Professional Documents

Culture Documents

TOCIEJ-9-388 Permeability of Subballast PDF

Uploaded by

PetruMarcuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TOCIEJ-9-388 Permeability of Subballast PDF

Uploaded by

PetruMarcuCopyright:

Available Formats

Send Orders for Reprints to reprints@benthamscience.

ae

388

The Open Civil Engineering Journal, 2015, 9, 388-393

Open Access

Permeability and Direct Shear Tests Characteristics of Railway Subballast

Guoqing Jing1, Zijie Wang1, Hongmei Huang1 and Yan Wang2,*

1

School of Civil Engineering, Beijing Jiaotong University, Beijing 100044, P.R. China

School of Civil Engineering and Architecture, Zhejiang Sci-Tech University, Hangzhou, 310018, P.R. China

Abstract: Permeability, filtration and shearing strength were widely considered to be the key properties in evaluating the

performance of railway subballast. An investigation on these key properties of railway subballast was presented in this

paper. A constant head permeability test and a middle scale direct shear test of railway subballast were conducted in the

research, aiming to investigate the subballast permeability and shear direct tests characteristics. Four different designed

gradations within the standards were subjected to the investigation in order to study the particle size distribution effect on

permeability performance of subballast. Lab results showed that drainage capacity and shearing strength of subballast

highly correlated with each other. Subballast with more large-size particles and a low coefficient of uniformity were

proved to acquire good drainage of water and strong resistance ability to shear.

Keywords: Drainage, particle size distribution, permeability test, subballast.

1. INTRODUCTION

Railway subballast which serves between ballast layer

and subgrade layer is composed of much finer particles than

the upper ballast. It was widely considered to work as a filter

which on the one hand prevented the mutual penetration between ballast and soft soil subgrade (known as the slurry

pumping), on the other hand permitted drainage of water

from the above rainfall and wet subgrade below [1]. Any

sand or gravel stones could serve as subballast provided that

they meet the grading standard and, most importantly, filtering requirements. Meanwhile as an important load-bearing

layer in the track structure, subballast needs adequate shearing strength to transmit and spread the cyclic load from to

the soft soil subgrade as trains roll by.

A good drainage of ballasted bed is necessary to ensure

an acceptable track performance. While as ballast ages, the

track bed becomes slowly fouled by slurry from the soil subgrade, wearing between particles and fines like sand and coal

ash from the surface ballast in some heavy-haul lines. For

instance, cyclic loading from the passing traffic transferred

to the subballast layer and enhanced the attribution and create fines at the particles interface [1]. The trapped fines in

the void changed the porosity and grading of ballast and, as a

result, reduced the drainage capability of subballast layer.

According to Huang about 15% of the fouling source was the

infiltration from subgrade and Selig regarded this percentage

as 13% [1, 2]. In some poorly drained situation like some

low lying coastal areas, cyclic rail load acted as a pump

which generated a huge pore water pressure and thus applied

a vertical seepage force which sucked the slurry into the ballast layer [3]. So drainage capability played a key role in

stability and safety of the track structure.

*Adress correspondence to this author at the School of Civil Engineering

and Architecture, Zhejiang Sci-Tech University, Hangzhou, Zhejiang,

310018, P.R. China; Tel: +8613867491189; E-mail: an_wangyan@126.com

1874-1495/15

Deep understanding of subballst function especially the

mechanism of drainage when serving as a filtration is of vital

importance to ensure a maximum performance of the subballast filter layer. While clogging of subballast and problems

concerned were generally ignored during the design of the

track. Previous design procedures for filters of granular material paid more attention to the soil erosion, stabilizing dams

and retaining structures which differ from subballast in structure and function [4-8]. Although some researchers proposed

amount of empirical models regarding to the filtration of

granular materials for the embankment dams [9-13], few of

them was fit for ballasted track construction as the loading

system of the railway track was cyclic different from the

slowly penetration force of embanks. According to Trani,

cyclic loading generated by the passing trains has a great

influence on the seepage of the filtration of the subballast

layer [14]. The subballast layer was subjected to a load of

30kPa at least and 70kPa at most which equals to the vertical

stress induced by heavy haul trains, according to Christie

[15]. Trani considered plastic deformation and accumulation

of the migration fine created during the cyclic load as the

main factors that contribute to the reduction of the porosity

and permeability over time [16]. Therefore, research on the

filtration performance of subballast was required to establish

a design criteria for the railway system. To solve the problems above, many other researchers even devoted in exploring possibilities of using bituminous subballast layers instead

of granular ones [17-20]. However this kind of theoretical

method is far from application and much expensive for

large-scale applications.

To satisfy the drainage requirement of subballast, uniformly graded particles were usually applied in the construction, which may lead to a structurally instability and poor

filtration due to the large void between particles. From the

perspective of the structure itself, demand of the main functions of subballast are contradictory to some extent. So a

2015 Bentham Open

Permeability and Direct Shear Tests Characteristics of Railway Subballast

The Open Civil Engineering Journal, 2015, Volume 9

balanced grading is needed to ensure the filtration, drainage

as well as enough shearing strength to reduce track pumping

and ballast fouling and prolong track lifetime.

389

with particles ranging from 0.075 to 45mm. As gradations

deeply influence performance of particles, the selection of

gradation has a great effect on the results of the test and research. Four gradations of subballast were designed according to the standard to ensure sufficient void which could

provide efficient drainage of water.

Abundant researches were conducted to better particles

composition [21-24]. Results revealed that particle size distribution have a deep influence on the subballast performance which showed well-graded packs of ballast which have

a high Cu usually have two problems which were size segregation and reduction of drainage [25]. Research by Jannati

also proved that a higher Cu often causes a higher rate of

breakage [19], while lab results showed that well-graded

subballast had enhanced filtration ability. For the uniformly

graded ballast which have a low Cu, researches were conducted to show that it have a poor resistance against deformation and its advantage of permeability would be weakened

sharply after the application of cyclic stress.

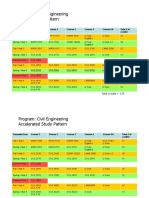

After carefully sieving the granular material into four

ranges of size by conducting sieve analysis test in Beijing

Jiao tong University, the particle size distributions of the

four samples were plotted in Fig. (1) and thus the following

parameters were determined and shown in Table 1: maximum size, minimum size, coefficient of uniformity (Cu) and

coefficient of curvature (Cc).

100

Sample A

Sample B

Sample C

Sample D

Standard

Percent Passing

In this paper four gradations of subballast were chosen

according to Chinese high speed railway standard to explore

the effect of aggregate gradation on the two structural contradictory properties, permeability and shearing strength of

the subballast, through constant head permeation experiment

and direct shear experiment. Results revealed that particle

size distribution have a deep influence on the performance of

subballast and specimen with more fine particles showed

good filtration while poor permeability and shearing

strength. Gradations of subballast have a deep impact on the

shearing strength and the permeability which demonstrate

that voids between particles played a key role on the performance of subballast. The resistance of the subballast layer

decreased as the percentages of fine particles increased

which retained more water which filled the voids in the same

situation. Meanwhile the permeability also decreased as the

voids were filled with more fine particles. Therefore, permeability and resistance were correlated and both have a strong

relation with particle size distribution.

80

60

40

20

0.1

Seive Size / mm

10

Fig. (1). Particle size distribution.

2.2. Permeability Test

A middle-scale permeameter which could accommodate

a specimen of 40mm in diameter and 40mm in height was

introduced in the test. It was made of transparent plastic to

allow visual observation and the constant head was put

above the apparatus with a 5cm diameter pipe installed below the fiber screen which was used to drain the water in the

cell. In order to prevent the fines going through, a fiber glass

layer was laid beneath the sample. The principle of constant

head permeameter which was shown as Fig. (2) was designed and assembled in Hydraulic Engineering Laboratory

in Shangdong University.

2. MATERIAL AND EXPERIMENTAL METHODOLOGY

This section includes descriptions of properties of subballast with different gradations applied in this research. Setups

and procedures of the constant head permeability test and

direct shear test were also introduced in this part. The hydraulic conductivity was determined through the permeability and then the same sample with the same gradations were

used in the following direct shear test.

In order to accurately record the pressure and water velocity during the test, two electrical water pressure sensors

and an ultrasonic velocity meter were introduced in the test.

All sensors were connected to the computer through an A/D

converter and a computer program was written before the

test to control the process of the test and record the data in

2.1. Material

The rail road subballast which meet Chinese railway

standard were supplied by CARS and involved materials

Table 1. Parameters of four kinds of specimen.

Sample

maximum size

45

35

30

25

minimum size

0.5

0.1

0.075

0.03

Cu

14

27

32

44

Cc

1.79

1.55

0.83

0.57

390

The Open Civil Engineering Journal, 2015, Volume 9

Jing et al.

real-time. Before the permeability test each sample was immersed into the water for more than one day to completely

fill the micro pours on the surface of subballast.

The middle-scale direct shear apparatus shown in Fig. (3)

has an upper and a lower shear box. Afterwards the subballast were packed by lift in the shear box where each lift

should be compacted with a vibratory, a certain normal stress

was applied to the subballast sample. With the lasting vertical pressure, the sample was sheared strain-controlled with a

loading rate of 5mm/min by pushing the upper shear box

horizontally during which the lateral displacement and the

shearing force were recorded through the sensor installed on

the inner surface of the box. For safety reasons, the maximum horizontal displacement was set to 10% strain which

equals to 3cm in total.

Fig. (2). Principle of apparatus of permeability test.

The cylindrical test cell as well as the fiber screen above

which the packed subballast was put should be washed before every test. To get accurate results, the fiber screen

should be fastened tight in the bottom and around the corner

of the cell to prevent the migrating of fine particles. A steady

state flow was established as water gradually filled the transparent test cell to ensure the applicable of Darcy law as follows:

k=

v

i

vL

!h

(1)

where k is the permeability; v is the velocity of water in

specimens; i is the hydraulic gradient; h is the head loss; L

is the length of the specimen.

Firstly, water drained out from the bottom pipe was collected for a recorded time period. Then this procedure should

be repeated twice or more for each grading of subballast

sample to get mean required values above. Finally, the permeability of each sample could be calculated through the

formula above.

2.3. Direct Shear Test

Direct shear test on subballast was then performed in

railway engineering laboratory of Beijing Jiaotong University. The specimens used in this test had the same grading

with those used in the permeability test in order to investigate the influence of size effect and three serials of test were

conducted for each gradation under the same condition.

Since aggregates studied in this test is small (45mm top sized

subballast sample), the middle-scale direct shear apparatus

used in this test with a size of 30*36*24cm could minimize

the size effect.

Fig. (3). Direct shear apparatus.

3. RESULTS AND DISCUSSIONS

Several constant head permeability tests were conducted

for each grading after which the calculated hydraulic conductivities of the four kinds of subballast with equation (1)

were plotted in Fig. (4) and indicated by different shapes and

colors of points and lines. An obvious increase of the conductivity could be founded as the size of the particle became

larger from sample D to A which may due to the increasing

of the void between aggregates since the grading curve of the

samples moved rightwards. While from this figure it could

be shown that the size effect of particles became deeper

when the dimension turned to be small enough. The value of

permeability for sample A B C lies above the 10-5m/s threshold. Lambe and Head indicated that these three kinds of gradations possess good drainage while sample D should only

be classified as relative poor drainage which may due to the

increasing percentage of fine particles in sample D [26, 27].

Size distribution played a major role in the permeability of

subballast. The research results indicate that the subballast

material should be well specified for the PSD, aiming the

good performance of water permeability, as well as the compression strength ability.

Permeability and Direct Shear Tests Characteristics of Railway Subballast

The Open Civil Engineering Journal, 2015, Volume 9

391

Hydraulic conductivity (m/s)

10

Hydraulic conductivity

(10 m/s)

1E-3

-4

9

8

7

1E-4

Sample A

Sample B

Sample C

Sample D

1E-5

Good drainage

Poor drainage

3

2

1E-6

Percent Passing

The shear force dramatically increased in the beginning

of shear displacement until the sample researched its shearing strength which also improved as the normal strength increased. For the test with large normal stress (150kpa,

200kpa) the shear stress slightly reduced after 1cm of the

shearing displacement.

Sample A

Sample of Trani

40

20

0

0.1

was reflected as a sudden falling in the curve could be observed visually in the shearing box after the test.

60

0.01

Group of Test

Fig. (6). Comparison of permeability of subballast.

Fig. (4). Permeability of subballast.

80

Group of Test

100

Sample A

Sample of Trani

Seive Size / mm

10

Fig. (5). Comparison of particle size distribution.

Trani also conducted a permeability experiment with

railway subballast which conforms to standard of Australia.

The particle size distribution of specimen he used in the test

is shown as the thicker line in Fig. (5). It can be concluded

from the comparison of these two distributions that two

samples were quite familiar, while sample A contained more

fine particles than sample used by Trani. Thus a relative big

distinction in the permeability of the two samples could be

found in the experiment results through Fig. (6). Sample A

showed an obvious reduction of drainage capability in the

test which may due to the presence of the particles with a

smaller size. These demonstrate that small-sized particle

played a key role in governing the permeability of subballast.

The accumulated fine particles generated from the abrasion

between particles and pollution greatly influenced the performance of subballast and ballast.

To investigate the influence of the confining pressure, the

direct shear test was conducted for different samples of subballast at four different normal pressures, 50kpa, 100kpa,

150kpa, 200kpa. Fig. (7) which reveals the behavior of each

sample shows the typical trend of the shear stress varying

with the lateral displacement of the shear box under the four

normal stresses for sample A to D. The curves plotted in this

figure are not smooth which may due to the crushing of the

particles during the shearing process and this crushing which

Meanwhile for the tests with relative low normal stress

which agreed with the actual situation, the shearing stress

versus the shear displacement of different gradations was

plotted in Fig. (8) which showed that samples with higher Cu

while lower Cc showed stronger resistance to shearing. This

may mainly due to the presence of larger amount of largesized particles which caused higher overall density and average stiffness of the sample. Results showed that there was no

significant gap between peak shear stresses of sample A to

C, while the shearing strength of sample D was much lower

than other samples with higher Cu. Whats more, samples

with more fine particles and higher Cu reached its shearing

strength earlier than the others. On the other hand, the dilatancy effect was observed during the lab test except for

small-sized sample D which exhibited a constant contraction

process all along.

CONCLUSION

The railway subballast constant head permeability test

and direct shear tests of railway subballast were employed to

investigate the possible relation between permeability and

shearing strength which both were the key properties for

subballast. During the laboratory test, four designed gradations were applied to the experimental materials according to

Chinese railway standard. A steady state laminar flow was

maintained to ensure the applicability of Darcys law in the

permeation experiment and four normal stresses ranging

from 50kpa to 200kpa were applied in the shear test. These

two lab test results suggested that grain compositions, to be

more specific the particle size gradations, influenced the

performance of subballast material. Some important conclusions are given as follows:

1.

The two lab tests suggested that the permeability and

shearing strength which are the two vital properties of

subballast are correlated significantly.

The Open Civil Engineering Journal, 2015, Volume 9

Jing et al.

250

250

200

200

Shear Stress (kPa)

Shear Stress (kPa)

392

150

150

100

100

50kpa

100kpa

150kpa

200kpa

50

Sample A

0

10

15

20

25

50kpa

100kpa

150kpa

200kpa

50

Sample B

0

30

10

Shear Displacement (mm)

15

20

25

30

Shear Displacement (mm)

(7-1)

(7-2)

200

Shear Stress (kPa)

Shear Stress (kPa)

150

150

100

100

50

50kpa

100kpa

150kpa

200kpa

50

Sample C

0

10

15

20

Shear Displacement (mm)

25

30

50kpa

100kpa

150kpa

200kpa

Sample D

0

10

15

20

25

30

Shear Displacement (mm)

(7-3)

(7-4)

Fig. (7). Shear displacements vs. shear stress under different normal stress.

160

100

Sample A

Sample B

Sample C

Sample D

Shear Stress (kPa)

Shear Stress (kPa)

140

120

100

50

80

60

40

Sample A

Sample B

Sample C

Sample D

0

0

20

Normal Stress=50kpa

10

15

20

25

30

Normal Stress=100kpa

0

Shear Displacement (mm)

10

15

25

Shear Displacement (mm)

(8-1)

30

(8-2)

200

250

Shear Stress (kPa)

Shear Stress (kPa)

200

150

150

100

100

50

20

Sample A

Sample B

Sample C

Sample D

0

Sample A

Sample B

Sample C

Sample D

50

Normal Stress=150kpa

10

15

20

Shear Displacement (mm)

(8-3)

Fig. (8). Shear displacements vs. shear stress.

25

30

10

Normal Stress=200kpa

15

20

Shear Displacement (mm)

(8-4)

25

30

Permeability and Direct Shear Tests Characteristics of Railway Subballast

The Open Civil Engineering Journal, 2015, Volume 9

2.

Drainage ability is vulnerable impacted by subballast gradations, and the sample direct shear tests are less correlated

by subballast gradations and particle grain composition.

[6]

3.

Samples with more fine grain and a higher Cu showed

relative poor resistance against the shearing deformation

and drainage of water.

[7]

4.

The influence of gradations of particles became larger

when the average diameter turned smaller.

[9]

5.

Particles with relative smaller size played a key role in

governing the properties of subballast, especially the

drainage capability.

[10]

6.

Coarse-grained sample A showed a relative good drainage of water and high shearing strength, while considering the significant filtration property of subballast, grading of sample B is recommended in construction of

railway lines.

However, in order to have a proper design for the layer of

subballast, an effective gradation is correlated performance

of both drainage and resistance of shear ability.

With an aim to microscopic understanding the interactions, an explicit time-integration scheme can be used to

evaluate the coupled fluid-particle response. The flow domain is discretized into parallelepiped cells and averaged

Navier-Stokes equations are solved using a finite volume

technique. Basic permeability test microscopic simulations

could be used to assess the capabilities of the DEM-CFD

model. The simulations can be performed to investigate the

range of validity of Darcys law for water interactions with

granular matter.

[8]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

CONFLICT OF INTEREST

The authors confirm that this article content has no conflict of interest.

ACKNOWLEDGEMENTS

[20]

[21]

Research reported in this paper was supported by the

Fundamental Research Funds for the Central Universities

(2014JBM095).

[22]

REFERENCES

[1]

[2]

[3]

[4]

[5]

E.T. Selig, J.M. Waters, Track Geotechnology and Substructure

Management, Thomas Telford Ltd, London, 1994.

H. Huang, E. Tutumluer, W. Dombrow, Laboratory characterization of fouled railroad ballast behavior, Transportation Research

Record: Journal of the Transportation Research Board, vol. 2117,

pp. 93-101, 2009,

I.M. Alobaidi, D.J. Hoare, Mechanism of pumping at the subgrade-subbase interface of highway pavements, Geosynthetics International, vol. 6, pp. 241-259, 1999.

G.R. Fischer, B.R. Christopher, R.D. Holtz, Filter criteria based

on pore size distribution, In: Proceedings of the 4th International

Conference on Geotextiles, The Hague, vol. 1, pp. 289-294, 1990.

J. Sherard, L. Dunnigan, J. Talbot, Basic properties of sand and

gravel filters, Journal of Geotechnical Engineering, vol. 110, pp.

684-700, 1984.

Received: September 16, 2014

[23]

[24]

[25]

[26]

[27]

393

B. Indraratna, M. Locke, Analytical modelling and experimental

verification of granular filter behaviour, In: 3rd, International Conference on Geofilters; Filters and Drainage in Geotechnical and

Environmental Engineering, pp. 3-26, 2000.

J.M. Shilstone, Concrete mixture optimization, Concrete International, vol. 12, no. 6, pp. 33-39, 1990.

D.M. Roy, B.E. Scheetz, M. R. Silsbee, Processing of optimized

cements and concretes via particle packing, MRS Bulletin, vol. 18,

pp. 45-49, 1993.

B. Indraratna, F. Vafai, Analytical model for particle migration

within base soil-filter system, Journal of Geotechnical and

Geoenvironmental Engineering, vol. 123, pp. 100-109, 1997.

F. de Larrard, T. Sedran, Optimization of ultra-high-performance

concrete by the use of a packing model, Cement and Concrete Research, vol. 24, pp. 997-1009, 1994.

P. Goltermann, V. Johanson, L. Palbol, Packing of aggregates: An

alternative tool to determine the optimal aggregate mix, Material

Journal, vol. 94, pp. 435-443, 1997.

M. Locke, B. Indraratna, G. Adikari, Time-dependent particle

transport through granular filters, Journal of Geotechnical and

Geoenvironmental Engineering, vol.127, pp. 521-528, 2001.

B. Indraratna, A.K. Raut, Enhanced criterion for base soil retention in embankment dam filters, Journal of Geotechnical and

Geoenvironmental Engineering, vol.132, pp. 1621-1627, 2006.

L.D. Trani, B. Indraratna, An assessment of subballast filtration

under cyclic loading, Journal of Geotechnical and Geoenvironmental Engineering, vol.136, pp, 1519-1528, 2010.

D. Christie, Bulli, Field trial: Vertical and lateral pressure measurement, Rail CRC Seminar, Australia, 2007.

L.D. Trani, B. Trani, Indraratna, A new method of filtration design on rail track subballast, Advances in Geotechnical Aspects of

Roads and Railways, pp. 89-88, 2012.

P.F. Teixeira, A.L. Pita, P.A. Ferreira, New possibilities to reduce

track costs on high-speed lines using a bituminous sub-ballast

layer, International Journal of Pavement Engineering, vol.11, pp.

301-307, 2010.

B. Indraratna, H. Khabbaz, W. Salim, D. Christie, Geotechnical

properties of ballast and the role of geosynthetics in rail track stabilization, Journal of Ground Improvement, vol.10, pp, 91-102, 2006.

R.J. Aghdam, A. Soroush, Interpretation of stress-dependent mechanical behaviour of rockfill materials, In: Proceedings of the

18th International Conference on Soil Mechanics and Geotechnical

Engineering, Paris, September 2-6, pp. 353-356, 2013.

T.M. Ferreira, Influence of incorporating a bituminous sub-ballast

layer on the deformations of railway trackbed, Dissertation for Integrated Master Degree in Civil Engineering. Instituto Superior

Tcnico Technical University of Lisbon, Portugal, 2007.

E. Tutumluer, H. Huang, Y.M.A. Hashash, J. Ghaboussi, AREMA

Gradations Affecting Ballast Performance Using Discrete Element

Modeling (DEM) Approach, In: Proceedings of the AREMA 2009

Annual Conference & Exposition, Chicago, IL - September 20-23,

2009.

T. Nakao, S. Fityus, Direct shear testing of a marginal material

using a large shear box, Geotechnical Testing Journal, vol. 31, pp.

393-403, 2008.

I. Alobaidi, D.J. Hoare, Mechanisms of pumping at the subgradesubbase interface of highway pavements, Geosynthetics International, vol.6, pp. 241-259, 1999.

B. Indraratna, S. Nimbalkar, D. Christie, C. Rujikiatkamjorn, J.

Vinod, Field assessment of the performance of a ballasted rail

track with and without geosynthetics, Journal of Geotechnical and

Geoenvironmental Engineering, vol. 136, pp. 907-917, 2010.

B. Indraratna, F. Vafai, E. Dilema, An experimental study of the

filtration of a lateritic clay slurry by sand filters, In: Proceedings

of the ICE - Geotechnical Engineering, April 1, vol. 119, no. 2,

pages 75-83, 1996.

T.W. Lambe, R.V. Whitman, Soil mechanics, John Wiley and

Sons, Inc., USA, 1969.

K.H. Head, Manual of Soil Laboratory Testing, Whittles Publishing, UK, 2006.

Revised: December 23, 2014

Accepted: December 31, 2014

Jing et al.; Licensee Bentham Open.

This is an open access article licensed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/

by-nc/3.0/) which permits unrestricted, non-commercial use, distribution and reproduction in any medium, provided the work is properly cited.

You might also like

- Development of Permeability Test Method For Porous Concrete Block Pavement Materials Considering CloggingDocument7 pagesDevelopment of Permeability Test Method For Porous Concrete Block Pavement Materials Considering CloggingRizal RifdoNo ratings yet

- Buna Bak Muhakkak Asphalt KıyasDocument22 pagesBuna Bak Muhakkak Asphalt KıyasMücahit AtalanNo ratings yet

- Effect of Cement Content, Fibers, Chemical Admixture and Aggregate Shape On Rheological Parameters of Pumping ConcreteDocument16 pagesEffect of Cement Content, Fibers, Chemical Admixture and Aggregate Shape On Rheological Parameters of Pumping ConcreteNam HuynhNo ratings yet

- 2008 Hadwidodo Et Al. Review of Testing Methods For Self Compacting ConcreteDocument14 pages2008 Hadwidodo Et Al. Review of Testing Methods For Self Compacting ConcreteSofiaTeixeiraCoutinhoNo ratings yet

- Exprimental Study On Permeable Concrete Pavement ForDocument28 pagesExprimental Study On Permeable Concrete Pavement ForVaidyanathan SivasubramanianNo ratings yet

- Experimental Study of Bond-Slip Performance of Corroded Reinforced Concrete Under Cyclic LoadingDocument10 pagesExperimental Study of Bond-Slip Performance of Corroded Reinforced Concrete Under Cyclic Loadingofreneo_joshua4437No ratings yet

- Pervious ConcreteDocument6 pagesPervious ConcreteraheelNo ratings yet

- Applsci 11 08118 v2Document17 pagesApplsci 11 08118 v2JHEIMY EDWIN CARIHUASAIRO NAZARIONo ratings yet

- By A.Jansi Lakshmi 111514: Self Compacting Concrete and Mortar Effect of Inclusion of Nano ParticlesDocument26 pagesBy A.Jansi Lakshmi 111514: Self Compacting Concrete and Mortar Effect of Inclusion of Nano ParticlesramNo ratings yet

- Comparison of Permeability Characteristics of Granular Sub Base Layer in A Model Pavement For Different Grades As Per MoDocument10 pagesComparison of Permeability Characteristics of Granular Sub Base Layer in A Model Pavement For Different Grades As Per MoSandeep BoraNo ratings yet

- Numerical and Experimental Study On Soil Plug Resistance of Open Ended Pipe Pile With A Restriction PlateDocument14 pagesNumerical and Experimental Study On Soil Plug Resistance of Open Ended Pipe Pile With A Restriction PlateShaoyang DongNo ratings yet

- Investigations of Mixing Technique On The Rheological Properties of Self-Compacting ConcreteDocument13 pagesInvestigations of Mixing Technique On The Rheological Properties of Self-Compacting ConcreteMajd M. KhalilNo ratings yet

- Lubrication Layer Properties During Concrete PumpingDocument10 pagesLubrication Layer Properties During Concrete PumpingsaiNo ratings yet

- Modelling Fresh Properties of Self-Compacting Concrete Using Neural Network TechniqueDocument21 pagesModelling Fresh Properties of Self-Compacting Concrete Using Neural Network TechniquejasimabdNo ratings yet

- A Method To Estimate The Jacking Force For Pipe Jacking in Sandy SoilsDocument13 pagesA Method To Estimate The Jacking Force For Pipe Jacking in Sandy SoilsmuhpratitoNo ratings yet

- Astm DurabiliyDocument63 pagesAstm Durabiliyosama anterNo ratings yet

- Computational Fluid Dynamics Modelling of Slurry Transport by PipelineDocument17 pagesComputational Fluid Dynamics Modelling of Slurry Transport by PipelinePrantik DasNo ratings yet

- Early-Age Dynamic Moduli of Crumbed Rubber Concrete For Compliant Railway Structures Kaewunruen at Al 2017Document13 pagesEarly-Age Dynamic Moduli of Crumbed Rubber Concrete For Compliant Railway Structures Kaewunruen at Al 2017Nii DmNo ratings yet

- Mechtcherine (2013) - Testing Pumpability of Concrete Using Sliding Pipe Rheometer PDFDocument12 pagesMechtcherine (2013) - Testing Pumpability of Concrete Using Sliding Pipe Rheometer PDFManu K Mohan100% (1)

- Laboratory Apparatus For Evaluating Slurry Pipeline Wear (Cooke, Johnson & Goosen)Document17 pagesLaboratory Apparatus For Evaluating Slurry Pipeline Wear (Cooke, Johnson & Goosen)Engr Sakher100% (1)

- Discrete Element Modelling of Rockfill Railway EmbankmentsDocument15 pagesDiscrete Element Modelling of Rockfill Railway EmbankmentsHerdin AsyidiqNo ratings yet

- Fibers in Continuously Reinforced Concrete Pavements: A SummaryDocument4 pagesFibers in Continuously Reinforced Concrete Pavements: A SummaryKhaled AldossariNo ratings yet

- Abdullah-2022-The Effect of Openings On The Performance of Self-CompactingDocument14 pagesAbdullah-2022-The Effect of Openings On The Performance of Self-Compactingsamurai shinsengumiNo ratings yet

- Research On Rock-Filled Concrete Dams: A Review: September 2018Document13 pagesResearch On Rock-Filled Concrete Dams: A Review: September 2018Marcelo ProtzNo ratings yet

- Informe FondagDocument6 pagesInforme FondagRafael CristiNo ratings yet

- Monterrosa 2019Document18 pagesMonterrosa 2019GERARDO TORRES RUIZNo ratings yet

- Materials: Lattice Boltzmann-Discrete Element Modeling Simulation of SCC Flowing Process For Rock-Filled ConcreteDocument16 pagesMaterials: Lattice Boltzmann-Discrete Element Modeling Simulation of SCC Flowing Process For Rock-Filled ConcreteIsmael Rojo AlvarezNo ratings yet

- Jce 68 2016 4 5 1232 enDocument8 pagesJce 68 2016 4 5 1232 enRui MatosNo ratings yet

- Experimental Study On The Adjustments of Servo Steel Struts in DeepDocument15 pagesExperimental Study On The Adjustments of Servo Steel Struts in DeepMar JanNo ratings yet

- 1321 3467 2 PBDocument8 pages1321 3467 2 PBomed muhammadNo ratings yet

- Umair (Rough Proposal)Document11 pagesUmair (Rough Proposal)Sumair AhmadNo ratings yet

- New Experiments On Shear Properties of Fibre Concre 2016 Procedia EngineerinDocument8 pagesNew Experiments On Shear Properties of Fibre Concre 2016 Procedia EngineerinPaulo De Araujo RegisNo ratings yet

- Research Paper Relation Between Workability and Compressive Strength of Self-Compacting ConcreteDocument4 pagesResearch Paper Relation Between Workability and Compressive Strength of Self-Compacting ConcreteArockia Berlin SoniaNo ratings yet

- Ground Movement and Tunnel Stability When TunnelinDocument13 pagesGround Movement and Tunnel Stability When TunnelinGeotech Designers IITMNo ratings yet

- Hung Et Al 2021Document13 pagesHung Et Al 2021Manaswini VadlamaniNo ratings yet

- 1 s2.0 S0950061816317093 Main PDFDocument11 pages1 s2.0 S0950061816317093 Main PDFDaniela Gonzalez BetancurNo ratings yet

- Finite Element Simulation and Multi-Factor Stress Prediction Model For Cement Concrete Pavement Considering Void Under SlabDocument15 pagesFinite Element Simulation and Multi-Factor Stress Prediction Model For Cement Concrete Pavement Considering Void Under SlabtaufiqadwNo ratings yet

- Range Lov 2017Document9 pagesRange Lov 2017Alberto Tupa OrtizNo ratings yet

- Silva 2016Document14 pagesSilva 2016sali8439443No ratings yet

- Long Rectangular Box Jacking Project: A Case Study: SciencedirectDocument25 pagesLong Rectangular Box Jacking Project: A Case Study: SciencedirectUnni prabhuNo ratings yet

- 2 11 1644040260 Ijcseierdjun20224Document10 pages2 11 1644040260 Ijcseierdjun20224TJPRC PublicationsNo ratings yet

- Structural Analysis of Pervious Concrete PavementDocument9 pagesStructural Analysis of Pervious Concrete PavementLondeka MnguniNo ratings yet

- Mei Et Al. (2018)Document4 pagesMei Et Al. (2018)Manaswini VadlamaniNo ratings yet

- Ground Movement and Tunnel Stability When TunnelinDocument13 pagesGround Movement and Tunnel Stability When TunnelinFreedom For everNo ratings yet

- Novel Clogging Resistant Permeable PavementsDocument4 pagesNovel Clogging Resistant Permeable PavementsAlalea KiaNo ratings yet

- Numerical Analysis of Concrete Gravity Dam SeepageDocument21 pagesNumerical Analysis of Concrete Gravity Dam SeepageKiamuddin TappiNo ratings yet

- 1 s2.0 S1877705817321549 MainDocument8 pages1 s2.0 S1877705817321549 MainAndrian SaptaaNo ratings yet

- Behaviour of Precast Connections Subjected To Shock LoadingDocument13 pagesBehaviour of Precast Connections Subjected To Shock LoadingJitendra PatelNo ratings yet

- No Fine Pervious Concrete.: Guided by Prof. B. Dean Kumar, Department of Civil EngineeringDocument11 pagesNo Fine Pervious Concrete.: Guided by Prof. B. Dean Kumar, Department of Civil EngineeringNatarajan SaravananNo ratings yet

- BrownSchindler GeoDenver 2007Document11 pagesBrownSchindler GeoDenver 2007BartoFreitasNo ratings yet

- Research ArticleDocument15 pagesResearch ArticledasdasdasdNo ratings yet

- Developments in How The Boundary Layer Lower The Pipe Drag Reduction in Transport of Dense PasteDocument10 pagesDevelopments in How The Boundary Layer Lower The Pipe Drag Reduction in Transport of Dense Pasteroberto gomezNo ratings yet

- An Improved Tie Force Method For Progressive Collapse Resistance of Precast Concrete Cross Wall StructuresDocument9 pagesAn Improved Tie Force Method For Progressive Collapse Resistance of Precast Concrete Cross Wall StructuresCristina VlaicuNo ratings yet

- Modelling Ballast Via A Non-Linear Lattice To Assess ItsDocument25 pagesModelling Ballast Via A Non-Linear Lattice To Assess ItsNelmarNo ratings yet

- 浸水环境下重载铁路改良土路基动力特性研究 商拥辉Document8 pages浸水环境下重载铁路改良土路基动力特性研究 商拥辉Feng GuishuaiNo ratings yet

- Corrosion Monitoring For Underground and Submerged Concrete Structures - Examples and Interpretation IssuesDocument6 pagesCorrosion Monitoring For Underground and Submerged Concrete Structures - Examples and Interpretation IssuesAntony Jacob AshishNo ratings yet

- Experimental Investigation On Ferrocement Water TankDocument6 pagesExperimental Investigation On Ferrocement Water TankMuthu KuttyNo ratings yet

- The Effect of Shrinkage Cracks On The Load Bearing Capacity of Steel-Fibre-Reinforced Roller-Compacted - Concrete PavementsDocument27 pagesThe Effect of Shrinkage Cracks On The Load Bearing Capacity of Steel-Fibre-Reinforced Roller-Compacted - Concrete PavementsLouis KiwaNo ratings yet

- An Experimental and Numerical Study On Water Permeability of ConcreteDocument8 pagesAn Experimental and Numerical Study On Water Permeability of ConcreteAndre'lo VillavicencioNo ratings yet

- Design of Tunnels Basic Principales 197 - 2004 - eDocument56 pagesDesign of Tunnels Basic Principales 197 - 2004 - ePetruMarcu100% (2)

- CFR Master Plan Cai FerateDocument55 pagesCFR Master Plan Cai FerateAndreea BarbulescuNo ratings yet

- 2013 Guide Vehicle Structure Sic Guide To British Gauging t926Document80 pages2013 Guide Vehicle Structure Sic Guide To British Gauging t926Praveen Kumar100% (1)

- Stabilisation of Ballast and Subgrade Rail Infrastructure PDFDocument13 pagesStabilisation of Ballast and Subgrade Rail Infrastructure PDFPetruMarcuNo ratings yet

- Emerging Technology SyllabusDocument6 pagesEmerging Technology Syllabussw dr100% (4)

- BV DoshiDocument6 pagesBV DoshiNimNo ratings yet

- Dependent ClauseDocument28 pagesDependent ClauseAndi Febryan RamadhaniNo ratings yet

- ManualDocument50 pagesManualspacejung50% (2)

- 8 X 56 M.-SCH.: Country of Origin: ATDocument1 page8 X 56 M.-SCH.: Country of Origin: ATMohammed SirelkhatimNo ratings yet

- NCP - Impaired Urinary EliminationDocument3 pagesNCP - Impaired Urinary EliminationFretzgine Lou ManuelNo ratings yet

- 95-03097 Ballvlv300350 WCB PDFDocument26 pages95-03097 Ballvlv300350 WCB PDFasitdeyNo ratings yet

- Thermal Physics Lecture 1Document53 pagesThermal Physics Lecture 1Swee Boon OngNo ratings yet

- LU 5.1 ElectrochemistryDocument32 pagesLU 5.1 ElectrochemistryNurAkila Mohd YasirNo ratings yet

- DHA - Jebel Ali Emergency Centre + RevisedDocument5 pagesDHA - Jebel Ali Emergency Centre + RevisedJam EsNo ratings yet

- City Limits Magazine, December 1981 IssueDocument28 pagesCity Limits Magazine, December 1981 IssueCity Limits (New York)No ratings yet

- Bill of Quantities 16FI0009Document1 pageBill of Quantities 16FI0009AJothamChristianNo ratings yet

- Reference GuideDocument88 pagesReference GuideAnonymous Qm0zbNk100% (1)

- 02 CT311 Site WorksDocument26 pages02 CT311 Site Worksshaweeeng 101No ratings yet

- Wordbank 15 Coffee1Document2 pagesWordbank 15 Coffee1akbal13No ratings yet

- Our Story Needs No Filter by Nagarkar SudeepDocument153 pagesOur Story Needs No Filter by Nagarkar SudeepKavya SunderNo ratings yet

- Department of Education: Raiseplus Weekly Plan For Blended LearningDocument3 pagesDepartment of Education: Raiseplus Weekly Plan For Blended LearningMARILYN CONSIGNANo ratings yet

- Financial Institutions Markets and ServicesDocument2 pagesFinancial Institutions Markets and ServicesPavneet Kaur Bhatia100% (1)

- Domesticity and Power in The Early Mughal WorldDocument17 pagesDomesticity and Power in The Early Mughal WorldUjjwal Gupta100% (1)

- Saudi Methanol Company (Ar-Razi) : Job Safety AnalysisDocument7 pagesSaudi Methanol Company (Ar-Razi) : Job Safety AnalysisAnonymous voA5Tb0No ratings yet

- Session 10. Value Proposition.Document69 pagesSession 10. Value Proposition.Bibhu R. TuladharNo ratings yet

- Essays of Warren Buffett - Lessons For Corporate America by Lawrence Cunningham - The Rabbit HoleDocument3 pagesEssays of Warren Buffett - Lessons For Corporate America by Lawrence Cunningham - The Rabbit Holebrijsing0% (1)

- Tenses English Grammar PresentationDocument14 pagesTenses English Grammar PresentationMaz Gedi60% (5)

- HKUST 4Y Curriculum Diagram CIVLDocument4 pagesHKUST 4Y Curriculum Diagram CIVLfrevNo ratings yet

- Chronic Renal FailureDocument54 pagesChronic Renal FailureAkia Cayasan BayaNo ratings yet

- Module 7 NSTP 1Document55 pagesModule 7 NSTP 1PanJan BalNo ratings yet

- Abas Drug Study Nicu PDFDocument4 pagesAbas Drug Study Nicu PDFAlexander Miguel M. AbasNo ratings yet

- UAP Grading Policy Numeric Grade Letter Grade Grade PointDocument2 pagesUAP Grading Policy Numeric Grade Letter Grade Grade Pointshahnewaz.eeeNo ratings yet

- Oil List: Audi Front Axle DriveDocument35 pagesOil List: Audi Front Axle DriveAska QianNo ratings yet

- Electronic Fundamentals: B) The Active ElementDocument45 pagesElectronic Fundamentals: B) The Active ElementZbor ZborNo ratings yet