Professional Documents

Culture Documents

BASF Inert Entry

Uploaded by

TammanurRaviOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BASF Inert Entry

Uploaded by

TammanurRaviCopyright:

Available Formats

Title:

Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.:

PA-020-0052

Port Arthur, TX.

Reviewed:

Preparer:

EHS Team Member

01/12

Effective:

Owner:

EHS Team Member

Page:

06/15/08

(Rev.01)

1 of 17

Supersedes: 01/05/06

(New)

Approver:

EHS Manager

Document Revision Change Table

Revision

Number

01

Revision Description

Revised By

Changed Header and Footer

Procedure Reviewed (No Changes)

Reviewed No changes

VB

TF

TD

Revision

Date

06/08

12/08

01/12

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

Page: 2 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

1. PURPOSE

This policy establishes requirements for inert confined space entry for the NROC Site.

This policy will be used in addition to the Sites Confined Space Procedure (PA-0200004). An Inert Entry is required when removing or loading catalyst, packing or

desiccants that are pyrophoric in nature and could create a fire when coming in contact

with air.

2. DEFINITIONS

2.1.

Inert Entry Attendant

An individual stationed outside the confined space who monitors the Authorized

Entrants.

2.2.

Authorized Entrant

An individual who is authorized by the employer to enter a confined space.

2.3.

Confined Spaces

Spaces which can be bodily entered, have limited or restricted means of egress,

are not designed for continuous employee occupancy, and have one or more of

the following characteristics:

Contain or have the potential to contain a hazardous atmosphere (such as

having held flammable, explosive, acidic, caustic, toxic materials) or where

oxygen enriched or deficient atmospheres or noxious odors may exist.

Contain a material that has the potential for engulfing an entrant.

Have an internal configuration such that an entrant could be trapped or

asphyxiated by inwardly converging walls or by a floor which slopes downward

and tapers to a smaller cross-section.

Contain any other recognized serious safety or health hazards; such as

ionizing radiation, electric shock, temperature extremes, or moving parts.

Such spaces include, but are not limited to: tanks, tank trucks, tank cars, duct

work, vats, tubs, hoppers, bins, boilers, kilns, cooling towers, stacks,

chimneys, sewers, trenches, pits, manholes, elevated or ground flares, or

other similar equipment/structures. This may also include structures greater

than four feet in height, or excavation that are greater than four feet in depth

that have limited or restricted means of egress.

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

2.

Page: 3 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

DEFINITIONS contd.

2.4.

Immediately Dangerous to Life or Health (IDLH)

Any condition that poses an immediate or delayed threat to life or that would

cause irreversible adverse health interfere with an individuals ability to escape

unaided from a confined space. Included in this definition is an oxygen deficient

atmosphere containing less than 19.5 percent oxygen by volume. (Refer to the

NIOSH Pocket Guide to Chemical Hazards for IDLH limits for toxic chemicals)

2.5.

Entry Rescue

A confined space rescue that must be performed by having the rescue team enter

the confined space.

2.6.

Inert Entry

The action by which a person passes through an opening into a confined space

that has been filled or is filled with an inert gas such as nitrogen. This constitutes

a IDLH environment where proper set-up and execution of work and safety

systems is critical. At the Port Arthur Site, Inert Entries are used for the unloading

and loading of potentially pyrophoric catalyst, packing or desiccants. These

entries are done in nitrogen environments.

2.7.

Hazardous Atmosphere

An atmosphere that may expose employees to the risk of death, incapacitation,

impairment of ability to self rescue, injury or acute illness from one or more of the

following causes:

Flammable gas, vapor or mist in any detectable concentration using a calibrated

combustible gas indicator operating in the percent range of sensitivity.

Airborne oxygen concentration below 19.5% or above 21.0%.

Atmospheric concentration of any substance for which a dose or permissible

exposure limit is published in 29 CFR 1910 Subpart G, Occupational Health and

Environmental Control, or in Subpart Z, Toxic and Hazardous Substances, and

which could result in the employee exposure in excess of its dose or permissible

exposure limit.

Any other atmospheric condition that is immediately dangerous to life or health.

NOTE:

For air contaminants for which OSHA has not determined a dose or permissible exposure

limit, other sources of information; such as, Material Safety Data Sheets, ACGIH TLVs,

published information, and internal documents may provide guidance in establishing

acceptable atmospheric conditions.

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

2.

Page: 4 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

DEFINITIONS contd

2.8.

Entry Supervisor

The person responsible for determining if acceptable entry conditions are present

where entry is planned, for authorizing entry and overseeing entry operations, and

for terminating entry as required. At the Port Arthur Facility, the shift coordinator

normally acts as the entry supervisor, with the exceptions of plant turnarounds or

shutdowns when others may act in this capacity.

3.

SCOPE

4.

PROCEDURE

4.1.

Contractor Selection

The Texas Hubs Contractor Selection Procedure (EHS Texas Hub Procedure)

will be followed. For Inert Entry Contractors, the following additional

reviews/discussions are required in the areas of training, medical records,

procedures, equipment inspections and management commitment. The

contractor must demonstrate to BASF a clear commitment to Safety as a core

value and an ongoing cycle of continuous improvement. The following are key

components of this review process:

4.1.1. Conduct a detailed review of the training program during the initial review

of any Inert Entry Contractor considered for addition to the Approved

Contractor List. This review should include quality of training materials,

review of training records, instructor qualifications, and experience

requirements in each position. It is critical that specific personnel who will

carry out the inert entry have adequate training and experience.

4.1.2. All contractors that perform Inert Entry work must have their Safety

Program reviewed, including Inert Entry and Rescue Procedures, against

the key requirements of this document.

4.1.3. Review fit test records to ensure that personnel working in breathing air are

routinely examined for medical fitness as required by OSHA 29 CFR

1910.134.

4.1.4. Review inspection and test records for all breathing air equipment, Life

Support Systems, emergency rescue equipment and gas testing

equipment to ensure it is routinely inspected and tested.

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

4.

Page: 5 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

PROCEDURE contd

4.2.

Management Presentation

Management of contractors who perform Inert Entry work must make a

presentation to BASF Site Management prior to award of contract and annually

thereafter. The presentation should include, at a minimum:

4.2.1. Demonstration of Management Commitment to Safety

Senior Management Site Visits for sole purpose of EHS review

Company Organizational Chart Review

Organizational Roles & Responsibilities

4.2.2. Environmental, Health and Safety Program Review

Equipment Program (Inspection, Replacement/Upgrade

Personnel (Training, Experience, Crew Size)

Company History (Experience in Type and Scope of job)

Auditing (Pre-Job, Execution, Follow-up Actions)

Job Observation Program

Hazard Recognition Program

Incident Investigation and Follow-up (Review of contractor incidents

with changes implemented & corrective action closure times.)

Three year history of near miss incidents

Three year history of Safety Statistics

4.3.

Pre-Job Planning

Because of the critical nature of inert entry, it is important that both BASF and the

contractor work together. Each party has critical tasks they must complete prior to

starting the inert entry. Pre-planning every aspect of the job is required in order to

complete the job successfully.

Company Management

Although a qualified contractor will perform the inert entry, BASF employees must

be involved in the operation to provide the contractor with the proper facility

knowledge, job expectations and accountability to complete the job safely.

4.3.1. Contractors written site safety and emergency/rescue plan will be reviewed

by Shift Coordinator, Area Team Lead and Site EHS personnel before the

start of work.

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

4.

Page: 6 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

PROCEDURE contd

4.3.

Pre-Job Planning contd

4.3.2. Prior to inert entry, the Area Maintenance Coordinator will coordinate a

meeting to discuss the contractors written plan for performing work under

inert conditions. Meeting attendees shall include:

Shift Coordinator

Area Team Lead

Contractor Safety Representative

EHS Representative

Contractor Foreman

Area Operations Coordinator

Area Operations Technician

Results of this meeting shall be documented and action items must be

completed prior to start of the inert entry job.

4.3.3. A BASF representative is required to be in the entry area throughout the

inert portion of the entry job. Extra coverage will be scheduled if necessary

to comply with this requirement.

4.3.4. Air Supply must be Certified Grade D quality breathing air. A quality

control check will be made by On-Site Safety Store personnel as the

bottles are brought to the Site. The bottles will be individually tested and

tagged.

4.3.5. Blended or synthetic air will NOT be used for supplied breathing air used

by employees or contractors.

Contractor

Written Documentation

Contractor must provide to BASF representative written documentation prior to

commencement of work supporting qualifications for working in an inert

environment. The minimum documentation required should include:

4.3.6. Employee service and current training records for all crew members.

4.3.7. Certification of emergency/rescue training.

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

4.

Page: 7 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

PROCEDURE contd

4.3.

Pre-Job Planning contd

4.3.8. Documentation of Confined Space Entry training consistent with OSHA 29

CFR 1910.146.

4.3.9. A written procedure for performing work.

4.3.10. A written emergency plan to include, but not limited to:

Loss of N2 supply

High N2 pressure

High equipment O2

High equipment temperature

Loss of Breathing Air Supply

Emergency inside the reactor/dryer

Plant Emergency outside of the reactor/dryer

4.3.11.

4.3.12.

Heat Stress Plan

Contractor must provide written program for control of heat stress, such

as work/rest regimens, monitoring workers and use of auxiliary cooling.

Job Safety Analysis

The contractor must prepare a JSA, which is specific to the vessel

being entered and the work being undertaken. The JSA needs to

address all the risks associated with the work such as:

Setting up the inert entry and catalyst handling equipment at the

work site

Access and egress to the equipment

Provision for adequate lighting

Control of access around the work site and around any open

manways where nitrogen is being vented

Lifting and rigging activities

Manual handling activities

Catalyst handling

Removal of vessel internals (if required)

Catalyst loading

Installation of warning signs utilizing international caution/danger

symbols

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

4.

Page: 8 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

PROCEDURE contd

4.3.

Pre-Job Planning contd

4.3.13.

Contractors Equipment

Inert entry requires specialized equipment that must be inspected and

in good working order. Contractors must supply the equipment

necessary for completing the job.

Contractors must maintain a communications system for use by the

employees working inside the inert atmosphere and those

monitoring the work from the outside. This system must be capable

of simultaneous communication with all connected personnel and

must include a redundant system in the event the primary system

fails.

Entrants can be lowered into the vessel using a winch/hoist

specifically designed for carrying people. A ladder can be used for

access as well if it meets Site Standards found in PA-020-0013.

All hand tools contractors bring on Site will be in good workable

order. All designed safeguards will be remain in place and not

tampered with or bypassed.

Inherent Safe Connections will only be used.

Labeling of all air and communications lines will be required.

Any pneumatic equipment used inside the confined space will use

nitrogen as the energy source.

4.3.14.

Personal Protective Equipment

A risk assessment should be conducted to determine the additional

PPE required to protect the persons working inside the equipment from

catalyst dust, any residual oil and any physical hazards.

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

4.

Page: 9 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

PROCEDURE contd

4.3.

Pre-Job Planning contd

4.3.15.

Life Support Systems

Two independent sources of air must be provided to a Helmet. The

secondary air supply should cut-in automatically whenever the

primary source is overextended or over breathing occurs.

The entrant must wear an auxiliary escape air bottle.

An Emergency Egress Line shall be supplied for each entrant for

emergency egress. Air for these Emergency Egress Lines shall be

supplied from an independent source.

The helmet must be sufficiently secured to prevent inadvertent

removal. The helmet must be in clean, workable order with all

inspections complete and documented.

The umbilical cord containing the air hoses must be adequately

sheathed to protect the hoses and be designed such that the hoses

cannot be detached should the umbilical cord be pulled or snagged.

A trained attendant, located outside the confined space, must

continuously monitor the air supply. An alarm, audible/visible, shall

be provided to warn of low air pressure. An alarm will also be

required to warn when secondary air has been activated.

If for any reason the primary communication link fails, the persons

working inside must be evacuated. BASF personnel will also be

notified.

The entrant working inside the vessel must be in visual contact of

the attendant. An additional standby may be necessary in addition

to other visual means such as CCTV.

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

4.

Page: 10 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

PROCEDURE contd

4.3.

Pre-Job Planning contd

4.3.16.

Rescue/Evacuation

Adequate emergency rescue facilities should be immediately available

at the vessel manway and the contractors should be trained in its use.

This should include:

Hoisting device and wire lifeline to extract person from the inside of

the confined space.

Persons working inside the vessel should wear a harness

(Shoulder D Ring Type), which enables the person to be lifted out

of the vessel in a vertical position.

A pre-planned means of lowering the person to the ground. (stokes

basket)

A radio or other means of summoning assistance.

The attendant at the vessel must wear standard inert entry

equipment so that in an emergency they can enter the vessel to

assist the injured person. A spare set of standard inert entry

equipment must be available at the vessel manway so that another

technician can replace the safety standby.

Trained personnel to provide emergency first aid and

cardiopulmonary resuscitation (CPR)

4.3.17.

When to Evacuate

An evacuation of the vessel must occur under the following

circumstances:

Loss of primary communications systems

Vessel temperature rise greater than 15 deg. F.

Loss or problems with primary air

Loss or problems with nitrogen purge

Loss of power and/or lighting

O2 concentration greater than 4%

Whenever the Sites Emergency Horn goes off (with the exception

of the weekly test that occurs every Monday at noon).

Use of emergency egress bottle

Anytime a vessel is evacuated, a thorough investigation must be

performed to identify the cause(s) that led to the condition requiring

evacuation. Entry shall not be permitted back into the space until

corrective actions have been implemented to address the cause(s).

The inert entry permitting process should be repeated and a new entry

permit issued.

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

4.

Page: 11 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

PROCEDURE contd

4.3.

Pre-Job Planning contd

4.3.18.

Process/Operations

There must be a primary (truck/trailer) supply and secondary nitrogen

(plant N2) supply to the vessel. The primary trailer supplying the

nitrogen must be backed up by a second trailer that is staged on site.

In the event that a nitrogen trailer runs empty, operations will switch

over to the secondary plant nitrogen system until a trailer swap is

accomplished. O2 and temperatures should be watched carefully

during this time. Ideally there will be two nitrogen trailers on site at all

times with a third trailer being in transport between the Site and the

Nitrogen fill facility.

Due to the potential for some catalyst to develop crust, planning the

introduction of nitrogen supply must address methods to eliminate

the potential for build-up of pressure below this crust.

Operations personnel preparing the job will perform atmospheric

testing to determine a safe zone. The area around the Inert Entry

Operation will then be barricaded to limit personnel in the area.

Warning signs should be posted at the point of access to the area

(ladder cage, elevator, etc.) and the entry point. These signs

should readIDLH Entry In Progress! Do not enter without

operations approval!

All open manways must be covered or otherwise protected from fall

hazards.

Operations must tag all valves in the N2 system to indicate OPEN

or CLOSED position. Tags should be weatherproof and be secured

with a tie wrap.

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

4.

Page: 12 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

PROCEDURE contd

4.4.

Field Execution

4.4.1. Pre-Job Checks

Prior to beginning the inert entry, a Pre-Job check is completed to ensure

all planning activities, meeting action items, emergency and rescue plans

have met BASF requirements. This step is to ensure all equipment is in

place, to make final checks of the job, and be sure the space and

personnel are prepared to complete the job safely. The following are key

components of a facility programs related to field execution:

Permit issuers must test all areas around the openings to determine

boundaries of regulated areas. The boundaries will be barricaded

to ensure non-entry personnel do not enter oxygen deficient

environments.

Open manways must be secured to prevent fall hazards.

Any deviations from the Confined Space Permit or Inert Entry

Procedure must be documented and signed off by appropriate

personnel.

4.4.2. PPE

The PPE hazard assessment completed during the planning phase should

clearly identify the PPE required for all task being performed during each

specific inert entry operation. Contractor supervision must enforce the

implementation of the requirements identified by the Safe Work Permit.

BASF will also audit the use of required PPE.

4.4.3. Emergency Plan Verification

The emergency plans developed during the planning phase must be

verified to ensure they are in place and all members of the rescue team

understand their roles and responsibilities under these plans. It is equally

important that entrants, attendants, support personnel and all employees

involved in an inert entry know what to do in the event of an emergency.

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

4.

Page: 13 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

PROCEDURE contd

4.4.

Field Execution contd

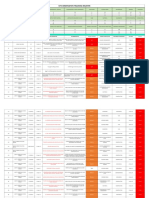

4.4.4. Entry Conditions

Vessel atmosphere requirements for inert entry with life support system

breathing apparatus are outlined in the following table. If these levels are

exceeded while an entry is in progress, the vessel must be evacuated until

these levels are restored:

Substance

Oxygen

Max Value

4%

Hydrocarbons

0%

H2S

10ppm

Benzene

1ppm

CO

50ppm

Comment

The max limit set by

API 2217A is 5%. The

maximum limit for

vacuum operations is

2%. This provides

time for emergency

action to be taken.

This to be determined

on a case by case

basis depending on

the individual job and

circumstances.

Limit based on

avoiding H2S levels

>10 ppm in the vicinity

of the reactor manway

platform.

Limit based on

avoiding benzene

levels >1 ppm in the

vicinity of the reactor

manway platform.

Should be tested when

catalyst contains

Nickel or Cobalt. This

is to prevent the

potential of highly toxic

metal carbonyls.

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

4.

Page: 14 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

PROCEDURE contd

4.4.

Field Execution contd

4.4.5. Ongoing Monitoring

Contractor

In order to maintain a safe environment, the contractor should maintain a

periodic log or checklist of continuous monitoring. BASF personnel will

periodically audit these readings. The checklist or log must included:

Vessel Temperature

LEL

Oxygen Concentration

Air Supply (Primary & Secondary) Checks

Communication Checks

Operations

Area operations technician will be responsible for maintaining a safe

working environment. Responsibilities include:

Audit of contractors to ensure ongoing monitoring is taking place

Contact will BASF board technicians to ensure temperatures and

other variables are maintaining

Performing LEL/O2 readings determined by permit requirements

Personal presence in the area of Inert Entry

Issuance of all permits required for work being performed

Ensuring adequate nitrogen flow is maintained

Informing contractors of any emergency situations

Ensuring company LEL meters are checked by bump testing at

least once per shift

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

4.

Page: 15 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

PROCEDURE contd

4.4.

Field Execution contd

4.4.6. Vacuum Operations

Vacuum operations can present additional and unique hazards during inert

entry. The nature of the operation can affect the atmosphere in the vessel

and present new physical hazards in and outside the space. These risks

must be addressed from the approval process through execution. The

following additional precautions need to be taken:

All components including the ducting, the cyclone and vacuum

equipment must be properly bonded together and must be

grounded to prevent build-up of an electrostatic charge.

Hoses can be eroded by catalyst and must be visually examined

prior to each use.

Vacuum equipment must be purged with nitrogen prior to use and a

nitrogen supply should remain connected at all times.

A vacuum system removes large amounts of nitrogen from the

vessel. Nitrogen levels in the vessel must be regulated to maintain

the proper concentration during vacuum operations. Exhaust

should be discharged to a safe location. A barricade should be

utilized to establish a safe zone around the vacuum truck.

Vacuum operations must be stopped if the vessel O2 level rises

above 4%.

The location of the vacuum hose could hamper emergency egress

from the vessel. This needs to be considered in the emergency

evacuation procedures.

Spent catalyst containers must be inerted before being loaded.

At the end of the vacuuming operation, the internal components of the

vacuum system should be thoroughly washed/cleaned to remove

pyrophoric dust/residues. Filters should be routinely cleaned to prevent

build-up of pyrophoric waste.

4.5.

Post Job Critique

At the conclusion of each inert entry job, there shall be a documented critique

facilitated by BASF Operations/Maintenance/EHS Teams and the Inert Entry

Contractor. The agenda for the critique shall include:

Contractor review of Highlights and Opportunities

Company review of Highlights and Opportunities

Review of evacuations that were required and corrective actions

Review of all audits performed during the job

Review of all near misses and corrective actions

Lessons learned

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

Title: Inert Confined Space Entry

Individual Unit

Procedure

Function: Health and Safety

No.: PA-020-0052

Port Arthur, TX.

Reviewed: 01/12

5.

Page: 16 of 17

Effective: 06/15/08 Supersedes:

(Rev.01)

01/05/06

(New)

RESPONSIBILITIES

5.1.

Port Arthur Site Leadership Team

Has primary responsibility for implementation of this procedure.

5.2.

Environmental, Health, and Safety Manager

Has primary responsibility for the initiation, re-issuance, administration, and/or

interpretation of this procedure.

5.3.

Port Arthur Employees and Contractors

Have primary responsibility for adherence to procedure including identifying

deficiencies in the procedure, and identifying, reporting and correcting activities

not in compliance with the procedure

6. RELATED DOCUMENTS

BC032.017 Confined Space Entry

29 CFR 1910.146 Confined Space Entry

Health & Safety Procedure PA-020-0004 Confined Space Entry

Health & Safety Procedure PA-020-0017 Personal Protective Equipment

Health & Safety Procedure PA-020-0013 Ladders

Attachment A Area Technician Checklist

***IMPORTANT*** If printed, this is an uncontrolled copy of this document.

The current version can be viewed in the Electronic Document Management System

PA-020-0052

Attachment A

Area Technician Checklist

Area Technician

Effective:06/15/08

Time

Date

Entry Contractor

Safety Checks

Current &

Updated?

Area

Housekeeping

Acceptable?

Approved by: EHS Manager

You might also like

- Pre Startup Safety ReviewDocument29 pagesPre Startup Safety ReviewAhsan100% (1)

- Understanding Oil and Gas HSE Management (37Document34 pagesUnderstanding Oil and Gas HSE Management (37Madhur ChopraNo ratings yet

- Process Safety Management: Kharil Ashidi B. Abdul Jabar Q-SHE-S Dept Nippon Steel Engineering Co., LTDDocument37 pagesProcess Safety Management: Kharil Ashidi B. Abdul Jabar Q-SHE-S Dept Nippon Steel Engineering Co., LTDKay Aay100% (1)

- Process Safety ManagementDocument74 pagesProcess Safety ManagementShankarMukherjeeNo ratings yet

- (III) PSSR Procedure (Rev00)Document19 pages(III) PSSR Procedure (Rev00)ahmedNo ratings yet

- Management of Change Procedure - Wyandotte: The Electronic Document Is Controlled. Printed Copies Are UncontrolledDocument21 pagesManagement of Change Procedure - Wyandotte: The Electronic Document Is Controlled. Printed Copies Are UncontrolledSusin LimNo ratings yet

- Draft Copy: Title: Permit To WorkDocument21 pagesDraft Copy: Title: Permit To Workفؤاد ابوزيد100% (1)

- ASSE 04 Process Safety ManagementDocument37 pagesASSE 04 Process Safety ManagementCarlos Cueva GallegosNo ratings yet

- FM200 KiddeDocument37 pagesFM200 KiddeNguyen Van TuanNo ratings yet

- Types of HazardsDocument2 pagesTypes of HazardsRosalie Tilos OritoNo ratings yet

- Process Safety Seminar SummaryDocument5 pagesProcess Safety Seminar SummaryBrijesh100% (1)

- LNG Fire Protection and Emergency Response - 4MechEngineer LNG Fire Protection and Emergency ResponseDocument6 pagesLNG Fire Protection and Emergency Response - 4MechEngineer LNG Fire Protection and Emergency ResponseDesigner ForeverNo ratings yet

- Tanker Checklist Incoming EmptyDocument4 pagesTanker Checklist Incoming Emptybuddy-20087751No ratings yet

- RAS MARKAZ CRUDE OIL PARK PSSR PROCEDUREDocument57 pagesRAS MARKAZ CRUDE OIL PARK PSSR PROCEDUREKhan Wasim100% (1)

- Pre-Start Up Safety Review (PSSR) : Akamigas Balongan IndramayuDocument18 pagesPre-Start Up Safety Review (PSSR) : Akamigas Balongan IndramayuRifky Haikal RamadhanNo ratings yet

- Pre-Mobilisation Assurance Checklist BackupDocument7 pagesPre-Mobilisation Assurance Checklist BackupNazrin SHONo ratings yet

- Process Safety Day Presentations 2014pptxDocument16 pagesProcess Safety Day Presentations 2014pptximafishNo ratings yet

- 51 Confined SpaceDocument1 page51 Confined SpaceAnonymous ANmMebffKRNo ratings yet

- Hazard of Sulfuric AcidDocument3 pagesHazard of Sulfuric AcidAlisameimeiNo ratings yet

- Process Safety Fundamentals: An IntroductionDocument32 pagesProcess Safety Fundamentals: An IntroductionCesar PumaNo ratings yet

- HAZAN Analysis Full Project ReportDocument53 pagesHAZAN Analysis Full Project Reportthirunavukarasu0% (1)

- The Mexico City Explosion of 1984 FinalDocument18 pagesThe Mexico City Explosion of 1984 FinalVikas KumarNo ratings yet

- I. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17Document15 pagesI. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17KehindeNo ratings yet

- Appendix: Appendix A1: Example PSSR Completion FormDocument5 pagesAppendix: Appendix A1: Example PSSR Completion FormSumantrra ChattopadhyayNo ratings yet

- PSUSR report checklistDocument3 pagesPSUSR report checklistkirandevi1981No ratings yet

- Objectives: CareerDocument14 pagesObjectives: CareerHedi Ben MohamedNo ratings yet

- Nebosh PSM SummaryDocument67 pagesNebosh PSM SummaryAhmed Hamad100% (1)

- 2.309-Near Miss Reporting ProcedureDocument4 pages2.309-Near Miss Reporting Procedurekirandevi1981No ratings yet

- PSSR Checksheet - Offshore Asset - DraftDocument6 pagesPSSR Checksheet - Offshore Asset - Draftjai kumar100% (1)

- Osh Communication: Document ID: MSP-005Document7 pagesOsh Communication: Document ID: MSP-005Kingsley AhanonuNo ratings yet

- PSM Compliance ManualDocument6 pagesPSM Compliance ManualMohammed Zubair100% (1)

- 3chemical and Process Safety Management 23111Document137 pages3chemical and Process Safety Management 23111DaNo ratings yet

- Process Safety StudyDocument33 pagesProcess Safety Studyadilmomin45100% (3)

- Process Safety and Risk Management PlansDocument3 pagesProcess Safety and Risk Management PlansSPIDERMAB330% (1)

- Hempel Paint - MSDSDocument14 pagesHempel Paint - MSDSbaseet gazaliNo ratings yet

- Hazid RecordDocument21 pagesHazid Recordavanish.vNo ratings yet

- iogIGC NEBOSH OIL & GASDocument10 pagesiogIGC NEBOSH OIL & GASParthasarathy Vadapalli100% (1)

- Exam 3Document2 pagesExam 3eng20072007No ratings yet

- 134 A - Flexible Hose SafetyDocument1 page134 A - Flexible Hose SafetyNibha100% (1)

- JOB SAFETY ANALYSIS FORMDocument7 pagesJOB SAFETY ANALYSIS FORMIulian Costin IonNo ratings yet

- 0014 HAZOP Automate The BRA & BRD Hydrocyclone Backflush Valves Rev.00 - SignedDocument25 pages0014 HAZOP Automate The BRA & BRD Hydrocyclone Backflush Valves Rev.00 - SignedMohd HisammudinNo ratings yet

- Hazid WorksheetDocument2 pagesHazid WorksheetHarry SiswajiNo ratings yet

- Tech Safety Vs HSE EngineerDocument5 pagesTech Safety Vs HSE EngineerIrsyad Ilhami100% (1)

- HSE Safety Permit to Work ProcedureDocument32 pagesHSE Safety Permit to Work Proceduregobi100% (1)

- Name: Contractor: Date: Encircle The Letter of The Best Answer. For True or False Questions, Encircle "True" or "False"Document4 pagesName: Contractor: Date: Encircle The Letter of The Best Answer. For True or False Questions, Encircle "True" or "False"Afroz AlamNo ratings yet

- Chapter No. 13: Hazop StudyDocument9 pagesChapter No. 13: Hazop StudyMudassir HashmiNo ratings yet

- GGC-HSEF 037 Site Daily ObservationDocument1 pageGGC-HSEF 037 Site Daily ObservationAmjadNo ratings yet

- Process Safety InformationDocument7 pagesProcess Safety InformationMohammed Zubair100% (1)

- PSBR 1 TemplateDocument2 pagesPSBR 1 TemplatesathishNo ratings yet

- Safety Talk On-Safety During ShutdownDocument10 pagesSafety Talk On-Safety During Shutdownchakri4all100% (1)

- HAZOP, SIL and LOPA Course: Kermanshah Polymer CompanyDocument92 pagesHAZOP, SIL and LOPA Course: Kermanshah Polymer CompanyVikas NigamNo ratings yet

- TN 015 Overrides 15Document8 pagesTN 015 Overrides 15Luis SantosNo ratings yet

- LMRA EnglishDocument5 pagesLMRA EnglishemmanueljosephNo ratings yet

- Industrial Hygiene Qualitative Risk Assessment - Dan Drown CIH CSPDocument27 pagesIndustrial Hygiene Qualitative Risk Assessment - Dan Drown CIH CSPMarcus Braga100% (1)

- Hazop & Check ListDocument39 pagesHazop & Check ListgarciaolinadNo ratings yet

- Health, Safety, and Environmental Management in Offshore and Petroleum EngineeringFrom EverandHealth, Safety, and Environmental Management in Offshore and Petroleum EngineeringRating: 5 out of 5 stars5/5 (1)

- Pre Start Up Safety ReviewDocument8 pagesPre Start Up Safety ReviewAhmed MorsyNo ratings yet

- Chemical Equilibrium Theory 1Document20 pagesChemical Equilibrium Theory 1TammanurRaviNo ratings yet

- DC MachineDocument20 pagesDC MachineTammanurRaviNo ratings yet

- How To Predict The Outcome of A DashaDocument25 pagesHow To Predict The Outcome of A DashaKALSHUBH100% (4)

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Electric Circuits Lab ManualDocument33 pagesElectric Circuits Lab Manualsheikmd80% (5)

- Lecture 3Document106 pagesLecture 3abhilashaNo ratings yet

- Clark's TablesDocument54 pagesClark's TablesTammanurRaviNo ratings yet

- Normality Study AddaDocument26 pagesNormality Study AddaTammanurRaviNo ratings yet

- Physics Grade 10Document228 pagesPhysics Grade 10Jan92% (26)

- Control Systems - ClassicalDocument130 pagesControl Systems - ClassicalTammanurRaviNo ratings yet

- Root Locus TechniqueDocument18 pagesRoot Locus TechniqueTammanurRaviNo ratings yet

- NUS Application Guide Cat DDocument10 pagesNUS Application Guide Cat DTammanurRaviNo ratings yet

- Polar NyquistDocument2 pagesPolar NyquistTammanurRaviNo ratings yet

- Multiple page document scanned with CamScanner appDocument26 pagesMultiple page document scanned with CamScanner appTammanurRaviNo ratings yet

- Virginia Tech Admission RequirementsDocument2 pagesVirginia Tech Admission RequirementsTammanurRaviNo ratings yet

- Fourier TransformDocument6 pagesFourier TransformTammanurRaviNo ratings yet

- 501 Critical Reading QuestionsDocument283 pages501 Critical Reading Questionsapi-3813392100% (9)

- ELG3311 Lab 6Document5 pagesELG3311 Lab 6Nabeel MosawedNo ratings yet

- A Guide To Selecting Appropriate Tools To Improve HSE CultureDocument24 pagesA Guide To Selecting Appropriate Tools To Improve HSE CultureSAYED100% (3)

- SCBA RefillingDocument8 pagesSCBA RefillingTammanurRaviNo ratings yet

- Arco Sat 2Document334 pagesArco Sat 2TammanurRaviNo ratings yet

- Sem Charts SingleDocument39 pagesSem Charts SingleAbdul Quadeer100% (1)

- SAT Writing Essentials (LearningExpress)Document170 pagesSAT Writing Essentials (LearningExpress)Shafik96100% (1)

- DR C A R - Article - 3 - Paean in The EmpyreanDocument2 pagesDR C A R - Article - 3 - Paean in The EmpyreanTammanurRaviNo ratings yet

- DR C A R Article 2 DedicationDocument4 pagesDR C A R Article 2 DedicationTammanurRaviNo ratings yet

- DR C A R Article 2 DedicationDocument4 pagesDR C A R Article 2 DedicationTammanurRaviNo ratings yet

- 2015 0005 Ar TheloveofmasterDocument6 pages2015 0005 Ar TheloveofmasterTammanurRaviNo ratings yet

- 2015 0002 Ar PralayaDocument4 pages2015 0002 Ar PralayaTammanurRaviNo ratings yet

- 2015 0004 Ar Harmonising Worldly LifeDocument5 pages2015 0004 Ar Harmonising Worldly LifeTammanurRaviNo ratings yet

- 2014-0041-AR-Special Characteristics of Sahaj Marg SadhanaDocument12 pages2014-0041-AR-Special Characteristics of Sahaj Marg SadhanaTammanurRaviNo ratings yet

- Procedure For Rescue From Confined Space - Revision#02Document4 pagesProcedure For Rescue From Confined Space - Revision#02muzamilarshad31No ratings yet

- Patos Confined SpaceDocument5 pagesPatos Confined SpacePj Apolonio0% (1)

- BP Toledo Inert EntryDocument32 pagesBP Toledo Inert EntrySam Mebarek100% (1)

- Batching Plant Cleaning: Karot Hydropower ProjectDocument1 pageBatching Plant Cleaning: Karot Hydropower Projectcuteboom1122No ratings yet

- Oil and Gas General Safety TaskDocument19 pagesOil and Gas General Safety TaskMohamed GhorabNo ratings yet

- MOG-HSEQ-In-G-051 Rev A3 Corporate HSE Requirements During Yearly Schedualed SHT Dwn.Document27 pagesMOG-HSEQ-In-G-051 Rev A3 Corporate HSE Requirements During Yearly Schedualed SHT Dwn.SamerNo ratings yet

- Confined Space SafetyDocument33 pagesConfined Space SafetyEneyo VictorNo ratings yet

- JSA Demolition and Formwork NKEDocument9 pagesJSA Demolition and Formwork NKEsaylendra widyahanantoNo ratings yet

- MDG 25 Guideline For Safe Cutting and Welding at MinesDocument65 pagesMDG 25 Guideline For Safe Cutting and Welding at MinesAnonymous 24lnhhNo ratings yet

- GEN-021 Fact FindingDocument3 pagesGEN-021 Fact Findingacanbasri1980No ratings yet

- Serious Injury and Fatality PreventionDocument20 pagesSerious Injury and Fatality PreventionISRAEL TOLANONo ratings yet

- Taqa Ti 009Document117 pagesTaqa Ti 009evenNo ratings yet

- NFPA 350 Guide For Safe Confined Space Entry and WorkDocument48 pagesNFPA 350 Guide For Safe Confined Space Entry and WorkFatih D. Prasetio100% (1)

- Martinplus Silo Solutions: Storage Vessel Cleaning Service and ProductsDocument8 pagesMartinplus Silo Solutions: Storage Vessel Cleaning Service and ProductstacosanchezbrayanNo ratings yet

- Safety Presentation Lucien Nel 2010Document44 pagesSafety Presentation Lucien Nel 2010Yan's Senora BescoroNo ratings yet

- Factory Act 1948 AmendementDocument101 pagesFactory Act 1948 AmendementPraveen Kumar Singh0% (1)

- Intro Confined Spaces TADocument25 pagesIntro Confined Spaces TAThupten Gedun Kelvin OngNo ratings yet

- NIOSH-PDD-CSAESPRDocument3 pagesNIOSH-PDD-CSAESPRJohn KurongNo ratings yet

- Method Statement: Conduit Condition EvaluationDocument21 pagesMethod Statement: Conduit Condition EvaluationAzhar KhanNo ratings yet

- CoP On Monitoring and Maintenance Water Carrying Services Affecting SlopesDocument96 pagesCoP On Monitoring and Maintenance Water Carrying Services Affecting SlopeschouszeszeNo ratings yet

- Confined Space PermitDocument1 pageConfined Space PermitNethiyaaRajendranNo ratings yet

- Hole Watcher TrainingDocument36 pagesHole Watcher TrainingMalik JunaidNo ratings yet

- Site Observation RegisterDocument9 pagesSite Observation RegisterSubzone ThreeNo ratings yet

- ACTIVITY HAZARDS ANALYSISDocument6 pagesACTIVITY HAZARDS ANALYSISarnel_ado4412No ratings yet

- OSHA Oil and Gas Well Drilling and Servicing eToolDocument4 pagesOSHA Oil and Gas Well Drilling and Servicing eToolIne Nurista100% (1)

- Hsse Slide (Contractor) PDFDocument25 pagesHsse Slide (Contractor) PDFelyasNo ratings yet

- Basic Safety Procedure in High Risk Activities and IndustriesDocument10 pagesBasic Safety Procedure in High Risk Activities and IndustriesKent Daniel DinopolNo ratings yet

- Review of Design Methods For ExcavationsDocument2 pagesReview of Design Methods For Excavationskhoahuyen_89No ratings yet

- Tier I Incident Consequence: AFPM Personal Safety Incident MatrixDocument4 pagesTier I Incident Consequence: AFPM Personal Safety Incident MatrixJohn LawingNo ratings yet

- GRE Pipe Method StatementDocument17 pagesGRE Pipe Method Statementjohn samuelNo ratings yet