Professional Documents

Culture Documents

Cable Jointing Practices

Uploaded by

JMV LPS LimitedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable Jointing Practices

Uploaded by

JMV LPS LimitedCopyright:

Available Formats

CABLE JOINTING PRACTICES

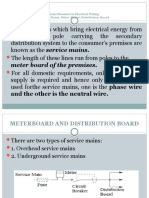

Safety is a foremost priority in every electrical installation if not considered, the chances of property loss and

human loss become more. We are spending huge amount on electrical installation to get safe working

environments. Yet at times, we can observe that an old and loosen the electrical contact may cause various

hazards like short circuit, damage of cable lugs, heating of any insulation nearby and may destroy electrical

instrument. The major reason behind these hazards to take place is Joint Failures.

Purpose of Cable Jointer:

It resolves the purpose of jointing two cables for making electrical connections indoor, outdoor, buried,

underwater and aerial applications.

When any project required more length of cable and we may get short length cable as per the logistic

supply policy the only way out is jointing.

While retaliating breakdown we cut the cable for Testing/Checking purpose and extending for any reason

we have to joint again.

For protecting electrical connections from environmental impact and direct touch by human and its

important to use the protective cover.

JMVs Gel Based Cable Jointing Kit

JMV introduces Gel Based Cable Jointing Kit for quick and reliable jointing of cables with self-sealing polymer

insulation, which provides safe electrical connections between two nodes or electric circuit and prevents

hazards. We offer this solution for all LT Cables, unarmoured & armoured cables buried, outdoor, underwater

or laying. It is constructed of a tough material specially formulated to resist UV radiation and atmospheric

contamination.

Technical Properties of Cable Jointer:

Suitable for low voltage upto 1.1 kV

High Dielectric Strength of 23 kV/mm

Water tight protection (IP68 compliant)

Ability to cross link at temperatures -100 C to 550 C

Insulation Material PVC is Fire Retardant as per UL 94 V1

No decomposition will take place in the temperature range from 40 0 C to 2000 C

Straight and branch jointing (Y /T and Customize) for single and multi-cores

Offering product life of minimum 25 years in every environmental conditions

Advantages of Cable Jointer:

No heat and light impact

No environmental impact

Easy and time saving operation

Cost Effective and easy installation

Fungus Resistant and Chemical Resistant

No temperature (heat, humidity, etc.) impact

Simple installation no special tools required

The kit has a high repeat value and can be used multiple times

During fault conditions the joint repairing is much more easier

Compact casing which eliminates the chances of electrocution

Single kit can be used for multiple conductors & for multiple connection

Rigid, two-part mould designed to withstand chemical and physical attack

In case of manual mistake (loose connections) the current will not spread outside the casing.

Applications of Cable Jointer

Oil and gas

Signalling & control

Telecommunication

Control and Instrumentation

Solar & Wind Turbines

Data Centers

For outdoor, direct-buried, under Water immersed installations

Railways

You might also like

- Lecture-6 Types of Electrical Wiring SystemDocument32 pagesLecture-6 Types of Electrical Wiring Systemaditya100% (1)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Lecture-6 Types of Electrical Wiring SystemDocument32 pagesLecture-6 Types of Electrical Wiring Systemaditya0% (1)

- Full E-Catalog March 14Document128 pagesFull E-Catalog March 14raulbd1No ratings yet

- Presentation Lightning Protection System by JMV LPSDocument62 pagesPresentation Lightning Protection System by JMV LPSMahesh Chandra ManavNo ratings yet

- Electrical WiringDocument11 pagesElectrical WiringRasydan AliNo ratings yet

- Electrical Installation and MaintenanceDocument25 pagesElectrical Installation and MaintenanceMarc HillNo ratings yet

- Writing Iap Smarten Up in Maths Age 7 8Document38 pagesWriting Iap Smarten Up in Maths Age 7 8lphoune100% (1)

- Cable Selection and Wiring SystemDocument34 pagesCable Selection and Wiring SystemMuhammad Faiz bin Ahmad Shafi0% (1)

- School of Electrical Engineering Lab RecordDocument14 pagesSchool of Electrical Engineering Lab RecordSudesha BasuNo ratings yet

- Electrical Safety and Earthing Design GuideDocument58 pagesElectrical Safety and Earthing Design GuideRajeshkumar MathiyazhaganNo ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- ELECTRICAL SAFETY AND WIRING TYPESDocument15 pagesELECTRICAL SAFETY AND WIRING TYPESSantosh KumarNo ratings yet

- Cable Construction Part 1Document5 pagesCable Construction Part 1Jesus RodriguezNo ratings yet

- Woodward MFR 13Document91 pagesWoodward MFR 13OryaNo ratings yet

- Building Services Design: Electrical Installation (Higher)Document55 pagesBuilding Services Design: Electrical Installation (Higher)Zaharadeen Muhammad HamdanaNo ratings yet

- School of Electrical Engineering Lab RecordDocument15 pagesSchool of Electrical Engineering Lab RecordSudesha BasuNo ratings yet

- Richard A. Nyquist and Ronald O. Kagel (Auth.) - Handbook of Infrared and Raman Spectra of Inorganic Compounds and Organic Salts. Infrared Spectra of Inorganic Compounds-Academic Press (1971)Document499 pagesRichard A. Nyquist and Ronald O. Kagel (Auth.) - Handbook of Infrared and Raman Spectra of Inorganic Compounds and Organic Salts. Infrared Spectra of Inorganic Compounds-Academic Press (1971)Patrícia Bodanese PratesNo ratings yet

- What Is XRF ?: Prepared by Lusi Mustika SariDocument34 pagesWhat Is XRF ?: Prepared by Lusi Mustika SariBayuNo ratings yet

- Electrical InstallationDocument18 pagesElectrical InstallationWayne Randa-LilaNo ratings yet

- ECM346 1.2.3 Function of Protection Devices HBI 02Document50 pagesECM346 1.2.3 Function of Protection Devices HBI 02Tiffany's LoveNo ratings yet

- IIEE - Electric Power CablesDocument48 pagesIIEE - Electric Power CablesAnonymous BBX2E87aHNo ratings yet

- Science8 Q2 Module3 (Week6)Document30 pagesScience8 Q2 Module3 (Week6)Mary Grace Lemon100% (1)

- TR2400 HF SSB Transceiver FeaturesDocument4 pagesTR2400 HF SSB Transceiver FeaturesAravind VinduNo ratings yet

- Self-Coached Climber - The Guide To Movem - Dan M (1) HagueDocument376 pagesSelf-Coached Climber - The Guide To Movem - Dan M (1) HagueBill Frisch100% (1)

- Offshore CablesDocument96 pagesOffshore Cableskutts76No ratings yet

- Arduino Microcontroller Based Underground Cable Fault Distance LocatorDocument13 pagesArduino Microcontroller Based Underground Cable Fault Distance LocatorIAEME PublicationNo ratings yet

- DS White-Papers Getting Started With Business Logic 3DEXPERIENCE R2017x V1Document52 pagesDS White-Papers Getting Started With Business Logic 3DEXPERIENCE R2017x V1AlexandreNo ratings yet

- Solar Power PV Presentation by JMV LPS LTDDocument69 pagesSolar Power PV Presentation by JMV LPS LTDMahesh Chandra ManavNo ratings yet

- ABB VD4 Catalogue EngDocument56 pagesABB VD4 Catalogue EngPuiu TiganasuNo ratings yet

- Interconnect Cable Design and AssemblyDocument56 pagesInterconnect Cable Design and Assemblyعبدالحافظ زايدNo ratings yet

- JOINTSDocument4 pagesJOINTSSceva AquilaNo ratings yet

- 5kV 10kV Test Lead An en V01Document16 pages5kV 10kV Test Lead An en V01Vishwanath TodurkarNo ratings yet

- Indian Smart Airports Presentation by JMV LPSDocument44 pagesIndian Smart Airports Presentation by JMV LPSMahesh Chandra ManavNo ratings yet

- One Nation-Pride Defence Presentation JMV LPSDocument41 pagesOne Nation-Pride Defence Presentation JMV LPSMahesh Chandra ManavNo ratings yet

- Fault Location On Power Cables - en - 002Document7 pagesFault Location On Power Cables - en - 002Poya ShefayeNo ratings yet

- Cabling Products and Solutions: CATALOGUE 2010/2011Document196 pagesCabling Products and Solutions: CATALOGUE 2010/2011Georgi PanayotovNo ratings yet

- TopCable Solar ENGDocument48 pagesTopCable Solar ENGashenjayawardana37No ratings yet

- Southwire - Cable Design - May 2020 - Water BlockingDocument5 pagesSouthwire - Cable Design - May 2020 - Water BlockingAli NaderianNo ratings yet

- CABLEDocument6 pagesCABLEyumicodm0987No ratings yet

- LESSON 2 Insulating Materials in Electrical EquipmentDocument10 pagesLESSON 2 Insulating Materials in Electrical Equipmentladrajojie.dNo ratings yet

- Chapter 4 Electrical Installation DesignDocument36 pagesChapter 4 Electrical Installation DesignfazlinNo ratings yet

- Isolated DownconductorDocument8 pagesIsolated DownconductorSherman HongNo ratings yet

- Elements of ElectricalDocument22 pagesElements of ElectricalDhruvaNo ratings yet

- Ecm216 Building Services Bab 1.5 CableDocument3 pagesEcm216 Building Services Bab 1.5 CableAZUAN BIN AHMAD FAUZI100% (1)

- Causes of Electrocution in the WorkplaceDocument6 pagesCauses of Electrocution in the WorkplaceAtiqah SyahminaNo ratings yet

- 5 KV & 10 KV Insulation Tester Lead Sets: Application NoteDocument16 pages5 KV & 10 KV Insulation Tester Lead Sets: Application Notetunglee091No ratings yet

- Cables (HT<) : Energy Estimation & Audit (15ee430)Document73 pagesCables (HT<) : Energy Estimation & Audit (15ee430)rohith mukkamalaNo ratings yet

- Environmental Noise DisturbersDocument6 pagesEnvironmental Noise DisturbersjeswinchNo ratings yet

- Basic Electrical Safety Fact SheetDocument2 pagesBasic Electrical Safety Fact SheetMANOJ KUMARNo ratings yet

- MVLC - FolletoDocument2 pagesMVLC - FolletoHoracio BerniNo ratings yet

- Electrical Safety Systems: TINIYE DANIEL: 0777686526Document14 pagesElectrical Safety Systems: TINIYE DANIEL: 0777686526Novic JohnsNo ratings yet

- Chapter 2 Lecture 1Document31 pagesChapter 2 Lecture 1Mengistu BirukeNo ratings yet

- Building Wiring Electrical Planning Design and EstimateDocument34 pagesBuilding Wiring Electrical Planning Design and EstimatePythiusNo ratings yet

- When to use medium-voltage cables: A guide to applications and safety considerationsDocument5 pagesWhen to use medium-voltage cables: A guide to applications and safety considerationsAries dNo ratings yet

- Condition Monitoring Program of HV Cable SystemsDocument5 pagesCondition Monitoring Program of HV Cable SystemsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Insulation MatDocument3 pagesInsulation MatKVRamananNo ratings yet

- Mineral Insulated Cables: Long Life, Safety, and Small DiameterDocument2 pagesMineral Insulated Cables: Long Life, Safety, and Small DiameterkmiqdNo ratings yet

- Digital Testing of High Voltage Circuit Breaker Seminar Topics With Reports and PPT in PDF DOC For EEE StudentsDocument3 pagesDigital Testing of High Voltage Circuit Breaker Seminar Topics With Reports and PPT in PDF DOC For EEE Studentssujendranarayana100% (2)

- Arc Guided Protection Devices: Aishwarya RaviDocument22 pagesArc Guided Protection Devices: Aishwarya RaviAishwarya RaviNo ratings yet

- Topic 1Document55 pagesTopic 1mohamad izzatNo ratings yet

- Lab # 1 Electrical Safety and PrecautionDocument14 pagesLab # 1 Electrical Safety and PrecautionNoumanShabbirNo ratings yet

- Lsa-Plus: Copper Connectivity Solutions For Telecommunication NetworksDocument24 pagesLsa-Plus: Copper Connectivity Solutions For Telecommunication NetworksStevenNo ratings yet

- John Mutarauswa Report JuneDocument11 pagesJohn Mutarauswa Report JunemutarauswajohnNo ratings yet

- BarrierDocument3 pagesBarrierSaurabh SharmaNo ratings yet

- Solutions Web PDFDocument24 pagesSolutions Web PDFfehim1No ratings yet

- 5kV 10kV Test Lead An en V01Document16 pages5kV 10kV Test Lead An en V01walcalNo ratings yet

- D ColorMF651 MF551 MF451 - To - Y110641 3 - enDocument265 pagesD ColorMF651 MF551 MF451 - To - Y110641 3 - enangevilessNo ratings yet

- Post GreeDocument15 pagesPost GreeDwi PraptiNo ratings yet

- OptQuest User ManualDocument190 pagesOptQuest User ManualYamal E Askoul TNo ratings yet

- Medical Oxygen Cylinder Filling System User ManualDocument57 pagesMedical Oxygen Cylinder Filling System User ManualAldo Tolaba QuirogaNo ratings yet

- 1-Newton Second Law-ForMATDocument5 pages1-Newton Second Law-ForMATVAIBHAV KUMARNo ratings yet

- JefimenkoDocument10 pagesJefimenkoBilly M. SpragueNo ratings yet

- Matriculation Chemistry Introduction To Organic Compound Part 1 PDFDocument24 pagesMatriculation Chemistry Introduction To Organic Compound Part 1 PDFiki292No ratings yet

- Biology Notes HSCDocument107 pagesBiology Notes HSCGouri DasNo ratings yet

- BIOLOGY Paper 1 Marking Scheme Asumbi Girls Final Prediction 2022Document4 pagesBIOLOGY Paper 1 Marking Scheme Asumbi Girls Final Prediction 2022balozi training InstituteNo ratings yet

- HP ALM FeaturesDocument51 pagesHP ALM FeaturesSuresh ManthaNo ratings yet

- A RANS-based Analysis Ool For Ducted Propeller Systems in Open Water ConditionDocument23 pagesA RANS-based Analysis Ool For Ducted Propeller Systems in Open Water ConditionLeonardo Duarte MilfontNo ratings yet

- JasminDocument125 pagesJasminudoraboxNo ratings yet

- Math10 Week3Day4 Polynomial-EqnsDocument44 pagesMath10 Week3Day4 Polynomial-EqnsMark Cañete PunongbayanNo ratings yet

- Using Topcon GR-3 GPS for Topographic SurveysDocument4 pagesUsing Topcon GR-3 GPS for Topographic SurveysFranco BaldiNo ratings yet

- Trenes de Engranajes - PresentaciónDocument17 pagesTrenes de Engranajes - PresentaciónPedro Jorge De los SantosNo ratings yet

- Hargreaves 2007Document15 pagesHargreaves 2007Sam GonçalvesNo ratings yet

- PEA ClocksDocument50 pagesPEA ClocksSuresh Reddy PolinatiNo ratings yet

- Quality Control Analysis of Chlorpheniramine Maleate Marketed in NigeriaDocument7 pagesQuality Control Analysis of Chlorpheniramine Maleate Marketed in Nigeriaحمزة الفنينيNo ratings yet

- Amber & Company: A Reliable Company of WaterproofingDocument20 pagesAmber & Company: A Reliable Company of WaterproofingRaj PatilNo ratings yet

- Connective TissueDocument6 pagesConnective TissuecrtgyhujikNo ratings yet

- The Pauli Exclusion PrincipleDocument33 pagesThe Pauli Exclusion Principle3449336893No ratings yet

- Sensitive Albuminuria Analysis Using Dye-Binding Based Test StripsDocument24 pagesSensitive Albuminuria Analysis Using Dye-Binding Based Test StripsВалерия БедоеваNo ratings yet

- Understanding Process ConditionsDocument41 pagesUnderstanding Process ConditionsIbrahim Al-HammadiNo ratings yet