Professional Documents

Culture Documents

Advanced Tube Design

Uploaded by

carlosmandopintoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advanced Tube Design

Uploaded by

carlosmandopintoCopyright:

Available Formats

Advanced tube design

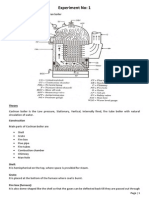

Typical Boiler Tube

Hot flue gases

enter boiler tube in

turbulent pattern

but quickly change

to a laminar, or

straight, flow

Boundary layer forms

along tube walls,

retarding heat transfer.

Cleaver-Brooks Advanced Heat Transfer Tube

Hot flue gases

enter boiler tube

in turbulent

pattern and remain

turbulent

+85%

more heat

transfer

Precisely designed ribs keep hot flue gases

in turbulent flow throughout the tube profile

The technology behind the CBEX:

Advanced heat

transfer tubes

In a firetube boiler, the hot flue gases travel through the boiler tubes and transfer heat to the water though the surface of

the tube. The greatest heat transfer occurs when the hottest gases come in contact with the surface of the tube for the

greatest amount of time.

In a traditional bare tube used in the majority of boiler designs, the hot combustion gases enter the tubes in a

turbulent flow pattern. This initial turbulent pattern produces good heat transfer initially, but the hot flue gas pattern

quickly changes to a laminar flow, or a straight parallel flow of gases. With the gases traveling in this straight pattern,

a boundary layer forms along the tube walls, increasing with the distance of the tube. This layer serves as a barrier,

retarding heat transfer. As a result, a bare tube only utilizes a fraction of its diameter for heat transfer, which equates to a

lot of wasted space.

Continued on back

Advanced tube design

Typical Boiler Tube

Hot flue gases

enter boiler tube in

turbulent pattern

but quickly change

to a laminar, or

straight, flow

Boundary layer forms

along tube walls,

retarding heat transfer.

Cleaver-Brooks Advanced Heat Transfer Tube

Hot flue gases

enter boiler tube

in turbulent

pattern and remain

turbulent

+85%

more heat

transfer

Precisely designed ribs keep hot flue gases

in turbulent flow throughout the tube profile

Because 30% to 40% of the boilers heat transfer takes place in the tubes, it is important to generate as much heat

transfer as possible within the tubes. Knowing that the laminar flow of the flue gases causes poor heat transfer, as

described above, over the past 10+ years engineers have been looking at ways to create turbulence of the flue gases

throughout the length of the tube to increase heat transfer and decrease the formation of boundary layers. By adding

helical ribs or embossed spiral patterns to the inside of the tube, engineers were able to create more turbulence of the

hot flue gases and thereby create more heat transfer. But more could still be done.

Using Computational Fluid Dynamics (CFD), finite element analysis, and mathematical modeling, Cleaver-Brooks

engineers began to improve the tube profile. Coupling the modeling technology with their extensive knowledge of

boiler systems, Cleaver-Brooks engineers dedicated countless hours to spiral tube engineering to perfect heat transfer

within the proprietary spiral tube. To obtain the right cross section for optimal tube performance, the engineering team

continuously made changes to the number of ribs, the angle of the ribs, and the height and width of the ribs. They would

then analyze the calculations, continuing to refine the geometry to achieve the optimal result.

In the end, the advanced heat transfer spiral tube for the CBEX utilizes 100% of the tube diameter and increases heat

transfer by 85% compared to a traditional bare tube. This proprietary tube is the only one to achieve these remarkable

results.

CB-8436c

01/12

You might also like

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Advanced Tube DesignDocument2 pagesAdvanced Tube DesignOmkarNo ratings yet

- EX Firetube Boiler Changed by Advances in Design TechnologyDocument7 pagesEX Firetube Boiler Changed by Advances in Design TechnologyXamir Suarez AlejandroNo ratings yet

- Boiler EfficiencyDocument2 pagesBoiler EfficiencycyruskuleiNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Fire Tube BoilerDocument14 pagesFire Tube BoilersadvdsNo ratings yet

- The Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827From EverandThe Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827No ratings yet

- Construction of Babcock and Wilcox BoilerDocument10 pagesConstruction of Babcock and Wilcox BoilerBalkunde100% (1)

- Steam Drum Systems As Well As Once-Through Steam Generators (OTSG) SystemsDocument8 pagesSteam Drum Systems As Well As Once-Through Steam Generators (OTSG) SystemsGobardhana swainNo ratings yet

- How it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useFrom EverandHow it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useNo ratings yet

- Tech Paper - Super Critical Boiler With Low Mass Flux, Vertical Wall DesignDocument6 pagesTech Paper - Super Critical Boiler With Low Mass Flux, Vertical Wall Designsbala_810No ratings yet

- 1 - Experiment No 1 - SGTC LABDocument13 pages1 - Experiment No 1 - SGTC LABRushi vedeNo ratings yet

- Water Turbines & BoilersDocument12 pagesWater Turbines & BoilersvinayakaulhaskulkarnNo ratings yet

- Bme ExperimentDocument4 pagesBme Experimentmspiso2000No ratings yet

- Applied Thermal Engineering: F.J. Gutiérrez OrtizDocument16 pagesApplied Thermal Engineering: F.J. Gutiérrez OrtizXamir Suarez AlejandroNo ratings yet

- Lancashire BoilerDocument12 pagesLancashire BoilerSNEH PODDARNo ratings yet

- CFD Analysis On Pulsating Heat Pipe To Improve Heat TransferDocument5 pagesCFD Analysis On Pulsating Heat Pipe To Improve Heat TransferijripublishersNo ratings yet

- Boilers - Types and ClassificationDocument4 pagesBoilers - Types and ClassificationSharif Muhammad HossainNo ratings yet

- To Study The Model of Lancashire and Babcock & Wilcox BoilerDocument5 pagesTo Study The Model of Lancashire and Babcock & Wilcox BoilerDr. AITH Kanpur100% (1)

- Rotary and Linear Movement of Lance TubeDocument2 pagesRotary and Linear Movement of Lance TubeAdityaJainNo ratings yet

- Report in Steam Generators: Schematic Diagram of A Boiler SystemDocument18 pagesReport in Steam Generators: Schematic Diagram of A Boiler SystemZa YonNo ratings yet

- ProjectDocument24 pagesProjectSantosh Kumar HottaNo ratings yet

- TYPES OF BOILERSDocument13 pagesTYPES OF BOILERSKalisetti AnilNo ratings yet

- InstrumentationDocument147 pagesInstrumentationAmapola San RafaelNo ratings yet

- Circulating Fluidized Bed TechnologyDocument20 pagesCirculating Fluidized Bed Technologytsraja100% (2)

- Basics OF Mechanical Engineering Laboratory: Practical ManualDocument7 pagesBasics OF Mechanical Engineering Laboratory: Practical ManualRyan TogononNo ratings yet

- Velox, Babcock, La-Mont and Loeffler boiler principles and workingDocument26 pagesVelox, Babcock, La-Mont and Loeffler boiler principles and workingDhushyanth KumarNo ratings yet

- #Lecture 3 - Steam GeneratorsDocument22 pages#Lecture 3 - Steam Generatorsmohamed EldesokyNo ratings yet

- Hairpin tube arrangements and multiple-bend designs for superheatersDocument2 pagesHairpin tube arrangements and multiple-bend designs for superheatersMArifHidayahNo ratings yet

- Modeling of Fire Tube BoilerDocument16 pagesModeling of Fire Tube BoilerVignesh AlagesanNo ratings yet

- Heating With Coils and Jackets - Spirax SarcoDocument14 pagesHeating With Coils and Jackets - Spirax SarcoWEN GIE KONGNo ratings yet

- Heat transfer & exchangersDocument19 pagesHeat transfer & exchangersSanadNo ratings yet

- Thermal LabDocument11 pagesThermal LabParam MehtaNo ratings yet

- High Flux Steam Reforming Design Lowers CostDocument6 pagesHigh Flux Steam Reforming Design Lowers CostAnissa Nurul BadriyahNo ratings yet

- Diploma 4 THERMAL ENGINEERING LAB MANUAL (Copy)Document19 pagesDiploma 4 THERMAL ENGINEERING LAB MANUAL (Copy)AjitKumarPandeyNo ratings yet

- Heat Exchanger With Helical BafflesDocument8 pagesHeat Exchanger With Helical BaffleshuangjlNo ratings yet

- Cooling Technology for ElectronicsDocument29 pagesCooling Technology for ElectronicsNikhil ShahNo ratings yet

- Experimental Study of Shell-Side Heat Transfer Coefficient and Pressure Drop For An Integrally Helical Baffled Heat Exchanger Combined With Different Enhanced Tubes PDFDocument6 pagesExperimental Study of Shell-Side Heat Transfer Coefficient and Pressure Drop For An Integrally Helical Baffled Heat Exchanger Combined With Different Enhanced Tubes PDFRengga Ahmad PrasetiaNo ratings yet

- Fire Tube BoilerDocument1 pageFire Tube BoilerJoanna MarieNo ratings yet

- Steam BoilerDocument7 pagesSteam BoilerVishnu VardhanNo ratings yet

- Babcock and Wilcox BoilerDocument3 pagesBabcock and Wilcox BoilerGautam GunjanNo ratings yet

- Basic Boiler ConstructionDocument37 pagesBasic Boiler ConstructionSudarmarine SudharNo ratings yet

- Tube Inserts in Fired Heaters - HCP 5Document8 pagesTube Inserts in Fired Heaters - HCP 5Reyes SanchezNo ratings yet

- Design and Experimental Analysis of Spiral Tube Heat ExchangerDocument6 pagesDesign and Experimental Analysis of Spiral Tube Heat ExchangergpcshfNo ratings yet

- Basics of Mechanical Engineering Lab ManualDocument7 pagesBasics of Mechanical Engineering Lab ManualRyan TogononNo ratings yet

- What Are The Types of Heat ExchangersDocument9 pagesWhat Are The Types of Heat Exchangersjr gajelesNo ratings yet

- Spiral Coil Radiator JournalDocument6 pagesSpiral Coil Radiator JournalTechnico TechnocratsNo ratings yet

- Twisted Tube Heat Exchanger TechnologyDocument8 pagesTwisted Tube Heat Exchanger TechnologyhuangjlNo ratings yet

- Boiler Basics: Design, Operation, Components & SystemsDocument5 pagesBoiler Basics: Design, Operation, Components & SystemsEng Waleed MouhammedNo ratings yet

- Twisted TubeDocument3 pagesTwisted TubePedro DiazNo ratings yet

- Heat pipe basics: structure, design, types and applicationsDocument12 pagesHeat pipe basics: structure, design, types and applicationsmokaNo ratings yet

- Basic Boiler ConstructionDocument8 pagesBasic Boiler ConstructionLuthfi Yulian FikriNo ratings yet

- Natural Circulation in BoilerDocument9 pagesNatural Circulation in BoilerSajjad AhmedNo ratings yet

- BoilerDocument48 pagesBoilerAbdallah Mansour100% (2)

- Experiment No. 9: To Study Construction Features and Working of A Cross Tube Vertical Cradely Boiler and Babcock and Wilcox BoilerDocument4 pagesExperiment No. 9: To Study Construction Features and Working of A Cross Tube Vertical Cradely Boiler and Babcock and Wilcox BoilerhloNo ratings yet

- Boiler and Boiler CalculationsDocument7 pagesBoiler and Boiler CalculationsChaya Stia ClaluiNo ratings yet

- BOILER SYSTEM COMPONENTSDocument20 pagesBOILER SYSTEM COMPONENTSKarthik GanesanNo ratings yet

- Tamilnadu 10th Timetable 2016 - RejinpaulDocument1 pageTamilnadu 10th Timetable 2016 - RejinpaulBabu AravindNo ratings yet

- Safety and Security of Women in IndiaDocument3 pagesSafety and Security of Women in IndiaBabu AravindNo ratings yet

- DiDocument14 pagesDiBabu AravindNo ratings yet

- Ibps Clerk Mains Capsule 2015 16Document73 pagesIbps Clerk Mains Capsule 2015 16Anonymous lt2LFZHNo ratings yet

- Safety and Security of Women in IndiaDocument3 pagesSafety and Security of Women in IndiaBabu AravindNo ratings yet

- Sbi CL Ass 009.anskeyDocument1 pageSbi CL Ass 009.anskeyBabu AravindNo ratings yet

- RBI Reference GuideDocument6 pagesRBI Reference GuideTanu BansalNo ratings yet

- Sbi CL Ass 009.anskeyDocument1 pageSbi CL Ass 009.anskeyBabu AravindNo ratings yet

- Sbi CL Ass 009.anskeyDocument1 pageSbi CL Ass 009.anskeyBabu AravindNo ratings yet

- Sbi CL Ass 009.anskeyDocument1 pageSbi CL Ass 009.anskeyBabu AravindNo ratings yet

- Ibpspo PT 010.anskeyDocument1 pageIbpspo PT 010.anskeyBabu AravindNo ratings yet

- Permutations & Combinations: ExplainedDocument9 pagesPermutations & Combinations: ExplainedBabu AravindNo ratings yet

- Sbi CL Ass 009.anskeyDocument1 pageSbi CL Ass 009.anskeyBabu AravindNo ratings yet

- Insurance Awareness - Recent Important UpdatesDocument4 pagesInsurance Awareness - Recent Important UpdatesBabu AravindNo ratings yet

- Sbi CL Ass 009.anskeyDocument1 pageSbi CL Ass 009.anskeyBabu AravindNo ratings yet

- Insunews: Insurance Institute of IndiaDocument6 pagesInsunews: Insurance Institute of IndiaBabu AravindNo ratings yet

- A Comparative Analysis On Qos Multicast Routing Protocols in ManetsDocument5 pagesA Comparative Analysis On Qos Multicast Routing Protocols in ManetsBabu AravindNo ratings yet

- Pradhan Mantri Jeevan Jyoti Beema YojnaDocument2 pagesPradhan Mantri Jeevan Jyoti Beema YojnaKunalKavirajNo ratings yet

- List of Important Organizations and Their Headquarters - Gr8AmbitionZDocument4 pagesList of Important Organizations and Their Headquarters - Gr8AmbitionZBabu AravindNo ratings yet

- Reasoning Skills Success in 20 Minutes A Day-ManteshDocument176 pagesReasoning Skills Success in 20 Minutes A Day-Manteshprashantvlsi100% (1)

- Banking Awareness Quick Reference Guide 2014 - Gr8AmbitionZDocument50 pagesBanking Awareness Quick Reference Guide 2014 - Gr8AmbitionZVaishnavi SubramanianNo ratings yet

- Dec 2014Document18 pagesDec 2014lavanyaNo ratings yet

- Real-Time Gesture Recognition and Robot ControlDocument2 pagesReal-Time Gesture Recognition and Robot ControlBabu AravindNo ratings yet

- Pure Math 30 Diploma Exam - Combinatorics AnswersDocument13 pagesPure Math 30 Diploma Exam - Combinatorics AnswersBabu AravindNo ratings yet

- Turbine Super eDocument6 pagesTurbine Super eBabu AravindNo ratings yet

- Formulas and concepts for profit, loss, time, distance, speed, partnership and moreDocument9 pagesFormulas and concepts for profit, loss, time, distance, speed, partnership and morePrashanth MohanNo ratings yet

- Turbine Supervisory GuideDocument2 pagesTurbine Supervisory GuideBabu AravindNo ratings yet

- Labview DSC Module Labview DSC Module: JJ - Arumugam C & I LabDocument5 pagesLabview DSC Module Labview DSC Module: JJ - Arumugam C & I LabBabu AravindNo ratings yet

- 06 Scada - OpcDocument11 pages06 Scada - OpcBabu AravindNo ratings yet

- Sample Process Application: 2. Adjusting The Sludge's PH To Neutralize Any Acid or AlkaliDocument2 pagesSample Process Application: 2. Adjusting The Sludge's PH To Neutralize Any Acid or AlkaliBabu AravindNo ratings yet