Professional Documents

Culture Documents

Answer Key For Cim Iat-3

Uploaded by

Siva RamanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Answer Key For Cim Iat-3

Uploaded by

Siva RamanCopyright:

Available Formats

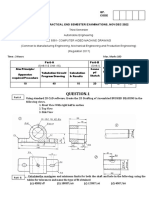

ST.

MOTHER THERESA ENGINEERING COLLEGE, VAGAIKULAM

DEPARTMENT OF MECHANICAL ENGINEERING

ME2402- COMPUTER INTEGRATED MANUFACTURING

(REGULATION 2008)

IAT-III

ANSWER KEY

PART-A

1. It may be defined as a system for utilizing data from the shop floor as well as data processing files to

maintain and communicate status information on shop orders and work centres.

2. The release of production orders to the factory, monitoring and controlling the progress of the orders

through the various work centers, acquiring information on the status of the orders.

3. A dedicated FMS is designed to produce a limited variety of part configurations. The random order

FMS is more flexible than the dedicated FMS.

4. Workstation/processing station control, distribution of control instructions to workstations, production

control, material handling system control.

5. The primary handling systems establishes the basic layout of the FMS and is responsible for moving

work-parts between workstations in the systems.

The secondary handling system transfer work-parts from the primary system to the machine tool or other

processing stations.

6. In online system the data are entered directly into the plant computer system and are immediately

available to the order progress module

In an off-line system, the data are collected temporarily in a storage device or a stand alone computer

system to be entered and processed by plant computer in a batch mode.

7. PPC may be defined as the direction and coordination of a firm material and physical facilities towards

the attainment of pre-specified production of goods, with highest production efficiency.

8. Production planning may be defined as the determination, acquisition and arrangement of all facilities

necessary for future production of products.

9. Aggregate planning is concerned with determining the quantity and timing of production for the

intermediate future ahead, setting employment, inventory, and subcontracting.

10. MRP is a computational technique that converts the master schedule for final products into a detailed

schedule for the raw materials and parts used in the final products.

PART-B

11.(a) (i) Introduction (2marks)

Bar code

(2marks)

Bar code symbols (2marks)

Bar code scanner (2marks)

(ii) Inline layout

(2marks)

Loop layout

(2marks)

Ladder layout

(2marks)

Open field layout (2marks)

(b) (i) Data acquisition system (2marks)

Data logging systems

(2marks)

Multilevel scanning

(4marks)

(ii) Primary handling system

(4marks)

Secondary handling system (4marks)

12. (a)(i) Scheduling (1marks)

Dispatching (1marks)

Follow up (1marks)

Providing actual output data for capacity control purposes (1marks)

Providing quantity by location by shop order for work in process inventory and accounting

purposes. (2marks)

Providing measurement of efficiency, utilization and productivity of manpower machines.

(2marks)

(ii) Each point carries 1 mark for functions of Material handling systems.

(b)(i) Each point carries 1 mark

Workstation/processing station control

Distribution of control instructions to workstations

Production control

Material handling system control

Workpiece monitoring

Tool control

Quality control

Failure diagnosis

(ii) Machining, Assembly, Sheet metal press working, forging, plastic injection moulding, Welding,

(4marks)

Advantages (2 marks), disadvantages (2marks)

13. (a) Order release (5marks) , Order scheduling (6marks), order progress (5marks)

(b) (i) Drawing (4marks) , Explanation (4marks)

(ii) Definition (3marks) Types (3marks) Objectives (2marks).

14 (a) Master production schedule (4marks) Bill of materials file (4marks)

inventory record file (4marks)

Concept (4marks)

(b) (i) Each point carry 1 mark

General design specifications.

Total anticipated quantity and the rate of production

Assembly or layout drawings

List of the proposed sub assemblies

Detailed drawings and a bill of material

Machine tool and equipment requirements

Packaging

Operation analysis

15. (a) ordering costs (4marks), Carrying costs (4marks), Shortage costs (4marks),

Purchase costs(4marks)

(b) Definition (3marks), Objectives (8marks), Concept (5marks)

You might also like

- Shop Floor Data Collection SystemsDocument43 pagesShop Floor Data Collection SystemsBrook EshetuNo ratings yet

- Shop Floor Control & FMSDocument40 pagesShop Floor Control & FMSMayank kumawatNo ratings yet

- PPC Chapter 2 Lecture 3Document13 pagesPPC Chapter 2 Lecture 3singhsujitNo ratings yet

- 4 CappDocument23 pages4 CappAnvit TiwariNo ratings yet

- Unit V SFC & FMSDocument40 pagesUnit V SFC & FMSPrabhaharMuthuswamyNo ratings yet

- Shop Floor ManagementDocument6 pagesShop Floor Managementyasheen94No ratings yet

- Advanced Manufacturing Quiz Solution and Course Guide - 2024Document3 pagesAdvanced Manufacturing Quiz Solution and Course Guide - 2024sannikimyoungNo ratings yet

- CNC, NC, FMS, Aps, RoboticsDocument7 pagesCNC, NC, FMS, Aps, RoboticskarthikkvskNo ratings yet

- Manu Fact UraDocument14 pagesManu Fact UraErick McNo ratings yet

- Dcs SystemDocument29 pagesDcs SystemSandeep Sachan100% (3)

- Flexible Manufacturing Systems PDFDocument10 pagesFlexible Manufacturing Systems PDFnathiya100% (1)

- Cim Technology DefinationsDocument3 pagesCim Technology DefinationsengmsaudanNo ratings yet

- SCM - GATP System Monitoring Support Processes DocumentDocument16 pagesSCM - GATP System Monitoring Support Processes DocumentSnehal PatilNo ratings yet

- Scada IeeeDocument5 pagesScada IeeeVarsha PaiNo ratings yet

- Parenteral Filling Facility: Automation Case StudyDocument10 pagesParenteral Filling Facility: Automation Case StudyRajuNo ratings yet

- Computer Integrated Manufacturing: Shop Floor ControlDocument26 pagesComputer Integrated Manufacturing: Shop Floor ControlAnjula PremarathnaNo ratings yet

- M.Tech: Automation in Manufacturing: Computer Numerical Control (CNC) MachinesDocument28 pagesM.Tech: Automation in Manufacturing: Computer Numerical Control (CNC) MachinesMohamed Essam MohamedNo ratings yet

- Transmisi Data PDFDocument5 pagesTransmisi Data PDFerick s.hNo ratings yet

- Automotive Glossary of TermsDocument2 pagesAutomotive Glossary of TermsRichard WiltsieNo ratings yet

- MES OverviewDocument29 pagesMES OverviewakitutNo ratings yet

- Production Information Monitoring System For CIM in Footwear IndustryDocument6 pagesProduction Information Monitoring System For CIM in Footwear IndustryLinh ChiNo ratings yet

- #2 Communication & IDMSDocument27 pages#2 Communication & IDMSHayelom KirosNo ratings yet

- SS 05 03 06Document11 pagesSS 05 03 06Vasantha PrasathNo ratings yet

- Control System For Balance of PlantDocument1 pageControl System For Balance of Plantman98_greyhoundzNo ratings yet

- SME Report FinalDocument3 pagesSME Report FinalAman GuptaNo ratings yet

- CSP Production Scheduling and Information System Using Web-Browser TechnologyDocument4 pagesCSP Production Scheduling and Information System Using Web-Browser TechnologyAdmon AutomationNo ratings yet

- 2.1 Evolution of Advanced Production Planning SystemDocument14 pages2.1 Evolution of Advanced Production Planning SystemzainNo ratings yet

- CadCam Lab Report FileDocument30 pagesCadCam Lab Report FileAzher Uddin100% (1)

- Embedded Fuzzy-Control System For Machining Processes Results of A Case StudyDocument14 pagesEmbedded Fuzzy-Control System For Machining Processes Results of A Case StudyMuhammad BagusNo ratings yet

- J96 - The Real-Time Supervisory Control of An Experimental Manufacturing CellDocument14 pagesJ96 - The Real-Time Supervisory Control of An Experimental Manufacturing CellMosharraf HossainNo ratings yet

- Lect 27 Nov 5Document13 pagesLect 27 Nov 5Prabhakar JayaramNo ratings yet

- Pplication of WINCC Redundant System in Production Line Wang NaDocument7 pagesPplication of WINCC Redundant System in Production Line Wang Naia2e techNo ratings yet

- Proposal of Strategies Improvement - Automation and New TechnologyDocument5 pagesProposal of Strategies Improvement - Automation and New Technologyzul0867No ratings yet

- Control System Scope and Job Activity in Various Designing/EPC & Process IndustriesDocument7 pagesControl System Scope and Job Activity in Various Designing/EPC & Process IndustriesSEP-PublisherNo ratings yet

- Unit - Vi:: Applications in MechatronicsDocument14 pagesUnit - Vi:: Applications in MechatronicsViswanathanBalajiNo ratings yet

- Automation HierarchyDocument25 pagesAutomation HierarchyObianuju Ezuka100% (3)

- Dcs PPT VijayDocument14 pagesDcs PPT VijayvijaykumarselvamNo ratings yet

- Dispatching Control System of The Concrete BatchinDocument6 pagesDispatching Control System of The Concrete Batchinyunus alfiansahNo ratings yet

- Strategies ImprovementDocument3 pagesStrategies Improvementzul0867No ratings yet

- Chapter 7the Conversion Cycle SummaryDocument13 pagesChapter 7the Conversion Cycle Summary0nionringsNo ratings yet

- SPC-0804.02-60.05 Rev D2 DCS SpecificationDocument31 pagesSPC-0804.02-60.05 Rev D2 DCS SpecificationharmlesdragonNo ratings yet

- Honeywell FSCDocument30 pagesHoneywell FSCManoj Kage100% (1)

- Unit 2 - Embedded SystemDocument75 pagesUnit 2 - Embedded Systemsujith100% (4)

- Ch8 FMSDocument39 pagesCh8 FMSImran KhanNo ratings yet

- CANTIER MES, FPS & QMS DetailsDocument8 pagesCANTIER MES, FPS & QMS DetailsMariver LlorenteNo ratings yet

- Supervisory Control & Data AcquisitionDocument34 pagesSupervisory Control & Data AcquisitionThuân Phạm NgọcNo ratings yet

- 00 - CASABLANCA - Supervisor System and Network Specifications - EnG VerDocument18 pages00 - CASABLANCA - Supervisor System and Network Specifications - EnG VerLinh TinhNo ratings yet

- DCS. Distributed Control System-1Document43 pagesDCS. Distributed Control System-1Aditia C PurnomoNo ratings yet

- Production Information SystemDocument15 pagesProduction Information SystemArun ManickNo ratings yet

- Conventional Numerical ControlDocument12 pagesConventional Numerical Controlsagar yadavNo ratings yet

- Hierarchy AutomDocument20 pagesHierarchy AutombaliNo ratings yet

- 2 Real-Time Control System and Real-Time NetworksDocument7 pages2 Real-Time Control System and Real-Time NetworksSam eagle goodNo ratings yet

- December 2010 TC4A1Document10 pagesDecember 2010 TC4A1Ahmed Raza MirNo ratings yet

- Application of SCADA in PSDocument5 pagesApplication of SCADA in PSupparahalNo ratings yet

- Automation Paper: (1) Power To Accomplish The Process and Operate The SystemDocument5 pagesAutomation Paper: (1) Power To Accomplish The Process and Operate The SystemAnmol SetiaNo ratings yet

- Computer Integrated Manufacturing (CIM)Document56 pagesComputer Integrated Manufacturing (CIM)Muhd Sabry AnwarNo ratings yet

- Computer Integrated Manufacturing Lab Manual: Subject Supervisor: Lab InchargeDocument53 pagesComputer Integrated Manufacturing Lab Manual: Subject Supervisor: Lab InchargePuneet G-man KoliNo ratings yet

- Vallathirakkottai Post, Pudukkottai-622305 Anna University-ChennaiDocument1 pageVallathirakkottai Post, Pudukkottai-622305 Anna University-ChennaiSiva RamanNo ratings yet

- Me8381 CadDocument20 pagesMe8381 CadSiva RamanNo ratings yet

- ME8512 Thermal Engineering Laboratory: Fifth SemesterDocument5 pagesME8512 Thermal Engineering Laboratory: Fifth SemesterKARTHINo ratings yet

- Me8381 CadDocument20 pagesMe8381 CadSiva RamanNo ratings yet

- ME8511-Kinematics and Dynamics Laboratory: Fifth SemesterDocument2 pagesME8511-Kinematics and Dynamics Laboratory: Fifth SemesterSiva RamanNo ratings yet

- Me8513 MMDocument2 pagesMe8513 MMSiva RamanNo ratings yet

- Me8361 - MT-1Document10 pagesMe8361 - MT-1Siva RamanNo ratings yet

- Me8781 MCTDocument2 pagesMe8781 MCTSiva RamanNo ratings yet

- DOM Manual Only ExperimentsDocument38 pagesDOM Manual Only ExperimentsSiva RamanNo ratings yet

- Robotics MCQ 1Document25 pagesRobotics MCQ 1Siva Raman100% (4)

- Robotics MCQ 1Document25 pagesRobotics MCQ 1Siva Raman100% (4)

- High Voltage Engineering: Unit 1Document9 pagesHigh Voltage Engineering: Unit 1Siva RamanNo ratings yet

- FM Lab Manual NewDocument73 pagesFM Lab Manual NewSiva RamanNo ratings yet

- ME-8361-MT-1 LAB MANUAL 2017 Reg FINALDocument101 pagesME-8361-MT-1 LAB MANUAL 2017 Reg FINALSiva RamanNo ratings yet

- Intro RoboticsDocument49 pagesIntro Roboticsariff05100% (2)

- ME8511-Kinematics and Dynamics Laboratory: Fifth SemesterDocument2 pagesME8511-Kinematics and Dynamics Laboratory: Fifth SemesterSiva RamanNo ratings yet

- MT II LAB MANUAL NewDocument51 pagesMT II LAB MANUAL NewSiva RamanNo ratings yet

- Thermal Lab-2 Manual CompletedDocument69 pagesThermal Lab-2 Manual CompletedSiva RamanNo ratings yet

- Simulation Lab Manual NewDocument90 pagesSimulation Lab Manual NewSiva RamanNo ratings yet

- Unit V-MinDocument68 pagesUnit V-MinVimal KekNo ratings yet

- EEE (University Examination)Document2 pagesEEE (University Examination)Siva RamanNo ratings yet

- Aucr2017 TIME TABLEDocument120 pagesAucr2017 TIME TABLESiva RamanNo ratings yet

- Semes Ter Subject Code Subject Name Ex Am Dat e TimingDocument7 pagesSemes Ter Subject Code Subject Name Ex Am Dat e TimingSiva RamanNo ratings yet

- Dme QNDocument3 pagesDme QNSiva RamanNo ratings yet

- Dme Model KeyDocument10 pagesDme Model KeySiva RamanNo ratings yet

- MECH (University Examination)Document1 pageMECH (University Examination)Siva RamanNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Me6503 Dome QB PDFDocument65 pagesMe6503 Dome QB PDFmaniNo ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- Me6503 Dme Mech VST Au Unit IV PDFDocument34 pagesMe6503 Dme Mech VST Au Unit IV PDFSandeep BadinehalNo ratings yet

- Chapter 4 - Maintenance Planning and Scheduling (Full Chapter) NewDocument44 pagesChapter 4 - Maintenance Planning and Scheduling (Full Chapter) NewMazlina Ashari40% (5)

- 23.XX All DetailsDocument4 pages23.XX All DetailsNajib DalhatuNo ratings yet

- PBN1Document10 pagesPBN1Vibhore Kumar SainiNo ratings yet

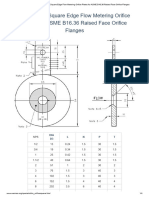

- Wermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice FlangesDocument4 pagesWermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice Flangestechnicalei sulfindoNo ratings yet

- Spring Hangers - AnvilDocument7 pagesSpring Hangers - AnvilRicardo De JesusNo ratings yet

- Student Guide Volume 2 Advanced SQLDocument36 pagesStudent Guide Volume 2 Advanced SQLapi-3748459No ratings yet

- Transportation Manager or International Manager or Logistics SupDocument3 pagesTransportation Manager or International Manager or Logistics Supapi-78592002No ratings yet

- IGST Claimed3Document66 pagesIGST Claimed3premierexim1No ratings yet

- G4a ElDocument6 pagesG4a ElEvan Valentine CalderwoodNo ratings yet

- 05 Enystar enDocument74 pages05 Enystar enAnonymous BBX2E87aHNo ratings yet

- Free Goods in Sales and Distribution Processing - Basic Functions and Master Data in SD Processing (SD-BF) - SAP LibraryDocument4 pagesFree Goods in Sales and Distribution Processing - Basic Functions and Master Data in SD Processing (SD-BF) - SAP LibraryBijay AgarwalNo ratings yet

- Gte QuestionsDocument46 pagesGte QuestionsMatt SantiagoNo ratings yet

- Coursework Structural Integrity 2023-24Document7 pagesCoursework Structural Integrity 2023-24Yacine HalwaneNo ratings yet

- Sofia ShewaregaDocument1 pageSofia ShewaregafiliNo ratings yet

- 17.01 General HSE Induction EmployeesDocument4 pages17.01 General HSE Induction EmployeesRetselisitsoeNo ratings yet

- 295 - 2012!08!16 - Inspection of The Flap Support Arm Attachments - SB57-006Document5 pages295 - 2012!08!16 - Inspection of The Flap Support Arm Attachments - SB57-006Elijah Paul MertoNo ratings yet

- Larsen Toubro C-WPS OfficeDocument7 pagesLarsen Toubro C-WPS OfficeNihal SonkusareNo ratings yet

- D46 Seam3 5 3 05Document3 pagesD46 Seam3 5 3 05James SilvozaNo ratings yet

- LFPG - Gates - Paris Charles de Gaulle Airport GatesDocument1 pageLFPG - Gates - Paris Charles de Gaulle Airport GatesAdhi SivanNo ratings yet

- Evolution and Future of Electronic Media in PakistanDocument6 pagesEvolution and Future of Electronic Media in PakistanAdilMirNo ratings yet

- Hazard Alert Working Safely With Scissor Lifts OSHA3842Document4 pagesHazard Alert Working Safely With Scissor Lifts OSHA3842ETNo ratings yet

- Deformation Behavior of The Surface Defects of Low Carbon Steel in Wire Rod RollingDocument6 pagesDeformation Behavior of The Surface Defects of Low Carbon Steel in Wire Rod RollingAvinash KumarNo ratings yet

- ECA Presentation Outline (Customer Copy)Document12 pagesECA Presentation Outline (Customer Copy)prabuharan89No ratings yet

- UNITRONICS V200-18-E1Document10 pagesUNITRONICS V200-18-E1eddieipenzaNo ratings yet

- IBM and Siemens PLM SoftwareDocument8 pagesIBM and Siemens PLM SoftwareImmanuel HenneNo ratings yet

- The Weathering - Aircraft - 20 - BASESDocument74 pagesThe Weathering - Aircraft - 20 - BASESjose vivarNo ratings yet

- 04) ZEEPod & Other Project ExperienceDocument72 pages04) ZEEPod & Other Project Experiencebapaobao100% (1)

- Connectivity Options Between Honeywell® and DeltaV™ SystemsDocument17 pagesConnectivity Options Between Honeywell® and DeltaV™ SystemsRicardo VillalongaNo ratings yet

- Cargo Handling EquipmentsDocument18 pagesCargo Handling EquipmentsRajeewa Wickramahewage100% (1)

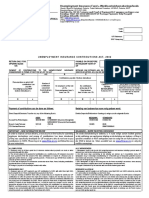

- Form - U17 - UIF - Payment AdviceDocument2 pagesForm - U17 - UIF - Payment Advicesenzo scholarNo ratings yet