Professional Documents

Culture Documents

WPS (1) 1

Uploaded by

Pedro José PadillaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS (1) 1

Uploaded by

Pedro José PadillaCopyright:

Available Formats

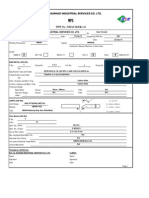

WELDING PROCEDURE SPECIFICATION

(WPS)

WPS No.:

Date:

WPS

(SPECIFICATION - RULE)

PRODUCCION DEPARTAMENT

13-OPV-09

Sust. PQR No.:

10/7/2009

Revision No.: 001

PAG 1 OF 2

WELDER AND CUTTING DIVISION

F-DEPRO-26-01

OWNER: ARC

WELDNIG PROCESS: FCAW

PROYECT: ARC OFFSHORE PATROL VESSEL, OPV

TYPE: SEMI-AUTOMATIC

TYPE OF JOIN TO WELDING:

TYPE OF JOIN (Details) :

Type of join: FILET WELD

Backing Yes _____ No __X____

Type of material : N/A

Groove angle: N/A____________________

Root face: N/A___________________________

Root opening: _2 to 3 mm______________________

POSITIONS:

Welding positions: 4F

Direction of avance: Overhead

Other: N/A

BASE METALS:

SHIELDING:

P No. __9____ Gr. No. __2____ to P No. __9____ Gr. No. ___2___

Gas : CO2__________________________________

Material specification: ASTM A131 GR AH32 to A131 GR AH32

Flow rate : 40 - 45 cfh_____________________________________

Material Thickness: ______8 mm________ to _____8 mm_________

Composition: CO2 100%_________________________

Diameter range: _____N/A__________ to _____N/A_________

Other: __N/A

Backrest Gas: N/A___________________________________

Flow rate : N/A______________________________________

Composition: N/A__________________________

FILLER METAL:

DESCRIPTION

PASS NUMBER (MULTIPASS)

1

3YH10S

GL quality grade

No. Of specification SFA

No. Clasification AWS

No. F

No. A

Made by

Electrode diameter

Amount of filler metal (Kg/h)

Fundent

Inserto consumible

Others. (Comercial mark)

No. Pass

AWS 5.20

AWS 5.20

E 71T-1C/9C

E 71T-1C/9C

LINCOLN ELECTRIC

LINCOLN ELECTRIC

0,045"

0,045"

2,75 - 9,11

2,75 - 9,11

N/A

N/A

N/A

LW-71

Corriente

Process

2 o/s

3YH10S

N/A

LW-71

Velocity of

Class

Inductance

Amperage

(Amp)

Polarity

Range of

Voltage

OTHER

avance

(mm/min)

1 (Raiz)

FCAW

DCEP

N/A

220 - 230

Inverse (+)

25 - 26

7 - 10

-------

2 (Presentacin)

FCAW

DCEP

N/A

220 - 230

Inverse (+)

25 - 26

7 - 10

-------

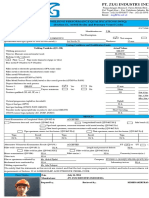

WELDING PROCEDURE SPECIFICATION

(WPS)

WPS

(SPECIFICATION - RULE)

PRODUCCION DEPARTAMENT

WELDER AND CUTTING DIVISION

PREHEATING:

Mn. Temp. :

THERMICAL TREATMENT:

Type : _______N/A_____________________

Ambient

Max. temp. Of interpass :

Star Temp. : _____N/A__________________

93C

Temp. Of thermal treatment: N/A

Heating Rate : ______N/A________________

Conformation Temp.: Ambient

Holding Temp. : _________N/A____________

Temp. Of root pass: Ambient

Holding time : _________N/A_____________

Temp. filling: N/A

Cooling Rate : ________N/A______________

Heating By: Torch

Mode of cooling: _________N/A___________

N/A

EQUIPMENT:

Class:

Estatic

Type: Rectificador -Transformador

Class A.W.S. of Tungsten : N/A

Mode of the material transfer FCAW :

Others:

Longitud:

X Short Circuit

N/A

Spray

N/A

TECHNICAL IMPLEMENTATION

DESCRIPTION

1

Nozzle size

Cordon continuous

Cordon swung or rectum

Manual, Semiautomatic mode

PASS NUMBER (MULTIPASS)

2 o/s

5/8"

5/8"

SWUNG

SWUNG

SEMI-AUTOMATIC SEMI-AUTOMATIC

Martilleo (Peening)

N/A

N/A

Form of endorsement

N/A

N/A

Method of removing the backing

N/A

N/A

18-22 mm

18-22 mm

MULTIPASS

MULTIPASS

PULISH

PULISH

7 - 10

7 - 10

N/A

N/A

Length of the point of contact work and tube

Pass simple or multiple

Clean and initial interpases

Speed application (in/min)

Others

APPROVED BY:

NOTES:

1. Keep the welding electrodes in the furnace

Information

2. Do not the welding prosess under rain

Qualification

Fabrication

3. The working area must be clean free from wind

Usae only in: UNLIMITED_________________

By: TF CAMILO GMEZ

WELDING DIVISION BOSS

Date:

7/23/2009

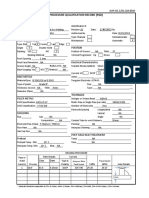

LDING PROCEDURE SPECIFICATION

(WPS)

WPS No.: 13-OPV-09

Sust. PQR No.:

Date:

WPS

(SPECIFICATION - RULE)

7/23/2009

Revision No.: 001

PAG 1 OF 2

F-DEPRO-26-01

Type : _______N/A_____________________________________

Star Temp. : _____N/A___________________________

Heating Rate : ______N/A_______________________

Holding Temp. : _________N/A__________________

Holding time : _________N/A__________________

Cooling Rate : ________N/A_______________________

Mode of cooling: _________N/A_____________________

Diameter:

N/A

Globular

PASS NUMBER (MULTIPASS)

1. Keep the welding electrodes in the furnace

2. Do not the welding prosess under rain

3. The working area must be clean free from wind and humidity.

You might also like

- Ch8. Welding Symbols PDFDocument66 pagesCh8. Welding Symbols PDFMEHMET SIDDIK TEKDEMİRNo ratings yet

- Steel Beam To Column-Welded ConnectionDocument2 pagesSteel Beam To Column-Welded ConnectionAbukalam MullaNo ratings yet

- Wps & PQR For Valve Installation - XLSX Fix TerbaruDocument20 pagesWps & PQR For Valve Installation - XLSX Fix TerbarufebriNo ratings yet

- Welding SlidesDocument334 pagesWelding SlidesAsad Bin Ala Qatari100% (13)

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument43 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesDinesh SinghNo ratings yet

- Fasteners WeightDocument4 pagesFasteners Weightpbp2956No ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- Welding Consumable Storage and Handling ProceduresDocument27 pagesWelding Consumable Storage and Handling ProceduresKannan MurugesanNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 pageWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- European standards for fusion welding quality requirementsDocument1 pageEuropean standards for fusion welding quality requirementshamed100% (1)

- WPS - EngineerDocument20 pagesWPS - Engineerhunghoanglong100% (1)

- WELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928Document2 pagesWELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928duyanhNo ratings yet

- 5 Material and Traceability RecordDocument6 pages5 Material and Traceability RecordEdha Ali100% (1)

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- WPS 204 NewDocument6 pagesWPS 204 Newarockiyathass100% (1)

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Document24 pagesPrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNo ratings yet

- Welding Procecure SpecificationDocument9 pagesWelding Procecure SpecificationNwoha PeterNo ratings yet

- Saudi Aramco WPS Procedure ApprovalDocument7 pagesSaudi Aramco WPS Procedure ApprovalAkansha SharmaNo ratings yet

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocument1 pageWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- WPS SAW D1.1 2015 FormDocument1 pageWPS SAW D1.1 2015 FormHoque AnamulNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- Color Coding Welding Consumables to Prevent MisuseDocument3 pagesColor Coding Welding Consumables to Prevent MisusefizanlaminNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- 177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQDocument4 pages177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- European Standard EN 288-1: 1992 + A1: 1997 Has The Status of A DIN StandardDocument9 pagesEuropean Standard EN 288-1: 1992 + A1: 1997 Has The Status of A DIN StandardSanjay C BhattNo ratings yet

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- AES-W-016 welding filler metalsDocument2 pagesAES-W-016 welding filler metalsmalika_00No ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPQ Form English US1Document2 pagesWPQ Form English US1Maria Louis ArputharajNo ratings yet

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- 5FPipe to plate welding procedureDocument2 pages5FPipe to plate welding procedureTrudie0% (1)

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Wps PQRDocument7 pagesWps PQRsobariNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Define of WPS & PQRDocument16 pagesDefine of WPS & PQRThanh Hua100% (1)

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- Sabari Engineering PQRDocument3 pagesSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- Welder Operators Qualification TestDocument2 pagesWelder Operators Qualification Testlokifarad100% (1)

- Welder Job Clearance Card: Nesma/TanmiaDocument8 pagesWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- PQR Al 6xxxDocument7 pagesPQR Al 6xxxAmin ThabetNo ratings yet

- Welder qualification test recordDocument3 pagesWelder qualification test recordTuTuy AnNo ratings yet

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDocument1 pagePDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينNo ratings yet

- Proposed Welding Procedure Specification (PWPS) : REV:A3Document1 pageProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakNo ratings yet

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNo ratings yet

- P Q R - 005Document2 pagesP Q R - 005Courtney DukeNo ratings yet

- WPQ Is 2062 Haresh Shah W1Document1 pageWPQ Is 2062 Haresh Shah W1Anand KesarkarNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- JIMT Visual Inspection ReportDocument1,913 pagesJIMT Visual Inspection Reportgomathyselvi100% (1)

- Itp GRPDocument4 pagesItp GRPJo FrancescNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- Welder Job Clearance Card Saudi AramcoDocument3 pagesWelder Job Clearance Card Saudi AramcoMohamed Reda Hussein SengarNo ratings yet

- Company Name Weld Procedure SpecificationDocument2 pagesCompany Name Weld Procedure SpecificationAekJayNo ratings yet

- Company Name Weld Procedure SpecificationDocument5 pagesCompany Name Weld Procedure SpecificationMayur KasarNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationSAKDA MAPRADITKULNo ratings yet

- WC4 M6S 2018 1604 MedirDocument2 pagesWC4 M6S 2018 1604 MedirPedro José PadillaNo ratings yet

- No Hieras Mi Vida Score - Acoustic BassDocument1 pageNo Hieras Mi Vida Score - Acoustic BassPedro José Padilla0% (1)

- Evidence 2 Recognising Body Parts - Pedro PadillaDocument3 pagesEvidence 2 Recognising Body Parts - Pedro PadillaPedro José PadillaNo ratings yet

- Evidence Sports and AnimalsDocument2 pagesEvidence Sports and AnimalsPedro José PadillaNo ratings yet

- Arc Welding, TIG Welding and Welding DVD CollectionDocument27 pagesArc Welding, TIG Welding and Welding DVD CollectionPedro José PadillaNo ratings yet

- Brazing Manual American Welding SocietyDocument8 pagesBrazing Manual American Welding SocietyJulio ValandroNo ratings yet

- Optimizing welding procedures for pressure vesselsDocument12 pagesOptimizing welding procedures for pressure vesselsBoran YelkenciogluNo ratings yet

- IIT GUWAHATI Lec2Document26 pagesIIT GUWAHATI Lec2DCNo ratings yet

- Laboratory Exercise-I Spot Welding Objective: AdvantagesDocument4 pagesLaboratory Exercise-I Spot Welding Objective: AdvantagesAsadRehmanNo ratings yet

- Especificacion de Torque EnglishDocument4 pagesEspecificacion de Torque EnglishpetercuriNo ratings yet

- Weidmuller Screw Connection Terminal AccessoriesDocument30 pagesWeidmuller Screw Connection Terminal AccessoriesPeralta FcoNo ratings yet

- Asme Sec Ix IndexDocument5 pagesAsme Sec Ix IndexOscar Newton LuvisNo ratings yet

- Rationalized List of Welding ConsumablesDocument7 pagesRationalized List of Welding Consumablespraveentien0% (1)

- Asignar Ubicacion - 6Document53 pagesAsignar Ubicacion - 6Recepción Pesquera diamanteNo ratings yet

- Visual Examination ProcedureDocument4 pagesVisual Examination ProcedureBudi IndraNo ratings yet

- 27 AprvdGmaDocument68 pages27 AprvdGmacereferNo ratings yet

- MIG Welding Safety and ProceduresDocument15 pagesMIG Welding Safety and Procedureshafi zackNo ratings yet

- Control Bop Ideal-NovDocument25 pagesControl Bop Ideal-NovpabloNo ratings yet

- Manual Partes QUINCYDocument32 pagesManual Partes QUINCYasistecoilcasablancaNo ratings yet

- Cahier de Soudage G 11950 - Ver B - WPS 14Document1 pageCahier de Soudage G 11950 - Ver B - WPS 14YassineElabdNo ratings yet

- IKH TootjaDocument104 pagesIKH TootjakamikazewuNo ratings yet

- Lap 2Document3 pagesLap 2Hussein Alaa AltaiNo ratings yet

- Delay On Timer Using BC547 Transitor 1 PDFDocument1 pageDelay On Timer Using BC547 Transitor 1 PDFNguyen Phuoc HoNo ratings yet

- Wps Smaw3g Smaw B-U2 (Vacio)Document1 pageWps Smaw3g Smaw B-U2 (Vacio)Richard Gonzales CapchiNo ratings yet

- Spare PartsDocument3 pagesSpare PartsERepublikPolskaNo ratings yet