Professional Documents

Culture Documents

Abutment Design

Uploaded by

dsureshcivilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abutment Design

Uploaded by

dsureshcivilCopyright:

Available Formats

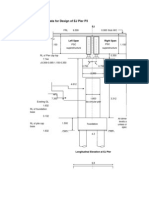

Design of Abutment

Design of Abutment AB-1

Data:

Road crest level

=

Bottom of deck

=

Bottom of bearing =

(Top of pedastal)

Top of bed block =

Top of pile cap

=

Bottom of pile cap =

Pile termination level =

103.165

101.890

101.842

101.692

99.240

97.740

83.740

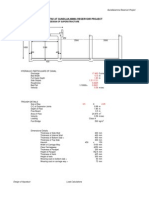

Design data:

Number of traffic lanes

Carriage way width

Length of abutment

Overall width of deck

Overall span (Excluding expansion gap)

Effective span (C/C of bearings)

Type of super-structure

Width of bearing

Length of bearing

Thickness of bearing

Number of bearings per support

Wearing coat thickness

Thickness of return wall

Materials used

Grade of concrete

Grade of steel

=

=

=

=

=

=

=

=

=

=

=

=

=

M

= Fe415

4 nos

7.5 m

17.20 m

17.2 m

19.96 m

18 m

PSC girder slab

250 mm

400 mm

48 mm

36

5

mm effective thick

Uniform 75 mm

0.5 m

35

Estimation of forces on abutment:

The following forces are acting on the abutment

1. Dead load of the super-structure system

2. Vehicular live load from super-structure

3. Self-weight of the abutment system

4. Self-weight of soil over burden

5. Earth pressure (or) Fluid pressure as per cl. 217.1 of IRC:6 (Which ever is sever)

6. Live load surcharge pressure

7. Braking force

8. Secondary effects

The abopve listed forces are determined in detail and presented below.

1. Dead load and superimposed dead load from super-structure:

Dead load and Superimposed dead load reaction on abutment is taken from the STAAD analysis results

Total dead load reaction on abutment

=

1460.62 kN

Total reaction on abutment due to FPLL =

0 kN

2. Vehicular live load reaction on abutment:

All the vehicles are kept in such a way that to get maximum reaction on the abutment

a) 70R - Wheeled loading

=

1539.58 kN

For two lane bridges one 70R vehicle or two Class-A vehicle can be allowed

Max of 70R loadinbg =

1539.58 kN

70R-Wheeled loading

Total support reaction for

4 lane =

1539.58 kN

TNHW

SAI Consulting Engineers Pvt. Ltd.,

Design of Abutment

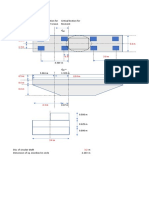

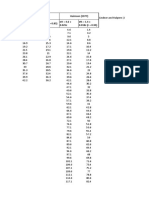

3. Self-weight of Abutment system:

300

103.165

200

1473

180

120

700 x 550

150

101.692

1000

500

1000

1451

99.24

97.74

1750

800

1750

3000

Self weight of Abutment system:

Sl.No

1

2

3

4

5

6

7

ITEM

DESCRIPTION

Dirt wall

Bracket

(i)

( ii )

Pedestals

Bed block

Abutment stem

Pile cap

Returns

Nos

1

1

0.5

5

1.00

1.000

0.5

1

2

Length

17.2

17.2

17.2

0.15

17.2

17.20

17.2

17.5

1.75

Width

0.3

0.2

0.2

0.55

1.8

0.8

1

4.30

3.925

Depth

1.473

0.18

0.18

0.7

0.3

2.152

1

1.5

0.5

Concrete

(m3)

7.601

0.270

0.090

0.289

9.288

29.612

0.500

112.875

6.869

c.g.fro

Self-wt. (kN) m (X)

182.416

2.4000

6.480

2.6500

2.160

2.6167

6.930

1.2500

222.912

1.6500

710.676

2.15

12.000

1.4167

2709.000

2.15

164.850

3.425

4. Self-weight of soil overburden:

Load due uo soil overburden over the heel slab =

(Assume unit weight of soil =

1.75

x

3.925 x

16.2 x

=

2336.7488 kN

Moment about 'X'

= 2336.7488 x

3.425 =

8003.36447 kNm

Moment

about 'X'

(kNm)

437.799

17.172

5.652

8.663

367.805

1527.954

17.000

5824.350

564.611

21 )

21

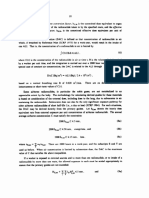

5. Earth pressure (or) Fluid pressure as per clause 217.1 of IRC:6, which ever is more:

As per Columb's Earth pressure theory

sin2(sinsinsqrt.(sinsinsinsin,where

Ka=

sin2(

0.750 ,sinsin

0.9396926

(sinsin

0.383 , sinsin

0.9396926208

ka

=

0.297

90 deg

1.570796327 rad

0 deg

0 rad

TNHW

SAI Consulting Engineers Pvt. Ltd.,

Design of Abutment

Pressure ordinate

=

Total active earth pressure force=

30 deg

20 deg

0.5235987757 rad

0.3490658504 rad

0.297 x

21

0.5

=

91.876393 kN/m

it acts at

2.2785 m away from X and at an inclination o

Total Horizontal component =

1398.64 k.N

Total Vertical component =

509.062 k.N

Moment at the bottom of pile cap to active earth pressure=

x

x

5.425

33.871 x

20

33.871 k.N/m2

5.425

deg with horizontal as shown in Fig.

x

0.42

x

=

3186.792593 k.Nm

Moment abiut 'X' due to vertical component of earth pressure =

509.06 x

2.55

=

1298.1079655 kNm

These forces are compared with the effects due to Fluid pressure.

Fluid pressure =

4.8 k.N/m2

(As per IRC:6)

Base pressure ordinate =

5.425 x

4.8 =

26.04 k.N/m2

Horizontal force=

70.634 k.N/m

Total Horizontal force=

1144.263 k.N

Moment at the base of abutment foundation due to fluid pressure=

1144.2627

x

5.425 /3

=

2069.2084 k.Nm

<

3186.792593 k.Nm

Hence

Earth Pr.

1398.64

is considered in the abutment design. =

5.425

3186.79259 kNm

Live Load Surcharge:

Clause 217.3 of IRC:6 states that if adequate length of approach slab is provided, no live load surcharge need to be considered.

However,Cl.714.4 of IRC:78 states thata live load surcharge equivalent to 1.2 m height of backfill shall be considered in the

design. Hence the same is considered.

Lateral pressure =

Total lateral load =

Horizontal component =

And, vertical component =

1.2

5.425

564.39565

564.39565

x

x

x

x

0.297

6.4219793

cos

sin

x

x

20

20

18 =

16.2 =

=

=

6.422

564.4

530.36

193.03

k.N/m2

k.N

k.N

k.N

Braking Force Calculations

Total Live load on the span =

1000 kN

Braking force = 20% of R, i.e.

200

and acts at 1.20m above RCL

Bearing level is RL(+)

101.890

Neglecting the extra vertical load on abutment due to eccentricity of braking force

Horizontal load on each support =

200

/2=

Horizontal load on each support (in longitudinal direction)=

Secondary effects

Secondary effects are due to temperature and shrinkage.

Refer Clause no. 218 and 220.3 of IRC:6-1966

Shrinkage strain =

0.0002

Coefficient of thermal expansion=

0.0000117

Maximum temperature variation =

25 deg.

Temperature strain =

0.0000117

x

25

Total strain =

4.93E-04

Total change in the length of the longitudinal girder

=

0.0004925

x

19960 =

Design change in length =

1.1

x

9.8303

Change in length effective per support =

10.81333 /2=

Effective depth of elastomer bearing =

36 mm

Plan size of the bearing =

250

x

400

Shear strain in bearing =

5.406665

/

36

As shear modulus of bearing material =

1 N/mm2

Shear stress in bearing =

0.1501851 x

1

Total number of bearings =

5

Induced shear force at the bottom of bearing =

0.1501851

100

kN

100.000 kN

9.8303

=

10.81333 mm

5.406665 mm

mm

=

0.15018514

0.15018514 N/mm2

=

69.343 k.N

Horizontal load on each support (in longitudinal direction)=

Moment abiut 'X'

=

69.3435 x

4.102 =

TNHW

0.0002925

238

388

/1000

69.343 kN

284.446965 kNm

SAI Consulting Engineers Pvt. Ltd.,

Design of Abutment

Seismic load calculations:

Road crest level =

103.165

Top of pile cap level =

99.240

Height of the abutment above pile cap =

3.925 m

Thickness of the abutment =

0.8 m

(or)

Length of abutment =

17.20 m

(or)

Moment if inertia of the abutment stem =

7.34E+11 mm4

Grade of concrete =

M 35

Youngs modulus of concrete =

31500 N/mm2

800 mm

17200 mm

Diflection of tip = PL3/3EI

The horizontal load required to produce 1mm deflection =

1146911.711 N

OR =

1146.912 kN

Dead load reaction from the super structure =

1460.62 kN

Live load reaction from the super structure =

1539.58 kN

Total load =

3000.2 kN

Fundamental time period (T) = 2 x sqrt(D/100xF) =

0.324 sec

Zone no =

Zone factor (Z) =

Importance factor (I) =

Reduction factor (R) =

Sa/g =

3

0.16

1.5

2.5

2.5 for T of

0.324 sec and for medium soils

Horizontal seismic coefficient =

Z x Sa x I /(2 x g x R)

Design horizontal seismic coefficient

Force due to dead load

=

Moment at the top of the pile cap =

Moment at the bottom of the pile cap =

Force due to Abutment System:

Dirt wall

=

Moment at the top of pile cap =

Moment at the bottom of the pile cap =

Braket

Rectangular portion =

6.480 x

Moment at the top of pile cap =

Moment at the bottom of the pile cap =

Triangilar portion =

2.160 x

Moment at the top of pile cap =

Moment at the bottom of the pile cap =

Load due to pedestals =

6.930 x

Moment at the top of pile cap =

Moment at the bottom of the pile cap =

0.12

175.2744 kN

175.2744 x

175.2744 x

3.925 =

5.425 =

687.95202 kNm

950.86362 kNm

182.416 x

21.890 x

21.890 x

0.12 =

3.1885 =

4.6885 =

21.890 kN

69.796 kNm

102.631 kNm

0.12 =

0.7776 x

0.7776 x

0.12 =

0.2592 x

0.2592 x

Load due to pile cap =

2709.000 x

Moment at the bottom of the pile cap =

TNHW

0.2592 kN

0.12 =

0.877 kNm

1.266 kNm

0.832 kN

2.527 =

4.027 =

0.12 =

2.101 kNm

3.349 kNm

26.74944 kN

2.302 =

3.802 =

0.12 =

61.577 kNm

101.701 kNm

85.281 kN

85.281 x

85.281 x

1.076 =

2.576 =

1.44 x

1.44 x

0.12 =

1.8186666667 =

3.3186666667 =

0.12 =

325.08 x

2.749 kNm

3.915 kNm

3.385 =

4.885 =

0.832 x

0.832 x

Load due to bed block =

222.912 x

Moment at the top of pile cap =

26.74944 x

Moment at the bottom of the pile cap =

26.74944 x

Abutment stem:

Uniform thick portion =

710.676 x

Moment at the top of pile cap =

Moment at the bottom of the pile cap =

Top haunch portion =

12.000 x

Moment at the top of pile cap =

Moment at the bottom of the pile cap =

0.7776 kN

3.535 =

5.035 =

91.763 kNm

219.684 kNm

1.44 kN

2.619 kNm

4.779 kNm

325.08 kN

0.75 =

243.810 kNm

SAI Consulting Engineers Pvt. Ltd.,

Design of Abutment

Load due to return walls =

164.850 x

Moment at the top of pile cap =

Moment at the bottom of the pile cap =

0.12 =

19.782 x

19.782 x

19.782 kN

1.9625 =

3.4625 =

38.822 kNm

68.495 kNm

Summary of forces due to abutment system at the bottom of the pile cap:

Total horizontal load due to seismic effects =

482.091 kN

Moment at the bottom of the pile cap =

749.631 kNm

Summary of forces due to abutment system at the top of the pile cap:

Total horizontal load due to seismic effects =

157.011 kN

Moment at the bottom of the pile cap =

270.305 kNm

Seismic load due to embankment fill:

Active earth pressure , Pa = h Ca

[(1+v)(Cos2( - -)]

Where, Ca =

cos x cos2 x cos(+ + )]

v =Vertical seismic coefficient

Angle of internal friction of soil

tan-1(h/(1+v))

Angle of earth face of the wall with vertical

=

Slope of earth fill

Angle of friction between wall and soil

h =

Horizontal seismic coefficient

=

v

v

1

[1+((sin() x sin ())/(cos() x cos())]1/2

0.06

30

0.113 &

0

0

20

0.12

0.524

0.127

0.000

0.000

0.349

rad

Radians

rad

rad

rad

1.06

0.94

Cos2( - -) =

cos =

cos2 =

cos(+ + ) =

(sin() =

sin ()) =

cos() =

cos() =

Ca =

Hence, the value of

0.840

0.994

1.000

0.895

0.766

0.399

1

0.895

0.399

&

&

0.851

0.992

&

0.889

&

0.386

&

0.889

&

0.365

0.399 is considered

Load calculations at the top of pile cap level/ unit length

Active earth pressure at the bottom of pile cap level =

32.875 kN/m2

Horizontal load =

64.517 kN

Additional horizontal load =

64.517 45.193 =

Moment due to extra load =

19.324 x

1.9625 =

19.324 kN

37.92 kNm

Seismic load calculations due to live load surcharge:

Pressure ordinate =

10.051 kN/m2

Horizontal load =

39.450 kN

Additional horizontal load =

39.450

Moment due to extra load =

15.764

x

15.764 kN

30.937 kNm

23.686 =

1.9625 =

Summary of seismic load at the top of pile cap:

Total horizontal load =

54.407 kN

Total moment due to seismic effects =

124.573 kNm

Load calculations at the bottom of pile cap level

Active earth pressure at the bottom of pile cap level =

Horizontal load =

1996.69 kN

Additional horizontal load =

1996.69 Moment due to extra load =

598.052 x

1398.636 =

2.7125 =

598.052 kN

1622.217 kNm

Seismic load calculations due to live load surcharge:

Pressure ordinate =

10.051 kN/m2

Horizontal load =

883.33 kN

Additional horizontal load =

883.33 -

530.358 =

352.969 kN

TNHW

45.44 kN/m2

SAI Consulting Engineers Pvt. Ltd.,

Design of Abutment

Moment due to extra load =

352.969 x

2.7125 =

957.429 kNm

Summary of seismic load at the bottom of th pile cap:

Total horizontal load =

1608.387 kN

Total moment due to seismic effects =

4280.141 kNm

Stability Analysis:

Presented below are the details of the stability analysis and loads on piles calcu;ations:

Sl.No

Load description

1

2

3

4

5

Axial load

(kN)

1460.62

1539.58

4017.425

2336.7488

HL

e'

(m)

1.25

1.25

2.183

3.425

(kN)

-

Moment

(kNm)

1825.775

1924.475

8771.006

8003.364

Dead load of Super-structure system

Vehicular live load

Self - weight of abutment system

Overburden soil load (on heel slab)

Earth pressure/Fluid pressure

1 Horizontal

1398.636

2.2785

3186.793

2 Vertical

509.06195

2.55

1298.108

6 Surcharge live load

1 Horizontal

530.358

2.7125

1438.597

2 Vertical

193.03468

2.55

492.238

7 Braking force

100.000

4.150

415.000

8 Secondary effects

69.343

4.102

284.447

9 Seismic effects

1608.387

4280.141

Total forces and moments

10056.47

2098.338

16990.130

Following load combinations were studied:

C1 =

DL+FPLL+VLL+self-weight+Overburden soil+Earth pressure+ Surchage load+Braking+Secondary effects

C2 =

Dislodge condition

C3 =

C1 + 50% of Live load + Seismic load

Horizontal

Comb.

Axial load

Load

ML

'e'

C1

10056.470

2098.338 16990.130

0.461

C2

6863.235

1928.995 13939.327

0.119

C3

9286.680

3656.725 11955.252

0.863

Piles and pile cap data:

diameter of piles

1000 mm

Number of rows of piles along bridge direction

=

2 spacing at

3.00 m

Number of rows in transverse direction

=

6 spacing at

3.19 m

Size of pile cap =

17.230

x

4.3

x

1.500

Grade of concrete for piles= M 35

Number of piles (n) =

12 nos.

ZL

=

18 m3

For load combination C1:

Maximum and minimum load on piles =

Maximum/minimum load on piles =

10056.470

12

838.03918

1095.3326

Total horizontal load at the bottom of pile cap level=

Horizontal load/pile

=

2098.3381 /

For load combination C2:

Maximum and minimum load on piles =

Maximum/minimum load on piles =

6863.235

12

571.93629

617.30458

Total horizontal load at the bottom of pile cap level=

Horizontal load/pile

=

1928.9946 /

For load combination C3:

Maximum and minimum load on piles =

Maximum/minimum load on piles =

TNHW

9286.680

12

773.890

1218.952

+

+

and

4631.28066 =

18

257.29337

580.745812 kN

2098.3381167 kN

12 =

+

+

and

816.629129 =

18

45.3682849

526.568006 kN

1928.995 kN

12 =

+

+

and

174.862 kN

160.750 kN

8011.111 =

18

445.062

328.828 kN

SAI Consulting Engineers Pvt. Ltd.,

Design of Abutment

Total horizontal load at the bottom of pile cap level=

Horizontal load/pile

=

3656.7253 /

3656.725 kN

12 =

304.727 kN

Flexural Design of Piles:

Design scour level =

99.240

Bott. of pile cap level =

97.740

Grade of concrete for piles = M

35

Fixity depth calculations are done as per 2911(part-II)

Medium sand

Type of soil

2

T = (EI/k1)0.2

Where

E = Youngs modulus of pile material in kg/cm 2

I = Moment of Inertia of pile cross section in cm 4

K1 = Constant depends on soil type in kg/cm 3

As per IS:2911(part-II) values of constants K1 for submerged condition is

SL.NO

Type of Soil

Value of K1

Loose sand

0.146

Medium sand

0.525

Dense sand

1.245

Very loose sand

0.040

K1 =

0.525 kg/cm3

E=

33.000 Gpa or

330000

I=

4908738.52 cm4

T=

314.677

L1/T =

0.000

From Fig.: 2 of IS:2911(part-II), for fixed head piles, Lf/T =

Length of fixity Lf =

6.923

Design length of pile =

0.00

+

6.923

(Free length

+

Grip length)

Design length of pile =

6.923 m

For load combination C1:

Design moment =

174.862

x

6.923

kg/cm2

2.2

m

=

/2

6.923 m

605.284 kNm

556.435 kNm

Adopt

2.000 % of steel and 75mm clear cover

Diameter of pile =

1000 mm

For maximum load condition:

Self-weight of pile =

130.495 kN

Maximum load =

1225.828 kN

Moment

=

605.284 kNm

As per cl. 709.1.5.2 of IRC:78-2000, 1 in 150 tilt shall be permitted

Extra moment due to the tilt =

113.153 kNm

Total design moment =

718.44 kNm

Stress in steel =

120.72 N/mm2

Stress in concrete =

9.79 N/mm2

For minimum load condition:

Axial load =

711.241 kN

Moment

=

605.284 kNm

As per cl. 709.1.5.2 of IRC:78-2000, 1 in 150 tilt shall be permitted

Extra moment due to the tilt =

65.653 kNm

Total design moment =

670.94 kNm

Stress in steel =

124.08 N/mm2

Stress in concrete =

8.34 N/mm2

For load combination C2:

Design moment =

Adopt

Diameter of pile =

For maximum load condition:

Self-weight of pile =

TNHW

160.750

2.000 % of steel

1000 mm

6.923 /2

and 75mm clear cover

130.495 kN

SAI Consulting Engineers Pvt. Ltd.,

Design of Abutment

Maximum load =

747.800 kN

Moment

=

556.435 kNm

As per cl. 709.1.5.2 of IRC:78-2000, 1 in 150 tilt shall be permitted

Extra moment due to the tilt =

69.027 kNm

Total design moment =

625.46 kNm

Stress in steel =

127.3 N/mm2

Stress in concrete =

8.62 N/mm2

For minimum load condition:

Axial load =

657.063 kN

Moment

=

556.435 kNm

As per cl. 709.1.5.2 of IRC:78-2000, 1 in 150 tilt shall be permitted

Extra moment due to the tilt =

60.652 kNm

Total design moment =

617.09 kNm

Stress in steel =

113.84 N/mm2

Stress in concrete =

7.67 N/mm2

For load combination C3:

Design moment =

304.727

6.923 /2

1054.813 kNm

Adopt

2.000 % of steel and 75mm clear cover

Diameter of pile =

1000 mm

For maximum load condition:

Self-weight of pile =

130.495 kN

Maximum load =

1349.447 kN

Moment

=

1054.813 kNm

As per cl. 709.1.5.2 of IRC:78-2000, 1 in 150 tilt shall be permitted

Extra moment due to the tilt =

124.563 kNm

Total design moment =

1179.38 kNm

Stress in steel =

208.37 N/mm2

Stress in concrete =

14.52 N/mm2

For minimum load condition:

Axial load =

459.324 kN

Moment

=

1054.813 kNm

As per cl. 709.1.5.2 of IRC:78-2000, 1 in 150 tilt shall be permitted

Extra moment due to the tilt =

42.399 kNm

Total design moment =

1097.21 kNm

Stress in steel =

275.21 N/mm2

Stress in concrete =

14.63 N/mm2

Permissible stresses:

cbc

Comb

(N/mm2)

C1

11.6666666667

C2

11.6666666667

C3

17.5

st

(N/mm2)

200

200

300

As the stresses are within the permissible limits, hence the adopted reinforcement is adequate.

Hence, provide 20-Y32 bars as mian longitudinal reinforcement.

Design of Pile cap:

Maximumm load on front piles

=

1095.3326 kN

Number of piles in the row =

6 nos

Total load from piles

=

6571.9953 kN

Flexural design

Moment at the face of the abutment stem

=

6571.9953093

x

= 6571.9953093 kNm

Grade of concrete adopted =

M 35

and fe415 steel

cbc =

11.5 N/mm2

Modular ratio considered

st =

200 N/mm2

k

=

0.3650794 ,

j =

0.8783068783 ,

Q =

Depth required = Sqrt(BM/Q x b) =

454.83647 mm

Depth provided =

1500 150 25

=

1309 mm

>

454.836466

Hence the provided section is

adequate

BM/st x j x d

Area of Steel required

=

TNHW

10

1.843747375

mm

16

SAI Consulting Engineers Pvt. Ltd.,

Design of Abutment

=

28581.257 mm2

Area of steel required / m length of pile cap

=

Hence provide

16

1658.8076947 mm2/m

bars @

121 mm c/c

Shear design

As the critical section for shear is at a distance 'd' from the face of the stem, hence the critical section is falling in the

column row line no shear check is required

Design of abutment stem at the top of the pile cap level:

Presented below are the details of forces and moments at the top of the pile cap level/unit length:

HL

Load

'e'

Sl.no.

Item description

(kN)

(kN)

(m)

1 Load due to self weight of stem

1. Dirt wall

10.606

0.250

2. Bracket

i)

0.900

0.500

ii)

0.300

0.467

4. Bed block

1

12.960

-0.500

5. Stem

i)

41.318

0.000

ii)

0.698

-0.400

iii)

0.000

-0.733

2 Dead load from super-structure

84.920

-0.900

3 Live load from super-structure

89.510

-0.900

(including of foot path live load)

4 Earth pressure/Fluid pressure

i) Horizontal

45.193

-1.649

ii)Vertical

16.449

0.400

5 Surcharge pressure

i) Horizontal

23.686

-1.963

ii)Vertical

8.621

0.400

6 Braking force

5.814

-2.650

7 Secondary effects

4.032

-2.602

8 Seismic effects

54.407

Total load

266.282

78.725

Eccentricity 'e' =

297.359 /

266.282 =

Moment

(kNm)

2.651

0.450

0.140

-6.480

0.000

-0.279

0.000

-76.428

-80.559

-74.500

6.580

-46.484

3.448

-15.407

-10.490

-124.573

-297.359

1.117 m

Reinforcement in the stem shall be designed assuming it as a cantilever member and the same is ckecked for

axial and bending condition.

Design bending moment for cantilever action condition

=

297.359 kNm

Grade of concrete adopted M 35

and fe415 steel

k = 0.3650794 , j =

0.8783069 , Q =

1.84374738

Depth required = Sqrt(BM/Q x b) =

401.59613 mm

Depth provided =

800 75 10

=

715 mm

>

401.596128 mm

The adopted section is

adequate

Hence,

OKAY

Area of Steel required

Provide

Y 20

Provide

Y 16

BM/st x j x d =

@

@

Checking the design for Seismic load combination:

Design bending moment =

Grade of concrete adopted M 35

cbc =

17.25

st =

300

k=

0.3651 , j =

Depth required = Sqrt(BM/Q x b) =

Depth provided =

800 =

715

The adopted section is

adequate

Area of Steel required

2367.544 mm2/m

133 mm c/c On tension face

265 mm c/c On comp. face

2368 mm2/m

758 mm2/m

373.95

kNm

and fe415 steel with 50% of increase in stresses

N/mm2

Modular ratio considered

=

N/mm2

0.878 , Q =

2.766

367.713 mm

75 10

mm

>

367.713 mm

Hence,

OKAY

BM/st x j x d =

10

1984.898 mm2/m

Design of return walls:

TNHW

SAI Consulting Engineers Pvt. Ltd.,

Design of Abutment

Aspect ratio =

3.925

/

1.75

=

Hence bending in horiziontal direction governs the design

Design of flexural reinforcement at the top of the pile cap

Earth pressure at the top of pile cap level =

24.50609467

Surcharge pressure =

6.4219793 kN/m2

Total pressure ordinate at the top of pile cap =

30.928073982

Horizontal bending moment

=

47.358613 kNm/m

Depth required = Sqrt(BM/Qb)

160.26872 mm

Depth provided =

500

75

=

415 mm

>

160.26872467

Hence the provided section is adequate

BM/st x j x d =

Area of steel required =

649.64275736

Minimum area of steel (0.12%) =

600 mm2/m

Hence area of reinforcement required =

649.64276 mm2/m

Provide

Y 12

@

174 mm c/c

Design of flexural reinforcement at mid height of stem

Earth pressure at mid height of the stem =

12.253047335

Surcharge pressure =

6.4219793 kN/m2

Total pressure ordinate at the top of pile cap =

18.675026648

Horizontal bending moment

=

28.596135 kNm/m

BM/st x j x d =

Area of steel required =

392.26806726

Minimum area of steel (0.12%) =

600 mm2/m

Hence area of reinforcement required =

600 mm2/m

Provide

Y 12

@

189 mm c/c

2.24285714

kN/m2

kN/m2

10

mm

mm2/m

kN/m2

kN/m2

mm2/m

Design of Dirt wall:

Height of the dirt wall

=

1.473 m

Earth pressure at the bottom of the dirt wall =

9.1968095409 kN/m2

Neglecting the vertical component of the load to be on conservative side

Horizontal load on the wall/m length of the wall =

6.7734502269 kN/m

Moment at the bottom of the dirt wall =

6.7734502 x

0.42 x

= 4.1904627 kNm/m

Surcharge pressure on the wall

=

6.4219793 kN/m2

Surcharge load on the dirt wall

=

9.4595755 kN/m

Moment at the bottom of the dirt wall =

9.4595755 x 0.5 x

1.473

= 6.9669774 kNm/m

Total design moment at the bottom of the dirt wall=

11.157440094 kNm/m

For M 35

grade concrete and fe415 steel

k = 0.3650794 , j =

0.8783069 , and Q =

1.84374738

Depth required = Sqrt(BM/Qb) =

77.791398 mm

Depth provided =

300

75

8

=

217 mm

>

77.7913976 mm

Provided depth is graterthan the required depth

the section is adequate

Area of steel reqiured

= BM/st x j x d =

292.70392783 mm2/m

Minimum area of steel (0.12%)

=

360 mm2/m

2

mm

/m

Hence the required steel =

360

Provide

Y 12

dia bars

@

314 mm c/c

TNHW

1.473

SAI Consulting Engineers Pvt. Ltd.,

You might also like

- Abutment DesignDocument49 pagesAbutment Designhemantkle2u100% (1)

- Design of Abutment BridgeDocument51 pagesDesign of Abutment BridgePrakash Singh Rawal92% (13)

- Abut DesignDocument32 pagesAbut DesignSubir Kunda100% (2)

- Limit StateDocument23 pagesLimit StateSubbarao Kakumanu100% (9)

- 001 R0 STK Substructure Design AMH To Be SentDocument91 pages001 R0 STK Substructure Design AMH To Be SentThulasi Raman KowsiganNo ratings yet

- Design of RCC PierDocument10 pagesDesign of RCC Piervijayunity40% (5)

- Shambhavi Techno Solutions, Patna: Project: Subject: Design of Cantilever Type AbutmentDocument22 pagesShambhavi Techno Solutions, Patna: Project: Subject: Design of Cantilever Type AbutmentRohit Prakash100% (5)

- Design of Abutment-ROBDocument10 pagesDesign of Abutment-ROBNandeesha Ramesh100% (1)

- Bridge Substructure With Pile Foundation at The State of JharkhandDocument82 pagesBridge Substructure With Pile Foundation at The State of JharkhandSree NivasNo ratings yet

- Design of Super StructureDocument30 pagesDesign of Super StructureHemraj Raj100% (16)

- B. Design of SubstructureDocument14 pagesB. Design of SubstructureDeepak Kr Gupta100% (4)

- RC Pier-F (Box & Girder)Document36 pagesRC Pier-F (Box & Girder)robynson banik100% (6)

- DESIGN AqueductDocument89 pagesDESIGN AqueductmukhleshNo ratings yet

- Abutment DesignDocument3 pagesAbutment DesignMalay Kumar DebNo ratings yet

- Design of BridgeDocument59 pagesDesign of BridgeMohd Aftab80% (5)

- Design of Gravity Abutment for Gagal BridgeDocument33 pagesDesign of Gravity Abutment for Gagal Bridgebkvs12340% (5)

- Replacement Bridge Design ProjectDocument64 pagesReplacement Bridge Design ProjectTri Angga Dio SimamoraNo ratings yet

- Design of PierDocument11 pagesDesign of PierNaveen Yadav100% (6)

- Wind Force Calculation Pier Superstructure IRC 6Document2 pagesWind Force Calculation Pier Superstructure IRC 6vasu7900No ratings yet

- Design of Abutment for Ex 5.15, Varsney vol IIDocument8 pagesDesign of Abutment for Ex 5.15, Varsney vol IIchandwanivinay100% (1)

- Design of Bridge PierDocument12 pagesDesign of Bridge PierSunita Chaurasia88% (8)

- Design of AbutmentDocument47 pagesDesign of AbutmentRaju Ranjan SinghNo ratings yet

- Design of Abutment For BridgeDocument28 pagesDesign of Abutment For BridgeMuhammad Wazim Akram100% (1)

- Computation of LoadDocument12 pagesComputation of Loadvasu7900No ratings yet

- Box Culvert Using Is CodeDocument14 pagesBox Culvert Using Is CodeYuvarasu40% (5)

- Computation of Reaction Factors Using Courbon's MethodDocument2 pagesComputation of Reaction Factors Using Courbon's Methodvasu790075% (4)

- Hydrology Analysis Calculation For Bridge As Per IRC 5 and 78 - 2014Document9 pagesHydrology Analysis Calculation For Bridge As Per IRC 5 and 78 - 2014jibendra mishra100% (1)

- Bridge Abutment Pier Design As Per IRCDocument41 pagesBridge Abutment Pier Design As Per IRCjibendra mishra88% (43)

- Design of BridgeDocument33 pagesDesign of BridgeAnu PathakNo ratings yet

- Pier Cap Dimension and Load AnalysisDocument7 pagesPier Cap Dimension and Load AnalysisShashank Srivastava0% (1)

- Abutment and Wingwall Design Example - US Units - Design Step 7Document96 pagesAbutment and Wingwall Design Example - US Units - Design Step 7rajsedasari100% (1)

- 1) Pier-P3Document89 pages1) Pier-P3Venkat Palli100% (1)

- Design Example PierDocument53 pagesDesign Example PierKasun Shidesh100% (11)

- Slab Bridge FinalDocument6 pagesSlab Bridge FinalRohan Persaud100% (1)

- Design of RCC T - Girder Deck Using Morice & Little MethodDocument33 pagesDesign of RCC T - Girder Deck Using Morice & Little Methodvasu7900100% (4)

- DESIGN OF GRAVITY RETAINING WALLDocument84 pagesDESIGN OF GRAVITY RETAINING WALLkadaliNo ratings yet

- Retaining Wall Counterfort PDFDocument48 pagesRetaining Wall Counterfort PDFSilver Olguín CamachoNo ratings yet

- Design of Bridge Superstructure ElementsDocument9 pagesDesign of Bridge Superstructure ElementsPrakash Singh Rawal100% (1)

- Design of Girder Type BridgeDocument21 pagesDesign of Girder Type Bridgekartick sanati100% (1)

- PSC Girder 23.75Document49 pagesPSC Girder 23.75ras_deep67% (3)

- Bridge design project for replacing bridge NoDocument51 pagesBridge design project for replacing bridge Noencikeddy100% (2)

- Substructure Final PDFDocument34 pagesSubstructure Final PDFSushmit Sharma100% (1)

- Design of Left Hand Side Abutment for Bridge CalculationDocument53 pagesDesign of Left Hand Side Abutment for Bridge Calculationmanoj_structureNo ratings yet

- 2 8 16 - Caculation As Per IRC 112Document203 pages2 8 16 - Caculation As Per IRC 112snehar redkar100% (1)

- AQUDUCTDocument139 pagesAQUDUCTMadhu SudhanNo ratings yet

- Design of RC AbutmentDocument15 pagesDesign of RC AbutmentSuman NakarmiNo ratings yet

- Circular Concrete Pile DesignDocument3 pagesCircular Concrete Pile DesignPn EkanayakaNo ratings yet

- Abutment WellDocument229 pagesAbutment WellGaurav GhaiNo ratings yet

- Positioning of Irc Live LoadsDocument3 pagesPositioning of Irc Live Loadsvasu7900100% (1)

- Gantry CraneDocument18 pagesGantry Craneamirthraj7494% (16)

- Gantry GirderDocument48 pagesGantry GirderVishnu SamyNo ratings yet

- Design and Detailing of Counterfort Retaining WallDocument48 pagesDesign and Detailing of Counterfort Retaining WallSWADES RANJAN PAIRANo ratings yet

- PSC Bridge Girder Design To BS5400 by D ChildsDocument321 pagesPSC Bridge Girder Design To BS5400 by D ChildsDuke50% (2)

- Design of Gantry GirderDocument25 pagesDesign of Gantry GirderYash DhabaliaNo ratings yet

- Design of Counterfort Retaining WallDocument14 pagesDesign of Counterfort Retaining WallMonjit Gogoi100% (5)

- Tower Crane Foundation Design 24.07.2016Document11 pagesTower Crane Foundation Design 24.07.2016Gihan Chathuranga92% (13)

- Design of RCC Retaing WallDocument12 pagesDesign of RCC Retaing WalldsureshcivilNo ratings yet

- Aqueduct Design CalculationsDocument58 pagesAqueduct Design Calculationsp_ignatiusNo ratings yet

- Design of PCC Abutment - Open FoundationDocument31 pagesDesign of PCC Abutment - Open FoundationAnantPawarNo ratings yet

- 1Document1 page1dsureshcivilNo ratings yet

- Output 1 11 PDFDocument1 pageOutput 1 11 PDFdsureshcivilNo ratings yet

- 3Document1 page3dsureshcivilNo ratings yet

- 2Document1 page2dsureshcivilNo ratings yet

- Output 1 9 PDFDocument1 pageOutput 1 9 PDFdsureshcivilNo ratings yet

- 1Document1 page1dsureshcivilNo ratings yet

- 1Document1 page1dsureshcivilNo ratings yet

- Gastrointestinal Absorption and Lung Clearance ClassesDocument1 pageGastrointestinal Absorption and Lung Clearance ClassesdsureshcivilNo ratings yet

- Iii. Changes in The Models For Derived Guides: SolubleDocument1 pageIii. Changes in The Models For Derived Guides: SolubledsureshcivilNo ratings yet

- 1Document1 page1dsureshcivilNo ratings yet

- 1Document1 page1dsureshcivilNo ratings yet

- Output 1 10Document1 pageOutput 1 10dsureshcivilNo ratings yet

- 1Document1 page1dsureshcivilNo ratings yet

- 1Document1 page1dsureshcivilNo ratings yet

- BT Fkext: Tissue Dose Cquivcalcnt Conversion Factor, E//cctive Dose Equivalent Conversion FactorDocument1 pageBT Fkext: Tissue Dose Cquivcalcnt Conversion Factor, E//cctive Dose Equivalent Conversion FactordsureshcivilNo ratings yet

- Output 1 8 PDFDocument1 pageOutput 1 8 PDFdsureshcivilNo ratings yet

- Output 1 9 PDFDocument1 pageOutput 1 9 PDFdsureshcivilNo ratings yet

- Output 1 12Document1 pageOutput 1 12dsureshcivilNo ratings yet

- Output 1 7Document1 pageOutput 1 7dsureshcivilNo ratings yet

- Output 1 8Document1 pageOutput 1 8dsureshcivilNo ratings yet

- Output 1 11Document1 pageOutput 1 11dsureshcivilNo ratings yet

- Output 1 12Document1 pageOutput 1 12dsureshcivilNo ratings yet

- Output 1 10Document1 pageOutput 1 10dsureshcivilNo ratings yet

- Control of Cracking Due To End Restraint: Input Parameters Symbol Unit ValueDocument1 pageControl of Cracking Due To End Restraint: Input Parameters Symbol Unit ValuedsureshcivilNo ratings yet

- Risk and Control of Cracking Due To Continuous Edge RestraintDocument1 pageRisk and Control of Cracking Due To Continuous Edge RestraintdsureshcivilNo ratings yet

- Control of Cracking Due To End Restraint: Input Parameters Symbol Unit ValueDocument1 pageControl of Cracking Due To End Restraint: Input Parameters Symbol Unit ValuedsureshcivilNo ratings yet

- Eatc-3-Crack - 2Document1 pageEatc-3-Crack - 2dsureshcivil100% (1)

- H Aoj Uuywq JkabjkfDocument6 pagesH Aoj Uuywq JkabjkfdsureshcivilNo ratings yet

- Risk and Control of Cracking Due To Continuous Edge RestraintDocument1 pageRisk and Control of Cracking Due To Continuous Edge RestraintdsureshcivilNo ratings yet

- Do Oho B JBF PDFDocument1 pageDo Oho B JBF PDFdsureshcivilNo ratings yet

- Shear Strengthening of T-Beam With FRPDocument3 pagesShear Strengthening of T-Beam With FRPRal GLNo ratings yet

- Lecture Notes On Mathematical Methods PH2130 - 2012/2013: Glen D. Cowan Physics DepartmentDocument8 pagesLecture Notes On Mathematical Methods PH2130 - 2012/2013: Glen D. Cowan Physics DepartmentbbteenagerNo ratings yet

- Technical specifications for JR3 multi-axis force-torque sensor modelsDocument1 pageTechnical specifications for JR3 multi-axis force-torque sensor modelsSAN JUAN BAUTISTANo ratings yet

- 5-1 Study Guide and Intervention: Trigonometric IdentitiesDocument15 pages5-1 Study Guide and Intervention: Trigonometric IdentitiesAnderson Alfred100% (2)

- LV 2000LowVolumeDocument2 pagesLV 2000LowVolumeDian MiauNo ratings yet

- Weather CardDocument2 pagesWeather Cardmekstone100% (1)

- Classification of The MeansDocument5 pagesClassification of The Meanserichamilt0n100% (2)

- 13thPMO Area Ver5Document3 pages13thPMO Area Ver5Yinkci Heart Entertainment StudioNo ratings yet

- Structural Design I: General Theory of BendingDocument8 pagesStructural Design I: General Theory of BendingHimanshu duaNo ratings yet

- NY Regents Chemistry Exam Scoring KeyDocument12 pagesNY Regents Chemistry Exam Scoring KeyAAVANINo ratings yet

- University Physics II - Thermodynamics, Electricity, MagnetismDocument924 pagesUniversity Physics II - Thermodynamics, Electricity, MagnetismFeiFei SunNo ratings yet

- Contrasts Between Finite and Infinite Dimensional Spaces and Between Normed and Inner Product SpacesDocument5 pagesContrasts Between Finite and Infinite Dimensional Spaces and Between Normed and Inner Product SpacesQuinton WestrichNo ratings yet

- Sandwich Panel Anchors - Precast ConcreteDocument40 pagesSandwich Panel Anchors - Precast ConcreteCorbean AlexandruNo ratings yet

- Astm 1500 2012Document5 pagesAstm 1500 2012Hugo MtzaNo ratings yet

- Wave OpticsDocument1 pageWave OpticsBhupeshNo ratings yet

- Ec8451 Emf Lecture NotesDocument61 pagesEc8451 Emf Lecture NotesNarenthra BaalaNo ratings yet

- Introduction To Chemical CleaningDocument28 pagesIntroduction To Chemical Cleaningmordidomi0% (1)

- V Dy DT A DV DT: Indian Language School GR Xi Physics Worksheet-1 2022-23 Chapter: Motion in A Straight Line SolutionsDocument3 pagesV Dy DT A DV DT: Indian Language School GR Xi Physics Worksheet-1 2022-23 Chapter: Motion in A Straight Line SolutionsRudra RoshanNo ratings yet

- Part Description AD500-9 TO Order # 3001380: First Sensor APD Data SheetDocument3 pagesPart Description AD500-9 TO Order # 3001380: First Sensor APD Data SheetAnish KumarNo ratings yet

- BSC Physics Iind SemDocument4 pagesBSC Physics Iind SemDavid JonesNo ratings yet

- B D Khosla Practical ChemistryDocument6 pagesB D Khosla Practical ChemistryJaswinder Sidhu18% (11)

- Titrimetry (anEm'pnmQwQy)Document102 pagesTitrimetry (anEm'pnmQwQy)AchindA FernandoNo ratings yet

- Cobar 1400 Yumlu Mining With Paste FillDocument26 pagesCobar 1400 Yumlu Mining With Paste FillSayantan ChakrabortyNo ratings yet

- Design of Cold Formed Steel Members 2003 LibroDocument246 pagesDesign of Cold Formed Steel Members 2003 LibroFelipeNo ratings yet

- Inductance Part 1 - MowryDocument4 pagesInductance Part 1 - MowryJacky FanNo ratings yet

- Physics QuestionsDocument25 pagesPhysics QuestionsCarlos KasambiraNo ratings yet

- Matrices and Linear Systems: Matrix AlgebraDocument11 pagesMatrices and Linear Systems: Matrix AlgebraPavirlene Escaño NorteNo ratings yet

- Exploration Archaeology (John M. Stanley)Document4 pagesExploration Archaeology (John M. Stanley)henarroNo ratings yet

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- The Long Hangover: Putin's New Russia and the Ghosts of the PastFrom EverandThe Long Hangover: Putin's New Russia and the Ghosts of the PastRating: 4.5 out of 5 stars4.5/5 (76)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- A Welder's Guide to Handrails and Railing Codes: Everything You Need to Know about Handrails and the Building Codes That Regulate ThemFrom EverandA Welder's Guide to Handrails and Railing Codes: Everything You Need to Know about Handrails and the Building Codes That Regulate ThemNo ratings yet

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Markup & Profit: A Contractor's Guide, RevisitedFrom EverandMarkup & Profit: A Contractor's Guide, RevisitedRating: 5 out of 5 stars5/5 (11)

- Shipping Container Homes: The complete guide to shipping container homes, tiny houses, and container home plans!From EverandShipping Container Homes: The complete guide to shipping container homes, tiny houses, and container home plans!No ratings yet

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItFrom EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItRating: 4 out of 5 stars4/5 (16)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Knifemaking: A Bladesmithing Guide on Forging Knives and Crafting Knife Sheaths with Simple Tools for BeginnersFrom EverandKnifemaking: A Bladesmithing Guide on Forging Knives and Crafting Knife Sheaths with Simple Tools for BeginnersNo ratings yet

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsFrom EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsRating: 1 out of 5 stars1/5 (4)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet