Professional Documents

Culture Documents

2.2 Attachment (B) HAZOP Matrix

Uploaded by

KrishnaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.2 Attachment (B) HAZOP Matrix

Uploaded by

KrishnaCopyright:

Available Formats

ELEMENT 2 - RISK ASSESSMENT & MANAGEMENT

KHURSANIYAH GAS PLANT DEPARTMENT SAFETY MANAGEMENT

SYSTEM

HAZARD AND OPERABILITY (HAZOP) STUDIES

2.2 Attachment B: HAZOP Risk Ranking Matrix

(HAZOP Recommendation Prioritization)

A FIVE POINTS SEVERITY LEVELS

1.

2.

3.

4.

5.

LEVEL

Very High

SEVERITY

Multiple employee fatalities

Public fatalities and injuries

Extensive property damage

Major environmental impact

Major adverse public reaction

Employee fatalities

Public injuries

Significant property damage

Significant environmental impact

Adverse public reaction

Employee injuries

Minor public injuries

Moderate property damage

Moderate environmental impact

Moderately adverse public reaction

Minor employee injuries

No public injuries

Minor property damage

Minor environmental impact

No adverse public reaction

HIGH

MEDIUM

LOW

INSIGNIFICANT

Operational upset

No

No

No

No

No

employee injuries

public injuries

property damage

environmental impact

adverse public reaction

B FIVE POINTS HAZARD LIKELHOOD LEVELS

LEVEL

LIKELIHOOD

1.

Very High

Expected to occur more than once in a year

2.

High

Expected to occur no more than once in a year

3.

Medium

once during the facility lifetime

4.

Low

Expected to occur no more than once in the facility lifetime

5.

Very Low

Not expected to occur during the facility lifetime

Expected to occur more than

C HAZOP Risk Ranking Matrix

Likelihood Level

1

1

10

10

10

4

1

2

Severity Level

4

5

Common HAZOP Analysis Terminology

Term

Process Section

(or study node)

Operating Step

Intention

Guide Word

Process

Parameter

Deviations

Cause

Consequences

Safeguards

Recommendation

s (or action)

Hazard

Definition

The location on P&ID at which the process parameters are

investigated for deviation (e.g., vessel)

Distinct actions in a batch process or a procedure analyzed

by a HAZOP team. May be manual, automatic, or software

implemented actions.

Definition of how the plant is expected to operate in the

absence of deviations.

Words or phrases, when considered together with a

parameter, form a hypothetical deviation for the HAZOP

team to consider.

Physical or chemical property associated with the process.

Includes general items reaction, concentration, pH and

specific items such as temperature, pressure, phase, flow.

Changes from the design intention which are discovered by

applying the guide word/parameter combination to the

study process.

These are the reasons why deviations might occur. Once a

deviation has been shown to have a conceivable or realistic

cause, it can be treated as meaningful.

Results of deviation (e.g., release of toxic materials).

Normally, the team assumes active protection system fails

to work. Minor consequences, unrelated to the study

objective, are not considered.

Engineered systems or administrative controls designed to

prevent the causes or mitigate the consequences of

deviations (e.g., process alarms, interlocks, procedures)

Suggestions for design changes, procedural changes, or

areas for further study (e.g., adding redundant pressure

alarm or reversing the sequence of two operating steps)

The sequences which can cause damage, injury or loss

Sample HAZOP Analysis Guide Words and Meanings

Guide Word

Meanings

No

Negation of the Design intent

Less

Quantitative Decrease

More

Quantitative Increase

Part of

Qualitative Decrease

As Well As

Qualitative Increase

Reverse

Logical Opposite of the Intent

Other than

Complete Substitution

Common HAZOP Analysis Process Parameters

Flow

Time

Composition

Temperature

pH

Speed

Frequency Mixing

Pressure

Viscosity

Addition

Voltage

Separation Level

Information

Reaction

You might also like

- Paediatric Triage PosterDocument1 pagePaediatric Triage PosterGenaro Olmos Garcia100% (2)

- Hazop Study TemplateDocument3 pagesHazop Study TemplateLunga Dan Patso100% (1)

- The Rules in Roman MosaicsDocument14 pagesThe Rules in Roman MosaicsPatSob100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- NORSOK Z-CR-007 Mechanical Completion and CommissioningDocument27 pagesNORSOK Z-CR-007 Mechanical Completion and CommissioningWilkin Llanca Blas100% (1)

- Savage Worlds Omega World W CSDocument41 pagesSavage Worlds Omega World W CSLucidMacabre100% (9)

- Hazid Hazop Sil TorDocument24 pagesHazid Hazop Sil Torabboud50% (2)

- Hazop StudyDocument7 pagesHazop StudyAnderson JoeNo ratings yet

- HAZOP ProcedureDocument10 pagesHAZOP Proceduresharjeel39100% (3)

- 4428 Industrial Hygiene BPDocument4 pages4428 Industrial Hygiene BPmohitNo ratings yet

- Aeration Control System Design: A Practical Guide to Energy and Process OptimizationFrom EverandAeration Control System Design: A Practical Guide to Energy and Process OptimizationNo ratings yet

- Risk Assessment - OSH AnswersDocument10 pagesRisk Assessment - OSH AnswersSARFRAZ ALI100% (1)

- Adult 3 FinalDocument29 pagesAdult 3 Finalأبوأحمد الحكيم100% (1)

- 2 4 HazopDocument14 pages2 4 HazopIMPG077080No ratings yet

- Hazop Analysis PDFDocument4 pagesHazop Analysis PDFsajid aliNo ratings yet

- CHAPTER 8 Hazop StudyDocument7 pagesCHAPTER 8 Hazop StudyNethiyaa50% (2)

- Lecture 8Document36 pagesLecture 8ashrfNo ratings yet

- A HAZOP AnalysisDocument2 pagesA HAZOP AnalysisSameer ShekharNo ratings yet

- Environmental Aspect ID and AnalysisDocument3 pagesEnvironmental Aspect ID and AnalysisAnonymous r3SWKnHbw100% (1)

- Environmental Aspects and Impacts Assessment Guide: PTS 60.3202 June 2006Document34 pagesEnvironmental Aspects and Impacts Assessment Guide: PTS 60.3202 June 2006enviroNo ratings yet

- Lecture-4 &5Document99 pagesLecture-4 &5Anusha DesaiNo ratings yet

- Hazard and Operability StudyDocument7 pagesHazard and Operability StudyJian HongNo ratings yet

- PCP & FmeaDocument4 pagesPCP & FmeaDaniela AscolaniNo ratings yet

- HazOP Report SummaryDocument13 pagesHazOP Report Summarymir shifayatNo ratings yet

- Process Safety Management: A Legal and Technical Overview: Session No. 526Document15 pagesProcess Safety Management: A Legal and Technical Overview: Session No. 526Waqas Ahmad KhanNo ratings yet

- How To Use Fmea To Reduce The Size of Your Quality ToolboxDocument4 pagesHow To Use Fmea To Reduce The Size of Your Quality ToolboxJosé Esqueda Leyva100% (2)

- Chapter 5 - Hazard IdentificationDocument53 pagesChapter 5 - Hazard IdentificationChieng Tiew Hing100% (1)

- Hazard Identification and HAZOP StudyDocument53 pagesHazard Identification and HAZOP StudyNur Rofium100% (2)

- Tentative Schedule For Environment and Safety: Week 11-12Document39 pagesTentative Schedule For Environment and Safety: Week 11-12EMILY BLANDFORDNo ratings yet

- Hazard Management in Pharma Industries: Design & Operation For Safety EnhancementDocument30 pagesHazard Management in Pharma Industries: Design & Operation For Safety EnhancementAjay TiwariNo ratings yet

- Risk ManagementDocument52 pagesRisk ManagementV. Balasubramaniam100% (1)

- HAZOP Study Methodology - 2 IEDOSH JB - StudentDocument116 pagesHAZOP Study Methodology - 2 IEDOSH JB - StudentAhmad Fauzie Ibrahim IsmailNo ratings yet

- Chapter # 7: Hazop StudyDocument6 pagesChapter # 7: Hazop StudyAli AhsanNo ratings yet

- Gerry BrennanDocument24 pagesGerry BrennancommiedaveNo ratings yet

- Safety: 1.2.1. Qualitative Hazard Analysis TechniquesDocument5 pagesSafety: 1.2.1. Qualitative Hazard Analysis TechniquesZeyad ZeitounNo ratings yet

- ODS-QHSE-SP-07 - Environmental Aspect ManagementDocument5 pagesODS-QHSE-SP-07 - Environmental Aspect ManagementFahmi AbdullahNo ratings yet

- Li LiDocument27 pagesLi LiSardar PerdawoodNo ratings yet

- Hazop-Gas Processing ComplexDocument2 pagesHazop-Gas Processing ComplexjavadNo ratings yet

- General Overview of HAZOP MethodDocument9 pagesGeneral Overview of HAZOP MethodSwaminathan ThayumanavanNo ratings yet

- Application of HAZOP Study in Key SOP of Oil and Gas PipelinesDocument7 pagesApplication of HAZOP Study in Key SOP of Oil and Gas PipelineshanselozgumusNo ratings yet

- P5-Procedure For Identification and Evaluation of Environmental Aspects.Document4 pagesP5-Procedure For Identification and Evaluation of Environmental Aspects.Samsu Sams100% (1)

- Stages of EiaDocument3 pagesStages of EiaAdrian HabitanNo ratings yet

- ASTM E2590-09 Standard Guide For Conducting Hazard Analysis-Critical Control Point (HACCP) Evaluations PDFDocument18 pagesASTM E2590-09 Standard Guide For Conducting Hazard Analysis-Critical Control Point (HACCP) Evaluations PDFsvp360No ratings yet

- RiskDocument5 pagesRiskAnkit PatelNo ratings yet

- Module 12: Operational Control: EMS Template Revision 2.0 (March 2002)Document15 pagesModule 12: Operational Control: EMS Template Revision 2.0 (March 2002)Ruth Job L. SalamancaNo ratings yet

- Industrial Safety & Maintenance HAZOP StudyDocument57 pagesIndustrial Safety & Maintenance HAZOP Studyhagos dargoNo ratings yet

- Applying Process Hazard Analysis To Laboratory HVAC Design: Ashrae JournalDocument4 pagesApplying Process Hazard Analysis To Laboratory HVAC Design: Ashrae JournalhvananthNo ratings yet

- HSE Risk Assessment ProcedureDocument6 pagesHSE Risk Assessment ProcedureAjas AjuNo ratings yet

- Fmeca ProcedureDocument11 pagesFmeca Procedurewarigiyatno100% (1)

- 6.1.2 Gasification ReactorDocument2 pages6.1.2 Gasification ReactorShemzinhoNo ratings yet

- 6.1.2 Gasification ReactorDocument2 pages6.1.2 Gasification ReactorShemzinhoNo ratings yet

- Asl Testing - Template Test PlanDocument12 pagesAsl Testing - Template Test PlanBalaji ElanchezhiyanNo ratings yet

- Performing HAZOP StudiesDocument7 pagesPerforming HAZOP Studieskforan1267No ratings yet

- Anomaly Management Plan and Tracking ProcessDocument15 pagesAnomaly Management Plan and Tracking ProcessNahar ElliasNo ratings yet

- Hazop CH 13Document7 pagesHazop CH 13Asma Fayyaz67% (3)

- Ch.E-403 Chemical Engineering Plant Design: Dr. Syed Zaheer AbbasDocument56 pagesCh.E-403 Chemical Engineering Plant Design: Dr. Syed Zaheer Abbasfarukh azeemNo ratings yet

- T12A Papierz Arkadiusz TORASDocument6 pagesT12A Papierz Arkadiusz TORASArek PapierzNo ratings yet

- Hazard Operability StudiesDocument8 pagesHazard Operability StudiesPendi Adi MertaNo ratings yet

- CEMS-Chapter 3Document8 pagesCEMS-Chapter 3api-3754841No ratings yet

- Environmental Aspects Identification and Assessment - ProcDocument9 pagesEnvironmental Aspects Identification and Assessment - ProcAamir MukhtarNo ratings yet

- Risk Assessment DeliverablesDocument7 pagesRisk Assessment DeliverablesHani AhmedNo ratings yet

- Long IFTPS 2015Document38 pagesLong IFTPS 2015Mohamed Ali BoumarafNo ratings yet

- HAZOPDocument7 pagesHAZOPfairusNo ratings yet

- Troubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingFrom EverandTroubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingRating: 4.5 out of 5 stars4.5/5 (3)

- Plantwide Control: Recent Developments and ApplicationsFrom EverandPlantwide Control: Recent Developments and ApplicationsGade Pandu RangaiahNo ratings yet

- Aquagaurd - Enhance - RO+UV - Manual by GKDocument1 pageAquagaurd - Enhance - RO+UV - Manual by GKKrishnaNo ratings yet

- Jazz - Installing LED DRLsDocument16 pagesJazz - Installing LED DRLsKrishnaNo ratings yet

- Thermal Power PlantDocument13 pagesThermal Power PlantThulasi RamNo ratings yet

- 2018 TeluguDocument13 pages2018 TeluguLeela KNo ratings yet

- Brochure Steam and Water Analysis System Brochure DataDocument8 pagesBrochure Steam and Water Analysis System Brochure DataKrishnaNo ratings yet

- Companywise Plant ListDocument1 pageCompanywise Plant ListKrishnaNo ratings yet

- Selection of Automatic Cars in 2020Document6 pagesSelection of Automatic Cars in 2020KrishnaNo ratings yet

- Location of Chassis and Engine NumbersDocument9 pagesLocation of Chassis and Engine NumbersWilliam Cj LyngdohNo ratings yet

- ReferenceDocument1 pageReferenceKrishnaNo ratings yet

- 2018 TeluguDocument13 pages2018 TeluguLeela KNo ratings yet

- Cost of Living in Bentonville, Arkansas. Oct 2018. Prices in BentonvilleDocument5 pagesCost of Living in Bentonville, Arkansas. Oct 2018. Prices in BentonvilleKrishnaNo ratings yet

- Part 2 Pharma Industry in India - Pharma Sector Overview, Market Size, Analysis..Document1 pagePart 2 Pharma Industry in India - Pharma Sector Overview, Market Size, Analysis..KrishnaNo ratings yet

- Calibration Fundamentals ExplainedDocument10 pagesCalibration Fundamentals ExplainedCris RonaldNo ratings yet

- Uses of Petrochemicals - Dyes, Synthetic Shoes, DetergentDocument1 pageUses of Petrochemicals - Dyes, Synthetic Shoes, DetergentKrishnaNo ratings yet

- List of Companies in India, Indian Companies Names, Biggest & Largest Industries in IndiaDocument1 pageList of Companies in India, Indian Companies Names, Biggest & Largest Industries in IndiaKrishnaNo ratings yet

- Process Analyzers - Yokogawa IndiaDocument4 pagesProcess Analyzers - Yokogawa IndiaKrishnaNo ratings yet

- List of Companies in India, Indian Companies Names, Biggest & Largest Industries in IndiaDocument1 pageList of Companies in India, Indian Companies Names, Biggest & Largest Industries in IndiaKrishnaNo ratings yet

- Template For Proposals enDocument3 pagesTemplate For Proposals enquark87100% (2)

- Agilent CareersDocument12 pagesAgilent CareersKrishnaNo ratings yet

- BioTector Data Analysis For TroubleshootingDocument27 pagesBioTector Data Analysis For TroubleshootingKrishnaNo ratings yet

- Oil & Gas Industry in India - Petroleum, Natural Gas, Market Stats IBEFDocument5 pagesOil & Gas Industry in India - Petroleum, Natural Gas, Market Stats IBEFKrishnaNo ratings yet

- PMI ExercisesDocument1 pagePMI ExercisesKrishnaNo ratings yet

- 7-Analytical Services Manager (CSE)Document3 pages7-Analytical Services Manager (CSE)KrishnaNo ratings yet

- English BasicsDocument3 pagesEnglish BasicsKrishnaNo ratings yet

- P S: B - T (A Names of Books Arrenged in Alphabetical Order of Devanågr Script)Document7 pagesP S: B - T (A Names of Books Arrenged in Alphabetical Order of Devanågr Script)KrishnaNo ratings yet

- BankingDocument38 pagesBankingArjun SainiNo ratings yet

- Application Note Flue Gas Analysis As A Boiler Diagnostic Tool DataDocument8 pagesApplication Note Flue Gas Analysis As A Boiler Diagnostic Tool DataKrishnaNo ratings yet

- IIT FTPA2000-400 Series - 4077Document4 pagesIIT FTPA2000-400 Series - 4077KrishnaNo ratings yet

- Chemical and Physical Properties of Refined Petroleum ProductsDocument36 pagesChemical and Physical Properties of Refined Petroleum Productskanakarao1No ratings yet

- Facts: The 'But For' TestDocument4 pagesFacts: The 'But For' TestRachit MunjalNo ratings yet

- Knee InjuryDocument44 pagesKnee Injuryhendi_filipus_90No ratings yet

- Lab Safety EssentialsDocument80 pagesLab Safety EssentialsJunior Jenis100% (1)

- Acknowledging help for a first aid projectDocument9 pagesAcknowledging help for a first aid projectAshish Goel100% (1)

- Hydraulic Fracture Mechanics: Peter Valk6 Michael EconomidesDocument6 pagesHydraulic Fracture Mechanics: Peter Valk6 Michael EconomidesAdib Wahyu HidayatNo ratings yet

- MGR Univ - PerioDocument8 pagesMGR Univ - PerioMohamed FaizalNo ratings yet

- NPC V Heirs of CasionanDocument2 pagesNPC V Heirs of CasionanAnonymous hS0s2moNo ratings yet

- Understanding Child Abuse: Causes, Signs, SolutionsDocument7 pagesUnderstanding Child Abuse: Causes, Signs, Solutionsdew23No ratings yet

- MSK Clin Skills Manual General GuideDocument5 pagesMSK Clin Skills Manual General GuideDr. Mohamed ElzakiNo ratings yet

- Navy SEAL Trainee Death Ruled A HomicideDocument15 pagesNavy SEAL Trainee Death Ruled A HomicideDan LamotheNo ratings yet

- Downward Movement - Left Hand Only: (Figure 3-7Document20 pagesDownward Movement - Left Hand Only: (Figure 3-7mamun31No ratings yet

- DAKE Press Model 75 H - 907003Document6 pagesDAKE Press Model 75 H - 907003mark_dayNo ratings yet

- Chaotic Sword God - Xin Xing Xiao Yao - 2Document300 pagesChaotic Sword God - Xin Xing Xiao Yao - 2Pain ExternoNo ratings yet

- 03.00 - Operating Instructions - en - SM150 Cooling UnitDocument100 pages03.00 - Operating Instructions - en - SM150 Cooling UnitCesar Eduardo ConejoNo ratings yet

- Scaffolding PresentationDocument57 pagesScaffolding PresentationRmr ReyesNo ratings yet

- IGC2 Ques and AnswersDocument6 pagesIGC2 Ques and AnswersChi IkkiNo ratings yet

- Subdural HematomaDocument5 pagesSubdural Hematomaluisse ann100% (1)

- ZM-MFC1 Combo: To Ensure Safe and Easy Installation, Please Read The Following PrecautionsDocument7 pagesZM-MFC1 Combo: To Ensure Safe and Easy Installation, Please Read The Following PrecautionsnegatronnNo ratings yet

- T60n02rg PDFDocument8 pagesT60n02rg PDFsandor9116100% (2)

- War Essay 2Document12 pagesWar Essay 2api-280869491No ratings yet

- Jotungard Large RacesDocument16 pagesJotungard Large Racesfishguts4ever100% (10)

- 14 Skeletal System PDFDocument43 pages14 Skeletal System PDFMeisseh Kirsten Estubio100% (2)

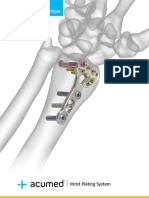

- Acu-Loc IIDocument36 pagesAcu-Loc IIEdnor GalvaoNo ratings yet

- 5.10.18 Full PaperDocument16 pages5.10.18 Full PaperLara LoveNo ratings yet

- The Science of ErgonomicsDocument43 pagesThe Science of Ergonomicspoonam_ranee3934No ratings yet