Professional Documents

Culture Documents

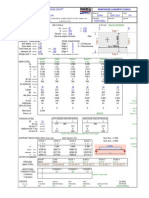

ACI 350-06 Example

Uploaded by

Ahmed Ben HmidaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACI 350-06 Example

Uploaded by

Ahmed Ben HmidaCopyright:

Available Formats

Sheet 1 of 1

NOTE:

Spreadsheet analyzes a given section of wall for flexure based on Mu for required As. Per ACI 350 - 06 - applies Sd factor (per section 9.2.6) to factored loads

Deflections are not calculated in this spreadsheet. Assumes Grade 60 Steel. Assumes single layer of flexural reinforcement. Assumes section is a rectangular beam.

Section profile is only used for checking flexural compression distance relative to flange thickness in T-sections

ENVIROMENTAL EXPOSURE AREA (PER 10.6.4.5)

Conditions in which the limits defining

normal environmental exposure are

exceeded.

SEVERE

MEMBER TYPE

ONE-WAY

CONCRETE COMPRESSIVE STRENGTH (psi), f'c (SEE TABLE 4.2.2 & 4.3.1)

Exposure Condition

Concrete exposed to freezing and

thawing in a saturated condition or to

corrosive or deicing chemicals

4500

USER OVER-RIDE (psi), f'c

0

enter 0 if over-ride is not utilized

Max. Water-Cement

Ratio, By Weight*

0.42

* A lower water-cementitious material ration or higher strength may be required

for durability of concrete exposed to sulfate (Table 4.3.1)

LENGTH BETWEEN MOVEMENT JOINTS (PER TABLE 7.12.2.1)

Minimum Shrinkage and Temperature Reinf. Ratio for Horz. Reinf.

0.0040

30 ft to less than 40 ft

Note: This data applies to spacing between expansion joints and full contraction joints.

When used with partial contraction joints, the minimum reinforcement ratio shall be determined

by multiplying the actual length between partial contraction joints by 1.5.

Section Profile =

Section Thickness =

Section Web Width, bw

R (Enter "R" for rectangular or "T" for T-section - see user notes)

12 in

12 in

Mx + Mxy Factored Moment

Mx + Mxy Service Moment

Reinforcement Bar Size

Bar Spacing =

Concrete Cover to Flexural Reinf. =

12 ft-kips/ft (per Risa 3D)

7 ft-kips/ft (per Risa 3D)

#5

8 in

2 in

3 N/A

USE 12 in. thick wall w/ #5 bars @ 8 o.c. for vertical reinforcement (min. 0.576 sq. in./section design width temp. & shrinkage reinf.)

Flexural Stress Check, fs (actual) =

d=

Flexural compression dist. a =

Moment Arm =

t=

t=

=

Strain Gradiant Amplification Factor, =

f'c (design) =

1 (design) =

Factored / Unfactored ()

Total Load Factor =

Mu w/ Total Load Factor =

As (provided) =

As (required) =

As min per 10.3a =

As min per 10.3b =

As min per 10.5.3 =

As (min) =

As(max) t<0.004 ?

As horz. (min) =

Lateral Ties for Vert. Reinf. 0.1Ag =

OK

9.69

0.5025

9.44

0.0108

0.90

1.35

4500

0.825

1.7143

2.59

18.14

0.465

0.384

0.390

0.388

0.511

0.390

OK

0.58

1.44

in

in

in

Tension Controlled

psi

(vs. Mu/Ms and with = 1.0)

ft. kips

sq. in.

sq. in.

sq. in.

sq. in.

sq. in.

sq. in.

sq. in.

sq. in.

OK

OK

OK

Not Needed

Normal Environment

fs (actual)=

fs max (lower bound) =

fs max =

fs (permissible) =

Sd =

19.14

20

25.65

25.65

1.23

ksi

ksi

ksi

ksi

OK

ONE-WAY

Severe Environment

fs (actual)=

fs max (lower bound) =

fs max =

fs (permissible) =

Sd =

19.14

17

20.84

20.84

1.51

ksi

ksi

ksi

ksi

OK

ONE-WAY

Sd (design) =

1.51

SEVERE

You might also like

- ACI 350 06 ACI224R 01 Rec Sec Flexural Crack Width Control Rev00 07 Sep 2013Document5 pagesACI 350 06 ACI224R 01 Rec Sec Flexural Crack Width Control Rev00 07 Sep 2013Aie Bantugan100% (5)

- ACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev01 - 04-Nov-2014Document13 pagesACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev01 - 04-Nov-2014jeanfatNo ratings yet

- Tables P.C.a..-.Rectangular Concrete TanksDocument377 pagesTables P.C.a..-.Rectangular Concrete TanksAdry Sarija100% (2)

- ACI 350M-06 Concrete Code RequirementsDocument487 pagesACI 350M-06 Concrete Code RequirementsKofi Daniel20% (15)

- AASHTO LRFD 2012 BridgeDesignSpecifications 6th Ed (US)Document33 pagesAASHTO LRFD 2012 BridgeDesignSpecifications 6th Ed (US)Joel H A VargasNo ratings yet

- Ring FoundationDocument4 pagesRing Foundationjorge01100% (2)

- Calculation of Environmental Durability Factor (Sd) per ACI 350-06Document2 pagesCalculation of Environmental Durability Factor (Sd) per ACI 350-06wafa100% (1)

- ACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014Document21 pagesACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014coreteamNo ratings yet

- Design of Liquid Cont A Inning Concrete Structures For EarthquakeDocument59 pagesDesign of Liquid Cont A Inning Concrete Structures For Earthquakejcvalencia100% (1)

- ACI 350 ExampleDocument1 pageACI 350 ExamplesitehabNo ratings yet

- ACI 421.1R-08 - Punching ShearDocument27 pagesACI 421.1R-08 - Punching ShearEdin Lissica75% (4)

- Aci 350.4R-04 PDFDocument18 pagesAci 350.4R-04 PDFMattStoneNo ratings yet

- Aci 350 3 Earthquake Forces in Tanks (Book)Document59 pagesAci 350 3 Earthquake Forces in Tanks (Book)Konstantinos Kalemis100% (13)

- ACI Column SheetDocument51 pagesACI Column SheetRajveer SinghNo ratings yet

- 3.0crack Width Check (Aci)Document48 pages3.0crack Width Check (Aci)klynchelle100% (1)

- Seismic Behaviour of Elevated Water TankDocument5 pagesSeismic Behaviour of Elevated Water TankFrederick TanNo ratings yet

- Asce Sei 7 22 Minimum Design Loads For Buildings andDocument2 pagesAsce Sei 7 22 Minimum Design Loads For Buildings andRoss Pour0% (2)

- ACI 350.3-06 - Seismic Desing of Liquid - Containing Concrete Structures and ComentaryDocument67 pagesACI 350.3-06 - Seismic Desing of Liquid - Containing Concrete Structures and ComentaryFilipe Gonçalves100% (7)

- Design of Neoprene Bearing Pads - DupontDocument25 pagesDesign of Neoprene Bearing Pads - Dupontnigst2100% (1)

- Pca Slab Grade Design ChartsDocument3 pagesPca Slab Grade Design ChartsTracy0% (1)

- ASTM A615-A615M-06aDocument6 pagesASTM A615-A615M-06aNadhiraNo ratings yet

- Water Tank Design (Aci 318-05 & 350-01)Document20 pagesWater Tank Design (Aci 318-05 & 350-01)Gertjan Duniceri100% (1)

- MBMAs New Low-Rise Building Systems Manual PDFDocument7 pagesMBMAs New Low-Rise Building Systems Manual PDFSudhanshu PalNo ratings yet

- DmTank Ring Wall Foundation+&+Annular+RaftDocument29 pagesDmTank Ring Wall Foundation+&+Annular+RaftpcmaraujoNo ratings yet

- ACI Detailing ManualDocument9 pagesACI Detailing Manualwinard21No ratings yet

- Aci 303.1-97Document10 pagesAci 303.1-97Carlos BernabeNo ratings yet

- Combined Systems SEAOC Blue BookDocument3 pagesCombined Systems SEAOC Blue BookHirad GrivaniNo ratings yet

- Design of Concrete Ring Beam For Storage TankDocument6 pagesDesign of Concrete Ring Beam For Storage TankMonty MathewsNo ratings yet

- Crack Check AnalysisDocument3 pagesCrack Check AnalysisFajar Fikriyansyah Sidik100% (1)

- REBARS (318-11).xlsDocument9 pagesREBARS (318-11).xlsmotiur basum100% (1)

- My - Spreadsheet - SlabDocument26 pagesMy - Spreadsheet - SlabBilal Ahmed Barbhuiya50% (2)

- Design Concrete I-Girder Bridge DeckDocument42 pagesDesign Concrete I-Girder Bridge Decksalman khanNo ratings yet

- Design of Two Way Slab by IS 456Document8 pagesDesign of Two Way Slab by IS 456Mohmmedhusain Fruitwala50% (2)

- Introduction to Steel Design Flexural Members and FactorsDocument10 pagesIntroduction to Steel Design Flexural Members and FactorsOlusegun S. Ajibola100% (1)

- Bearing Pad Design ExampleDocument16 pagesBearing Pad Design ExampleAhirul Yahya100% (1)

- SlabsDocument29 pagesSlabsPimpa Mwiinga100% (2)

- Concrete Design - Comparison is-BSDocument10 pagesConcrete Design - Comparison is-BSStephen Rajkumar JayakumarNo ratings yet

- Ce591plategirders F13Document67 pagesCe591plategirders F13cocococo1100% (1)

- 40 KL DesignDocument10 pages40 KL DesignSung Woong MoonNo ratings yet

- Semi-Integral-Abutment Design Example (USA Unit)Document20 pagesSemi-Integral-Abutment Design Example (USA Unit)Ya YangNo ratings yet

- Plate GirderDocument74 pagesPlate Girderarif_rubin100% (1)

- Structural Analysis Is A: Science, Having Definite ValueDocument34 pagesStructural Analysis Is A: Science, Having Definite ValueRamanathan SenthilNo ratings yet

- Two Way Slab DesignDocument9 pagesTwo Way Slab DesignChan Kin Cheung100% (1)

- Slab DesignDocument23 pagesSlab DesignRajendra AcharyaNo ratings yet

- Min Reinf To - BS 8007 and Crack Width - NZS 3106 - 2009 - MH01 PDFDocument2 pagesMin Reinf To - BS 8007 and Crack Width - NZS 3106 - 2009 - MH01 PDFAnonymous 9LWbwMZNNo ratings yet

- Cladding Annex 1Document7 pagesCladding Annex 1dawg1503No ratings yet

- TransferDiaphragm WoodDocument1 pageTransferDiaphragm WoodMarianne Aravilla Dela CruzNo ratings yet

- Einforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcreteDocument24 pagesEinforced Oncrete: Bridge Design Manual - 2002 Reinforced Concretetonying86No ratings yet

- Einforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcreteDocument24 pagesEinforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcretemuradNo ratings yet

- 3.10.1 - LRFD Pile Design - 2Document15 pages3.10.1 - LRFD Pile Design - 2Minahil SherazNo ratings yet

- Flooring Design GuideDocument81 pagesFlooring Design GuideArmin KovacevicNo ratings yet

- LRFD Deck Design Using Strip MethodDocument17 pagesLRFD Deck Design Using Strip MethodSachin SithikNo ratings yet

- Reinforced Isolation Joint DesignDocument11 pagesReinforced Isolation Joint DesigncalidadjmsingNo ratings yet

- Rclect5 11Document24 pagesRclect5 111man1bookNo ratings yet

- Tension Member Design-1Document39 pagesTension Member Design-1Arfan Haider100% (2)

- Conc Short ColDocument13 pagesConc Short ColEngDbtNo ratings yet

- 1-RC DesignDocument4 pages1-RC DesignOSCARTAWNNo ratings yet

- T.7.7.6 Shrinkage Curvature: RAPT User ManualDocument16 pagesT.7.7.6 Shrinkage Curvature: RAPT User Manualtailieuxaydung2019No ratings yet

- Design of Slabs-on-Ground (ACI 360R-06Document7 pagesDesign of Slabs-on-Ground (ACI 360R-06Ivan Pacompia Calcina50% (2)

- RC Slab Design (BS8110)Document5 pagesRC Slab Design (BS8110)Mike0% (1)

- Fill in RulesDocument1 pageFill in RulesAhmed Ben HmidaNo ratings yet

- Geometrical DescriptionDocument1 pageGeometrical DescriptionAhmed Ben HmidaNo ratings yet

- Geometrical DescriptionDocument1 pageGeometrical DescriptionAhmed Ben HmidaNo ratings yet

- AaaaaaaaaaaaaaaaaaaaaaDocument32 pagesAaaaaaaaaaaaaaaaaaaaaaAhmed Ben HmidaNo ratings yet

- Ferraillage plan de poteaux et dalles béton arméDocument1 pageFerraillage plan de poteaux et dalles béton arméAhmed Ben HmidaNo ratings yet

- Node Displacement Summary: Job No Sheet No RevDocument1 pageNode Displacement Summary: Job No Sheet No RevAhmed Ben HmidaNo ratings yet

- Thrust BlockDocument3 pagesThrust BlockAhmed Ben HmidaNo ratings yet

- Geometrical Description: WATER TANK Geometry DEGASSER GeometryDocument1 pageGeometrical Description: WATER TANK Geometry DEGASSER GeometryAhmed Ben HmidaNo ratings yet

- Cementatious Grout DASDocument3 pagesCementatious Grout DASAhmed Ben HmidaNo ratings yet

- Structural steel shapes and propertiesDocument176 pagesStructural steel shapes and propertiesAhmed Ben HmidaNo ratings yet

- 7357.what's New in STAAD Foundation Advanced 61Document27 pages7357.what's New in STAAD Foundation Advanced 61Panneer Selvam EaswaranNo ratings yet

- RESOLTECH Chemical Resistance GuideDocument45 pagesRESOLTECH Chemical Resistance GuideAhmed Ben HmidaNo ratings yet

- Description and Job SpecificationDocument10 pagesDescription and Job SpecificationAhmed Ben HmidaNo ratings yet

- Facture C3 ShineDocument1 pageFacture C3 ShineAhmed Ben HmidaNo ratings yet

- SA Journal of Tech 2016Document90 pagesSA Journal of Tech 2016mack_eausNo ratings yet

- Hand Calculations 2 Way Flat Plate SlabDocument18 pagesHand Calculations 2 Way Flat Plate SlabAhmed Ben HmidaNo ratings yet

- Ferraillage plan de poteaux et dalles béton arméDocument1 pageFerraillage plan de poteaux et dalles béton arméAhmed Ben HmidaNo ratings yet

- Aciers Mottard 1 6 PDFDocument2 pagesAciers Mottard 1 6 PDFAhmed Ben HmidaNo ratings yet

- Peyrot WindDocument25 pagesPeyrot WindMuhannad AbdulRaoufNo ratings yet

- Sustainability at HDRDocument4 pagesSustainability at HDRAhmed Ben HmidaNo ratings yet

- Isolated Footing Design (ACI 318-11) : ElevationDocument12 pagesIsolated Footing Design (ACI 318-11) : ElevationAhmed Ben HmidaNo ratings yet

- EPD Mineral Wool Panel PRMDocument7 pagesEPD Mineral Wool Panel PRMAhmed Ben HmidaNo ratings yet

- Geometric Properties of The Cross-Section Parameter Value: Interval of The Stresses Values: (,) KN/CM 2 - 6,66e+2Document2 pagesGeometric Properties of The Cross-Section Parameter Value: Interval of The Stresses Values: (,) KN/CM 2 - 6,66e+2Ahmed Ben HmidaNo ratings yet

- Structural Enterprise Infographic 0417Document1 pageStructural Enterprise Infographic 0417Ahmed Ben HmidaNo ratings yet

- Metallic Materials for FGD SystemsDocument21 pagesMetallic Materials for FGD SystemsClaudia MmsNo ratings yet

- Above Ground Pipe Installation With Non-Restrained JointsDocument36 pagesAbove Ground Pipe Installation With Non-Restrained JointsWerner100% (1)

- Pole LoadingDocument27 pagesPole LoadingKho C AhlNo ratings yet

- FLOWTITE Install GuideDocument72 pagesFLOWTITE Install GuideRanjit RjtNo ratings yet

- TrnsLine PDFDocument495 pagesTrnsLine PDFMomayKradookkradicNo ratings yet

- Sika Casestudy HighstrengthDocument7 pagesSika Casestudy HighstrengthAhmed Ben HmidaNo ratings yet

- Principles of Shear SlittingDocument26 pagesPrinciples of Shear SlittingMaureen Baird100% (1)

- Santiago Calatrava Liège Guillemins TGV Station: Model Photo: Heinrich HelfensteinDocument17 pagesSantiago Calatrava Liège Guillemins TGV Station: Model Photo: Heinrich HelfensteinMuhammad Fuad AlhudaNo ratings yet

- A A 59326BDocument17 pagesA A 59326Bcvz240159No ratings yet

- Bulk Carrier Inspection in Critical AreasDocument5 pagesBulk Carrier Inspection in Critical AreasAbdel Nasser Al-sheikh YousefNo ratings yet

- Api 574Document3 pagesApi 574kirubha_karan2000100% (1)

- Maruti SuzukiDocument16 pagesMaruti SuzukiMohammed Salman67% (3)

- Voyage Charter Example PDFDocument39 pagesVoyage Charter Example PDFNguyễn Phương Liên100% (1)

- How To Start A Flight Training UnitDocument48 pagesHow To Start A Flight Training UnitWilliam Rios100% (1)

- Pharma Test Dissolution Testing Portfolio BrochureDocument5 pagesPharma Test Dissolution Testing Portfolio Brochurefatih usluNo ratings yet

- Viking FP So PresentationDocument21 pagesViking FP So PresentationJym Genson100% (1)

- Super BAZZAR InfoDocument39 pagesSuper BAZZAR InfoSonali ShiralkarNo ratings yet

- EFUDocument57 pagesEFUAyesha MalikNo ratings yet

- Index Siemens Smoke DetectorsDocument5 pagesIndex Siemens Smoke Detectorsajaydce05No ratings yet

- 002 PCAR Personnel Licensing (2) 2011Document216 pages002 PCAR Personnel Licensing (2) 2011Carl Vir AmabaoNo ratings yet

- 11 2Document4 pages11 2Logadhasan SuwedanNo ratings yet

- 13 Chapter 5Document64 pages13 Chapter 5yoganaNo ratings yet

- Quality Parts Case StudyDocument5 pagesQuality Parts Case Studyesmeralda6333% (3)

- Value Chain StrategyDocument21 pagesValue Chain StrategyDonald PicaulyNo ratings yet

- IMT 69 Logistics and Supply Chain Management M2Document4 pagesIMT 69 Logistics and Supply Chain Management M2solvedcareNo ratings yet

- Pedestrian Mobility and Safety Audit GuideDocument48 pagesPedestrian Mobility and Safety Audit GuidePaco TrooperNo ratings yet

- Basf Masterbrace 4500 TdsDocument2 pagesBasf Masterbrace 4500 TdsShivanan SinghNo ratings yet

- High-Capacity Production and MachineryDocument3 pagesHigh-Capacity Production and MachineryMark Justin LicuanNo ratings yet

- C-146A, USA - Wolfhound Transport AircraftDocument13 pagesC-146A, USA - Wolfhound Transport Aircrafthindujudaic100% (1)

- Tank Cleaning Guide - BP New 2006Document1 pageTank Cleaning Guide - BP New 2006reda hmr100% (1)

- Tank Storage Magazine Edisi Okt 2014 (Pages 36-70)Document35 pagesTank Storage Magazine Edisi Okt 2014 (Pages 36-70)samyomatrixNo ratings yet

- Laser Cutting Sheet Metal Fabrication Melior Laser Company Intro 05 2013Document14 pagesLaser Cutting Sheet Metal Fabrication Melior Laser Company Intro 05 2013Kirke71No ratings yet

- Improving APQP Process For Effective Program Execution: Dele AwofalaDocument31 pagesImproving APQP Process For Effective Program Execution: Dele AwofalaSelvaraj SNo ratings yet

- E 22 Mashop IDocument11 pagesE 22 Mashop ISi Aniel TohNo ratings yet

- A Tangled WebDocument78 pagesA Tangled WebElizabeth HayesNo ratings yet

- Tool and Die Maker PDFDocument9 pagesTool and Die Maker PDFArun PrasathNo ratings yet