Professional Documents

Culture Documents

1 s2.0 0378775395022309 Main PDF

Uploaded by

Izabôr Carvalho OliveiraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 0378775395022309 Main PDF

Uploaded by

Izabôr Carvalho OliveiraCopyright:

Available Formats

JOURHAI OF

POWEg

ELSEVIER

SOU

Journal of Power Sources 57 ( 1995) 9-12

Impact of household batteries in landfills

S. Panero, C. Romoli, M. Achilli, E. Cardarelli, B. Scrosati

Dipartimento di Chimica, Sezione di Elettrochimica, Universith 'La Sapienza ', 00185 Rome, Italy

Abstract

Heavy metals are present at different levels and concentrations in all the household dry batteries. The related environmental hazard is well

known. The heavy metals are toxic and thus liable to produce serious problems for the health of the population and for the maintenance of

the biosphere. Therefore, there has been recently an increasing concern on the risk associated with uncontrolled disposal of exhausted dry

batteries. In this paper, we report on the efforts in progress in Italy for collecting spent batteries, as well as the most suitable strategies which

can be followed to assure their safe disposal.

Keywords: Batteries; Disposal; Household batteries; Italy

1. I n t r o d u c t i o n

2~o~:

Typical household portable devices, such as watches, cameras, radios, tape recorders, toys, etc., are conveniently powered by dry batteries, namely by primary cells using

immobilized electrolytes [ 1,2]. Consequently, the world production of these batteries amounts to several billions of units

per year [ 2]. In Italy alone, the dry battery market is estimated

to be approximately 400 million units per year, with a procapita consumption of 0.4 kg for a total of 20 000 tons [ 3].

From Fig. 1, which illustrates the annual turnover of the

Italian household battery market, it appears that the most used

are the zinc-carbon and the alkaline manganese dry batteries,

which alone contribute to more than 90% of the total national

market. While these two cells are used for mass consumption,

mercury and lithium cells are directed to a somewhat more

specialized market which may involve sophisticated devices,

such as expensive cameras, medical and military equipment.

Following the general trend of industrial countries, including

Italy, there is a decline of zinc-carbon in favour of alkaline

manganese cells and, in specialized area, a constant increase

in the innovative lithium batteries over traditional systems,

such as the mercury cells (Fig. 1).

As is well known, all the common dry batteries use zinc as

the negative electrode. In fact, this metal offers a series of

advantages as the electrode material, which include a favourable electrochemical factor (i.e. a favourable ratio between

potential and mass), a relatively low-cost and versatile processability. However, to prevent corrosion and to increase

the mechanical resistance o f the zinc anode, until recently,

small quantities of mercury and cadmium were added to the

200-

0378-7753 / 95 / $09.50 1995 Elsevier Science S.A. All rights reserved

SSDI0378-7753 (95) 02230-E

i 1990

l,.t9931

500zinc-carbon

mercury

alkalinemanganese

lithium

Battery Type

Fig. 1. Evolution of the Italian market of household dry batteries.

battery system [2]. Consequently, these heavy metals - and

mercury in particular - were inevitably present, even if at

different levels and concentrations, in all the exhausted dry

batteries.

The related environmental hazard is well known: mercury

and cadmium are very toxic metals and are liable to induce

serious risk for the health of the population and the environment. Thus, in recent years, concern over the environmental

risk associated with the uncontrolled disposal of exhausted

batteries has consistently increased. Accordingly, in 1991 the

Commission of the European Community has passed a draft

imposing directions on the member Countries for issuing a

legislation on the evaluation and on the disposal of batteries

containing hazardous materials [4]. In synthesis, the draft

imposes a reduction in the heavy metal content in dry household batteries and the promotion and commercialization of

new batteries with reduced the amount of hazardous materials

S. Panero et aL / Journal of Power Sources 57 (1995) 9-12

10

2. Experimental

00 00'45 t

0

0,35I

.2t

0,1 t

o "--1985

1986

1987

1988

1989

1990

1992

YEAR

Fig. 2. Evolution of mercury content (wt.%) in alkaline-manganese household dry batteries.

and/or based on non-polluting components. In particular, the

draft fixes at 0.025 wt.% the maximum mercury content

allowed in commercial alkaline-manganese batteries.

The major battery producers have adapted their products

to this recommendation and consistent improvements have

been achieved in the recent years, to the point that the mercury

and cadmium content in dry batteries sold for mass consumption has been reported to be reduced to almost 0% for

both in the case of alkaline manganese (Fig. 2) and zinccarbon (Fig. 3) cells.

This is certainly a promising result; however, the above

numbers have to be taken with some care since they are

deduced from average figures and without considering the

contribution from batteries arriving to the European market

from Countries where control in the content in heavy metals

may not be a major concern and which may still represent a

significant fraction of the total sale in Italy. Furthermore,

although the elimination of mercury and cadmium is certainly

of importance, this does not necessarily mean that the batteries are safe and suitable to be directly inserted in the solid

urban waste stream. Indeed, various aspects of battery disposal are far from being solved and the procedures for

approaching this important problem vary from country to

country. In this work, we report on efforts presently in progress in various Italian cities for collecting and disposing

exhausted batteries. Furthermore, the results of an analysis

of the heavy metal content of a few different commercial

battery prototypes, as well as simple methods for their inertization and recovery, are also reported and discussed.

The determination of the total heavy metal content in seven

'spot' samples of different commercial batteries was carried

out by the following procedure. The dismantled battery sample was placed in a beaker containing diluted 1: 1 ( v / v ) HNO3

for 24 h. The dissolution was completed with a microwave

mineralizator (Model CEM MDS-81D) by exposing the

sample to an acid attack program which develops in two steps,

namely 10 min 20% full power followed by 10 min at 50%

full power (full power corresponding to 600 W). Afterwards,

the sample was concentrated to 5 ml and then filtered (using

a 0.45 micrometry millipore filter on a Swinnex support) and

brought to a final volume of 100 ml with distilled water.

The heavy metal content was determined using plasma

emission spectrophotometry for the detection of Mn, Zn, Pb,

Ni, and atomic absorption spectrophotometry (VARIAN

Spectra 400) for the determination of Cd (GTA-96 graphite

furnace) and of Hg (cold water technique). The releasing

tests were carried out on two samples for each of the selected

seven commercial battery types. Each sample was reduced to

a maximum of 9.5 mm granuiometry, placed in a beaker in

which distilled water was poured up to 16 times the weight

of the introduced solid material. The whole was stirred for

24 h keeping the pH < 5 by continuous and programmed

additions of 0.5 M acetic acid, maintaining the total amount

of added acid within 4 c m 3 g - J of the battery material. The

heavy metal content was then determined by inductively coupled plasma (Jobin-Yvon-Type III Sequential) spectrophotometry for Mn, Zn and Ni, while Pb, Cd and Hg due to their

low content were determined by atomic absorption spectrophotometry (see above).

The recovery of zinc was carried out by placing the dismantled battery sample in a beaker in which 50 cm 3 of HCI

(1:9) were poured until complete solution of the metals, as

chlorides, was achieved. The solution was left at rest for 24

h and then submitted to electrolysis. The latter was conducted

at constant current using a steel working electrode (0.07 cm 2

surface) and a steel (or platinum) counter electrode. To

prevent water splitting, the acidity was lowered by the addition of ammonium tartrate and by drop-by-drop addition of

sodium hydroxide. The amount of deposited zinc was

detected gravimetrically.

This treatment process was a modification of the traditional

lithosynthesis inertization processes which involve mixing of

the waste with a cement/silicate slurry. It was optimized by

introducing a third component (a complex silicate) into the

slurry.

3. Results and discussion

3.1. Collection and disposal of exhausted batteries in Italy

Fig. 3. Evolution of mercury and cadmium content (wt.%) in zinc-carbon

household dry batteries.

At the present state of knowledge, it is difficult to assume

that the exhausted batteries can be directly dumped in corn-

S. Panero et al./Journal of Power Sources 57 (1995) 9-12

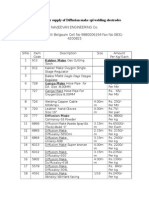

Table 1

Separated collectionof exhausted batteries in some Italian cities

Cities

Inhabitants

(1994)

(millions)

Special containers

(N)

Amountof

exhausted

batteries

(t/year)

Milan

1.3

90

Padua

0.213

Modena

0.175

Bologna

Florence

Rome

Naples

0.391

0.405

3.5

1.1

Palermo

1.27

501 (street)

1360 (others)

547 (street)

40 (others)

40 (street)

68 (others)

2029 (total)

1353 (total)

1215 (total)

separated collection

in program

400 (total)

17

16

44

39

44

mon landfills without affecting the ambient conditions. A

proper environmental control requires an appropriate disposal, which can only be obtained with a separate collection

of exhausted batteries, followed by inertization and/or by

recycling processes.

In fact, the Italian Government has listed exhausted dry

batteries in the category of hazardous wastes and has imposed

their collection separate from the other solid urban waste.

However, although this law has been in force for several

years, the results have not been very encouraging: reasonable

efforts have been undertaken only in some regions of the

central and the northern part of the country. Even in these

cases, separate collections amount only to 20-30% of total

battery consumption, as indicated by the data in Table 1 which

reports the results obtained in some sample Italian cities.

There are various reasons, mainly related to promotional and

economical aspects, which may account for such a somewhat

disappointing result. In fact, a successful treatment of the

exhausted batteries requires the promotion of an adequate

ana persistent campaign to solicit public opinion on the

opportunity of separate disposal, as well as a consistent investiment for assuring a widespread collection and an efficient

disposal. Consequently, only the richest municipalities have

so far had the possibility of affording an efficient and widespread battery collection policy. In fact, it is not surprising

that the most successful results have been achieved in the

central and northern part of Italy, namely in these regions

which are traditionally the wealthest in the country. In the

south, where most of the cities are still affected by serious

economical and social problems, the separate collection of

batteries is still an action to be started or even to be programmed.

The collection of exhausted batteries in Italian cities is

generally organized by installing street or shop containers

from where the disposed batteries are collected and stored.

However, the collection is only one part of the procedure:

disposal and, hopefully, recycling are still the most crucial

and often unsolved parts of the battery waste cycle. According

lI

to the present legislation, the collected batteries should either

be disposed in special 'type C' landfills or, in the case of the

unavailability of the latter, they should be treated for inertization before being disposed in common 'type 2B' landfills 1

Because of the lack of special landfills and of adequate treatment and separation plants, most of the Italian municipalities

simply store the batteries, to eventually ship them abroad to

those countries having landfills available for battery waste

acceptance.

The Italian situation is not unique; in fact, apart from Switzerland where two plants for the treatment and recycling of

batteries are presently in operation [5,6], other European

countries suffer from a lack of appropriate procedures for the

disposal of spent batteries. It is therefore quite surprising that

relatively little attention has been devoted to the problem of

the battery waste so far. Apart from a few research reports

[7,8] and international conferences [9], no special and systematic work has been so far dedicated to the solution or, at

least, to the identification of the difficulties which still prevent

the establishment of effective procedures for recycling spent

batteries.

Many questions are still to be answered. First, whether the

commercial, so called 'mercury-free' or 'green' batteries can

be directly disposed in common landfills with no consequent

environmental risk. Second, whether simple, low-cost treatment processes can be identified and proposed for appropriate

inertization of the battery waste prior to its disposal. Third,

the major question whether recycling plants operating with

economical benefits can be effectively realized.

With the aim of providing some contribution to the answer

of these questions we have first analysed seven different types

of commercial batteries to establish their residual metal content. Then, we have identified and tested an experimental

process for battery treatment and metal recovery. No attempt

has been made to provide an answer to the third question,

since this is expected to be provided by the Conference to

which this Proceeding Volume is devoted.

3.2. Analysis o f spot samples o f spent commercial

household batteries

Seven different types of commercial dry household batteries were dismantled and analysed for their metal content. The

results, obtained as the average of four different determinations for each battery type sample, provided the following

indications.

(i) Mercury is absent in most of the batteries. However,

in a few cases traces of the metal are still present. Therefore,

the 'true' mercury-free condition is not reached by all the

products examined.

(ii) Cadmium is present in traces in all samples, probably

as an impurity of other metals.

2B and 2C are designations for 'second category' landfills by Italian

law.

12

S. Panero et al. /Journal of Power Sources 57 (1995) 9-12

(iii) Lead is present in amounts ranging from 0.024 to

0.114 wt.%, and to even 0.26 wt.% in the case of one sample.

These contents are somewhat high, and may be a matter of

concern.

(iv) Obviously, zinc and manganese are at high levels. A

high content of manganese may give rise to environmental

risks.

3.3. Releasing tests

Further information on the disposal impact of commercial

batteries has been obtained by performing a releasing test

using an acetic acid solution as the extracting liquid. The aim

of this test was to evaluate the impact of the eluate on waste

waters. In fact, eluating with acetic acid is a procedure used

to mimic the biochemical action occurring in typical urban

waste landfills. Although this method is obviously recommended for evaluating the effect of wastes of organic type, it

is also considered suitable to define the release of toxic metals

from dismantled batteries. From the results of the test (where

the concentration of the detected metals is expressed in terms

of mg 1-1), the following may be noticed.

(i) As expected and obvious from the chemical analysis,

mercury is not released by the effective mercury-free batteries; in the two other analytical methods, the mercury content

is slightly higher than the limit (0.05 mg 1-1 ) fixed by present

the Italian law for the acceptance of wastes in common 'type

2B' landfill [10].

(ii) The cadmium concentration is very low and within

the accepted limit (0.02 mg 1-1) for all cases. A similar

situation applies for lead, whose concentration limit is set to

0.2 mg 1-1

(iii) As expected, an opposite situation occurs for the

concentrations of zinc and manganese which, for all cases,

are greater than the fixed limits of 0.5 and 2 mg 1-1, respectively.

(iv) Finally, the content of nickel is low and always within

the fixed limit of 2 mg 1- 1.

forward and economical way of recovering zinc. The second

step involved the treatment of the residue by a modification

of traditional lithosynthesis inertization processes. The latter

achieves the entrapment of the heavy metals in a siliceous

matrix [8 ]. The main drawback of these processes, namely

their inability of trapping Hg, was solved by introducing a

complex silicate to the liquid cement slurry [ 11 ]. Our modified process leads to a final residue which was again submitted to the acetic acid releasing test in order to establish its

validity. The results clearly indicated that, following the treating process, all the metal levels were indeed reduced well

below the fixed limits.

4. Conclusions

The processes of battery disposal in Italy and, presumably,

in most European countries, are far from being optimized.

The collection of the exhausted household battery amounts

to only a fraction of the total scale, and the waste procedures

are not yet clear and uniformally established. The major battery producing companies have consistently reduced the mercury and cadmium content. However, tests run on commercial

batteries, although far from being conclusive, considering the

small number of samples examined, tend to suggest that even

the so-called 'green batteries' cannot be disposed directly in

common urban landfills. Pretreating processes are always

necessary to reduce the Mg and Zn levels. These processes

do not appear to be too complicated or too expensive. A

simple example, based on Zn recovery by electrolysis followed by inertization, is proposed here as an effective action

to reduce the metal levels to values well below the limits set

for common 'type 2B' landfills. These results are very preliminary but they are promising in suggesting that with efforts

from the battery community the problem of a safe disposal

of exhausted batteries could possibly be achieved with consequent great benefit for the conservation of the environment

and the health of the population.

3.4. Recovery and treating processes

References

The data of the above described tests suggest that, although

with a low level of Hg, Cd and Pb, the batteries cannot yet

be accepted for direct disposal in common landfills without

a pretreatment to remove the residual high Mn and Zn content.

The question here is whether such pretreatment processes can

be easily achieved and carried out on a large scale at low

costs from the urban municipalities. In an attempt to provide

some elements of evaluation, we have considered a simple

treatment process which first involves the recovery of zinc

by electrolysis, followed by an inertization process of the

residue.

The first step involved the dissolution of the dismantled

battery samples using a HC1 attack. The resulting chloride

solution was separated from the residue and then electrolyzed

using stainless-steel as the working and the counter electrode.

This first step is operationally simple and provides a straight-

[ 1] B. Scrosati, Renewable Energy, 5 (1994) 285.

[ 2] C.A. Vincent, F. Bonino, M. Lazzari and B. Scrosati, Modern Batteries,

E. Arnold, London, 1987.

[3] B. Scrosati, Waste disposal and recycling of dry batteries in Italy:

status and prospectives, 3rd Int. Seminar on Battery Waste

Management, Deerfield Beach, FL, USA, 4-6 Nov. 1991.

[4] Off. J. Eur. Communities, No. L 78/38, 26 Mar. 1991.

[5] W. Plieth and J. Fiala-Goldiger, GDMB, 63 (1992) 353.

[6] R. Burri, A. Antenen and P. Stolz, FallMeet. ElectrochemicalSociety,

Toronto, Canada, 11-16 Oct. 1992, Abstr. No. N.20.

[7] P. Barbenni, R. Galli and L. Zanderighi, Ecol. Mag., 9 ( 1991 ) 26.

[8] M. Bartolozzi, G. Braccini, P.F. Marconi and S. Bovini, J. Power

Sources, 48 (1994) 389.

[9] Int. Seminar Battery Waste Management, Deerfield Beach, FL, USA,

1993, 1995.

[10] Metodi analitici per le acque, Leggi e Decreti 1976 No. 319, CNR

Rome and following updating.

[ 11 ] A. Rossi, Chim. Oggi, (Jan./Feb.) (1985).

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Stainless Steels & Nickel AlloysDocument108 pagesStainless Steels & Nickel AlloysAhmad Aloudah50% (8)

- Palmitic Acid 98 FGK MSDSDocument3 pagesPalmitic Acid 98 FGK MSDSDave ImpresoNo ratings yet

- Usha Pipe CoDocument19 pagesUsha Pipe CoAnoop MittalNo ratings yet

- Kalviseithi 11th STD Chemistry School Guides SampleDocument119 pagesKalviseithi 11th STD Chemistry School Guides SampleslogeshwariNo ratings yet

- Names and Formulas of InorganicDocument24 pagesNames and Formulas of InorganicMae SocialNo ratings yet

- Basics of SinteringDocument50 pagesBasics of SinteringKeyur PatelNo ratings yet

- Operational Pollution of ShippingDocument24 pagesOperational Pollution of ShippingKamal RahimNo ratings yet

- Practical Lab Report Typed Burning Fuels Fill inDocument6 pagesPractical Lab Report Typed Burning Fuels Fill inAh Yeong LeeNo ratings yet

- Engineering Field Manual PDFDocument195 pagesEngineering Field Manual PDFMahmoud Ahmed Ali AbdelrazikNo ratings yet

- CH 06Document34 pagesCH 06Firas Abu talebNo ratings yet

- NQE 2008 ChemistryDocument24 pagesNQE 2008 Chemistryaleth felicianoNo ratings yet

- IRC SP 100 - 2014 Cold Mix Technology in Construction PDFDocument95 pagesIRC SP 100 - 2014 Cold Mix Technology in Construction PDFrjg_vijay50% (2)

- Brand Neopor-Flyer - Product Range Styropor Neopor Und Peripor-EnglishDocument4 pagesBrand Neopor-Flyer - Product Range Styropor Neopor Und Peripor-EnglishlmunaycomNo ratings yet

- BIOCELL Product ListDocument9 pagesBIOCELL Product ListBiocell PharmaNo ratings yet

- Chem Qs MolesDocument7 pagesChem Qs MolesWinson LauNo ratings yet

- Plga StructureDocument16 pagesPlga StructuredharanisparkNo ratings yet

- LESSON 3.1 (Iron Ore and Pig Iron) (Autosaved)Document27 pagesLESSON 3.1 (Iron Ore and Pig Iron) (Autosaved)Lovely Jaze SalgadoNo ratings yet

- INChO 2016Document29 pagesINChO 2016Deepak kumarNo ratings yet

- Estimate The Capital Cost of Shale-Gas Monetization ProjectsDocument7 pagesEstimate The Capital Cost of Shale-Gas Monetization ProjectsCamila Martinez CasasNo ratings yet

- Diffusion Make Welding ElectrodeDocument9 pagesDiffusion Make Welding ElectrodeSarah FrazierNo ratings yet

- Property Evaluation of Magnesium Phosphate Cement MortarDocument6 pagesProperty Evaluation of Magnesium Phosphate Cement MortarUfuk AKKAŞOĞLUNo ratings yet

- Charles FryerDocument16 pagesCharles FryerAMANo ratings yet

- Muscle - Phosphotungstic Acid-Hematoxylin, Mallory's (Ptah)Document5 pagesMuscle - Phosphotungstic Acid-Hematoxylin, Mallory's (Ptah)TEO COAQUIRANo ratings yet

- Oxidation ReductionDocument7 pagesOxidation ReductionZul Abror Bin Ya'akopNo ratings yet

- Exercise BM With Chemical ReactionDocument2 pagesExercise BM With Chemical ReactionSergio Rugerio TorresNo ratings yet

- Is.3399.2013 Zinc Oxide PDFDocument9 pagesIs.3399.2013 Zinc Oxide PDFvedNo ratings yet

- Saf-202 TDSDocument1 pageSaf-202 TDSHar DsrNo ratings yet

- Scheduled Waste Management PDFDocument36 pagesScheduled Waste Management PDFnuraini arbainNo ratings yet

- NWwtr09 - Hamrick DGA For TransformersDocument3 pagesNWwtr09 - Hamrick DGA For TransformersshuwingNo ratings yet

- Juba Form Two ExamDocument8 pagesJuba Form Two ExamHossam Abdalla SalehNo ratings yet