Professional Documents

Culture Documents

Transf. de Calor-Tablas, Gráficos, Diagramas PDF

Uploaded by

Antonela PortaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transf. de Calor-Tablas, Gráficos, Diagramas PDF

Uploaded by

Antonela PortaCopyright:

Available Formats

TRANSFERENCIA DE CALOR VOLUMEN I

38

APPENDIX

Transferencia de Calor

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

Appendix D-13.

HEAT CAPACITIES

(1 Btu/lb) F = 4184.2 J/kg C

(a) gas and liquid at 1 atm

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

39

TRANSFERENCIA DE CALOR VOLUMEN I

CALOR ESPECIFICO: Btu/lbmF o cal/g C

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

40

TRANSFERENCIA DE CALOR VOLUMEN I

41

Appendix D-12. DENSITIES OF VARIOUS MATERIALS

(1b)(By permission of Mc Graw-Hill, copyright 1950)(1 lb/ft3 = 16.08 kg/m3 )

Densidad de varios materiales (lb)

(1 lb/ft3= 16.018 kg/ m3)

(a) Gases at 1 atm and 0 C

Gas

Formula

Acetylene

Air

Ammonia

Argon

Bitane

Carbondioxide

Chlorine

Ethane

Ethylene

Helium

Hydrogen

Methane

Methylchlotyde

Nitrogen

Oxygen

Sulfur dioxide

C2H2

NH3

Ar

C4H10

CO2

Cl2

C2H6

C2H4

He

H2

CH4

CH3Cl

N2

O2

SO2

Molecular

Weight

Density

lb/ft3

26.02

17.03

39.91

58.08

44.00

70.91

30.05

28.03

4.00

2.016

16.03

50.48

28.022

32.00

64.06

0.0732

0.0808

0.0482

0.1114

0.1623

0.1235

0.2011

0.0848

0.0783

0.0111

0.0056

0.0448

0.1440

0.0782

0.0892

0.1828

(b) Liquids at 20 C

Liquids

Acetic acid

Acetone

Ammonia

Benzene

Carbon thetracloride

Ethyl ether

Ethyl alcohol

Methyl alcohol

Mercury

Pentane (n)

SAE 10 oil (21 API)

Sodium

Toluene

Water

Density, lb / ft3

65.4(-79C)

49.4

51.0

54.8

99.5

44.2

49.2

49.4

849

39.2

57.8

58.0(100C)

54.7(600F)

54.0

62.3

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

42

(c) Solids

Metals

Aluminium

Copper

Iron, cast

Lead

Nickel

Steel, mild

Tin

Zinc

Density, lb / ft3

165

556

450

710

537

489

459

440

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

APPENDIX D-9 VISCOSITIES OF LIQUIDS AS A FUNCTIONS OF TEMPERATURE AT 1 ATM (3)

(1 cp =0.1 Ns/m2)

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

43

TRANSFERENCIA DE CALOR VOLUMEN I

44

THERMAL CONDUCTIVITY OF VARIOUS MATERIALS

[1 BTU / hr ft2(F/ ft) =1.7296 J/s m2(C / m)]

(a) Gases and Vapors.

k = Btu / hr-ft-F

Substance

T, F

Acetone

32

115

212

363

Acetylene

-103

32

122

212

Air

-148

32

212

392

572

Ammonia

-76

32

122

212

Benzene

32

115

212

363

413

Butane (n-)

32

212

Carbon dioxide

-58

32

392

572

Carbon tetrachloride

115

212

363

Chlorine

32

Dichiorodifluoromethane 32

122

212

302

Ethane

-94

-29

32

212

Ethyl alcohol

68

212

Ethyl ether

32

115

212

363

413

k

0.0057

0.0074

0.0099

0.0147

0.0068

0.0108

0.0140

0.0172

0.0095

0.0140

0.0183

0.0226

0.0265

0.0095

0.0128

0.0157

0.0185

0.0052

0.0073

0.0103

0.0152

0.0176

0.0078

0.0135

0.0068

0.0085

0.0181

0.0228

0.0041

0.0052

0.0065

0.0043

0.0048

0.0064

0.0080

0.0097

0.0066

0.0086

0.0106

0.0175

0.0089

0.0124

0.0077

0.0099

0.0131

0.0189

0.0209

Substance

Ethylene

Heptane (n-)

Hexane (n-)

Hydrogen

Methane

Methyl alcohol

Methyl chloride

Nitrogen

Oxygen

Pentane (n-)

Propane

Sulfur dioxide

Water vapor,

zero pressure

T, F

-96

32

122

212

212

392

32

68

-148

-58

32

122

212

572

-148

-58

32

122

32

212

32

115

212

363

413

-148

122

212

-148

-58

32

122

212

32

68

32

212

32

212

32

200

400

600

800

1000

For saturated vapor:

psia

T, F

k

250

500

1000 1500 2000

401

467

545

596

636

0.0248 0.0299 0.0395 0.0486 0.0578

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

k

0.0064

0.0101

0.0131

0.0161

0.0103

0.0112

0.0072

0.0080

0.065

0.083

0.100

0.115

0.129

0.178

0.0100

0.0145

0.0175

0.0215

0.0083

0.0128

0.0053

0.0072

0.0094

0.0130

0.0148

0.0140

0.0160

0.0180

0.0095

0.0119

0.0142

0.0164

0.0185

0.0074

0.0083

0.0087

0.0151

0.0050

0.0069

0.0132

0.0159

0.0199

0.0256

0.0306

0.0495

TRANSFERENCIA DE CALOR VOLUMEN I

45

(b) Liquids

k = BTU / hr - ft - F

Liquid

T, F

Liquid

k

0.086

0.081

4.83

Acetic acid, 100%

50%

Acetone

68

68

86

0.099

0.20

0.102

Kerosene

Mercury

8

167

2

Ammonia

167

0.095

Methyl alcohol, 100%

0.124

Benzene

5-86

86

0.29

0.092

122

Methyl chloride

0.114

0.111

140

32

154

20

60

100

140

0.087

0.107

0.094

0.057

0.053

0.048

0.043

86

6

140

6

167

100

0.089

0.083

0.081

0.078

0.074

0.074

0.071

Ethyl alcohol 100%

180

68

0.038

0.105

200

300

0.068

0.066

Ethyl Ether

122

86

0.087

0.080

Sodium

12

410

49

46

Ethylene glycol 167

0.078

32

0.164

212

86

Sulfuric acid, 90%

Sulfur dioxide

0.153

0.164

0.081

Toluene

Water

86

6

2

0.21

0.128

0.111

0.086

0.343

140

86

140

0.079

0.080

0.078

100

200

300

420

620

0.363

0.393

0.395

0.376

0.275

Carbon tetrachloride

Dichlorodifluoromethane

Glycerol, 100% 68

Heptane (n-)

Hexane (n-)

Octane (n-)

Pentane (n-)

SAE 10 oil (21 API) (3)

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

46

(c) Solids

k = BTU / hr - ft - F

Metals

Density lb/ft3 T, C k

Aluminium

165

Copper

556

Iron, cast

450

Lead

710

0

100

200

300

400

500

0

100

200

300

400

500

54

102

0

100

200

300

117

119

124

133

144

155

224

218

215

212

210

207

27.6

26.8

20

19

18

18

Metals

Density lb/ft3 T, C k

Nickel

537

Steel, mild

489

Tin

459

Zinc

440

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

0

100

200

300

100

200

300

400

500

0

100

200

0

100

200

300

400

36

34

33

32

26

26

25

23

22

36

34

33

65

64

62

59

54

TRANSFERENCIA DE CALOR VOLUMEN I

47

( c ) (continued) - Miscellaneous

k = BTU / hr - ft - F

Miscellaneous

Asbestos

Asphalt

Bricks:

Alumina ( 92 99% Al2O3 by wt.) fused

Alumina ( 64 65% Al2O3 by wt.) fused

Building brick work

Carbon

Chrome brick (32% Cr2O3 by wt.)

Diatomaceous earth, natural, across strata

Diatomaceous earth, natural, parallel strata

Diatomaceous earth, natural, molded and fired

Diatomaceous earth and clay, natural, molded and fired

Diatomaceous earth, high burn, large pores

Fire clay ( Missouri )

Kaolin insulating brick

Apparent Density

3

( ), lb/ft at

Room

Temperature

29.3

29.3

36

36

36

36

43.5

43.5

132

115

115

96.7

200

200

200

27.7

27.7

27.7

27.7

38

38

42.3

42.3

37

37

Calcium carbonate, natural

Carbon stock

27

27

19

19

158

158

158

162

94

Cardboard, corrugated

Celluloid

Coke, petroleum

87.3

Concrete ( cinder )

( stone )

( 1:4 dry )

Cork board

Cork ( regranulated )

( ground )

Diatomaceous earth powdered, coarse

10

8.1

9.4

20.0

20.0

17.2

17.2

26.0

26.0

Kaolin insulating firebrick

Magnesite (86.8% MgO2, 6.3% Fe2O3, 3% CaO, 2.6% SiO2 by wt.)

fine

molded pipe covering

T, C

-200

0

0

100

200

400

-200

2

20

k

0.043

0.090

0.087

0.111

0.120

0.129

0.090

0.135

0.43

427

1315

800

1100

20

200

650

1315

204

871

204

871

204

871

204

871

200

1000

200

600

1000

1400

500

1150

200

760

204

650

1200

30

-184

0

30

100

500

30

30

30

38

871

204

871

204

871

1.8

2.7

0.62

0.63

0.4

3.0

0.67

0.85

1.0

0.051

0.077

0.081

0.106

0.14

0.18

0.14

0.19

0.13

0.34

0.58

0.85

0.95

1.02

0.15

0.28

0.050

0.113

2.2

1.6

1.1

1.3

0.55

3.6

0.037

0.12

3.4

2.9

0.20

0.54

0.44

0.025

0.026

0.025

0.038

0.082

0.040

0.074

0.051

0.088

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

48

( c ) (continued) - Miscellaneous

k = BTU / hr - ft - F

Miscellaneous

4 vol. calcined earth and 1 vol. Cement, poured and fired

Glass

Borosilicate type

Window glass

Soda glass

Granite

Graphite, longitudinal

powdered, through 100 mesh

Gypsum ( molded and dry )

Ice

Kapok

Leather, sole

Limestone ( 15.3 vol. % H2O

Magnesia ( powdered )

Magnesia ( light carbonate )

Magnesium oxide ( compressed )

Marble

Mineral wool

Paper

Porcelain

Portland cement, see concrete

Rubber ( hard )

( soft )

Sand ( dry )

Sandstone

Sawdust

Slag, blast furnace

Slag, wool

Slate

Snow

Wallboard, insulating type

Wallboard, stiff paste board

Wood ( across grain ):

Balsa

Oak

Maple

Pine, white

Teak

White fir

Wood ( parallel to grain ):

Pine

Wool, animal

Apparent Density

3

( ), lb/ft at

Room

Temperature

T, C

61.8

61.8

139

30

78

57.5

0.88

62.4

103

49.7

13

49.9

9.4

19.7

94.6

140

12

12

34.7

14.8

43

204

871

30 - 75

20

40

20

0

20

24

47

21

20

30

30

200

90

21 - 66

0

21

20

40

21

24 - 127

30

94

0

21

30

0.16

0.23

0.2 0.73

0.63

0.3 0.61

0.3 0.44

1.0 2.3

95

0.104

0.25

1.3

0.25

0.092

0.54

0.35

0.034

0.32

1.2 1.7

0.0225

0.024

0.075

0.88

0.17

0.14

0.087

0.075 0.092

0.19

1.06

0.03

0.064

0.022

0.86

0.27

0.028

0.04

7-8

51.5

44.7

34.0

40.0

28.1

30

15

50

15

15

60

0.025 0.03

0.12

0.11

0.087

0.10

0.062

34.4

6.9

21

30

0.20

0.021

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

CONDUCTIVIDADES CALORICAS, k

Metales

Cobre

Aluminio

Latn (70-30)

Nquel

Acero dulce

Acero inoxid. (304)

Materiales aislantes

Madera contrachapada de pino abeto

17 % de humedad

0 % de humedad

Plancha de corcho

194 kg/m3

104 kg/m3

Fibra de amianto

576 kg/m 3

Fibra de vidrio

144 kg/m3

48 kg/m3

Vidrio celular Densidad. 160 kg/m3

Lana mineral (Zeolita) Densidad. 240 kg/m3

Magnesia (85 %)

Conductividad equivalente a 25 mm de aire

Entre materiales de emisividad ordinaria

Con aluminio en el lado caliente

Lquidos

Agua (lquida)

Amonaco (lquido)

Tetracloruro de carbono

Acetona

Gasolina

Destilado 37 API

Aceite lubr. SAE 10 (21 API)

Alcohol etlico (100)

Benceno

n - Pentano

Gases

Aire

Amonaco

Dixido de carbono

Cloro

Hidrgeno

Metano

Oxgeno

Propano

n - pentano

Vapor de agua

Materiales refractarios y aislantes

-100

245

228

112

54

37.6

27

7.7

224

114

56

36.5

26.6

8.1

0.062

0.047

0.021

0.018

0.019

0.016

0.052

0.037

0.006

0.0080

0.0074

Btu / (hr) (pie cuadrado) ( F / pie) *

Temperatura F

0

100

-200

49

200

300

400

500

220

117

57.2

35.4

26.2

8.55

218

119

59

34.5

26.0

9.0

215

122

61

34.0

25.7

9.5

212

128

63

33.0

25.5

10.0

210

130

65

32.0

25.2

10.4

0.069

0.053

0.076

0.060

0.083

0.067

0.0235

0.020

0.026

0.022

0.0285

0.024

0.082

0.097

0.11

0.115

0.12

0.125

0.010

0.013

0.028

0.021

0.036

0.011

0.015

0.038

0.024

0.039

0.020

0.025

0.042

0.028

0.041

0.023

0.035

0.046

0.032

0.043

0.031

0.047

0.050

0.035

0.046

0. 043

0. 065

0.055

0.038

0.049

0.078

0.038

0.104

0.039

0.130

0.041

0.298

0.290

0.098

0.108

0.091

0.082

0.074

0.109

0.10

0.083

0.350

0.290

0.086

0.103

0.089

0.079

0.071

0.103

0.09

0.0775

0.402

0.290

0.074

0.0975

0.085

0.076

0.068

0.0983

0.08

0.072

0.470

0.082

0.075

0.066

0.080

0.072

0.64

0.0141

0.0150

0.0085

0.0049

0.113

0.0205

0.0149

0.0105

0.0093

0.0115

0.0162

0.0185

0.01

0.0061

0.127

0.025

0.0171

0.0146

0.0125

0.0140

0.0181

0.0215

0.0126

0.0075

0.14

0.0295

0.019

0.0190

0.0160

0.0165

0.0197

0.025

0.0135

0.0211

0.029

0.0156

0.153

0.0347

0.0206

0.024

0.0198

0.0192

0.168

0.0398

0.0221

0.029

0.024

0.0225

0.0089

0.0088

0.0057

0.0108

0.0118

0.007

0.072

0.0125

0.011

0.095

0.0165

0.0126

0.0076

0.0066

Densidad en kg/m3

500

1000

1500

2000

3200

2000-2080

0.56

0.47

0.70

0.55

0.64

0.81

0.66

0.82

0.89

0.76

0.91

0.96

0.86

0.97

1760

1200

0.24

0.13

0.28

0.13

0.31

0.15

0.34

0.15

0.38

0.16

640

448

272

0.13

0.07

0.035

0.14

0.08

0.05

0.16

0.10

0.06

0.18

0.11

0.07

0.19

0.12

0.08

Ladrillo

300% de cromita

Ladrillo refractario

Arcilla refractaria de Missouri

Refractario moldeado

A base de silicato de aluminio

A base de silicato de poca densidad

Tierra de diatomeas

Ladrillo moldeado

Ladrillo natural

Polvo

*Multiplquese por 1.488 los valores de la conductividad que da esta tabla, para obtener Kcal / (hr)(m2 )(C/m)

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

Appendix D-1. Vapor pressures of common liquids

2

50

2

(By permission of McGraw-Hill Copyright 1950)(TF = 1.8TC +32: 1 Lbf/in =6.8948 kN/m )

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

51

Appendix C- 6b. METRIC STANDARD STEEL PIPE

(steel tubes suitable for screwing, ISO R-65). By permission of the publisher.

Outside

Diameter

Nominal Size

Wall Thickness, mm

in

mm

mm

Medium Weight

Heavy Weight

1

8

10.2

2.0

2.65

1

4

13.5

2.35

2.9

3

8

10

17.2

2.35

2.9

1

2

15

21.3

2.65

3.25

3

4

20

26.9

2.65

3.25

25

33.7

3.25

4.05

1 41

32

42.4

3.25

4.05

1 21

40

48.3

3.25

4.05

50

60.3

3.65

4.5

2 21

65

76.1

3.65

4.5

80

88.9

4.05

4.85

100

114.3

4.5

5.4

125

139.7

4.85

5.4

150

165.1

4.85

5.4

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

Appendix C-7a.

52

DIMENSIONS OF HEAT- EXCHANGER TUBESa

2

(1 in = 25.4 mm; 1 in = 645.16 mm ; 1 ft = 0.3048 m; 1 ft = 0.0929 m )

Tube O.D.

In

B.W.G. Thickness

Gage

In

Tube I.D.

In

Internal

Area Sq. In

Ft2 External Surface

Per Foot Length

Ft2 Internal Surface

Per Foot Length

1/4

1/4

22

24

0.028

0.022

0.194

0.206

0.0295

0.0333

0.0655

0.0655

0.0508

0.0539

1/2

1/2

1/2

18

20

22

0.049

0.035

0.028

0.402

0.430

0.444

0.1269

0.1452

0.1548

0.1309

0.1309

0.1309

0.1052

0.1126

0.1162

3/4

3/4

3/4

3/4

10

14

16

18

0.134

0.083

0.065

0.049

0.482

0.584

0.620

0.652

0.1825

0.2679

0.3019

0.3339

0.1963

0.1963

0.1963

0.1963

0.1262

0.1529

0.1623

0.1707

1

1

1

1

8

14

16

18

0.165

0.083

0.065

0.049

0.670

0.834

0.870

0.902

0.3526

0.5463

0.5945

0.6390

0.2618

0.2618

0.2618

0.2618

0.1754

0.2183

0.2278

0.2361

0.165

0.920

0.6648

0.3272

0.2409

14

0.083

1.084

0.9229

0.3272

0.2838

16

0.065

1.120

0.9852

0.3272

0.2932

18

0.049

1.152

1.042

0.3272

0.3016

11

12

13

14

0.120

0.109

0.095

0.083

1.760

1.782

1.810

1.834

2.433

2.494

2.573

2.642

0.5236

0.5236

0.5236

0.5236

0.4608

0.4665

0.4739

0.4801

1 41

1 41

1 41

1 41

2

2

2

2

A more complete listing may be found in the Chemical Engineers Handbook, V, 11-10

From Stds. Of TEMA VI ed; with permission of TEMA; Copyright 1978.

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

53

DIMENSIONS OF HEAT- EXCHANGER TUBES

Tube

O. D. in

BWG

Gage

Thickness

in

Tube

I. D. in

Internal

2

area, in

External

surface

2

per ft, ft /ft

Internal

surface

2

per ft, ft /ft

1

1

1

1

1

1

1

1

1

1

1

2

2

12

14

16

18

12

14

16

18

12

14

16

18

10

12

14

16

10

12

14

16

10

12

14

10

12

0.109

0.083

0.065

0.049

0.109

0.083

0.065

0.049

0.109

0.083

0.065

0.049

0.134

0.109

0.083

0.065

0.134

0.109

0.083

0.065

0.134

0.109

0.083

0.134

0.109

0.407

0.459

0.495

0.527

0.532

0.584

0.620

0.652

0.657

0.709

0.745

0.777

0.732

0.782

0.834

0.870

0.982

1.032

1.084

1.120

1.232

1.282

1.334

1.732

1.782

0.000903

0.00115

0.00134

0.00151

0.00154

0.00186

0.00210

0.00232

0.00235

0.00274

0.00303

0.00329

0.00292

0.00334

0.00379

0.00413

0.00526

0.00581

0.00641

0.00684

0.00828

0.00896

0.00971

0.0164

0.0173

0.1636

0.1636

0.1636

0.1636

0.1963

0.1963

0.1963

0.1963

0.2291

0.2291

0.2291

0.2291

0.2618

0.2618

0.2618

0.2618

0.3272

0.3272

0.3272

0.3272

0.3927

0.3927

0.3927

0.5236

0.5236

0.1066

0.1202

0.1296

0.1380

0.1393

0.1529

0.1623

0.1707

0.1720

0.1856

0.1950

0.2034

0.1916

0.2047

0.2183

0.2278

0.2571

0.2702

0.2838

0.2932

0.3225

0.3356

0.3492

0.4534

0.4665

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

54

Table 1.3. Steel-Pipe dimensions

1

2

Nominal

pipe size,

in

OD, in

0.405

0.540

0.675

0.840

1.05

1.32

1.66

1.90

2.38

2.88

3.50

4.50

6.625

8.625

10

10.75

12

Schedule

N

ID, in

Flow area

per pipe,

2

in

Surface per lineal ft, ft

Outside

Inside

Weight

per lineal,

lb steel

40

2

80

0.269

0.215

0.058

0.036

0.106

0.106

0.070

0.056

0.25

0.32

40

80

40

80

40

80

40

80

40

80

40

80

40

80

40

80

40

80

40

80

40

80

40

80

40

80

40

60

0.364

0.302

0.493

0.423

0.622

0.546

0.824

0.742

1.049

0.957

1.380

1.278

1.610

1.500

2.067

1.939

2.469

2.323

3.068

2.900

4.026

3.826

6.065

5.761

7.981

7.625

10.02

9.75

0.104

0.072

0.192

0.141

0.304

0.235

0.534

0.432

0.864

0.718

1.50

1.28

2.04

1.76

3.35

2.95

4.79

4.23

7.38

6.61

12.7

11.5

28.9

26.1

50.0

45.7

78.8

74.6

0.141

0.141

0.177

0.177

0.220

0.220

0.275

0.275

0.344

0.344

0.435

0.435

0.498

0.498

0.622

0.622

0.753

0.753

0.917

0.917

1.178

1.178

1.734

1.734

2.258

2.258

2.814

2.814

0.095

0.079

0.129

0.111

0.163

0.143

0.216

0.194

0.274

0.250

0.362

0.335

0.422

0.393

0.542

0.508

0.647

0.609

0.804

0.760

1.055

1.002

1.590

1.510

2.090

2.000

2.62

2.55

0.43

0.54

0.57

0.74

0.85

1.09

1.13

1.48

1.68

2.17

2.28

3.00

2.72

3.64

3.66

5.03

5.80

7.67

7.58

10.3

10.8

15.0

19.0

28.6

28.6

43.4

40.5

54.8

12.75

30

12.09

115

3.338

3.17

43.8

16

16.0

30

15.25

183

4.189

4.00

62.6

20

20.0

20

19.25

291

5.236

5.05

78.6

24

24.0

20

23.25

425

6.283

6.09

94.7

Schedule 40 designates former standard pipe.

Schedule 80 designates former extra-strong pipe.

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

do, in

BWG

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

22

24

26

18

20

22

24

16

18

20

22

12

13

14

15

16

17

18

19

20

10

11

12

13

14

15

16

17

18

20

10

11

12

13

14

16

18

20

8

10

11

12

13

14

15

16

18

20

7

8

10

11

12

Table 11.2 Tubing Characteristics

di, in

Wall

Inside cross

thickness,

sectional

2

xw, in

area, in

0.194

0.028

0.0295

0.206

0.022

0.0333

0.214

0.018

0.0360

0.277

0.049

0.0603

0.305

0.035

0.0731

0.319

0.028

0.0799

0.331

0.022

0.0860

0.370

0.065

0.1075

0.402

0.049

0.1269

0.430

0.035

0.1452

0.444

0.028

0.1548

0.407

0.109

0.1301

0.435

0.095

0.1486

0.459

0.083

0.1655

0.481

0.072

0.1817

0.495

0.065

0.1924

0.509

0.058

0.2035

0.527

0.049

0.2181

0.541

0.042

0.2298

0.555

0.035

0.2419

0.482

0.134

0.1825

0.510

0.120

0.2043

0.532

0.109

0.2223

0.560

0.095

0.2463

0.584

0.083

0.2679

0.606

0.072

0.2884

0.620

0.065

0.3019

0.634

0.058

0.3157

0.652

0.049

0.3339

0.680

0.035

0.3632

0.607

0.134

0.2892

0.635

0.120

0.3166

0.657

0.109

0.3390

0.685

0.095

0.3685

0.709

0.083

0.3948

0.745

0.065

0.4359

0.777

0.049

0.4742

0.805

0.035

0.5090

0.670

0.165

0.3526

0.732

0.134

0.4208

0.760

0.120

0.4536

0.782

0.109

0.4803

0.810

0.095

0.5153

0.834

0.083

0.5463

0.856

0.072

0.5755

0.870

0.065

0.5945

0.902

0.049

0.6390

0.930

0.035

0.6793

0.890

0.180

0.6221

0.920

0.165

0.6648

0.982

0.134

0.7574

1.010

0.120

0.8012

1.032

0.109

0.8365

55

External

surface

2

per ft, ft /ft

0.0655

0.0655

0.0655

0.0982

0.0982

0.0982

0.0982

0.1309

0.1309

0.1309

0.1309

0.1636

0.1636

0.1636

0.1636

0.1636

0.1636

0.1636

0.1636

0.1636

0.1936

0.1936

0.1936

0.1936

0.1936

0.1936

0.1936

0.1936

0.1936

0.1936

0.2291

0.2291

0.2291

0.2291

0.2291

0.2291

0.2291

0.2291

0.2618

0.2618

0.2618

0.2618

0.2618

0.2618

0.2618

0.2618

0.2618

0.2618

0.3272

0.3272

0.3272

0.3272

0.3272

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

Internal

surface

2

per ft, ft /ft

0.0508

0.0539

0.0560

0.0725

0.0798

0.0835

0.0867

0.0969

0.1052

0.1126

0.1162

0.1066

0.1139

0.1202

0.1259

0.1296

0.1333

0.1380

0.1416

0.1453

0.1262

0.1335

0.1393

0.1466

0.1529

0.1587

0.1623

0.1660

0.1707

0.1780

0.1589

0.1662

0.1720

0.1793

0.1856

0.1950

0.2034

0.2107

0.1754

0.1916

0.1990

0.2047

0.2121

0.2183

0.2241

0.2278

0.2361

0.2435

0.2330

0.2409

0.2571

0.2644

0.2702

TRANSFERENCIA DE CALOR VOLUMEN I

56

Table 11.2 Tubing Characteristics (continued)

do, in

BWG

di, in

1

1

1

1

1

1

1

1

1

2

2

2

13

14

16

18

20

10

12

14

16

11

13

9

1.060

1.084

1.120

1.152

1.180

1.232

1.282

1.334

1.370

1.760

1.810

2.204

Wall

thickness,

xw, in

0.095

0.083

0.065

0.049

0.035

0.134

0.109

0.083

0.065

0.120

0.095

0.148

Inside cross

sectional

2

area, in

0.8825

0.9229

0.9852

1.042

1.094

1.192

1.291

1.398

1.474

2.433

2.573

3.815

External

surface

2

per ft, ft /ft

0.3272

0.3272

0.3272

0.3272

0.3272

0.3927

0.3927

0.3927

0.3927

0.5236

0.5236

0.6540

Internal

surface

2

per ft, ft /ft

0.2775

0.2838

0.2932

0.3016

0.3089

0.3225

0.3356

0.3492

0.3587

0.4608

0.4739

0.5770

Standards of Tubular Exchanger Manufacturers Association.

Standards of Tubulars Exchangers Manufactured Association, 5th. Ed, 1968

3

Weights are based on low carbon steel with a density of 0.2833 lb/in for other metals multiply by the following factors

Aluminium

A.I.S.I. 400 series stainless steels

A.I.S.I. 300 series stainless steels

Aluminium bronze

Aluminium brass

Nickel chrome iron

Admiralty

Cooper and cupronickels

liquid

velocity =

0.35

0.99

1.02

1.04

1.06

1.09

1.13

1.14

lb tube per hr

in ft/sec (sp. gr. of water a 60 F =1.0)

C s.gr .of liquid

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

ANALISIS DE CAMBIADORES DE CALOR DE CONTRAFLUJO Y DE TUBO Y CORAZA

57

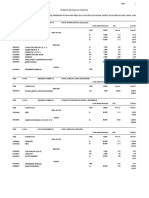

Los arreglos de flujo ms complejos que los estudiados en la secciones anteriores, son mucho

ms difciles de tratar analticamente. Los factores de correccin que van a usarse con la ecuacin

(22-10) han sido presentados por Bowman, Mueller y Nagle, as como por tubular Exchanger

Manufacturing Association en forma de tabla. Las figuras muestran factores de correccin

correspondientes a seis tipos de configuracin de cambiadores de calor. Los primeros tres son para

diferentes configuraciones de tubo y coraza y las ltimas tres para diferentes condiciones de flujo

cruzado.

Los parmetros de las figuras siguientes se calculan como sigue:

Y=

Z=

Ttsal Tten

Tsen Tten

(mc p ) tubo

(mc ) coraza

p

C t Tsen Tssal

=

C s Ttsal Tten

donde los subndices s y t se refieren a los fluidos que estn del lado de la coraza y del lado

del tubo, respectivamente. La cantidad que se lee en la ordenada de cada grfica, para valores

dados en Y y Z, y F, 0 sea, el factor de correccin que debe aplicarse en la ecuacin (22- 10) y, por

lo tanto, estas configuraciones ms complicadas se pueden manejar en la misma forma que el

R. A. Bowman, A. C. Mueller y W. M. Nagle, Trans. A.S.M.E., 62, 283 (1940).

Tubular Exchanger Manufacturers Association, Standars, TEMA, Tercera Edicin Nueva York, 1952.

a.

Grfica de factores de correccin para cambiar

con un paso de coraza y dos, cuatro o

cualquier mltiplo, de pasos de tubos.

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

58

b.

c.

Grfica de factores de correccin para cambiador con dos pasos de corazas y cuatro, ocho o cualquier

mltiplo de cuatro pasos de tubo.

Las figuras muestran los factores de correccin correspondientes a las configuraciones de tres

cambiadores de calor y tubo y coraza. (a) Un paso en la coraza y dos o mltiplo de dos en el tubo. (b)

Un paso en la coraza y tres o mltiplo de tres en el tubo. (c) Dos pasos en la coraza y dos o mltiplo

de dos en el tubo (de R. A. Bowman, A. C. MuelIer y W. M. Nagle, Trans. A.S.M.E., 62, 284, 285

(1940). Factores de correccin, F, basados en contraflujo L.M.T.D.

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

59

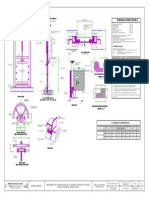

Caso de doble tubo de un solo paso. Se hace notar al lector que debe tener cuidado de aplicar

la ecuacin (22-10), usando el factor como en la ecuacin (22-14).

q = UA (F Tlm)

(22-14)

Calculando la diferencia logartmica media de temperatura en base al contra-flujo.

La ecuacin para la resistencia total a la transferencia de calor en un intercambiador de haz

tubular es la siguiente;

1/ U = 1/ h 0 + 1/ h io + ( x w / k w ) /(OD / dlm ) + 1/ h d

h io = hi(ID / OD)

dlm = (OD ID) / ln(OD / ID)

h d = factor de ensuciamie nto

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

F is expressed in relations to the two terms

X=

2 1

T1 1

and

Y=

T1 T2

2 1

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

60

TRANSFERENCIA DE CALOR VOLUMEN I

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

61

TRANSFERENCIA DE CALOR VOLUMEN I

A Bayonet Type Heat Exchanger for a polyethylene plant. Tube Have finned sections near end.

Shell and tube bundles of an order for 19 high pressure soap heaters. Double tube sheet construction.

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

62

TRANSFERENCIA DE CALOR VOLUMEN I

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

63

TRANSFERENCIA DE CALOR VOLUMEN I

Reactors for catalytic polymerisation unit.

Design pressure 670 psi for shell side and

1,730 psi for tube side.

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

64

TRANSFERENCIA DE CALOR VOLUMEN I

65

Figure 14-10 Disk and doughnut baffles.

Table 3. Individual Heat-transfer Coefficient to Account for Fouling

2

hd for water, Btu/(h)(ft )(F)

Temperature of heating medium:

Temperature of water

Water velocity, ft/s

Up to 240F

125F or less

240-400F

Above 125F

3 and less

Over 3

3 and less

Over 3

Distilled

2000

2000

2000

2000

Sea water

2000

2000

1000

1000

Treated boiler feedwater

1000

2000

500

1000

Treated make -up for cooling tower

1000

1000

500

500

City, well, great lakes

1000

1000

500

500

Brackish clean river water

1000

1000

330

500

River water: muddy silty

330

500

250

330

Hard (over 15 grains/gal)

330

330

200

200

Chicago sanitary canal

130

170

100

130

hd for miscellaneous

process services,

2

Btu/(h)(ft )(F)

Organic vapours, liquid gasoline

2000

Refined petroleum fractions (liquids), organics liquids, refrigerating

Liquids brine oil bearing steam

1000

Distillate bottoms (above 25 API) gas oil or liquid naphtha below

500F, scrubbing oil, refrigerant vapors, air dust

500

Gas oil above 500F, vegetable oil

330

Liquid naphtha above 500f, quenching oils

250

Topped crude (below 25 API ), fuel oil

200

Cracked residuum, coke-oven gas, illuminating gas

100

________________________________________________________________

Mississippi, Schuylkill, Delaware, and East rivers and New York Bay

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

66

Table 7.10. Thermal Resistance of Heat Exchanger Tubes

Values of xw /kw (ft2hF/Btu)

Gauge(BWG)

Thickness (in)

Copper

Steel

18

16

14

12

0.049

0.065

0.083

0.109

0.000018

0.000024

0.000031

0.000041

0.00011

0.00014

0.00018

0.00024

0.00047

0.00062

0.0008

0.001

Admiralty Metal

0.000065

0.000086

0.00011

0.00026

Aluminium

0.000031

0.000042

0.000053

0.000071

Values of xw/ kw (m2K / kW)

(mm)

18

16

14

12

Stainless Steel

1.24

1.65

2.10

2.77

0.0031

0.0042

0.0055

0.0072

0.019

0.025

0.032

0.042

0.083

0.109

0.141

0.176

0.011

0.015

0.019

0.046

0.0054

0.0074

0.0093

0.0123

Table 7.11. Thermal Resistances of Scale Deposits from Water, etc.

2

(ft h F/Btu)

Water (3 ft/s velocity,

temperatures less than50 C)

Distilled

Sea

Clear river

Untreated cooling tower

Treated cooling tower

Treated boiler feed

hard well

(1 m/s velocity, < 320 K)

(m K/kW)

(ft hF/Btu)

(m K/kW)

Steam

0.0005

0.0005

0.0012

0.0033

0.0015

0.0015

0.0033

0.09

0.09

0.21

0.58

0.26

0.26

0.58

Good quality-oil free

Poor quality-oil free

Exhaust from reciprocating

engines

Liquids

Treated brine

Organics

Fuel oils

tars

Gases

Air

Solvent vapours

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

0.0003

0.0005

0.052

0.09

0.001

0.176

0.0015

0.001

0.006

0.01

0.264

0.176

1.056

1.76

0.0015

0.003

0.0008

0.26-0.53

0.14

TRANSFERENCIA DE CALOR VOLUMEN I

67

Table 7.13. Approximate Film Coefficients (hi or h0)

Btu/h ft2 F

W/m2K

No change of state

Water

Gases

Organic solvents

Oils

300 -2000

3 -50

60 -500

10 -120

1700 -11350

17-280

340 -2840

60 -680

Condensing

Steam

Organic solvents

Light oils

Heavy oils (vacuum)

Ammonia

1000 -3000

150 - 500

200 - 400

20-50

500 -1000

5680 -17030

850 -2840

1140 -2270

115 -285

2840 -5680

Evaporation

Water

Organic solvents

Ammonia

Light oils

Heavy oils

800 -2000

100 -300

200 -400

150 -300

10 -50

4540 -11350

570 -1700

1140 -2270

850 -1700

60 -285

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

68

Table 10-10. Typical Overall Heat-transfer Coefficients In Tubular Heat Exchangers

Design U

Includes total dirt

Jet fuels

Water

Water

100-150

10-20

300-500

0.0015

0.01

0.001

Water or DEA , or MEA solutions

140-200

0.003

Water

Oil

Water

Heavy oils

Water

Hydrogen rich reformer stream

Water

Oil

Trichlorethylene

Water

Water

Water

Oil

Water

Oil

Water

Brine

Organic Solvents

Water

Caustic Soda solutions(10-30%)

Water

Water

Oil

15-25

10-15

60-100

10-40

15-50

90-120

25-50

20-35

40-50

230-300

25-50

40-80

11-20

50-70

25-35

50-150

35-90

20-60

20-50

100-250

200-250

15-25

13-23

0.007

0.008

0.003

0.004

0.005

0.002

0.005

0.005

0.0015

0.002

0.002

0.003

0.006

0.005

0.005

0.003

0.003

0.002

0.004

0.003

0.003

0.005

0.005

100-200

40-60

60-80

80-120

40-50

20-50

80-200

0.002

0.006

0.004

0.0015

0.0055

0.003

0.003

25-40

0.004

100-200

20-60

50-120

30-65

20-30

50-75

20-30

80-120

400-1000

15-25

60-90

0.003

0.003

0.003

0.004

0.005

0.005

0.005

0.003

0.0005

0.0055

0.0025

Shell side

Tube side

Liquid-liquid media

Aroclor 1248

Cutback asphalt

Demineralized water

Dhanol amine (MEA or DEA)10-25%

solutions

Fuel oil

Fuel oil

Gasoline

Heavy oils

Heavy oils

Hydrogen rich reformer stream

Kerosene or gas oil

Kerosene or gas oil

Kerosene or jet fuels

Lacket water

Lube oil (low viscosity)

Lube oil (high viscosity)

Lube oil

Naphtha

Naphtha

Organic Solvent

Organic Solvent

Organic Solvent

Tall oil derivatives, vegetable oil, etc

Water

Water

Wax distillate

Wax distillate

Condensing vapor-liquid media

Alcohol vapor

Asphalt (450F)

Dowtherm vapor

Dowtherm vapor

Gas-plant tar

High boiling hydrocarbons V

Low boiling hydrocarbons A

Hydroncarbon vapors (partial

condenser)

Organic Solvet A

Organic Solvet high NC, A

Organic Solvet low NC, V

Kerosene

Kerosene

Naphtha

Naphtha

Stabilizer reflux vapors

Steam

Steam

Steam

Water

Dowtherm vapor

Tall oil and derivatives

Dowtherm

Stream

Water

Water

Oil

Water

Water or brine

Water or brine

Water

Oil

Waters

Oil

Water

Feed water

No. 6 Fuel oil

No. 2 Fuel oil

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

Shell side

Tube side

69

Design U

Includes total dirt

Condensing vapor-liquid media (continued)

Sulfure dioxide

Tall oil derivatives, vegetable oils

(vapor)

Water

Water

150-200

0.003

Water

20-50

0.004

Aromatic vapor stream azcotrope

40-80

0.005

40-80

10-50

20-40

5-20

0.005

0.005

0.005

0.005

80-125

0.003

150-300

150-300

40-60

200-300

250-400

0.0015

0.0015

0.0015

0.0015

0.0015

Gas-liquid media

Air, N2, etc (compressed)

Air, N2, etc A

Water or brine

Water or brine

Water

Water or brine

Water or brine

Air, N2, (compressed)

Air, N2, etc A

Hydrogen containing natural-gas

mixtures

Vaporizers

Anhydrous ammonia

Chlorine

Chlorine

Propane, butane, etc

Water

Stream condensing

Stream condensing

Light heat-transfer oil

Stream condensing

Stream condensing

NC = non-condensable gas present

V = vacuum

A = atmosphere pressure

Dirt (of fouling factor) units are (hr.)(sq ft.)(F)/B.t.u

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

Table 15.1.

TYPICAL OVERALL COEFFICIENTS OF HEAT TRANSFER

Inside or Tube

Type of Exchanger

70

Fluid

Velocity, ft/s

Outside or Shell

Fluid

Velocity, ft/s

Btu/hr ft F

Shell and tube

Brine

1 -3

Water

1-5

50-400

Shell and tube

Water

Gas oil

3.0

50-70

Shell and tube

Water

Lube oil

0.2

15

Shell and tube

Water

Gasoline

Condensing

90

Shell and tube

Crude oil

Gasoline

Condensing

20-30

Shell and tube

Crude oil

10

Gas oil

6.0

80-90

Shell and tube

Water

4-6

Steam

Condensing

400-800

Double pipe

Water

3-8

Brine

3-8

150-300

Coil in box

Gas oil

Condensing

Water

Natural convection

8-20

Tube bank

Steam

Condensing

Air

10

Basket evaporator

Brine

Boiling

Steam

Condensing

150-225

Vertical tube evaporator

Water

Boiling

Steam

Condensing

400-1000

Vaporizer Steam

Condensing

Organic

Boiling

300

Vaporizer Steam

Condensing

Acetic acid

Boiling

450

(With the permission of John Wiley; Copyright @ 1950, and the Amer. lnst. of Chem. Engrs., Copyright@ 1959)

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

71

Table 7.12. Approximate Overall Heat Transfer Coefficient U for Shell and Tube Equipment

Hot side

CoId side

Overall U

2

Btu/h f t F

W/m K

Condensers

Steam (pressure)

Steam (vacuum)

Saturated organic solvents (atmospherics)

Saturated organic solvents (vacuum some non-condensable)

Organic solvents (atmospheric and high non-condensable)

Organic solvents (vacuum and height non-condensable)

Low boiling hydrocarbons (atmospheric)

High boiling hydrocarbons (vacuum)

Water

Water

Water

Water-brine

Water-brine

Water-brine

Water

Water

350-750

300-600

100-200

50-120

20-80

10-50

80-200

10-30

2000-4250

1700-3400

570 -1140

300-680

110-455

60-300

455-1140

60-170

Heaters

Steam

Steam

Steam

Steam

Steam

Dowtherm

Dowtherm

Water

Light oils

Heavy oils

Organic solvent

Gases

Gases

Heavy oils

250-750

50-150

10-80

100-200

5-50

4-40

8-60

1420-4250

300-850

60-170

570-1140

30-300

20-200

45-340

Water

Organic solvents

Light oils

Heavy oils (vacuum)

Refrigerants

Refrigerants

350-750

100-200

80-180

25-75

75-150

30-100

2000-4250

570-1140

455-1020

140-425

425-850

170-570

Water

Water

Water

Water

Water

Light oil

Brine

Brine

Brine

Organic solvents

Heavy oils

150-300

50-150

3-50

60-160

10-50

20-70

100 200

30-90

3-50

20-60

8-50

850-1700

280-850

17-280

340-910

60-280

115-400

570-1140

170-510

20 -280

115-340

45-280

Evaporators

Steam

Steam

Steam

Organic solvents

Heat exchangers (no change of state)

Water

Organic solvents

Gases

Light oils

Heavy oils

Organic solvents

Water

Organic solvents

Gases

Organic solvents

Heavy oils

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

72

Table 5. Order of Magnitude of Individual Film Coefficients

Condition

h, Btu/ (h) (ft2) (F)

Dropwise condensation of steam

Film-type condensation of steam

Boiling water

Film- type condensation of organic vapors

Heating or cooling of water

Heating or cooling of organic solvents

Heating or cooling of oils

Superheated steam

Heating or cooling of air

(Low value for free convectionhigh value for forced convection)

10,000-20,000

1,000-3,000

300-9,000

200-400

50-3,000

30-500

10-120

5-30

0.2-20

Table 6. Approximate Design Values of Overall Heat Transfer Coefficient

The following values of overall heat transfer coefficients are based primarily on results obtained

in ordinary engineering practice. The values are approximate because variation in fluid velocities,

amount of non-condensable gases, viscosities, cleanliness of heat-transfer surfaces, type of baffles,

operating pressure and similar factors can have a significant effect on the overall heat-transfer

coefficient. The values are useful for preliminary design estimates or for rough cheeks on heat transfer

calculations.

Upper range of overall coefficient given for coolers may also be used for condensors. Upper

range of overall coefficient given for heaters may also be used for evaporators.

Units of coefficients are Btu/ (h) (ft2) (F)

Hot fluid

Water

Methanol

Ammonia

Aqueous solutions

Light organics-viscosities less than 0.5

CP(benzene, toluene, acetone, ethanol,

Gasoline, light kerosene, and naphtha)

Medium organics-viscosities between 0.5

And 1.0 cP (kerosene, straw oil, hot gas

Oil, hot absorber oil some crude oils )

Heavy organics-viscosities greater than

1.0cP (cold gas oil lube oil fuel oils,

reduced crude oils, tars, and asphalts )

Gases

Water

light organics

Cold fluid

Fouling

coefficient

hd

Overall

coefficient

Ud

Coolers

Water

Water

Water

Water

1000

1000

1000

1000

250-500

250-500

250-500

250-500

Water

300

75-150

Water

300

50-125

Water

Water

Brine

Brine

300

300

300

300

5-75

2-50

100-200

40-100

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

73

Table 6. Approximate Design Values of Overall Heat-Transfer Coefficients

(continued)

Units of coefficients are Btu/ (h) (ft2) (F)

Hot fluid

Cold fluid

Heaters

Water

Methanol

Ammonia

Aqueous solutions

Less than 2.0 cP

More than 2.0 cP

Light Organics

Medium Organics

Heavy Organics

Gases

Gases

Heavy Organics

Steam

Steam

Steam

Steam

Steam

Steam

Steam

Steam

Dowtherm

Dowtherm

Exchangers (no phase change)

Water

Aqueous solutions

Light Organics

Medium Organics

Heavy Organics

Light Organics

Heavy Organics

Water

Aqueous solutions

Light Organics

Medium Organics

Heavy Organics

Heavy Organics

Light Organics

Fouling

coefficient

hd

Overall

coefficient

Ud

1000

1000

1000

200-700

200-700

200-700

1000

1000

300

300

300

300

300

300

200-700

100-500

100-200

50-100

6-60

5-50

4-40

6-60

1000

1000

300

300

300

300

300

250-500

250-500

40-75

20-60

10-40

30-60

10-40

Table 7. Numbers of Tubes in Conventional Tubes Heat Layouts

Shell

ID, dS

in

Square

Pitch

One-pass

Triangular

Pitch

8

12

15

21

25

31

37

32

81

137

277

413

657

934

37

92

151

316

470

745

1074

8

12

15

21

25

31

37

21

48

81

177

260

406

596

21

55

91

199

294

472

674

Square

Pitch

Two-pass

Triangular

Pitch

Square

Pitch

Four-pass

Triangular

Pitch

-in. OD tubes on 1-in pitch

26

76

124

270

394

640

914

30

82

138

302

452

728

1044

20

68

116

246

370

600

886

24

76

122

278

422

678

1012

16

52

86

188

282

454

664

14

40

68

158

238

380

562

16

48

80

170

256

430

632

1-in. OD tubes on 1-in pitch

13

45

76

166

252

398

574

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

74

Tube Counts for Split Ring Floating Head Exchanges

Shell Inside

Diameter

Tube Bundle

Circle

Tube Size and Pitch

1 Pass

2 Pass

4 Pass

6 Pass

50

38

32

37

46

32

26

30

42

26

20

24

40

24

20

24

88

62

52

61

86

56

52

52

74

47

40

40

70

42

36

36

1

1

137

109

80

90

132

98

74

84

112

86

68

76

110

82

68

74

1

1

181

127

95

110

165

114

90

101

150

96

81

90

142

90

77

82

1

1

244

170

138

163

230

160

132

162

216

140

116

136

208

136

112

133

5/8

13/16

339

239

188

211

322

224

178

201

298

194

168

181

288

188

164

176

410

301

236

273

394

282

224

256

376

252

216

242

366

244

208

236

478

361

278

318

462

342

264

308

442

314

246

279

426

306

240

269

1

1

578

442

341

381

558

420

321

369

530

386

308

349

518

378

296

326

1

1

698

532

413

470

676

506

391

452

640

408

370

422

630

446

360

394

1

1

824

637

465

559

800

602

452

534

766

550

427

488

760

536

418

474

5/8

13/16

966

721

554

630

944

692

542

604

904

640

525

556

890

620

509

538

5/8

1

8

8

10

12

6.8

8.77

3

4

10

1

1

5/8

13/16

13

12

1

1

5/8

13/16

5/8

1

4

15

1

4

17

1

4

19

21

1

4

23

14

16

18

19 21

1

2

21

25

23

27

28

25

3

4

27

13/16

15/16

13/16

15/16

15/16

1

1

5/8

13/16

15/16

1

1

5/8

13/16

15/16

1

1

5/8

13/16

5/8

3

4

15/16

5/8

3

4

15/16

5/8

1

4

15/16

13/16

15/16

13/16

15/16

13/16

15/16

15/16

1

1

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

Table 11-3. TUBE-SHEET TUBE HOLE COUNT

A. o. d. tubes on

Shell

i. d.,

in.

8

10

12

13

15

17

19

21

23

25

27

29

31

33

35

37

39

42

45

48

54

60

1

55

88

140

178

245

320

405

502

610

700

843

970

1127

1288

1479

1647

1840

2157

2511

2865

3656

4538

13

16

square pitch

TEMA P or S

Number of passes

2

4

48

34

78

62

138

112

172

146

232

208

308

274

392

352

484

442

584

536

676

618

812

742

942

868

1096

1014

1250

1172

1438

1330

1604

1520

1794

1700

2112

2004

2458

2326

2808

2686

3600

3462

4472

4310

6

24

56

100

136

192

260

336

424

508

600

716

840

984

1148

1308

1480

1664

1968

2288

2656

3404

4256

TEMA U

Number of passes

2

4

6

52

40

32

90

80

74

140

128

108

180

164

148

246

232

216

330

312

292

420

388

368

510

488

460

626

596

562

728

692

644

856

816

780

998

956

920

1148

1108

1060

1318

1268

1222

1492

1436

1388

1684

1620

1568

1882

1816

1754

2196

2136

2068

2530

2464

2402

2908

2832

2764

3712

3624

3556

4608

4508

4426

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

75

TRANSFERENCIA DE CALOR VOLUMEN I

B. o. d. tubes on

Shell

i. d.,

in.

8

10

12

13

15

17

19

21

23

25

27

29

31

33

35

37

39

42

45

48

54

60

66

72

78

84

90

96

108

120

15

16

76

triangular pitch

TEMA L or M

Number of passes

1

2

4

6

64

48

34

24

85

72

52

50

122

114

94

96

151

142

124

112

204

192

166

168

264

254

228

220

332

326

290

280

417

396

364

348

495

478

430

420

579

554

512

488

676

648

602

584

785

762

704

688

909

878

814

792

1035

1002

944

920

1164

1132

1062

1036

1304

1270

1200

1168

1460

1422

1338

1320

1703

1664

1578

1552

1960

1918

1830

1800

2242

2196

2106

2060

2861

2804

2682

2660

3527

3476

3360

3300

4292

4228

4088

4044

5116

5044

4902

4868

6034

5964

5786

5740

7005

6934

6766

6680

8093

7998

7832

7708

9203

9114

8896

8844

11696 11618 11336 11268

14459 14378 14080 13984

1

34

60

109

126

183

237

297

372

450

518

618

729

843

962

1090

1233

1365

1611

1875

2132

2730

3395

TEMA P or S

Number of passes

2

4

32

16

62

52

98

78

120

106

168

146

228

202

286

258

356

324

430

392

498

456

602

548

708

650

812

744

934

868

1064

990

1196

1132

1346

1266

1580

1498

1834

1736

2100

1998

2684

2574

3346

3228

6

18

44

68

100

136

192

248

316

376

444

532

624

732

840

972

1100

1244

1464

1708

1964

2536

3196

TEMA U

Number of passes

2

4

6

32

24

24

64

52

52

98

88

78

126

116

108

180

160

148

238

224

204

298

280

262

370

352

334

456

428

408

534

500

474

628

600

570

736

696

668

846

812

780

978

928

904

1100 1060 1008

1238 1200 1152

1390 1336 1290

1632 1568 1524

1882 1820 1770

2152 2092 2044

2748 2680 2628

3420 3340 3286

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

C. o. d. tubes on 1 square pitch

Shell

i. d.,

in.

8

10

12

13

15

17

19

21

23

25

27

29

31

33

35

37

39

42

45

48

54

60

1

28

52

80

104

136

181

222

289

345

398

477

554

637

730

828

937

1048

1224

1421

1628

2096

2585

TEMA P or S

Number of passes

2

4

26

16

48

44

76

66

90

70

128

128

174

154

220

204

272

262

332

310

386

366

456

432

532

510

624

588

712

682

812

780

918

882

1028

996

1200

1170

1394

1350

1598

1548

2048

2010

2552

2512

6

12

24

56

80

114

160

198

260

308

344

424

496

576

668

760

872

972

1140

1336

1536

1992

2476

TEMA U

Number of passes

2

4

6

28

24

12

52

44

32

78

72

70

96

92

90

136

132

120

176

176

160

224

224

224

284

280

274

348

336

328

408

392

378

480

468

460

562

548

530

648

636

620

748

728

718

848

820

816

952

932

918

1056

1044

1020

1244

1224

1212

1436

1408

1398

1640

1628

1602

2108

2084

2068

2614

2584

2558

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

77

TRANSFERENCIA DE CALOR VOLUMEN I

D. o. d. tubes on

Shell

i. d.,

in.

8

10

12

13

15

17

19

21

23

25

27

29

31

33

35

37

39

42

45

48

54

60

66

72

78

84

90

96

108

120

15

16

78

triangular pitch

TEMA L or M

Number of passes

1

2

4

6

42

40

26

24

73

66

52

44

109

102

88

80

136

128

112

102

183

172

146

148

237

228

208

192

295

282

258

248

361

346

318

320

438

416

382

372

507

486

448

440

592

574

536

516

692

668

632

604

796

774

732

708

909

886

836

812

1023

1002

942

920

1155

1124

1058

1032

1277

1254

1194

1164

1503

1466

1404

1372

1726

1690

1622

1588

1964

1936

1870

1828

2519

2466

2380

2352

3095

3058

2954

2928

3769

3722

3618

3576

4502

4448

4324

4280

5309

5252

5126

5068

6162

6108

5964

5900

7103

7040

6898

6800

8093

8026

7848

7796

10260 10206 9992

9940

12731 12648 12450 12336

1

31

56

88

121

159

208

258

320

400

450

543

645

741

843

950

1070

1209

1409

1635

1887

2399

2981

TEMA P or S

Number of passes

2

4

26

16

48

42

78

62

106

94

148

132

198

182

250

228

314

290

384

352

442

400

530

488

618

574

716

666

826

760

930

878

1052

992

1184

1122

1378

1314

1608

1536

1842

1768

2366

2270

2940

2832

6

12

40

68

88

132

180

220

276

336

392

468

556

648

740

856

968

1096

1296

1504

1740

2244

2800

TEMA U

Number of passes

2

4

6

32

24

24

52

48

40

84

76

74

110

100

98

152

140

136

206

188

182

266

248

234

330

316

296

400

384

356

472

440

424

554

528

502

648

616

588

744

716

688

852

816

788

974

932

908

1092 1056 1008

1224 1180 1146

1434 1388 1350

1652 1604 1560

1894 1844 1794

2426 2368 2326

3006 2944 2884

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

TRANSFERENCIA DE CALOR VOLUMEN I

E. 1 o. d. tubes on 1 square pitch

Shell

i. d.,

in.

8

10

12

13

15

17

19

21

23

25

27

29

31

33

35

37

39

42

45

48

54

60

1

17

30

52

61

85

108

144

173

217

252

296

345

402

461

520

588

661

776

900

1029

1310

1641

TEMA P or S

Number of passes

2

4

12

8

30

16

48

42

56

52

78

62

108

104

136

130

166

154

208

194

240

230

280

270

336

310

390

366

452

432

514

494

572

562

640

624

756

738

882

862

1016

984

1296

1268

1624

1598

6

12

18

24

50

64

96

114

156

192

212

260

314

368

420

484

548

620

724

844

972

1256

1576

TEMA U

Number of passes

2

4

6

14

8

6

30

24

12

44

40

32

60

48

44

80

72

74

104

100

100

132

132

120

172

168

148

212

204

198

244

240

230

290

284

274

340

336

328

400

384

372

456

444

440

518

504

502

584

576

566

664

644

640

764

748

750

902

880

862

1028

1008

1004

1320

1296

1284

1634

1616

1614

Universidad Mayor Dr. Carlos Martnez Pavez - Marzo 2002

79

TRANSFERENCIA DE CALOR VOLUMEN I

80

F. 1 o. d. tubes on 1 triangular pitch

Shell

i. d.,

in.

8

10

12

13

15

17

19

21

23

25

27

29

31

33

35

37

39

42

45

48

54

60

66

72

78

84

90

96

108

120

1

27

42

64

81

106

147

183

226

268

316

375

430

495

579

645

729

808

947

1095

1241

1577

1964

2390

2861

3368

3920

4499

5144

6546

8117

TEMA L or M

Number of passes

2

4

26

8

40

34

66

52

74

62

106

88

134

124

176

150

220

204

262

236

302

274

360

336

416

390

482

452

554

520

622

586

712

662

792

744

918

874

1068

1022

1220

1176

1572

1510

1940

1882

2362

2282

2828

2746

3324

3236

3882

3784

4456

4370

5104

4986

6494

6360

8038

7870

6

12

24

44

56

92

114

152

186

228

272

324

380

448

504

576

648

732

868

1000

1148

1480

1832

2260

2708

3216

3736

4328

4936

6300

7812

1