshana MeeranNo ratings yet

- Adjustment: - Electronic Modulated Air SuspensionDocument2 pagesAdjustment: - Electronic Modulated Air SuspensionThar KyiNo ratings yet

- List of British StandardsDocument6 pagesList of British StandardsPankajNo ratings yet

- Decision Tree Classifier On Private DataDocument8 pagesDecision Tree Classifier On Private DataBianca RodriguesNo ratings yet

- Beamware 2: Users ManualDocument14 pagesBeamware 2: Users ManualAdi FaizinNo ratings yet

- How To Review A Book in Up To 5,000 Words: First StepsDocument3 pagesHow To Review A Book in Up To 5,000 Words: First StepsAnnaNo ratings yet

- Wellmark Series 2600 PDFDocument6 pagesWellmark Series 2600 PDFHomar Hernández JuncoNo ratings yet

- Curios AllianceDocument32 pagesCurios AllianceyesterowNo ratings yet

- Vision and Mission Analysis ChapterDocument15 pagesVision and Mission Analysis Chapterzaza bazazaNo ratings yet

- 3 To 8 Decoder in NGSPICEDocument14 pages3 To 8 Decoder in NGSPICEJaydip FadaduNo ratings yet

- Meinrad 2018 All Symbols With NumbersDocument4 pagesMeinrad 2018 All Symbols With NumbersXer N. AcostaNo ratings yet