Professional Documents

Culture Documents

Electron Beam Drilling-Ebopulse

Uploaded by

pil;zoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electron Beam Drilling-Ebopulse

Uploaded by

pil;zoCopyright:

Available Formats

The idea drilling without tool wear

EB drilling process

The first electron beam machine was a

drilling machine which was used for

drilling holes in the jewel bearings of

watches. It was developed by the

physicist Karl-Heinz Steigerwald at

Carl Zeiss in the early "fifties".

47.20.01e/16

The machine utilized the high kinetic

energy of accelerated electrons and

the facility for focussing them to a high

power density. It is this property that

enables materials to be melted and

vaporised.

Use was also made of the advantage

of deflecting the electron beam virtually inertia-free by simple means.

At that time, single drill-holes were

produced per workpiece. Today, the

electron beam or EB drilling process is

particularly economical when it comes

to drilling many holes in one workpiece. Workpieces with tens of thousands or even millions of drill-holes

are no exception. And drilling frequencies of up to 3000 drill-holes per

second are no dream.

Page 2

Maximum energy density and

ultra-precise positioning

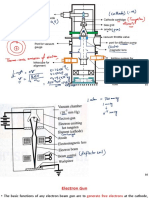

Beam generation

Drilling depth effect

Backing material

An electrically heated cathode

produces electrons which are

accelerated to three-fifths the speed

of light by the electrical field applied

between the cathode and anode at a

voltage of 120 kV. A modulating

electrode controls the intensity of the

diverging electron beam which is

focussed onto the workpiece through

an electromagnetic lens to power

densities of 108 W/cm2 and above.

With almost all materials, the power

density of 108 W/cm2 is sufficient to

produce a vapour capillary in the

material which is surrounded by a

cylinder of molten material. The

vapour capillary constitutes the basic

hole.

In order to ensure close diameter tolerances from one drill-hole to another,

a backing material which produces a

large volume of gas through the

effects of the electron beam is employed on the reverse side of the

workpiece to be drilled. This gas

expands explosively through the capillary and ejects the cylinder of molten

material surrounding the capillary.

5 mm

0.5

2.5

5.0

5.5

[ms]

The principle of EB drilling

Drilling pulse

The electron beam works with a steep

current pulse and sharp up-slope and

down-slope edges at the drilling position. The main drilling parameters are

controlled very precisely. The pulse

time and the beam current level of the

pulse ensure that a highly reproducible

quantity of energy is made available

from pulse to pulse where no variation

in pulse energy is desired.

Flying drilling

The high frequencies used for drilling

with the electron beam result from an

optimized combination of the deflection of the beam, the workpiece

manipulating device and a process

control which fulfils all the require

ments of sophisticated EB applications. The workpiece is continuously

rotated in the drilling process. During

the drilling operation, the beam is

simultaneously moved along the workpiece surface.

In between drilling operations, the

beam is cut off and is restarted exact

at the new drilling position with the

next drilling pulse.

No competitive drilling process uses

this so-called flying drilling technique

which forms the basis of the outstanding efficiency of EB drilling technology.

Steigerwald drilling technology is an

unrivalled expertise. There are numerous industrial applications for the EB

drilling process - a technology that is

technically mastered by Steigerwald

Strahltechnik. The optimum results are

obtained in terms of drill-hole shape,

reproducibility of shape, roundness

and diameter tolerance from hole to

hole with the single pulse method in

which only one pulse is used per drillhole. This process calls for power of a

magnitude which can only be provided

by a new switched-mode high voltage

power supply with a direct bias control

and a Steigerwald drilling generator power which no other drilling technology can match.

Page 3

EB drilling in action

Hard material - no problem

Virtually all metallic materials as well as

ceramics can be drilled with the electron

beam, regardless of their hardness,

reflectivity, special alloy components or

high thermal conductivity. The illustrations show workpieces comprising hightemperature alloys which cannot be

Combustion chamber housing

3,746 drill-holes with 0.9 mm diameter

47.45.01

Spinner used in glass fibre production

47.45.01b/7

25,600 drill-holes with 0.55 mm diameter

drilled at all with other drilling processes

or only considerably less efficiently.

a40

Hole pattern, hole angle freely selected positioning

The permissible minimum distance between drill-holes (a) is of the order of

two to three times the hole diameter (d)

and is dependent on the dimensions of

the hole. For example, holes with a diameter of 0.9 mm can be made in

7 mm thick material at intervals of twice

the hole diameter. In the case of

extremely small drill-holes with free

diameters of 0.1 mm in 0.5 mm thick

sheet, the minimum distance between

drill-holes is three times the hole

diameter. The conical form of small

drill-holes with large diameter to depth

ratios (1:8 to 1:10) places restrictions

on the distance between drill-holes in

this example. If one uses the densest

possible hole arrangement, open areas

of up to 22 % can be achieved.

d10

Limits for the distance between drill-holes

Mixer disc

47.45.01g/03

2,340 drill-holes with 0.9 mm diameter

The accuracy of the drilling positions

is dependent both on the workpiece dimensions and on the positioning accuracy of the manipulating equipment.

For example, a positioning tolerance of

14 m is achieved on a sheet which

is clamped on a rotation / linear-feed

unit with the 630 mm drum.

The centre line of the drilled holes can

be inclined at an angle to the surface of

the workpiece. This is possible over a

wide range whereby angles of 25 in

relation to the workpiece surface can

be achieved; 20 is possible in exceptional cases.

Page 4

Shapes of EB drill-holes

Typical shapes of drill-hole cross-sections

0.1 mm

0.5 mm

1.0 mm

3.0 mm

Drill-hole shape

EB drilling can produce the drill-hole

shapes shown in the diagram.

Specifically required forms can be

obtained by varying and optimising

the work parameters over a wide

range. The diameter-to-length ratio

also influences the drill-hole shape.

At the beam entry point, the drill-hole

normally features a slight rounding.

The edge at the beam exit point is

always sharp and burr-free.

5.0 mm

Metallurgy minimum thermal influence

The EB drilling process is a thermal

process. The material to be removed

is locally heated, melted and partly

vaporised. Although the major part of

the molten material around the vapour

capillary is ejected, a thin, 5 - 10 m

thick, resolidified layer is left behind

on the wall of the drill-hole.

8.0 mm

No oxidation is likely in these layers

as the drilling process is carried out

under vacuum.

Cross-sections of EB drill-holes

in CrNi steel

Page 5

EB drilling technology hole sizes and drilling frequencies

Application range for EB drilling

Electron beam drilling speed

with single pulse technique

The green marked area of the diagram

shows the range of applications for drilling ferrous materials covered by the

standard generator G 96 PM.

Fast up to 2000 drill-holes per second

An important advantage of electron

beam drilling lies in the high drilling frequencies which no other process can

match. The diagram shows the relationship between the drilling frequency and

the length of the drill-hole.

For example, 100 m diameter drillholes can be drilled in 0.3 mm filter

sheet at frequencies of 1500 to 2000

holes per second. In this example, each

individual hole has a volume of around

0.004 mm3. With larger drill-holes of, for

instance, 0.7 mm diameter and 5 mm

length, frequencies up to nearly 20 Hz

are possible. Here, the drill-hole volume

is approximately 2 mm3.

The diagram assumes that the holes are

drilled in a suitable drill-hole arrangement on a cylindrical workpiece

which permits the use of flying drilling.

G 33 PM

G 96 PM

G 120 PMS

Hole

0.1

0.2

1000

0.3

Holes per second

For drilling very small holes as for example with a diameter of only 50 m in

0.3 mm thick stainless steel sheets the

special generator G 33 PM is available. Contradictory to this the high

power generator G 120 PMS extends

the drilling range to hole diameters up

to 1.1 mm and 7 mm in length. The application boundaries can vary with other

base metals.

5000

0.4

0.5

0.6

100

0.7

0.8

0.9

1.0

1.1

1.2

10

5

0.05

1.0

0.1

10

Hole length (mm)

Application range for EB drilling

Laboratory tests have also been carried

out at Steigerwald Strahltechnik with

multiple pulse drilling. This technique is

used only in isolated industrial

applications.

In high-frequency trepanning, the pulses

are positioned along given contours by

means of a computer control.

The drilling of oval holes or slots in thin

sheets is particularly straight-forward.

Even at high drilling speeds, it is possible to vary the process parameters In the percussion process for producing

from hole to hole as all parameters are deep holes by multiple pulses, the focal

point of the electron beam is controlled

outputted as electrical quantities.

right inside the drill-hole.

Page 6

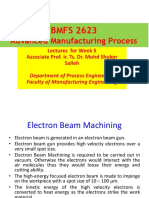

The electron beam

drilling gun

The EB-generator, the work chamber

with the workpiece manipulating unit,

the vacuum installation and the CNC

control are the main assemblies of a

drilling machine.

The generator

On standard machines, the EB generator is mounted vertically on the

work chamber. It consists of several

sections.

The top section contains the beam

generating system comprising the

thermally operated cathode, the

Wehnelt cylinder and the anode. An

accelerating voltage of 120 kV is applied between the cathode and anode.

The vacuum system of the generator,

consisting of the turbomolecular pump,

the backing pump, gauge heads and

valves, is connected to the second

section. When the work chamber is

vented for changing the workpieces, a

valve protects the beam generating

section from the work chamber with a

vacuum-tight seal.

The third section is an intermediate

control tube which is added due to

electron-optical reasons.

The fourth section contains a movable

Faraday cup and the beam diagnosis

system which monitors the intensity of

the beam.

Drilling generator G 120 PMS

The fourth section is followed by the

electromagnetic system containing the

focussing lens, stigmators and the

beam spot following system which

makes flying drilling possible.

The only replacement part is the inexpensive filament of the cathode.

A screening device below the generator ensures that the material which is

ejected during the drilling process cannot enter the generator and cause

malfunctions.

Excellent beam properties are a vital

prerequisite for good drilling results.

The roundness of the beam, the constancy of its diameter and the symmetry of the energy distribution in the

beam are the most important features

here. Therefore, the requirements that

must be fulfilled by an electron beam

An EB drilling generator has no wearing parts - unlike a solid-state laser.

Beam quality the key to drill-hole quality

P47.20.02 f2

for drilling are much more stringent

than for welding. The beam current,

the pulse duration, the current of the

focussing lens and the working

distance are the main parameters in

the drilling process.

Page 7

Sophisticated manipulator systems

The chamber

The size of the work chamber is determined by the size of the workpieces and

by the drilling application. Various workpiece manipulating units are available to

suit different workpiece types and drilling

duties.

Rotation/feed units (PDS) for flat workpieces (sheets) and 4 or 5-axis manipulators for symmetrical and asymmetrical

shaped workpieces have proved successful as standard manipulating units.

The PDS unit, with adjustment in the zaxis, accepts sheets which are loaded in

cylinder form on a drum or other cylindrical workpieces. The backing material is

pressed on from inside either mechanically or pneumatically or is poured on so

that it adheres to the reverse side of the

sheet. During the drilling process, the

drum is rotated continuously beneath the

beam. When one row of holes is finished,

the x axis adjustment facility pushes the

drum into position for the next row. The

mechanical height adjustment of the drum

shaft allows the optimum working distance

to be set for the drum or workpiece

diameter concerned.

Workpieces of other shapes can be positioned by means of multi-axis manipulators. Two or three linear axes and two rotational axes offset by 90 permit virtually

any drilling position in relation to the beam

axis, including for applications involving

holes to be drilled at an angle to the workpiece surface.

4-axes manipulator 'oszillant'

47.20.01b/3

Schemes of the manipulator systems

A rotation/feed unit and a 4-axis manipulator can also be combined on a single

chamber. In this case, the 4-axis manipulator is arranged on a mobile slide with its

own chamber door on the left-hand side of

the chamber, while the rotation/feed unit is

arranged - likewise with its own chamber

door - on the right.

Custom-designed machine concepts can

be realized for drilling duties which cannot

be fulfilled with standard equipment.

Rotation/Linear-feed unit PDS 3-12

47.20.02b/18

Page 8

The control console

Two control systems which communicate with each other form the command centre of a drilling machine - a

freely programmable control (PLC) for

the logic sequences of the machine

and a process control (CNC) which

controls the drilling process.

The process control and the PLC are

linked via a data and signal transfer

line to enable the EB drilling machine

to be operated with automatic work

sequences. Apart from observing the

machine, all what the operators have

to do is change the workpieces and

start the automatic process.

The control console of a drilling

machine consists of:

- the integrated CNC/PLC monitor

- the CNC keyboard

- a control panel

- optionally a video monitor

The CNC process control

The EBCON 6 CNC control has been

specially developed for EB drilling

applications. It is the sole key to the

efficient use of EB technology, the

precision of the process and the

flexibility of the drilling systems for

different drilling applications.

The CNC is extremely simple to operate. Programs can be entered either

directly through the keyboard of the

control or generated at an external

programming station.

Internal computing programs simplify

programming considerably. For instance, in order to program a row of

holes along the circumference of a

workpiece, it is only necessary to enter the number of drill-holes required.

From this, the CNC calculates the

positions of the individual holes.

Control console of an EB drilling machine

If a malfunction should occur during

the drilling process which could lead to

undrilled holes, the CNC memorizes

the position of the last completed drillhole and, when the fault has been

remedied, resumes drilling at the next

drilling pulse with pinpoint accuracy.

All the main parameters of the drilling

process are controlled by the CNC.

These are the pulse current and the

duration, the drilling frequency and the

frequency-related beam spot following

as well as the current of the focussing

lens.

The CNC is also responsible for the

commands for controlling the axes of

motion, this means in particular the

positions and the speed of the axes.

47.20.02 f29

The control monitor

The monitor screen shows in free

selectable function displays all information and data which are necessary

to operate the machine. Different program menus and submenus are available and enable an orderly and userfriendly operation. For instance the

monitor displays the start-up and

switch-off routine, a pump status diagram, the set-up and adjustment of

the generator, all electrical and

mechanical actual values of the

generator parameters and manipulating units as well as error and maintenance messages and at last the CNC

programs themselves or their status

during a program run.

Page 9

Technical data

Generator

Type

G 33 PM

G 96 PM

G 120 PMS

120

Beam current at workpiece

mA

1 28

1 80

1 100

Maximum pulse power at workpiece

kW

3.3

9.6

12.0

Working distance

mm

35 100

35 150

35 150

Pulse length

50 - 30,000

Maximum frequency of spot following

Hz

3,000

Chamber

Chamber volume

Type

K6

K 12

K 16

K 19

K 24

0.63

1.28

1.63

1.91

2.54

Maximum processable workpiece dimensions

Diameter

mm

320

637

1,000

1,000

637

Length

mm

400

600

500

500

950

Manipulating units

Type

4-axes manipulator

Oszillant

EBOPULS-E

Rotation/linear feed unit

PDS

E-Mail:

info@steigerwald-eb.de

Homepage: http://www.steigerwald-eb.de

Steigerwald Strahltechnik GmbH

Emmy-Noether-Str. 2 D-82216 Maisach

Tel.: +49/(0)8141-3535-0 Fax: +49/(0)8141-3535-215

Steigerwald Strahltechnik GmbH 10/2006

kV

The descriptions, technical data and illustrations contained in this document are provided for guidance purposes only

and are non-binding. The manufacturer reserves the right to make alterations to products without notice.

Accelerating voltage

You might also like

- Electron Beam MachiningDocument17 pagesElectron Beam Machiningnashk18No ratings yet

- Drilling: Precise Drilling With Electron BeamsDocument4 pagesDrilling: Precise Drilling With Electron BeamsAleksandarIvankovićNo ratings yet

- Electron Beam: MachiningDocument37 pagesElectron Beam: MachiningraghurockramNo ratings yet

- Assignment Advance Manufacturing Processes: by Vaibhav M. Enroll No. 171E021 May 8, 2020Document11 pagesAssignment Advance Manufacturing Processes: by Vaibhav M. Enroll No. 171E021 May 8, 2020Vaibhav MishraNo ratings yet

- A.K.das - Resistance WeldingDocument26 pagesA.K.das - Resistance WeldingAsad Bin Ala QatariNo ratings yet

- Me2026 Unconventional Machining Process 43Document7 pagesMe2026 Unconventional Machining Process 43CHARANNo ratings yet

- Ultrasonic and Electric Discharge Machining To Deep and Small Hole On Titanium AlloyDocument6 pagesUltrasonic and Electric Discharge Machining To Deep and Small Hole On Titanium AlloysatishmaanNo ratings yet

- Electron Beam MachiningDocument5 pagesElectron Beam MachiningpapupassNo ratings yet

- 4A. Electron Beam Machining (EBM)Document3 pages4A. Electron Beam Machining (EBM)Tanu RdNo ratings yet

- Reference: Diffusion Bonded EDM Electrode With Micro Holes For Jetting Dielectric Liquid, CIRP Annals - Manufacturing Technology, 2006Document11 pagesReference: Diffusion Bonded EDM Electrode With Micro Holes For Jetting Dielectric Liquid, CIRP Annals - Manufacturing Technology, 2006EdinNo ratings yet

- Fabrication of Er3 - Doped Fluoride Fibres With Single-ModeDocument6 pagesFabrication of Er3 - Doped Fluoride Fibres With Single-Modeqinetiq15No ratings yet

- Electo Stream DrillingDocument3 pagesElecto Stream DrillingShubhamNo ratings yet

- Journal of Manufacturing Processes: SciencedirectDocument13 pagesJournal of Manufacturing Processes: SciencedirectPrabhataNo ratings yet

- Testing WeldingDocument7 pagesTesting Weldingwebs.usuarioNo ratings yet

- Precision Engineering: Ravinder Kumar, Inderdeep Singh TDocument7 pagesPrecision Engineering: Ravinder Kumar, Inderdeep Singh TAnonymous 5AmJ13mLkNo ratings yet

- The Role of Tip DressingDocument4 pagesThe Role of Tip DressingLutfi Ismail100% (1)

- Electron Beam Machining Processes and ApplicationsDocument20 pagesElectron Beam Machining Processes and ApplicationsShuvroneil Sinha RoyNo ratings yet

- Electromagnetic FormingDocument14 pagesElectromagnetic FormingTochi Krishna AbhishekNo ratings yet

- 1 s2.0 S0141635916302793 MainDocument8 pages1 s2.0 S0141635916302793 MaingokulanathanNo ratings yet

- Electron Beam MachiningDocument19 pagesElectron Beam MachiningHarshal NilNo ratings yet

- Ultrasonic Vibration Assisted Electro-Discharge MachiningDocument8 pagesUltrasonic Vibration Assisted Electro-Discharge MachiningnanusergiuNo ratings yet

- Electrical Discharge Machining (Edm) : Process PrinciplesDocument11 pagesElectrical Discharge Machining (Edm) : Process PrinciplesPrasad ChikkamNo ratings yet

- Electron Beam MachiningDocument7 pagesElectron Beam MachiningDiaz LaksmanaNo ratings yet

- Electron Beam MachiningDocument9 pagesElectron Beam MachiningYunitha RatnadillaNo ratings yet

- Electron BeamDocument13 pagesElectron BeamAbhay PrakashNo ratings yet

- Electron Beam WeldingDocument20 pagesElectron Beam WeldingkumarNo ratings yet

- EBMDocument6 pagesEBManeesh19inNo ratings yet

- ECM Process for Drilling Small Holes in MetalsDocument4 pagesECM Process for Drilling Small Holes in MetalsKaustubh Joshi50% (2)

- Using Workpiece Vibration Cutting For Micro-Drilling (Discussion and Conclusion Ideas)Document5 pagesUsing Workpiece Vibration Cutting For Micro-Drilling (Discussion and Conclusion Ideas)PRIVILEGEASTROSNo ratings yet

- How Can You Use Eddy Current NDT For Tube InspectionDocument2 pagesHow Can You Use Eddy Current NDT For Tube InspectionWoodrow FoxNo ratings yet

- 261 - MMP Lecture Notes-Ilovepdf-Compressed 66Document7 pages261 - MMP Lecture Notes-Ilovepdf-Compressed 66BABAJINo ratings yet

- Shaped Tube MachiningDocument14 pagesShaped Tube MachiningVaibhavNo ratings yet

- PC-ME701 Class2 15092021 EBMDocument23 pagesPC-ME701 Class2 15092021 EBMDeepak KumarNo ratings yet

- An Ultrasonic Vibration Assisted Electrical Discharge Machining Device With Workpiece VibrationDocument12 pagesAn Ultrasonic Vibration Assisted Electrical Discharge Machining Device With Workpiece VibrationDu RoyNo ratings yet

- Electron Beam MachineDocument23 pagesElectron Beam MachineMQ ZerooNo ratings yet

- Electron Beam Machining 1Document9 pagesElectron Beam Machining 1Anonymous NUIEgENo ratings yet

- Material Removal by Arc Ablation: Robert H SturgesDocument6 pagesMaterial Removal by Arc Ablation: Robert H SturgesinventionjournalsNo ratings yet

- Compact Large-Range Cryogenic Scanraer: Department Physics, The University Michigan, Ann Arbol Michigan 48109Document4 pagesCompact Large-Range Cryogenic Scanraer: Department Physics, The University Michigan, Ann Arbol Michigan 48109Muraleetharan BoopathiNo ratings yet

- Advanced Deep Reactive Ion Etching: A Versatile Tool For Microelectromechanical SystemsDocument7 pagesAdvanced Deep Reactive Ion Etching: A Versatile Tool For Microelectromechanical SystemsMehdi NaderiNo ratings yet

- Effect of Process Parameters On The Surface Integrity of Micro-Holes of Ti6Al4V Obtained by Micro-EdmDocument8 pagesEffect of Process Parameters On The Surface Integrity of Micro-Holes of Ti6Al4V Obtained by Micro-EdmTJPRC PublicationsNo ratings yet

- Narrow Gap WeldingDocument6 pagesNarrow Gap WeldingRinshad Abdul RahimanNo ratings yet

- 05 (Ebm Pam)Document26 pages05 (Ebm Pam)ssNo ratings yet

- Electro-Discharge Machining (EDM) - Industrial EngineeringDocument24 pagesElectro-Discharge Machining (EDM) - Industrial EngineeringshahadNo ratings yet

- Electrochemical Machining (ECM) Provides Creative LatitudeDocument2 pagesElectrochemical Machining (ECM) Provides Creative Latitudedavid2404No ratings yet

- Influence of EDM Process Parameters in Deep Hole Drilling of Inconel 718Document11 pagesInfluence of EDM Process Parameters in Deep Hole Drilling of Inconel 718Pranes RainaNo ratings yet

- Chapter 9 - Electron Beam WeldingDocument14 pagesChapter 9 - Electron Beam WeldingrafikdmeNo ratings yet

- Ebw LBWDocument58 pagesEbw LBWAnish AmanNo ratings yet

- EDG Study Using Rotary Disk ElectrodeDocument9 pagesEDG Study Using Rotary Disk ElectrodeSarath ChandraNo ratings yet

- Some Information About Edm EBM and LBMDocument6 pagesSome Information About Edm EBM and LBMRuchin ChahwalaNo ratings yet

- Study On Wear Mechanisms in Drilling of Inconel 718 SuperalloyDocument5 pagesStudy On Wear Mechanisms in Drilling of Inconel 718 SuperalloyPalash RoyChoudhuryNo ratings yet

- SPE 107240 4th-Generation Coiled-Tubing Manufacturing TechnologyDocument3 pagesSPE 107240 4th-Generation Coiled-Tubing Manufacturing Technologymsmsoft90No ratings yet

- Manufacture_of_a_Home-Made_Spot_Welding_Machine_frDocument4 pagesManufacture_of_a_Home-Made_Spot_Welding_Machine_frkimtuan835958549964No ratings yet

- RC Circuit Analysis and EDM Process ParametersDocument21 pagesRC Circuit Analysis and EDM Process ParametersSahil SundaNo ratings yet

- Document 1Document8 pagesDocument 1sadiqali4244No ratings yet

- Micro Electrochemical Machining of 3D Micro Structure Using Dilute Sulfuric AcidDocument4 pagesMicro Electrochemical Machining of 3D Micro Structure Using Dilute Sulfuric AcidResearch AssistanceNo ratings yet

- 13 Electron Beam WeldingDocument11 pages13 Electron Beam WeldingVarun KajaNo ratings yet

- Micro Machining of Metals, Ceramics, Silicon and Polymers Using Nanosecond LasersDocument11 pagesMicro Machining of Metals, Ceramics, Silicon and Polymers Using Nanosecond LasersglzrNo ratings yet

- Electroformed Vs Lasercut StencilDocument5 pagesElectroformed Vs Lasercut StencilAndersonNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Agiecharmilles Laser 4000 enDocument8 pagesAgiecharmilles Laser 4000 enpil;zoNo ratings yet

- TALAT Lecture 1201: Introduction To Aluminium As An Engineering MaterialDocument22 pagesTALAT Lecture 1201: Introduction To Aluminium As An Engineering MaterialCORE MaterialsNo ratings yet

- Process Planning For Sheet Metal Parts Based On Information ManagementDocument13 pagesProcess Planning For Sheet Metal Parts Based On Information Managementpil;zoNo ratings yet

- Tension TestDocument9 pagesTension Testoniel888No ratings yet

- Application Note Hardness Testing EnglishDocument12 pagesApplication Note Hardness Testing EnglishAnubhav LakhmaniNo ratings yet

- Naald 5LDocument3 pagesNaald 5Lpil;zoNo ratings yet

- Electron Beam Drilling-EbopulseDocument10 pagesElectron Beam Drilling-Ebopulsepil;zoNo ratings yet

- 05 LuEtAlDocument8 pages05 LuEtAlpil;zoNo ratings yet

- Matsuura High SpeedDocument16 pagesMatsuura High Speedpil;zoNo ratings yet

- 05 LuEtAlDocument8 pages05 LuEtAlpil;zoNo ratings yet

- Charpy Test Explained - Impact Strength MeasurementDocument7 pagesCharpy Test Explained - Impact Strength MeasurementKa Chian100% (1)

- Charpy Impact Test and Fracture Toughness Transition TemperaturesDocument10 pagesCharpy Impact Test and Fracture Toughness Transition TemperaturesmesipaNo ratings yet

- Ampli LaserDocument48 pagesAmpli Laserpil;zoNo ratings yet

- 27087Document31 pages27087pil;zoNo ratings yet

- Metal HydroxideDocument4 pagesMetal Hydroxidepil;zoNo ratings yet

- MT II Exercise 5Document10 pagesMT II Exercise 5pil;zoNo ratings yet

- Sumit ThesisDocument41 pagesSumit ThesisGyanendra Kumar PadhiNo ratings yet

- Micro MachiningDocument34 pagesMicro MachiningAyodhya KarthikNo ratings yet

- Reinigung Von Oberflächen en V2 1 NetDocument4 pagesReinigung Von Oberflächen en V2 1 Netpil;zoNo ratings yet

- 115 MedicalDocument3 pages115 Medicalpil;zoNo ratings yet

- Sterilisation Und Desinfektion en 2 2 NetDocument2 pagesSterilisation Und Desinfektion en 2 2 Netpil;zoNo ratings yet

- Web Techno v24Document8 pagesWeb Techno v24pil;zoNo ratings yet

- Practical Applications of TD and ECD 2011Document13 pagesPractical Applications of TD and ECD 2011pil;zoNo ratings yet

- 115 MedicalDocument3 pages115 Medicalpil;zoNo ratings yet

- runnerInstaGuide PDFDocument190 pagesrunnerInstaGuide PDFpil;zoNo ratings yet

- Genius Plus: Electronic Engineering LTDDocument2 pagesGenius Plus: Electronic Engineering LTDpil;zoNo ratings yet

- Genius Plus: Electronic Engineering LTDDocument2 pagesGenius Plus: Electronic Engineering LTDpil;zoNo ratings yet

- 2019.2.25 UniGear ZS3. 2 Manual EN PDFDocument48 pages2019.2.25 UniGear ZS3. 2 Manual EN PDFDrago AndrijevicNo ratings yet

- WWW - Spartan.ca Media Library Engine-And-Compressor-Automation Amot Manual Amot 8630B Hawk-I Hardware ManualDocument57 pagesWWW - Spartan.ca Media Library Engine-And-Compressor-Automation Amot Manual Amot 8630B Hawk-I Hardware ManualAnonymous GKTRypNo ratings yet

- Avanti Fridge Instructions Manual (Model FF993W)Document20 pagesAvanti Fridge Instructions Manual (Model FF993W)oxotnicNo ratings yet

- Operating Manual en HF Inverter E@Sydrive 4624, 4625, 4626Document48 pagesOperating Manual en HF Inverter E@Sydrive 4624, 4625, 4626Ezequiel Victor HugoNo ratings yet

- MCCB 400A-600A Eaton Cutler HammerDocument8 pagesMCCB 400A-600A Eaton Cutler HammerWiratama TambunanNo ratings yet

- SP 01 en Schnellladegeraet - UFC 2 PDFDocument4 pagesSP 01 en Schnellladegeraet - UFC 2 PDFfpertreusNo ratings yet

- Panel AUO T320XVN02-A CELL 1 (DS) PDFDocument25 pagesPanel AUO T320XVN02-A CELL 1 (DS) PDFekamuktyNo ratings yet

- Columbs LawDocument6 pagesColumbs Lawasadaliawanatd1No ratings yet

- Industrial Cables LP No. 04 DTD 23rd June 2021Document2 pagesIndustrial Cables LP No. 04 DTD 23rd June 2021Dinesh KumarNo ratings yet

- Understanding The Resting Potential Lesson 1 The Resting Potential Fundamentals of Neuroscience, Part 1 The Electrical ProDocument1 pageUnderstanding The Resting Potential Lesson 1 The Resting Potential Fundamentals of Neuroscience, Part 1 The Electrical ProMar CosNo ratings yet

- Half-Duplex Rs-485-/Rs-422-Compatible Transceiver With Autodirection ControlDocument17 pagesHalf-Duplex Rs-485-/Rs-422-Compatible Transceiver With Autodirection ControlleftoverchopsNo ratings yet

- EMI Emission From Gate Drive Circuit of Boost Converter: Guang Ling, Henglin ChenDocument5 pagesEMI Emission From Gate Drive Circuit of Boost Converter: Guang Ling, Henglin Chenkeerthi_1989No ratings yet

- The Relay Protection Coordination For PHDocument6 pagesThe Relay Protection Coordination For PHgrigore mirceaNo ratings yet

- A Presentation ON Solar Wind Hybrid SystemDocument21 pagesA Presentation ON Solar Wind Hybrid Systemindian4uuNo ratings yet

- PLC01 Psu1 AI/O1: SiemensDocument1 pagePLC01 Psu1 AI/O1: SiemensSyachrial YusufNo ratings yet

- CH 1Document15 pagesCH 1demos2011No ratings yet

- South Bihar Power Citizen Charter for ConsumersDocument2 pagesSouth Bihar Power Citizen Charter for ConsumersAlok AmanNo ratings yet

- Power Transmission, Distribution and Utilization: Lecture# 13 &14: Underground CablesDocument29 pagesPower Transmission, Distribution and Utilization: Lecture# 13 &14: Underground CablesPhD EENo ratings yet

- Maninder Seminar Word1 PDFDocument44 pagesManinder Seminar Word1 PDFsankesh burdakNo ratings yet

- Arc Flash and Electrical Safety HazardsDocument24 pagesArc Flash and Electrical Safety HazardsJulios Charl Panuncialman TagupaNo ratings yet

- Sma SMC 9000tl-11000tl enDocument2 pagesSma SMC 9000tl-11000tl enTomuta StefanNo ratings yet

- Group 3 Section (H) (Lab Report 2)Document8 pagesGroup 3 Section (H) (Lab Report 2)Shoaib KhanNo ratings yet

- Tutorial Optical Sources and DetectorsDocument2 pagesTutorial Optical Sources and DetectorsMir Sameer HassanNo ratings yet

- Mathcad Tutorial: Solving Systems of Equations and Circuit AnalysisDocument6 pagesMathcad Tutorial: Solving Systems of Equations and Circuit AnalysisYadi PermadiNo ratings yet

- ELECS1 Module 1 Introduction and HistoryDocument20 pagesELECS1 Module 1 Introduction and HistoryJuan Miguel VillarroelNo ratings yet

- Growatt 1500-US/2000-US/3000-US TL technology datasheetDocument2 pagesGrowatt 1500-US/2000-US/3000-US TL technology datasheetJonathan León100% (1)

- LG Color TV Service ManualDocument26 pagesLG Color TV Service ManualVadakkevalappilNo ratings yet

- Electromagnetic Fields and Waves: Lecture Notes OnDocument145 pagesElectromagnetic Fields and Waves: Lecture Notes OnSaswat RaysamantNo ratings yet

- Easergy P3 Protection Relays - REL52007 PDFDocument6 pagesEasergy P3 Protection Relays - REL52007 PDFAchira Dasanayake100% (1)

- Accessory Cable GuideDocument9 pagesAccessory Cable GuideCarmelo BayonNo ratings yet