Professional Documents

Culture Documents

ESEM

Uploaded by

Robert MihaiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESEM

Uploaded by

Robert MihaiCopyright:

Available Formats

The ESEM - The Environmental Scanning Electron Microscope

Short overview about the

ESEM

Environmental Scanning

Electron Microscope

2/12/01

Krisada Kimseng / Marcel Meissel

Page 1 (12)

The ESEM - The Environmental Scanning Electron Microscope

ESEM

Environmental Scanning Electron Microscope

What is an ESEM and how does it work ?

Scanning Electron Microscopes (SEM) began to appear commercially in the mid nineteen

sixties. The SEMs primary limitations, as a general imaging and analytical technique,

were the restrictions it imposed on samples by requiring a high vacuum sample environment. The samples had to be clean, dry and electrically conductive. Nonconductive

specimen had to be coated with a conductive film to avoid specimen charging.

The ESEM was developed in the mid eighties. Its primary advantages lie in permitting the

microscopist to vary the sample environment through a range of pressures, temperatures

and gas compositions. The Environmental SEM retains all of the performance advantages

of a conventional SEM, but removes the high vacuum constraint on the sample environment. Wet, oily, dirty, non-conductive samples may be examined in their natural state

without modification or preparation. The ESEM offers high resolution secondary electron

imaging in a gaseous environment of practically any composition, at pressures as high as

50 Torr, and temperatures as high as 1500 C.

All SEMs consist of an electron column, that creates a beam of electrons; a sample

chamber, where the electron beam interacts with the sample; detectors, that monitor a variety of signals resulting from the beam-sample interaction; and a viewing system, that

constructs an image from the signal.

Figure 1.

A schematic representation

of a SEM. The electron column accelerates and focuses

a beam of electrons onto the

sample surface. Interactions

between the sample and the

beam electrons cause a variety of signal emissions.

The signals are detected and

reconstructed into a virtual

image displayed on a CRT.

An electron gun at the top

2/12/01

Krisada Kimseng / Marcel Meissel

Page 2 (12)

The ESEM - The Environmental Scanning Electron Microscope

of the column generates the electron beam. In the gun, an electrostatic field directs electrons, emitted from a very small region on the surface of an electrode, through a small

spot called the crossover. The gun then accelerates the electrons down the column toward

the sample with energies typically ranging from a few hundred to tens of thousands of

electron volts.

The electrons emerge from the gun as a divergent beam. A series of magnetic lenses and

apertures in the column reconverges and focuses the beam into a demagnified image of

the crossover. Near the bottom of the column a set of scan coils deflects the beam in a

scanning pattern over the sample surface. The final lens focuses the beam into the smallest possible spot on the sample surface.

The beam exits from the column into the sample chamber. The chamber incorporates a

stage for manipulating the sample, a door for inserting and removing the sample and access ports for mounting various signal detectors and other accessories. As the beam electrons penetrate the sample, they give up energy, which is emitted from the sample in a

variety of ways. There are two major ways of emission:

Secondary Electrons (SE) are sample atom electrons that have been ejected by interactions with the primary electrons of the beam. They generally have very low energy (by

convention less than fifty electron volts). Because of their low energy they can escape

only from a very shallow region at the sample surface. As a result they offer the best imaging resolution. Contrast in a secondary electron image comes primarily from sample

topography. More of the volume of interaction is close to the sample surface, and therefore more secondary electrons can escape, for a point at the top of a peak than for a point

at the bottom of a valley. Peaks are bright. Valleys are dark. This makes the interpretation

of secondary images very intuitive. They look just like the corresponding visual image

would look.

Backscattered Electrons (BSE) are primarily beam electrons that have been scattered back

out of the sample by elastic collisions with the nuclei of sample atoms. They have high

energy, ranging (by convention) from fifty electron volts up to the accelerating voltage of

the beam. Their higher energy results in a larger specific volume of interaction and degrades the resolution of backscattered electron images. Contrast in backscattered images

comes primarily from point to point differences in the average atomic number of the

sample. High atomic number nuclei backscatter more electrons and create bright areas in

the image. Backscattered images are not as easy to interpret, but properly interpreted, can

provide important information about sample composition.

Each emission mode is potentially a signal from which to create an image.

2/12/01

Krisada Kimseng / Marcel Meissel

Page 3 (12)

The ESEM - The Environmental Scanning Electron Microscope

Figure 2.

The interactions of beam electrons and

sample atoms generate a variety of signals. The most commonly used signals

are secondary electrons, backscattered

electrons and characteristic X-rays.

What is the new technology in ESEM ?

High vacuum conditions are required in the electron gas and throughout the column,

where gas molecules can scatter electrons and degrade the beam. Instead of using a single

pressure limiting aperture in conventional SEM, ESEM uses multiple Pressure Limiting

Apertures (PLAs) to separate the sample chamber from the column. The column is still

high vacuum, but the chamber may sustain pressures as high as 50 Torr.

Figure 3.

In the ESEM the vacuum system is divided into as many as five stages of increasing vacuum, separated by pressure

limiting apertures. In this schematic the

stages are the sample chamber, first environmental chamber (EC1), second environmental chamber (EC2), column and

gun chamber.

ESEM uses a proprietary Environ-

2/12/01

Krisada Kimseng / Marcel Meissel

Page 4 (12)

The ESEM - The Environmental Scanning Electron Microscope

mental Secondary Detector (ESD) which can function in non-vacuum environment instead of Everhart-Thornley (ET) detector used in SEM

The ESD uses the principle of gas ionization. By applying a positive potential of a few

hundred volts to the detector, the secondary electron emitted by the sample when interacts

with electron beam is attracted to detector. As the electrons accelerate in the detector

field, they collide with gas molecules. The resulting ionizations create additional electrons, amplifying original secondary electron signal, and positive ions. The detector collects secondary electron signal and passes it directly to an electron amplifier. In nonconductive samples the positive ions created in gas ionization process are attracted to the

sample surface and they effectively suppress charging artifacts.

Figure 4.

The Environmental Secondary Detector uses

gas ionization to amplify the secondary electron signal. In nonconductive samples, positive ions are attached to the sample surface

as charge accumulates from the beam. There

they effectively suppress charging artifacts.

2/12/01

Krisada Kimseng / Marcel Meissel

Page 5 (12)

The ESEM - The Environmental Scanning Electron Microscope

What can ESEM do ?

Gas ionization in the sample chamber eliminates the charging artifacts, typically seen

with nonconductive samples. So the specimens do not need to be coated with a conductive film. ESEM gets rid of the preparation process.

The ESEM can image wet, dirty and oily samples. The contaminants do not damage

the or degrade the image quality.

ESEM can acquire electron images from samples as hot as 1500C, because the

Environmental Secondary Detector (ESD) is insensitive to heat.

The detector is also insensitive to light. Light from the sample, for example incandescence from heated samples, cathodoluminescence and fluorescence do not interfere

with imaging.

ESEM eliminates the need for conductive coating, so delicate structure, which was

often damaged during the sample preparation, can be imaged.

ESEM can acquire x-ray data from insulating samples at high accelerating voltage.

Eliminating the need for sample preparation, particularly the need for conductive

coating, makes it possible to investigate specimen in dynamic processes, such as tension, compression, deformation, crack propagation, adhesion, heating, cooling, freezing, melting, hydration, dehydration and sublimation.

The concerns of using ESEM in PEMs

The condition of the ball bond. (Intermetallic growth and corrosion).

The condition of the die (short-circuits caused by intermetallic growth and corrosion).

The condition of the interface after cross section between each component of the

PEM. (Delamination or crack).

2/12/01

Krisada Kimseng / Marcel Meissel

Page 6 (12)

The ESEM - The Environmental Scanning Electron Microscope

How to operate the ESEM ?

For simple examination of PEMs, for example, the PEMs have to be decapsulated before

using the ESEM to examine for cracking in the passivation layer, dendrite growth on the

die surface, fatigue damage of the bond wires and corrosion of the metallization on the

surface of the die. For this examination, ESEM users can follow this instruction.

Chamber

Window

Stage

Pressure control

Figure 5.

ESEM chamber and stage.

Image screen

Control screen

Control panel

Polaroid camera

Figure 6.

ESEM control panel

and monitors.

2/12/01

Krisada Kimseng / Marcel Meissel

Page 7 (12)

The ESEM - The Environmental Scanning Electron Microscope

1) Heating filament

If you put your name on the schedule the day before or if anyone used the ESEM before you, the ESEM is normally already turned on and the filament is heated. If not,

go to the gun menu and click heat filament (1.86 A). It can take up to several minutes to heated it up.

2) Placing the sample on the stage

Before you can put your sample in, you will have to vent the chamber. To do so, go to

the vacuum menu and hit vent chamber. After the chamber is vented you can open

the door and put your sample into the sample holder. When you put your sample in,

close the door and hit wet in the vacuum menu. If the wet button is not accessible, press the override button. Make sure the door is closed by pressing it softly

against the chamber. Remember to wet the chamber when you finished all your

tests.

3) Adjust pressure

Use the knob on the left board to adjust the pressure to 2.0 Torr. Wait till pressure in

chamber has reached the adjusted value. (Actual pressure shown at the bottom of the

image screen.)

4) Adjust position of sample

Adjust the position of the sample by using the X-Y position stick on the control panel

and adjust Z-position until the distance between the sample and the beam header is

about 5-10 mm.

5) Adjust condenser

Adjust the condenser value to about 50. (On the static section of the screen)

6) Adjust beam

Adjust the beam value to about 25 keV. (On the static section of the screen)

7) Adjust scan rate

A lower scan rate produces sharper images. Use high scan rates for searching a sample or when moving the stage with higher speed. Different scan rates can be chosen

within the range of 8.6 fr/sec to 26 sec/fr.

8) Adjust brightness and contrast

Use contrast and brightness knob to adjust for the best figure. The three knobs on the

top of the electron column can be used to adjust the best position of the electron beam

on the specimen.

9) Locate die

Begin with lowest magnification to locate the position of the die you would like to

examine.

2/12/01

Krisada Kimseng / Marcel Meissel

Page 8 (12)

The ESEM - The Environmental Scanning Electron Microscope

10) Focus image

Press the focus button on the panel, choose higher magnification and focus image

with the focus knob on the panel. When the image is sharp, release focus button.

11) Check alignment of the image

You can rotate the image by clicking on the cw or ccw button in the image menu.

12) Measuring

To measure the specimen use the annotation button in the image menu. The image has

to be aligned. You can only measure horizontal distances. Click on the white boxes on

the image screen and move them to the part you want to measure. The shown distance

is the distance between the two white dots. A higher magnification is more precisely.

13)Taking pictures

First adjust the focus, adjust the scan rate to 26 sec/frame and after the picture is

scanned completely, press the hold button. To take a picture with the video printer

press the print button on the front panel of the video printer. To take a Polaroid picture, go to the record menu, choose your type of film, insert the film into the holder

and pull it till it stops and click the photo button. Wait till the light of the photo button

comes off. Push the film back in, lock the film holder and pull the whole film out. To

continue scanning push the live button first. (On the static section of the screen.)

2/12/01

Krisada Kimseng / Marcel Meissel

Page 9 (12)

The ESEM - The Environmental Scanning Electron Microscope

Conclusion

The ESEM has several advantages towards SEM. For example the samples do not have to

be prepared and the chamber environment can be controlled through a range of pressure,

temperature and gas composition. The following examples show some failure analysis on

PEMs.

By using ESEM to examine decapsulated PEM, ball bonds of some packages showed

intermetallic growth between ball bond and bond pad as seen in Figure 6.

After cross sectioning the interface between each components can be examined by

using ESEM, delamination and crevice can be seen in Figure 7 and Figure 8.

Ball bond

Bond pad

Figure 7.

Good ball bond (good

shape, no intermetallic

growth and corrosion).

2/12/01

Krisada Kimseng / Marcel Meissel

Page 10 (12)

The ESEM - The Environmental Scanning Electron Microscope

Ball bond

Bond pad

Intermetallic growth

Figure 8.

Bad ball bond (intermetallic growth between ball

bond and bond pad).

Ball bond

Crevice

Bond pad

Figure 9.

Bad interface. (Crevice between Ball Bond and Die

Pad)

2/12/01

Krisada Kimseng / Marcel Meissel

Page 11 (12)

The ESEM - The Environmental Scanning Electron Microscope

Die

Delamination

Die paddle

Figure 10.

Bad interface (Delamination between Die and Die

Paddle)

2/12/01

Krisada Kimseng / Marcel Meissel

Page 12 (12)

You might also like

- Deco Noel ArhivareDocument24 pagesDeco Noel ArhivareRobert MihaiNo ratings yet

- MR Food Nonfood OnlineDocument24 pagesMR Food Nonfood OnlineRobert MihaiNo ratings yet

- p222 14406 19 Food PDFDocument16 pagesp222 14406 19 Food PDFRobert MihaiNo ratings yet

- Preturi ImbatabileDocument4 pagesPreturi ImbatabileRobert MihaiNo ratings yet

- Walser 2016Document19 pagesWalser 2016Robert MihaiNo ratings yet

- Formation of BaTiO3 From Barium Oxalate and TiO2Document7 pagesFormation of BaTiO3 From Barium Oxalate and TiO2Robert MihaiNo ratings yet

- Batio 3Document6 pagesBatio 3Robert MihaiNo ratings yet

- Systematic Optimization of Spray Drying For YAG Transparent Ceramics 2015 Journal of The European Ceramic SocietyDocument11 pagesSystematic Optimization of Spray Drying For YAG Transparent Ceramics 2015 Journal of The European Ceramic SocietyRobert MihaiNo ratings yet

- All-Poly-Crystalline Ceramics Nd:YAG/Cr4+:YAG Monolithic Micro - Lasers With Multiple-Beam OutputDocument25 pagesAll-Poly-Crystalline Ceramics Nd:YAG/Cr4+:YAG Monolithic Micro - Lasers With Multiple-Beam OutputRobert MihaiNo ratings yet

- Direct Probing of Semiconductor Barium Titanate Via Electrostatic Force MicroscopyDocument5 pagesDirect Probing of Semiconductor Barium Titanate Via Electrostatic Force MicroscopyRobert MihaiNo ratings yet

- Formation of BaTiO3 From Barium Oxalate and TiO2Document7 pagesFormation of BaTiO3 From Barium Oxalate and TiO2Robert MihaiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Paper Chromatography of Gel Ink PensDocument4 pagesPaper Chromatography of Gel Ink PensdaveNo ratings yet

- Chromatographic Separation PDFDocument7 pagesChromatographic Separation PDFNicolle CletoNo ratings yet

- Cell Biology TechniquesDocument38 pagesCell Biology TechniquesIrisoanga Itamuno RobertsNo ratings yet

- NMR Problems Dec 2012Document8 pagesNMR Problems Dec 2012Biswajit Gopal RoyNo ratings yet

- 5990-8583EN 6400 Supplies QRG LowresDocument3 pages5990-8583EN 6400 Supplies QRG LowresAGF DHJNo ratings yet

- Chem 26.1 Experiment 11 Atq Questions and Data SheetDocument4 pagesChem 26.1 Experiment 11 Atq Questions and Data SheetMatthew Rei De LeonNo ratings yet

- Monitoring of Macroinvertebrates Along Streams of Bilah River, Labuhanbatu Regency, North Sumatra IndonesiaDocument10 pagesMonitoring of Macroinvertebrates Along Streams of Bilah River, Labuhanbatu Regency, North Sumatra IndonesiazulfadlyNo ratings yet

- Lab Report DNA ExtractionDocument1 pageLab Report DNA ExtractionEzio Auditore100% (1)

- Lect 1 Introduction To Histo PathologyDocument14 pagesLect 1 Introduction To Histo PathologyAbdul Hafeez100% (1)

- Supplier ContactsDocument2 pagesSupplier ContactsJustine Marie AbarroNo ratings yet

- The Analysis of Alkylphenol EthoxysulphonateDocument13 pagesThe Analysis of Alkylphenol EthoxysulphonateelenitabastosNo ratings yet

- Label ImmunoassayDocument92 pagesLabel ImmunoassayCherry Reyes-Principe100% (3)

- Quotation - FTIR-650Document3 pagesQuotation - FTIR-650TaseerNo ratings yet

- BRM941LSA: Product DescriptionDocument2 pagesBRM941LSA: Product DescriptionBayu AjiNo ratings yet

- تحليل الي نهائيDocument20 pagesتحليل الي نهائيMaoth AhmedNo ratings yet

- Agarose Gel Electrophoresis (AGE)Document16 pagesAgarose Gel Electrophoresis (AGE)Nenita AlonzoNo ratings yet

- Spec Minicap FPDocument3 pagesSpec Minicap FPMuhammad AlmadaNo ratings yet

- Lab Report Scientific Communiation PDFDocument9 pagesLab Report Scientific Communiation PDFMuhammad QasimNo ratings yet

- Sapoin HPLCDocument1 pageSapoin HPLCGigih LintangNo ratings yet

- Thin Layer ChromatographyDocument2 pagesThin Layer ChromatographyMigena CanajNo ratings yet

- DNA Profiling by Ms. Priya SoniDocument21 pagesDNA Profiling by Ms. Priya SoniSaurabh Singh RajputNo ratings yet

- Electron MicroscopyDocument35 pagesElectron MicroscopyAwais FaizyNo ratings yet

- HPLCDocument22 pagesHPLCKafi Mahmood NahinNo ratings yet

- Flow Cytometry IIDocument26 pagesFlow Cytometry IIOlaitan AdebayoNo ratings yet

- Quantitative Analysis of UV-Vis SpectrosDocument15 pagesQuantitative Analysis of UV-Vis SpectrosSalwa KamiliaNo ratings yet

- 5990 8296enDocument4 pages5990 8296enGiriraj T KulkarniNo ratings yet

- Angstrom General Brochure 3.0 PDFDocument27 pagesAngstrom General Brochure 3.0 PDFJoseNo ratings yet

- Group B. ChromatographyDocument1 pageGroup B. ChromatographywiwidNo ratings yet

- Chapter 7Document4 pagesChapter 7ram sunderNo ratings yet

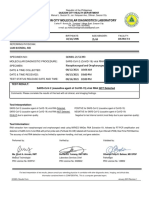

- QCMDL 21 51393 Relata Leonardo NacionalDocument1 pageQCMDL 21 51393 Relata Leonardo NacionalAngel DetablanNo ratings yet