Professional Documents

Culture Documents

EM6400 QSG V01.d18 (Web) PDF

Uploaded by

Gillala RamakanthOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EM6400 QSG V01.d18 (Web) PDF

Uploaded by

Gillala RamakanthCopyright:

Available Formats

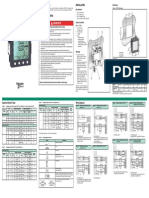

EM6400 Series Power Meter

Quick Start Guide

English

CTD7302

01/2011

Safety Precautions

Introduction

Read and follow all the safety precautions and instructions before installing and working with

this equipment.

The power meter ships in five different configurations.

Table 1: EM6400 series power meter models and parameters (continued)

Param et er

Table 1: EM6400 series power meter models and parameters

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

?

Apply appropriate personal protective equipment (PPE) and follow safe electrical work

practices. In the USA, see NFPA 70E.

?

Only qualified electrical workers should install this equipment. Such work should be performed

only after reading this entire set of instructions.

If the equipment is not used in the manner specified by the manufacturer, the protection

?

provided by the equipment may be impaired.

?

NEVER work alone.

?

Before performing visual inspections, tests, or maintenance on this equipment, disconnect all

sources of electric power. Assume that all circuits are live until they have been completely deenergized, tested, and tagged. Pay particular attention to the design of the power system.

Consider all sources of power, including the possibility of backfeeding.

?

Turn off all power supplying the power meter and the equipment in which it is installed

before working on it.

?

Always use a properly rated voltage sensing device to confirm that all power is off.

?

Before closing all covers and doors, carefully inspect the work area for tools and objects that

may have been left inside the equipment.

?

Use caution while removing or installing panels so that they do not extend into the energized

bus; avoid handling the panels, which could cause personal injury.

?

The successful operation of this equipment depends upon proper handling, installation, and

operation. Neglecting fundamental installation requirements may lead to personal injury as

well as damage to electrical equipment or other property.

?

NEVER bypass external fusing.

?

NEVER short the secondary of a PT.

?

NEVER open circuit a CT; use the shorting block to short circuit the leads of the CT before

removing the connection from the power meter.

?

Before performing Dielectric (Hi-Pot) or Megger testing on any equipment in which the power

meter is installed, disconnect all input and output wires to the power meter. High voltage

testing may damage electronic components contained in the power meter.

?

The power meter should be installed in a suitable electrical enclosure.

Failure to follow these instructions will result in death or serious injury

EM

6459

Models and Parameters

Param et er

RMS

EM

6459

EM

6433

EM

6434

EM

6436

EM

6400

EM

6436

EM

6400

IE

R.VARh

-R.VARh

Run hours

A A1 A2 A3

OLD

Fwd

Neutral Current

Wh

VAh

VARh

%Load

%A Unbal %V UnbaU

-VARh

PF PF1 PF2 PF3

Run hours

%AFS Analog load bar

OLD

Rev

RPM

A" Phase Angle

EM

6434

INTG R.Wh

Rev

R.VAh

V V1 V2 V3 V12 V23 V31

An

EM

6433

A1 A2 A3

W1 W2 W3

VA

VA1 VA2 VA3

R.Wh

IE

R.VAh

R.VARh

-R.VARh

Run hours

VAR VAR1 VAR2 VAR3

DM

Demand VA/ W/ A

NOTE:

Rising demand

DM

Time remaining

= Standard

= Option specified while ordering

C = Only through communication

= User selectable VAh/Wh through setup mode (EM6436, EM6433)

MD Maximum demand

Hr MD occurred

Box Contents

INTG Wh

Fwd

VAh

Additional Resources

VARh

Go to http://www.schneider-electric.co.in > in the search window enter EM6400

dual > On the EM6400 screen, click Downloads tab, then click on tech publications tab >

click on the document name to download or read the document file.

-VARh

?

One (1) EM6400 series power meter

?

One (1) quick start guide (QSG)

?

One (1) test and calibration certificate for the power meter

Run hours

ON hours

INTR

Power Meter Physical Description

Front Panel

Quick Setup, While Powering ON

It is much easier to set up the power meter before you mount the power meter into

the panel. This section explains you, how to set up the power meter before mounting.

Figure 3: Quick setup

Figure 1: Front panel

L1

Giga

120 %A FS

110

100

90

L2

Giga

80

Indicators

Giga

60

40

30

20

Eight-segment LED

display

1. Connect the auxiliary supply

(control power) 44 to 300 VAC/DC to

the terminals 12 and 13.

Press and hold

for two seconds, while

powering up the power meter.

The display directly enters into PROG

menu setup and displays EDIT A.PRI

100.0.

70

50

L3

Color-coded

analog load bar

Use CT1

Use PT1

Use PT2

Use PT3

Use CT2

Use CT3

10

Conzerv

EM6400

Keys

RS 485

communication

Aux supply

(control power)

44 to 300 VAC/DC

4

Rear Panel

Figure 2: Rear panel

Input current

terminals

A1, A2, A3

Input voltage terminals

V1, V2, V3, VN

Auxiliary supply

(control power) terminals

RS 485 communication

terminals

Refer to Edit set parameters for

programming.

Program the following readings for accurate readings:

A.PRI, A.SEC: Set these values to match your CT primary and secondary values. For

example, if your CT ratio is 200:5, set A.PRI =200.0 and A.SEC = 5.000.

V.PRI, V.SEC: Set these values to your input voltage VLL of circuit, if your input voltage

is < 600 VACLL. For example, if the input voltage is 300 VACLL, set V.PRI = 300.0 and

V.SEC = 300.0.

Use potential transformer (PT/VT), if the input voltage > 600 VACLL. Set the V.pri and

V.sec values to match the primary and secondary of the PT(VT) respectively. For

example, if PT(VT) ratio is 11 kV: 110, set V.pri = 11.00 k and V.sec = 110.0.

Select one of the following systems according to your wiring configuration.

SYS = Star for 4-phase 3-wire system

SYS = Delta for 3-phase 3-wire system

SYS = 2-phase for 2-phase 3-wire system

SYS = Single-phase for single-phase 2-wire system

2. Connect the current transformers (CTs).

CT1

1, 2

CT2

3, 4

Installation

Dimensions and Mounting

Connecting Cable Requirements

Figure 4: Power meter dimensions

Table 2: Connecting cable requirements

Voltage circuit

Insulation rating

> 600 VAC

Current rating

> 0.1 A

Current circuit

> 600 VAC

> 7.5 A

2

or 2.5 mm /14 AWG minimum

83.0

3.26

8.0

0.31

90.0

3.54

Tools and Fasteners

Table 3: Tools and fasteners

Driver

Tip

Screw head Diameter

Shaft diameter

Torque

Torque driver preferred; may use hand screwdriver.

Philips tip preferred, but you can also use flat.

Do not use Pozidriv tip.

3.5 mm

< 5 mm. Diameter

5 mm will get stuck in the cover.

Tightening Torque: 0.25 to 1 N.m

Torque > 1 N.m may strip the screw or break the cover.

96.0

3.78

Power Meter Mounting

Figure 5: Power meter mounting angle

Loosening Torque: 1.2 N.m

Screw Travel

6 mm less wire thickness

90

90

NOTE: Installation should include a disconnecting device, like a switch or circuit breaker, with

clear ON/OFF markings, to turn-off the auxiliary supply (control power). The disconnecting

device should be within the reach of the equipment and the operator.

Figure 6: Power meter mounting steps

CT3

5, 6

3. Connect the voltage inputs. Use PT(VT) if input voltage exceeds 600 VLL.

PT1

8

PT2

9

PT3

10

Neutral

11

4. Connect the RS 485 communication terminals.

+ve

7

-ve

14

1. Remove the mounting clamps from the power meter.

2. Gently slide the power meter through the cut-out.

3. Put the mounting clamps back in the power meter and tighten the mounting clamp

screws.

Terminal Connections using Lugs

Wirings

Terminal Connections using Ring Lugs

Figure 10: 3-phase 3-wire delta connection

Supported System Types

Lug: Ring lug

Cross-section: 2.5 mm2/14 AWG

Table 4: Supported system types

System type

Figure 8: Terminal connections using ring lugs

Figure 7: Terminal connections using U lugs

L1

Meter configuration

L2

L3

LINE

Figure number

Star/Wye

StAr

Delta, open delta

dLtA

10, 11

2-phase

2-phase

12

Single-phase

Single-phase

13

PT if VAC LL 601 V

CT

S1

N998

Lug: Insulated sleeved U lug

Cross-section: 2.5 mm2/14 AWG

*

S2

80 to 600 Vac LL

Terminal Connections using U Lugs

0.25 A

CT

S1

Fuse

S1

Current transformer (CT)

S2

D1

S2

LOAD

L3

44 to 300 VAC/DC

Aux Supply

(Control power)

D0

Communication

(In Series)

Figure 11: 3-phase 3-wire open delta connection

Figure 9: 3-phase 4-wire star/wye connection

L1 L2

Other Meters

RS 485

*Other Meters

Wiring Diagrams

50mA to 6A

Description

S/N:COYWWDXXXX Acc CI: X.X

Symbol

44 to 300 V 50/60 Hz <5 VA

Wiring Diagram Symbols

Table 5: Wiring diagram symbols

LINE

L1

L2

L3

LINE

S2

* Other Meters

Keys Description

80 to 600 Vac LL

Right key:

Go forward to sub-parameter pages. When changing parameters, moves one position to the

right.

Left key:

Go backward to main parameter pages. When changing parameters, moves one position to

the right.

Up key:

Scroll up through the display pages at the level, within the same function. When changing

parameters, increases value by one.

44 to 300 V 50/60 Hz <5 VA

Table 6: Keys description

N998

50mA to 6A

S/N:COYWWDXXXX Acc CI: X.X

D1

Down key:

Scroll down through the display pages at the same level through all the functions. When

changing the parameters decreases the value by one.

TURBO key:

The TURBO key is the one-touch access to the most commonly used parameters (factory-set).

The TURBO key scrolls through RMS (home page), VLL A PF, VLN A F, VA W PF

VA, W VAR W, VAR, PF PF1 PF2 PF3, V% 1 2 3 A % 1 2 3, VAd RD TR, MD HR, VAh, Wh,

RVAh,Rwh, tVAh, tWh. If you are lost, use the TURBO key to quickly return to RMS page.

NOTE: THD values are indicative only.

D0

RS 485

Keys Operation

L1

LINE

* Other meters (in series)

N998

50mA to 6A

LOAD

D1

S/N:COYWWDXXXX Acc CI: X.X

S2

0.25 A

80 to 600 Vac LL

RMS

44 to 300 V 50/60 Hz <5 VA

CT

S1

Other Meters

44 to 300 VAC/DC

Aux Supply

(Control power)

D0

RS 485

Communication

VLL

A

PF

VLN

A

F

S1

44 to 300 VAC/DC

Aux Supply

(Control power)

*

S2

D0

RS 485

D1

LOAD

Communication

(In Series)

*Other Meters

1. Press

PF.

2. Press

3. Press

Other Meters

44 to 300 VAC/DC

Aux Supply

(Control power)

D0

RS 485

Communication

(In Series)

Enter Setup Menu in Edit Mode

The PROG menu setup gives the complete list of user-programmable parameters.

?

You must set up the power meter to match the application settings before use.

Otherwise, readings will be wrong.

?

All the setup parameters can be re-programmed, using SET. However, the following

settings critically determine the scaling of the measured readings: SYS (star or delta),

Vpri, Vsec, Apri, Asec.

?

The scaling may be used to minimize the errors in reading due to Instrument

Transformer errors. However, wrong settings will introduce errors in readings on other

running systems.

- Means blinking

1 - Means blinking 1

You can enter PROG menu setup in

?

View mode: To view the set parameters.

?

Edit mode: To view or edit the set parameters.

HAZARD OF UNINTENDED OPERATION

Only qualified personnel are authorized to set up the power meter.

, from RMS page. The display shows VLL A

1. Press from RMS page. The display shows SET.

2. Press . The display shows CLR.

3. Press . The display shows VIEW.

4. Press . The display shows EDIT.

CODE entry is required to edit the parameters.

5. Press

for two seconds. The display shows CODE 2000 with blinking 2.

The factory set CODE is 1000.

6. Press . The display shows CODE 1000 with blinking 1.

7. Press once or

four times to accept the new CODE value.

The display flashes PASS and shows EDIT A.PRI 100.0. This indicates that you have

successfully entered the setup menu in edit mode.

. The display shows VLN A F.

, to return to RMS page.

NOTE: If you enter a wrong CODE, the display flashes FAIL and shows EDIT. Repeat the

steps and make sure that you enter the correct CODE.

The following example explains how the different keys in the power meter operates.

The example explains, how to navigate from the RMS page to VLN A F page and back to

RMS page, in EM6400 power meter.

NOTE: The following symbols are used to explain the different operations of the keys.

for right key operation.

for left key operation.

for up key operation.

for down key operation.

Figure 13: Single-phase connection

CT

Other Meters

PROG Menu - Setup

Keypad Setup

0.25 A

44 to 300 V 50/60 Hz <5 VA

D1

44 to 300 VAC/DC

S2

50mA to 6A

CT

LOAD

AC

S/N:COYWWDXXXX Acc CI: X.X

S1

S2

* Other meters (in series)

0.25 A

44 to 300 V 50/60 Hz <5 VA

50mA to 6A

*

S2

Figure 12: 2-phase 3-wire connection

N998

N998

CT

CT

S1

S/N:COYWWDXXXX Acc CI: X.X

1. Loosen the terminal screw.

2. Connect the wire with the U lug to the power meter terminal.

3. Tighten the terminal screw.

1. Remove the protective cover from the power meter.

2. Remove the terminal screw from the power meter.

3. Connect the wire with the ring lug to the power meter terminal.

4. Place the terminal screw back and tighten the terminal screw.

5. Place the protective cover back and tighten the protective cover.

80 to 600 Vac LL

S1

80 to 600 Vac LL

PT if VAC LL 601 V

PT if VAC LL 601 V

S1 CT

NOTE: Use to go forward to sub-parameter pages.

Use to go back to main parameter pages. Use and

to scroll up and down through the display pages.

Failure to follow these instructions can result in injury or equipment damage.

Enter Setup Menu in View (Read-only) Mode

1. Press from RMS page. The display shows SET.

2. Press . The display shows CLR.

3. Press . The display shows VIEW.

4. Press . The display shows VIEW A.PRI 100.0. Use

parameters and their default values.

and

to view the setup

Setup Parameters in View and Edit Modes

A.PRI = Current primary winding (CT)*; Input range 1 A to 99 kA.

Default value is 100.0

d.PAR = Demand parameter selection*; Select from VA, W, A; Default value

is VA.

A.SEC = Current secondary winding (CT);

Default value is 5.000

d.PRD = Demand period; Select from 5, 10, 15, 20, 25, 30; Default value is

15.

Edit Set Parameter

CLR INTG and MD

This section explains how you can edit the setup parameter A.PRI from 100.0 to

5000 in the EM6400 series power meter.

For better understanding, the editing is explained in two parts: Edit and accept setup, save

new value to the setup.

EM6400 series power meters are equipped with INTG, where the energy parameters

are accumulated.

INTG clear - clears both INTG and MD

MD clear - clears only MD (where MD is maximum demand)

Edit and Accept Setup

Press

times

Press

four

four times

- Means blinking

V.PRI = Voltage primary winding (PT), line to line*; Input range 100 V to 999

kV; Default value is 415.0

Baud = Baud rate; Select from 1200, 2400, 4800, 9600, 19200; Default value

is 9600.

1 - Means blinking 1

- Means blinking

1 - Means blinking 1

V.SEC = Voltage secondary winding (PT), line to line*; Input range 80 V to

600 V; Default value is 415.0

PRTY = Parity and stop bit settings; Select from EVN.1, EVN.2, OD.1,

ODD.2, no.1, no.2; Default value is EVN.1.

SYS = System configuration; Select from StAR, dLtA, 2 ph, 1 ph; Default

value is StAR.

ID = RS 485 device ID number; Select from 1.000 to 247.0; Default value is

1.000.

LAbL = Phase labeling; Select from 123, RYB, RST, PQR, ABC; Default value

is 123.

F.S% = Full scale percentage; Set the full scale between 1.000 to 100.0;

Default value is 100.0

VA.Fn = VA function selection; Select between 3D, ARTH; Default value

is 3D.

OFLO = Overflow parameter selection; Select from Wh, VAh;

1. After you have successfully entered into setup menu in edit mode (Refer to Enter Setup

Menu in Edit mode for more information), press . The display shows EDIT A.PRI 100.0

with blinking 1.

2. Press four times. The display shows EDIT A.PRI 500.0 with blinking 5.

3. Press four times. The display shows EDIT A.PRI 500.0 with blinking..

4. Press . The display shows EDIT A.PRI 5000. with blinking . .

5. Press to accept the new value.

To edit the next parameter, press and repeat the above steps.

Save New Value to Setup

- Means blinking

d.SEL = Demand selection*; Select from AUTO, User; Default value is

AUTO.

POLE = Number of poles for RPM; Select from 2.000, 4.000, 6.000, 8.000,

10.00, 12.00, 14.00, 16.00; Default value is 4.000.

CLR INTG and MD (Continued)

NOTE: * Changing these values is not recommended, while the device

is in use.

Energy Integrator INTG, OLD, Overflow

y - Means blinking y

1. After you edit the parameter as described above, press

with blinking y.

2. Press . The display flashes PASS and shows EDIT.

3. Press . The display shows SET.

1. From RMS, Press . The display shows CLR.

CODE entry is required to clear the MD values.

2. Press for two seconds. The display shows CODE 2000 with blinking 2.

The factory set CODE is 1000.

3. Press . The display shows CODE 1000 with blinking 1.

4. Press

once or

four times to accept the new value.

After the successful CODE entry, the display shows CLR INTG.

5. Press . The display shows CLR MD.

6 To clear MD, press

. The display shows CLR MD y with blinking y.

7. Press

or

to clear MD. The display flashes PASS and then CLR MD.

8. Press

9. Press

. The display shows CLR.

to return to RMS page.

NOTE: If you do not want to clear the integrators, press

to change the value from CLR

MD y to CLR MD n in step 6. Then press

or

. The display flashes FAIL and then

shows CLR MD. Proceed to step 8.

Your EM6400 series power meter is equipped with an energy integrator function which

provides several parameters for Energy Management: VAh, Wh, VARh (Ind), -VARh (Cap),

RUN.h (run hours), ON.h (on hours), INTR (Interruptions / outages). All the values stored in

INTG are direct readings and have high resolution.

A few of these need explanation:

RUN.h: Indicates the period the load is ON and has run. This counter accumulates as long

as the load is ON.

ON.h: The period for which the auxiliary supply (control power) is ON.

INTR: Number of supply outages, means the number of auxiliary supply interruptions. If

power meter auxiliary supply is from a UPS then the INTR (number of interruptions) will be

zero (as long as the UPS stays ON), even if the voltage signals die out from time to time.

Integrator Overflow

The energy values stored in INTG are based on V.Pri x A.Pri; they are independent of

secondary values of V and A.

The energy value readings will overflow based on V.Pri x A.Pri of the primary settings in

setup, when 9999 run hours is reached.

The energy parameter for overflow is user selectable (Wh or VAh) through setup. By

default it is Wh or by the Run hours which is fixed 9999 Run hours (almost 13.88 months).

For power systems ranging from 1 VA to 1000 MVA, the integrator will overflow at 9999

run hours. The duration required for the integrator to overflow will be 13.88 months if the

power meter is constantly running at full scale.

However, in case of power systems greater than 1000 MVA, the integrator will overflow at

a value less than 9999 run hours. The duration required for the integrator to overflow will

be less than a year if the meter is constantly running at full scale.

After the successful CODE entry, the display shows CLR INTG.

5. To clear INTG, press

. The display shows CLR INTG y with

blinking y.

6. Press

or

to clear INTG. The display flashes PASS and then CLR INTG.

. The display shows CLR.

to return to RMS page.

NOTE: If you do not want to clear the integrators, press

to change the value from CLR

INTG y to CLR INTG n in step 5. Then press

or

. The display flashes FAIL and then

shows CLR INTG. Proceed to step 7.

Features

Table 7: Integrator Overflow

V.PRI x A.PRI

x 1.732

1. From RMS, Press . The display shows CLR.

CODE entry is required to clear the INTG values.

2. Press for two seconds. The display shows CODE 2000 with blinking 2.

The factory set CODE is 1000.

3. Press . The display shows CODE 1000 with blinking 1.

4. Press

once or

four times to accept the new value.

7. Press

8. Press

NOTE; If you do not want to save the new value, press to change SAVE y to SAVE n.

Press . The display flashes FAIL and shows EDIT. Then proceed to step 3.

Energy Integrator INTG

MD CLR

. The display shows SAVE y

INTG CLR

Max Reading Max time to reset Max time to overflow in

the integrator in months at full scale

(Wh/VAh)

Run Hours

Auto-scroll

?

Auto-scroll allows you to view a group of display pages sequentially every five seconds

without manual key operation.

?

During auto-scroll, the power meter displays parameter name for one second and value

for four seconds.

1 VA to 1000 VA

9999 K

9999

13.88

1 kVA to 1000 kVA

9999 M

9999

13.88

Auto-scroll within the Page Group

9999

13.88

1. Go to a particular page in the desired page group.

2. Press

continuously for three seconds and release. The display flashes AUTO and

starts auto-scroll within the page group.

<9999

< 1 year

1 MVA to 1000 MVA

>1000 MVA

9999 G

OLD Data Register

When the integrator is cleared (manually or due to overflow), the energy values stored in

the integrator will be transferred to the OLD register.

Thus the old energy values are not lost even after the integrator is cleared and can be

viewed with the OLD parameter.

NOTE: For energy studies clear the Integrator at the end of each

observation. This transfers all the stored energy values to the OLD register,

where they are held while the Integrator begins accumulating data for

the next observation. Remember that the next time the Integrator is

cleared, the OLD values will be overwritten.

?

The power meter has three different types of auto-scroll as explained below.

Auto-scroll Down the Entire Column of Pages

1. Go to the desired page.

2. Press

continuously for three seconds and release. The display flashes AUTO and

starts auto-scroll down the column of pages.

TURBO Auto-scroll

Press

continuously for three seconds and release. The display flashes AUTO and

starts auto-scroll down the TURBO pages.

NOTE:

Press any key to revert to manual scrolling.

Auto scrolling is not possible in setup parameters.

Indicators

Table 8: Indicators

Kilo: When lit, indicates that the reading is in Kilo (10^3). 10,000 is displayed

as 10.00 K and 1.0 K is displayed as 1000.

Mega: When lit, indicates that the reading is in Mega (10^6). 10,000 K is displayed

as 10.00 M and 1.0 M is displayed as 1000 K.

Giga: When both K and M are lit, indicates that the reading is in Giga (10^9).

10,000 M is displayed as 10.00 G and 1.0 G is displayed as 1000 M.

Negative: When lit, indicates that the reading is in negative as per IEEE 100 and

industry standard.

When power factor(PF) is lead (capacitive load): Both PF and VAR will be negative

When current is reversed, W will be negative.

Default Display Page

Menu Hierarchies

EM6436: Menu Hierarchy

EM6433: Menu Hierarchy

The default display page feature enables you to select any display page as user-set display

page. You can scroll to other pages, when the default display page is active. The default

display page will be displayed two minutes after you stop the manual key operation.

RMS = RMS value display pages are in sub level

A 1

2

3

RMS

To LOCK default display page:

Go to the desired page you want to set as default display page.

Press and together. The display shows LOCK and the display page is locked.

NOTE:

Entry to PROG menu setup is possible only when the default display page is unlocked.

A = Current average

W = Watt total

W1

2

3

INTG

Fwd

VLL

RMS A

PF

A1 = RMS current, phase 1

A2 = RMS current, phase 2

A3 = RMS current, phase 3

A

W

To unlock default display page:

Once the default display page is active, press and together.

The display shows ULOC and the default display page is unlocked.

V 12

23

31

VLN

A

F

V 1

2

3

A

W

PF

A 1

2

3

W1

2

3

Run.h

Wh = Forward Watt hours. Wh integrates always in the

forward direction irrespective of the direction of flow of

current for star (Wye) mode

On.h

Run.h = Forward run hours, Total hours the load was

ON

INTG

Fwd

INTR

Wh

Run.h

V 12

23

31

VLL

A

PF

V 1

2

3

V12 = RMS voltage, phase 12

V23 = RMS voltage, phase 23

V31 = RMS voltage, phase 31

A 1

2

3

V1 = RMS voltage phase 1 to neutral

V2 = RMS voltage phase 2 to neutral

V3 = RMS voltage phase 3 to neutral

L%1

2

3

VLN

A 1

A

2

F

3

A.UNB

V.UNB

RPM

Wh

VA

W

PF

On.h

Wh = Forward Watt hours. Wh integrates always in the

forward direction irrespective of the direction of flow of

current for star (Wye) mode

INTR

Run.h = Forward run hours, Total hours the load was

ON

DIAG

W

VAR

1

PF PF 2

3

INTR = No of power interruptions

Dia1

OLD Fwd = The energy values stored in the integrator will

be transferred to the OLD register when the integrator is

cleared (manually or due to overflow)

Wh = OLD Forward Watt hours.

THD

Dia1

Dia2

Run.h = OLD Forward run hours

Dia2

SET

SET

VIEW

VLL = Phase-Phase voltage average

A = Current average

PF = Power Factor average

VLN = Phase-Neutral voltage average

A = Current average

F = Frequency in Hz

VA = Apparent power total

W = Active power total

PF = Power factor average

V12 = RMS voltage, phase 12

V23 = RMS voltage, phase 23

V31 = RMS voltage, phase 31

V1 = RMS voltage phase 1 to neutral

V2 = RMS voltage phase 2 to neutral

V3 = RMS voltage phase 3 to neutral

A1 = RMS current, phase 1

A2 = RMS current, phase 2

A3 = RMS current, phase 3

L1% = % of load, phase 1

L2% = % of load, phase 2

L3% = % of load, phase 3

DM

VA

VIEW

VA1 = Volt-amperes, phase 1

VA2 = Volt-amperes, phase 2

VA3 = Volt-amperes, phase 3

W1 = Watts, phase 1

W2 = Watts, phase 2

W3 = Watts, phase 3

VAR1 = VAR, phase 1

VAR2 = VAR, phase 2

VAR3 = VAR, phase 3

PF1 = Power factor, phase 1

PF2 = Power factor, phase 2

PF3 = Power factor, phase 3

THD = Total Harmonic Distortion

A00 1

2

3

V00 1 = Voltage THD, Phase 1

V00 2 = Voltage THD, Phase 2

V00 3 = Voltage THD, Phase 3

VAd

Rd

TR

MD

HR

EDIT

EDIT

A.UNB = Current unbalance

V.UNB = Voltage unbalance

RPM = RPM of the motor

V00 1

2

3

Dia3

Dia3

W1

2

3

VAR1

2

3

Wh

Run.h

VA 1

2

3

VA

W

VAR

On,h = Duration of supply ON

Wh = OLD Forward Watt hours.

OLD

Fwd

RMS = RMS value display pages are in sub level

A1 = Current phase angle, phase 1 in degrees

A2 = Current phase angle, phase 2 in degrees

A3 = Current phase angle, phase 3 in degrees

Run.h

OLD Fwd = The energy values stored in the integrator will

be transferred to the OLD register when the integrator is

cleared (manually or due to overflow)

RMS

INTR = No of power interruptions

Run.h = OLD Forward run hours

DIAG

A1 = RMS current, phase 1

A2 = RMS current, phase 2

A3 = RMS current, phase 3

PF 1

2

3

On,h = Duration of supply ON

OLD

Fwd

VLL = Phase-Phase voltage average

A = Current average

PF = Power Factor average

VLN = Phase-Neutral voltage average

A = Current average

F = Frequency in Hz

Wh

Default display page through communication:

! You can lock and unlock the default display page through communication (ConPAD).

! If an operator locks the default display page through communication, any user can

unlock it from the front panel.

! If a supervisor locks the default display page through communication, an operator

cannot unlock it. Only a supervisor can unlock it through communication.

EM6400: Menu Hierarchy

RMS = RMS value display pages are in sub level

A00 1 = Current THD, Phase 1

A00 2 = Current THD, Phase 2

A00 3 = Current THD, Phase 3

DM VA = VA Demand

VAd = VA demand

Rd = Rising demand

TR = Time remaining

MD = Maximum demand

HR = On hours at which maximum demand has

occurred

CLR

CLR

NOTE: THD values are indicative only

EM6400: Menu Hierarchy (Continued)

EM6400: Menu Hierarchy (Continued)

2

1

VAh = OLD Fwd Volt-ampere hours

Wh

Wh

INTG Fwd = Forward Integrator

Wh = OLD Fwd Watt hours

VARh

VARh

INTG R.VAh

Rev

R.Wh

-VARh = Fwd Reactive energy, capacitive

Auxiliary supply (control power)

Run.h = OLD Fwd Run hours

Input voltage

Four voltage inputs (V1, V2, V3, VN)

110 or 415 VACLL nominal (80 to 600 VACLL)

Input current

(energy measurement)

Current inputs (A1, A2, A3); 5 A Class 1.0/0.5: 5 mA (starting) to 6 A*

5 A Class 0.5S/0.2S: 5 mA (starting) to 6 A

1 A Class 0.5S/0.2S: 1 mA (starting) to 1.2 A

Frequency

45 to 65 Hz

Burden

Voltage and current input < 0.2 VA per phase

Auxiliary supply (control power) < 3 VA

Overload

5 A: 10 A max continuous

1 A: 2 A max continuous

R.VAh = OLD Reverse Volt-ampere hours

R.VAR = OLD Reverse Reactive energy, inductive

-R.VAR

-R.VAR = OLD Reverse Reactive energy, capacitive

R.VAh = Reverse Volt-ampere hours

R.Run

R.Run = OLD Reverse Run hours

OLD t.VAh

TOT

-R.VAR = Reverse Reactive energy, capacitive

t.Wh

OLD Rev = OLD Reverse Integrator

R.VAR

R.VAR = Reverse Reactive energy, inductive

INTG t.VAh

TOT

t.Wh

t.VAh = OLD Total Volt-ampere hours

Display and resolution

Alphanumeric LED display; RMS: Four digits; INTG: Eight digits

t.Wh = OLD Total Watt hours

Standards

- Measurement category III,

Pollution degree 2

- Double insulation at user-accessible area

Communication (optional)

RS 485 serial channel connection industry standard Modbus RTU

protocol

Isolation

2 k VAC isolation for one min between all isolated circuits including

communication port.

Environmental

Operating temperature: -10 C to 60 C (14 F to 140 F)

Storage temperature: -25 C to 70 C (-13 F to 158 F)

Humidity 5 % to 95 % non-condensing

Weight

400 gms approx, unpacked

500 gms approx, shipping

Protection against dust and water

Front panel: IP 51

Rear panel: IP 40

t.Run

INTG TOT = Total Integrator

OLD TOT = OLD Total Integrator

t.VAR

-t.VAR

R.Run = Reverse Run hours

t.VAR = OLD Total Reactive energy, inductive

-t.VAR = OLD Total Reactive energy, capacitive

t.Run = OLD Total Run hours

t.VAh = Total Volt-ampere hours

DIAG Dia1

DIAG = represents diagnostic pages. The values

contained in these pages are for factory testing only

Dia2

t.VAR

t.Wh = Total Watt hours

Dia1 = Communication settings

Dia3

-t.VAR

t.Run

On.h

t.VAR = Total Reactive energy, inductive

-t.VAR = Total Reactive energy, capacitive

SET

VIEW

EDIT

t.Run = Total Run hours

On.h = Duration of supply ON

INTR

CLR

Dia2 = Product model and version number

Dia3 = Display scanning for display LED check

SET = Has two modes: EDIT/VIEW set parameters

VIEW = To view simultaneous setup parameter

name and value display

EDIT = To edit simultaneous setup parameter

name and value display

INTR = Number of power interruptions

CLR = Clears INTG and MD values

Class 1 .0 as per IEC 62052-11 and IEC 62053-21; Class 0.5S

(optional) as per IEC 62052-11, 62053-22 and ANSIC12. 20

Class 0.2S (optional) as per IEC 62052-11 and IEC 62053-22

44 to 300 VAC/DC

R.Wh = OLD Reverse Watt hours

Run.h = Fwd Run hours

-R.VAR

R.Run

Accuracy

-VARh = OLD Fwd Reactive energy, capacitive

R.Wh

INTG Rev = Reverse Integrator

R.Wh = Reverse Watt hours

True RMS, one second update time, four quadrant

power and energy

Run.h

OLD R.VAh

Rev

R.VAR

Sensing/measurement

-VARh

VARh = Fwd Reactive energy, inductive

Run.h

Specification

VARh = OLD Fwd Reactive energy, inductive

VAh = Fwd Volt-ampere hours

Wh = Fwd Watt hours

-VARh

Description

OLD Fwd = OLD Forward Integrator

OLD VAh

Fwd

INTG VAh

Fwd

Technical Specifications

Table 9: Technical specifications

Note: For 5 A universal power meter additional error of 0.05% of full scale, for power meter

input current below 100 mA.

Schneider Electric India Pvt Ltd

44 P, Electronics City East Phase,

Hosur Road,

Bangalore - 560 100 , India

E:in-care@in.schneider-electric.com

Toll Free Help desk Numbers:

1800 180 1707, 1800 103 0011

www.schneider-electric.co.in

Electrical equipment should be installed,

operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed

by Schneider Electric for any consequences

arising out of the use of this material.

SEI/EM6400/0111/V01.d18

2011 Schneider Electric All Rights Reserved

You might also like

- Pm1000 Quickstart Guide-SchneiderDocument8 pagesPm1000 Quickstart Guide-SchneiderTran LeNo ratings yet

- EL Meaure MeterDocument40 pagesEL Meaure MeterRangasamyNo ratings yet

- 6400 ManualDocument44 pages6400 ManualSuresh BabuNo ratings yet

- Calibration InformationDocument16 pagesCalibration InformationJuf ConstableNo ratings yet

- Em6438 6436 Dual Quick Start GuideDocument10 pagesEm6438 6436 Dual Quick Start GuideReji KurianNo ratings yet

- Conzerv 6438Document10 pagesConzerv 6438Pur WantoNo ratings yet

- Em306a User ManualDocument2 pagesEm306a User ManualNguyễnĐìnhDầnNo ratings yet

- R8605B M300 V2Document268 pagesR8605B M300 V2Rinda_Rayna100% (2)

- PG 5310Document32 pagesPG 5310vyadunandana0% (1)

- Asco 7000 Series Operator Manual-381333 - 202CDocument11 pagesAsco 7000 Series Operator Manual-381333 - 202CMarito Luis MarquezNo ratings yet

- HIGH POWER FREQUENCY-STABILIZED 300mW DIODE LASER FOR RAMAN SPECTROSDocument17 pagesHIGH POWER FREQUENCY-STABILIZED 300mW DIODE LASER FOR RAMAN SPECTROSRussell Decotis100% (1)

- Cadel 601 Energy MTR ManualDocument22 pagesCadel 601 Energy MTR Manualchidambaram kasiNo ratings yet

- Users Manual: MultimeterDocument20 pagesUsers Manual: MultimeterchepebotellaNo ratings yet

- 508 - Asco 7000 Series - Operator's Manual-381333 - 283bDocument10 pages508 - Asco 7000 Series - Operator's Manual-381333 - 283bGeorge AsuncionNo ratings yet

- Manual Serie PL3000Document13 pagesManual Serie PL3000Anonymous j3b9ApBpNo ratings yet

- Wireless TRMS Multimeter: User's GuideDocument17 pagesWireless TRMS Multimeter: User's Guidespock_65No ratings yet

- TX-28/25/21MD4 Service ManualDocument36 pagesTX-28/25/21MD4 Service ManualIpko SalimNo ratings yet

- Lock Out Relay PDFDocument10 pagesLock Out Relay PDFshaikhsajid242No ratings yet

- 63230-500-282A1 PM8 Install GuideDocument8 pages63230-500-282A1 PM8 Install GuideJohan M. CcoriNo ratings yet

- Yokogawa WT110 Digital Power MeterDocument204 pagesYokogawa WT110 Digital Power MeterCristian BandilaNo ratings yet

- ATV71 Supplementary Info 30072-452-25Document8 pagesATV71 Supplementary Info 30072-452-25Lucian GuzganNo ratings yet

- Syl 2372Document8 pagesSyl 2372Ismael 8877No ratings yet

- Manual Generador ENGGADocument20 pagesManual Generador ENGGAmanuel100% (2)

- Spectrum Analyzer: User ManualDocument40 pagesSpectrum Analyzer: User ManualBenjaminBaezNo ratings yet

- Asco 4000 Manual Transfer Switch PDFDocument12 pagesAsco 4000 Manual Transfer Switch PDFPedro Bermudez100% (1)

- PM710Document2 pagesPM710A. IvanNo ratings yet

- Installation Guide PM200Document2 pagesInstallation Guide PM200Carlos AguiarNo ratings yet

- DATAKOM DK40 Installation ManualDocument45 pagesDATAKOM DK40 Installation ManualVykintas ImbrasasNo ratings yet

- DataKom 040 USERDocument45 pagesDataKom 040 USERsebastianNo ratings yet

- DataKom 040 - USERDocument45 pagesDataKom 040 - USERKhaleel Khan100% (1)

- Franklin SubMonitorDocument20 pagesFranklin SubMonitor15265562No ratings yet

- KDE200 Series User Manual 20180412Document88 pagesKDE200 Series User Manual 20180412Thanh Tuyền TrươngNo ratings yet

- Chassis CTC186 187ABDocument20 pagesChassis CTC186 187ABjujorokoNo ratings yet

- CadelMannual PDFDocument22 pagesCadelMannual PDFVijaya KumarNo ratings yet

- UT130 Manual 1Document4 pagesUT130 Manual 1soka2030No ratings yet

- 1/16 Din Microbased Controller: Operators ManualDocument69 pages1/16 Din Microbased Controller: Operators ManualJosue Camacho100% (2)

- SAKO SKI780 ManualDocument74 pagesSAKO SKI780 ManualJordi Garcia100% (1)

- Zeeta308d PDFDocument25 pagesZeeta308d PDFGeorcchi CheeckNo ratings yet

- 700W1000W User ManualDocument19 pages700W1000W User Manualvanhuong87No ratings yet

- Title: Model Ut60F/G: Operating ManualDocument42 pagesTitle: Model Ut60F/G: Operating ManualindianmonkNo ratings yet

- 067k PDFDocument20 pages067k PDFcarlosvillamar1234No ratings yet

- .J N I - .J N - P U1 0 S : 0Document15 pages.J N I - .J N - P U1 0 S : 0Montse TovarNo ratings yet

- Sanyo Mod. DS20425 NTSCDocument26 pagesSanyo Mod. DS20425 NTSClondon335No ratings yet

- CV7300 Instruction Manual 11-05Document132 pagesCV7300 Instruction Manual 11-05boomdenNo ratings yet

- MCDocument300 pagesMCdiegobenitezNo ratings yet

- Operator's Manual: Rating LabelDocument20 pagesOperator's Manual: Rating LabelNeptali NaveaNo ratings yet

- Novar 305 Commissioning InstructionsDocument8 pagesNovar 305 Commissioning InstructionsJason Berry100% (2)

- Fuente Goldstar PDFDocument11 pagesFuente Goldstar PDFdirectNo ratings yet

- 2000A True RMS 3-Phase Clamp Power Analyzer: User's GuideDocument18 pages2000A True RMS 3-Phase Clamp Power Analyzer: User's GuideAdam SonenshineNo ratings yet

- Varlogic NRC12Document56 pagesVarlogic NRC12ViverSharinganUchihaNo ratings yet

- CL60A - Version 1.5 (Core Loss)Document34 pagesCL60A - Version 1.5 (Core Loss)Asencios MiguelNo ratings yet

- Avm 1309S PDFDocument0 pagesAvm 1309S PDFcarlosavictoriaNo ratings yet

- Im PK 1603Document32 pagesIm PK 1603James James MorrisonNo ratings yet

- DataKom 409 - INSTEDocument7 pagesDataKom 409 - INSTEKhaleel KhanNo ratings yet

- Primary Current InjectorDocument2 pagesPrimary Current Injector021804No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Base Bootstrap PDFDocument36 pagesBase Bootstrap PDFGillala RamakanthNo ratings yet

- FaqDocument1 pageFaqGillala RamakanthNo ratings yet

- 35010529K01000 PDFDocument452 pages35010529K01000 PDFGillala RamakanthNo ratings yet

- SeminarDocument36 pagesSeminarGillala RamakanthNo ratings yet

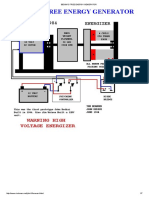

- Bedini's Free Energy Generator PDFDocument7 pagesBedini's Free Energy Generator PDFturangga ranayaNo ratings yet

- Electrical BusDocument11 pagesElectrical BusAbdul AlimNo ratings yet

- Powersafe Batterie - VF - BrochureDocument20 pagesPowersafe Batterie - VF - BrochureMarco MatteucciNo ratings yet

- Arduino Solar TrackerDocument20 pagesArduino Solar TrackerANJALINo ratings yet

- 356821WH-RP - Rev G - 100161820 - 2000019117Document4 pages356821WH-RP - Rev G - 100161820 - 2000019117lugelderkNo ratings yet

- Submitted By-Binay Ku. Tripathy 3 Year Civil Engg Vssut, BurlaDocument10 pagesSubmitted By-Binay Ku. Tripathy 3 Year Civil Engg Vssut, BurlaPrateek TripathiNo ratings yet

- Air-Preheater Leakage TestDocument2 pagesAir-Preheater Leakage TestAamirMalikNo ratings yet

- Sgt-700 Dle Combustion System Extending The Fuel FlexibilityDocument13 pagesSgt-700 Dle Combustion System Extending The Fuel FlexibilityMahsaNo ratings yet

- WartsilanDocument140 pagesWartsilanbrennomourabmcNo ratings yet

- 1 - General Arrangement DrawingDocument1 page1 - General Arrangement Drawingnimish.aquamarineNo ratings yet

- Jayashree Make Soft Starter TheoryDocument14 pagesJayashree Make Soft Starter TheoryMihirNo ratings yet

- Power Supplies TutorialDocument9 pagesPower Supplies TutorialBarry Bj ShaideNo ratings yet

- 1MW PV Power Project ECDocument11 pages1MW PV Power Project ECsbaqirNo ratings yet

- RahulDocument4 pagesRahulEr Suraj KumarNo ratings yet

- 6.2 Gas Turbine Power Plant: Engr. Jonathan S. RodolfoDocument23 pages6.2 Gas Turbine Power Plant: Engr. Jonathan S. RodolfoIvy Joy UbinaNo ratings yet

- Eaton Power Xpert 9395 High Performance Datasheet BR153048ENDocument2 pagesEaton Power Xpert 9395 High Performance Datasheet BR153048ENHector TroselNo ratings yet

- Presentation On Distribution Automation System (DAS)Document18 pagesPresentation On Distribution Automation System (DAS)A I Md. Sajed Arefin83% (6)

- Fan Coil Room Thermostat RDF510, RDF530 : en ZHDocument2 pagesFan Coil Room Thermostat RDF510, RDF530 : en ZHمحمد عليNo ratings yet

- DB Fravega Midwall Split R22Document2 pagesDB Fravega Midwall Split R22Stefan Pieter StromNo ratings yet

- 2011 Physics 5058 O-Level AnswersDocument7 pages2011 Physics 5058 O-Level Answersheyitsvan100% (1)

- Figure 1: T2000xCF-0C0 and T2000xCC-0C0 Low Voltage Fan Coil ThermostatsDocument4 pagesFigure 1: T2000xCF-0C0 and T2000xCC-0C0 Low Voltage Fan Coil ThermostatsVictor AANo ratings yet

- Awarded Biomass Projects As of 31 December 2021: Region Province City / Municipality Project Name Company NameDocument3 pagesAwarded Biomass Projects As of 31 December 2021: Region Province City / Municipality Project Name Company NameCo Tam BehNo ratings yet

- Sample Documentation For Technical SeminarDocument21 pagesSample Documentation For Technical Seminar18-208 LingaNo ratings yet

- Module 2Document32 pagesModule 2Mark Joseph BolanteNo ratings yet

- ACME Details PDFDocument12 pagesACME Details PDFBalramShuklaNo ratings yet

- Grade 4 Science - FrictionDocument5 pagesGrade 4 Science - FrictionMis Gloria67% (3)

- IECEx TOTAL Standards AngolaDocument31 pagesIECEx TOTAL Standards AngolaIso macnamareNo ratings yet

- EasyPact EZC - EZC250F3125Document6 pagesEasyPact EZC - EZC250F3125EMCC EzekielNo ratings yet

- 10MW Solar Plant DesignDocument3 pages10MW Solar Plant DesignKishore0% (1)

- Unitor Catalytic Fines Test KitDocument2 pagesUnitor Catalytic Fines Test KitMOULALINo ratings yet