Professional Documents

Culture Documents

Es BBFP

Uploaded by

WattsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Es BBFP

Uploaded by

WattsCopyright:

Available Formats

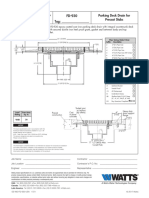

ES-BBFP

For Non-Health Applications

Job Name Contractor

Job Location Approval

Engineer

Contractors P.O. No.

Approval Representative

Series BBFP

Dual Check Valve with

Intermediate Atmospheric Vent

Sizes: 12" (15mm), 34" (20mm)

Series BBFP is specially made for smaller supply lines and ideally suited for laboratory equipment, processing tanks, sterilizers,

dairy equipment and similar applications. It is particularly recommended for boiler feed lines to prevent backflow when supply

pressure falls below system pressure.

Series BBFP is suitable for use on hot or cold water and can

be used under continuous pressure. It features a primary check

valve utilizing a rubber disc seating against a mating rubber part

to ensure tight closing. A secondary check valve utilizes a rubber

disc-to-metal seating. In the event of fouling of the downstream

check valve, leakage would be vented to atmosphere through

the vent port thereby safeguarding the potable water system.

Construction is brass body with stainless steel working parts,

integral strainer and durable rubber discs. Female union inlet

and outlet connections. Sizes 12" (15mm) and 34" (20mm). Drain

is 12" (15mm) thread connection.

BBFP May also be installed vertically

Union outlet

Rugged mesh

stainless strainer screen

Primary

check valve

Secondary

check valve

Vent and drain

connections

Features

True line-sized construction allows the check modules to

open further allowing dirt and debris to pass more freely

reducing check fouling

Brass body construction and stainless working parts throughout

Stainless steel internal parts

Maximum flow at low pressure drop

Available Models

Furnished with union connections to facilitate removal and

replacement for maintenance

Suffix:

Compact for economy combined with performance

Design simplicity for easy maintenance

Can be installed vertically or horizontally

Specifications

For Backflow Preventers with Atmospheric vents

A Dual Check Valve with Atmospheric Vent shall be installed at

referenced cross-connections. Valve shall feature stainless steel

and rubber internals protected by an integral strainer. Primary

check shall be rubber to rubber seated, backed by the secondary

check with rubber to metal seating. The device shall be ASSE approved under Std. 1012 and shall be a Watts Series BBFP.

S for 12" (15mm) union end solder connections.

SC for satin chrome finish

LU less union

NOTICE

The information contained herein is not intended to replace the

full product installation and safety information available or the

experience of a trained product installer. You are required to

thoroughly read all installation instructions and product safety

information before beginning the installation of this product.

NOTICE

Inquire with governing authorities for local installation requirements

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only.

For precise measurements, please contact Watts Technical Service. Watts reserves the right to change or modify

product design, construction, specifications, or materials without prior notice and without incurring any obligation to

make such changes and modifications on Watts products previously or subsequently sold.

Materials

Capacity

Forged brass body construction

Performance Curve

kPa psi

207 30

Stainless steel internal parts

Durable, tight seating rubber check valve assemblies

Reduced Pressure Drop

172 25

Pressure Temperature

138 20

Temperature Range 33F 250F (0.5C 121C).

103 15

Maximum Working Pressure:175psi (12.1 bar)

Minimum Required Pressure: 25psi (172 kPa).

Standards

69 10

34 5

ASSE 1012

CSA B64

0 0

0 2 4 5 8 10

12 14 16 18 20

gpm

0 8 15 23 30 38 46 53 61 68 76

lpm

Flow

Approvals

39769

Installations

Certified by CSA

Boiler Installation

N.Y.C. BSA 104-75-SM

Watts BBFP Heating System Installation

Tested and approved Conformance with Standard 1012 of the

American Society of Sanitary Engineers and by all principal cities, states and areas having these requirements.

Integral

Strainer

Supply

Watts

BBFP

Watts Model 1156F Feed

Valve with Union

NOTICE

This valve should only be used and properly installed so that

spillage of water could not cause damage. To avoid water

damage due to valve operation, a drain pipe must be installed.

It should terminate approximate 12" (305mm) above a floor

drain or through an air gap piped to a floor drain, or other suitable place of disposal. Under no circumstances, should the

vent opening or drain line be plugged.

Vent

Drain

Return

Boiler

Floor Drain

Livestock Drinking Fountains

Watts

BBFP

Dimensions Weight

A

Up Stream

Control

Valve

Water Hammer Shock Arrestor

Drain

Air Gap

Drinking Cups

Water

Supply Line

E

E1

Dimensions

Model

BBFP

BBFP-S

BBFP

BBFP-S

Ordering

Code No.

0063190

0063191

0063192

0063193

Size

E1

Weight

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

lbs.

kg.

12

12

34

34

15

15

20

20

41516

438

412

41316

125

111

114

122

2916

2916

2916

2916

65

65

65

65

11516

11516

11516

2116

49

49

49

52

2916

2916

2916

234

65

65

65

70

112

112

134

134

.68

.68

.79

.79

A Watts Water Technologies Company

ES-BBFP 1534

USA: Tel: (978) 689-6066 Fax: (978) 975-8350 Watts.com

Canada: Tel: (905) 332-4090 Fax: (905) 332-7068 Watts.ca

Latin America: Tel: (52) 81-1001-8600 Fax: (52) 81-8000-7091 Watts.com

2015 Watts

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Es FHBDocument1 pageEs FHBWattsNo ratings yet

- Es WQ PWSRDocument2 pagesEs WQ PWSRWattsNo ratings yet

- Es WD TD 300 UsaDocument1 pageEs WD TD 300 UsaWattsNo ratings yet

- Es Lf474aDocument2 pagesEs Lf474aWattsNo ratings yet

- ES WD DeadLevel S USADocument1 pageES WD DeadLevel S USAWattsNo ratings yet

- Es 757isrDocument2 pagesEs 757isrWattsNo ratings yet

- ES PW SmartStream ADocument4 pagesES PW SmartStream AWattsNo ratings yet

- Es LFRC105Document2 pagesEs LFRC105WattsNo ratings yet

- ES WD DeadLevel Z USADocument1 pageES WD DeadLevel Z USAWattsNo ratings yet

- Es-Of1465tm 1665TMDocument3 pagesEs-Of1465tm 1665TMWattsNo ratings yet

- Es LFMMV HTKDocument2 pagesEs LFMMV HTKWattsNo ratings yet

- Basic Construction Operation Troubleshooting: WarningDocument2 pagesBasic Construction Operation Troubleshooting: WarningWattsNo ratings yet

- Es WD FD 930 UsaDocument1 pageEs WD FD 930 UsaWattsNo ratings yet

- Series LFMMV-HTK: Hot Water Tank EnhancerDocument2 pagesSeries LFMMV-HTK: Hot Water Tank EnhancerWattsNo ratings yet

- Es WD 100 L Csa CanDocument1 pageEs WD 100 L Csa CanWattsNo ratings yet

- Es WD Si 770 CanDocument1 pageEs WD Si 770 CanWattsNo ratings yet

- Es WD FD 320 Eg CanDocument1 pageEs WD FD 320 Eg CanWattsNo ratings yet

- Es Acv M115F M1115FDocument4 pagesEs Acv M115F M1115FWattsNo ratings yet

- Es WD RD 800 CT UsaDocument1 pageEs WD RD 800 CT UsaWattsNo ratings yet

- Series LFN55B Specification SheetDocument2 pagesSeries LFN55B Specification SheetWattsNo ratings yet

- Es WD RD 300 CP15 85 UsaDocument1 pageEs WD RD 300 CP15 85 UsaWattsNo ratings yet

- Series LFN55B-M1 Specification SheetDocument2 pagesSeries LFN55B-M1 Specification SheetWattsNo ratings yet

- Es WD RD 100 CP 85 UsaDocument1 pageEs WD RD 100 CP 85 UsaWattsNo ratings yet

- Es WD RD 800 UsaDocument1 pageEs WD RD 800 UsaWattsNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- E Voting GanttDocument2 pagesE Voting Ganttpikes89No ratings yet

- Case Study: Engineering Design ServicesDocument3 pagesCase Study: Engineering Design ServicesMehul PatelNo ratings yet

- Managing The Windows Server Platform: DHCP Service Product Operations GuideDocument85 pagesManaging The Windows Server Platform: DHCP Service Product Operations GuideBartosz SlusarczykNo ratings yet

- Section 334626 - Filter FabricsDocument3 pagesSection 334626 - Filter Fabricsabdullah sahibNo ratings yet

- Jadual Pembahagian Penilaian Berterusan ScribdDocument7 pagesJadual Pembahagian Penilaian Berterusan ScribdZAKEY ABDULNo ratings yet

- Alegria 860 Instant HandleidingDocument16 pagesAlegria 860 Instant HandleidingrapiNo ratings yet

- 489-Diseno de MicropilotesDocument379 pages489-Diseno de MicropilotesfabioNo ratings yet

- B.V. Ramana RaoDocument4 pagesB.V. Ramana Raonikhil2loginNo ratings yet

- Make or Buy ANalysisDocument15 pagesMake or Buy ANalysisTRISHANo ratings yet

- Season Processing in SAP (is-AFS)Document23 pagesSeason Processing in SAP (is-AFS)Anupa Wijesinghe89% (19)

- Annexure D - SPIR PDFDocument4 pagesAnnexure D - SPIR PDFharmlesdragonNo ratings yet

- Raja of CorruptionDocument335 pagesRaja of CorruptionMadhu Mohan100% (1)

- Piled Foundation ReportDocument7 pagesPiled Foundation ReportDijo Mathews100% (1)

- Network Computing: Discovery, Communication, and CollaborationDocument25 pagesNetwork Computing: Discovery, Communication, and Collaborationangelhope64No ratings yet

- SSHRDocument505 pagesSSHRkpat3No ratings yet

- Implementation of Single Channel Queuing Modelto Enhance Banking ServicesDocument8 pagesImplementation of Single Channel Queuing Modelto Enhance Banking ServicesAbhishek TripathiNo ratings yet

- Kinduz Lean Six Sigma Yellow BeltDocument2 pagesKinduz Lean Six Sigma Yellow BeltpavankksNo ratings yet

- Overmold Design GuideDocument18 pagesOvermold Design GuideCuco MartinezNo ratings yet

- Cortacircuitos. Catalogo de HUBBELLDocument16 pagesCortacircuitos. Catalogo de HUBBELLLuis LaraNo ratings yet

- A109LUH Brochure PDFDocument2 pagesA109LUH Brochure PDFLavern P. SipinNo ratings yet

- BS en 10228-2-2016Document20 pagesBS en 10228-2-2016Sorin Mirt100% (1)

- Input Rate (Unit/hr) Throughput Rate Output Rate (Unit/hr) Min (Demand, Capacity)Document3 pagesInput Rate (Unit/hr) Throughput Rate Output Rate (Unit/hr) Min (Demand, Capacity)Tanvi S PurohitNo ratings yet

- 2014.05.09 GN Jet Mud Mixer MaualDocument17 pages2014.05.09 GN Jet Mud Mixer MaualHamed GeramiNo ratings yet

- Application of Loss of ProfitDocument3 pagesApplication of Loss of ProfitBritton WhitakerNo ratings yet

- Fire Risk Assesment-Dave SibertDocument11 pagesFire Risk Assesment-Dave SibertSam OyelowoNo ratings yet

- How To Modify SAP Released Transport To Unreleased Status - SAP BASIS ANSWERS - SAP BASIS ADMIN BLOGDocument2 pagesHow To Modify SAP Released Transport To Unreleased Status - SAP BASIS ANSWERS - SAP BASIS ADMIN BLOGivanNo ratings yet

- Albion TradingDocument1,074 pagesAlbion TradingalcatéiaNo ratings yet

- Using Earned Value Management System (EVMS)Document21 pagesUsing Earned Value Management System (EVMS)Ashik RaoNo ratings yet

- MM WM NotesDocument37 pagesMM WM NotesRakesh Kumar BeheraNo ratings yet

- Sat SahebDocument7 pagesSat SahebAMIT JHANo ratings yet