Professional Documents

Culture Documents

SOPyhj

Uploaded by

Anonymous PN6h7s8hOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOPyhj

Uploaded by

Anonymous PN6h7s8hCopyright:

Available Formats

MASTER COPY

Page No.: 1 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

1.0

PURPOSE

The purpose of this SOP compiles the RB standards for working near or on live parts

2.0

SCOPE

This SOP is applicable and complied with, by BOTH RB personnel and outside contractors.

3.0

RESPONSIBILITY

Competent Person

4.0

SAFETY, HEALTH & ENVIRONMENT PRECAUTIONS

PPE Required

Hot sticks

Voltage rated hand tools

Approved high and low voltage testers

Red danger locks

Red danger tags

Temporary protective grounds

Flame resistant (FR) long sleeve shirt and pants (or coveralls)with a minimum arc rating of 8 cal/cm

Leather electrical hazard (EH) - rated work shoes/boots

Non metallic safety glasses with side shields

Class E hard hat

Voltage rated gloves with leather protectors

Hearing protection (ear canal inserts)

5.0

DEFINITIONS

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 2 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

Working on/near Live Parts

Working on live circuits means actually touching energized parts. Working near live circuits means

working close enough to energized parts to pose a risk even though you make be working on deenergized parts. Common tasks where you need to work on or near live circuits include:

5.1

5.2

5.3

5.4

Taking voltage measurements

Opening and closing disconnects and breakers

Racking breakers on and off the bus

Removing panels and dead fronts

Opening electric equipment doors for inspection

When a person is exposed to a bare (exposed), energized conductor he or she is

at risk of injury not only to themselves, but also to others nearby. The hazards

of working on or near bare energized electrical conductors can result in

electrical shock, electrocution, arc flash burns, arc blast, thermal burns,

respiratory contamination and other physical trauma injuries related to falling or

being struck by objects due to an arc blast.

Energized Work

The definition of energized work is Work on or near (e.g. part of tools being used or workers body

less then the minimum working distance (restricted approach boundary) energized or potentially

energized lines (i.e., grounding, live line tool (hot stick) work, gloving and bare hand work)

Electrically Safe Work Condition

A state in which the conductor or circuit part to be worked on or near has been

disconnected from energized parts, locked/tagged out (or equivalent) in

accordance with established standards, tested to ensure the absence of voltage,

and grounded if determined necessary.

Shock Protection BoundariesLimited Approach Boundary a distance from an exposed live part within

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 3 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

which a shock hazard exists.

Restricted Approach Boundary a distance from an exposed live part, within

which there is an increased risk of shock due to electrical arc, for personnel

working in close proximity to the live part.

Prohibited Approach Boundary a distance from and exposed live part within

which work is considered the same as making contact with the live part.

5.5

5.6

5.7

6.0

Potential Energy Sources

AC electrical potential above 50 volts, DC electrical potential above 50 volts and

associated mechanical devices.

Flash Protection BoundaryA distance from exposed live parts within which a person could receive a second

degree burn if an electrical arc flash were to occur.

a. At voltage levels above 600 volts the Flash Protection Boundary is physical

limits of the equipment room, inside of which ALL personnel shall be protected.

b. At voltage levels of 600 volts and less the Flash Protection Boundary shall be

4.0 feet

Qualified Person

One who has skill and knowledge related to the construction and operation of

electrical equipment and installation and who has received safety training on

the hazards involved.

PROCEDURE

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 4 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

6. 1

All energized work requires written task specific procedures approved by the Safety Officer

containing all appropriate safe work practices and PPE as required

6.2

Limits of Approach:

The approach boundaries are specified distances from an exposed energized conductor that identify

established requirements for additional safety measures. The voltages to be used in determining the

approach boundaries are the nominal phase-to-phase voltages. See Table 1 for approach distances for

various system voltages. When working on systems of a lower voltage requires working near a higher

voltage the approach boundaries of the higher voltage are also applicable. If the lower voltage work

requires working inside the restricted approach boundary of high voltage (above 600 volts), the

worker shall be a qualified /competent person (CP) for high voltage work and wear the appropriate

PPE or the high voltage circuits shall be put in a safe work condition.. Overhead conductors on utility

poles shall always be considered exposed (bare) regardless of the appearance of insulation.

Limited Approach Boundary

Any activity within the limited approach boundary is considered working near. A CP shall take

measures as necessary to prevent anyone from entering the limited approach boundary that is not a

qualified person or is knowledgeable of the task to be performed. This may involve the use of

barricades, barricade tape, signs, or other means as necessary to control access. If signs and

barricades do not provide sufficient warning and protection from the electrical hazards, an attendant

shall be stationed to warn and protect employees or a safe work condition re-established.

o The minimum approach distance for an unqualified person is 10 ft (3m).

o An unqualified person, wearing the required PPE, can be allowed to cross the limited

approach boundary only if a qualified person advises him or her of the possible

hazards, provide the proper PPE and provides a continuous escort while inside the

approach boundary.

Minimum Working Distance (MWD) (Restricted Approach Boundary (RAB))

Under no circumstances shall an unqualified person be permitted to cross the restricted approach

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 5 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

boundary prior to a safe work condition being established. No qualified person shall approach or

take any conductive object, hot stick or voltage rated hand tool closer to the exposed energized

conductor then the restricted approach boundary, unless he or she meets all the following conditions:

o Follow either a standard operating procedure / job hazard analysis

(SOP) or a special permission energized electrical work permit with a

project safety plan written for a specific energized task and signed

by the Safety Officer

o Use only voltage rated tools.

o Use appropriate PPE for protection from shock.

o Use appropriate PPE for arc flash protection.

o Minimize the risk from inadvertent movement by keeping as much of the body out of

the restricted space as possible, using only protected body parts in the restricted space

as necessary to accomplish the work.

o Be certain that no un-insulated part of the body crosses the prohibited boundary.

Prohibited Approach Boundary (PAB)

No un-insulated part of the body shall be allowed to cross the prohibited approach boundary.

Crossing the prohibited approach boundary is considered the same as making contact or working

on. Troubleshooting, taking voltage readings, applying safety grounds, insertion or removal of

revenue meters, installing or removal of individual starter buckets in a motor control center, and any

work involving moving an exposed, energized conductor are also considered working on.

Flash Protection Boundary (FPB)

The flash protection boundary is intended to trigger the need for PPE that can

protect the worker from thermal injury. A conservative default flash protection

boundary has been established at 4 feet for voltages between 50 and 600 volts

& for voltages above 600 volts FPB has been established at 20 feet.

6.3

Prohibited Energized Work Practices:

Gloving above 600 volts and the bare hand technique over 50 volts is prohibited.

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 6 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

6.4

Required Safe Work Practices for Energized Work

Procedures written for energized work shall identify safe work practices in step by step detail using

the below outline as a guide.

Step 1 Access job site

Only qualified persons shall perform energized work.

Examine job site, look for hazardous conditions, determine means to abate hazards

Notify immediate supervisor prior to starting any energized work, if work is after hours

contact the safety officer.

Step 2 Job site setup

Flash protection boundary for low voltage systems is 4 feet unless determined

otherwise by a flash hazard analysis.

Determine limited approach boundary and restricted approach boundary using table 1.

Limit access within the limited approach and flash protection boundaries to qualified

personnel only.

Identify and clear an escape route to an area 10 or more beyond the flash protection

boundary.

Ensure the area is well lighted

Determine required PPE for specific task per table 2.

Step 3 Job brief

Conduct a pre-job briefing to address all hazards and plan work.

Step 4 Inspect PPE, voltage rated tools and test instruments

Perform a pre-use rubber goods and hot sticks inspection.

Perform a pre-use inspection of other PPE.

Perform a pre-use inspection on voltage rated hand tools.

Perform a pre-use inspection on test instruments.

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 7 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

Step 5 Don PPE

Remove all conductive articles of clothing or jewelry.

Don all PPE as required in table 2.

6.5

Step 6 Perform task

Follow listed requirements for work within limited approach boundaries..

Follow listed requirements for work within minimum working Distance .

PPE for Electrical Shock and Arc Flash Protection:

Any worker whose normal job includes working on or near exposed energized electrical

conductors/equipment shall wear to work as a minimum long sleeve shirts and pants (or

coveralls) with a minimum arc rating of 8 cal/cm, cotton underwear (conventional short

sleeve T shirt and brief/shorts) and leather EH rated safety shoes/boots.

All employees who approach within 4 feet of exposed energized electrical

conductors/equipment operating at a voltage of 600 volts or less shall wear at a minimum

long sleeve shirts and pants (or coveralls) with a minimum arc rating of 8 cal/cm, cotton

underwear (conventional short sleeve T shirt and brief/shorts), leather EH rated safety

shoes/boots, a class E hard hat, safety glasses with side shields plus additional PPE as

required by tables 2 and 3 for the specific tasks involved. Flash Protection Boundary for the

conditions when this approach distance is required to be determined by a flash hazard

analysis. Any employee not wearing all the required PPE for any of the specific tasks listed

below shall maintain a distance greater than 10 feet from the task being performed.

Insertion or removal (racking) of CBs from cubicles with doors open for 600 V

class switchgear (with power circuit breakers or fused switches)

Removal of bolted covers (to expose bare, energized parts) of 600V class

switchgear (with power circuit breakers or fused switches)

Work on control circuits with energized parts > 120V(fused contactor motor

starters 2.3 kV through 7.2 kV)

Work on control circuits with energized parts > 120V, exposed for metal clad

switchgear, 1 kV and above.

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 8 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

All employees within 10 feet of the specific task involved shall wear at a minimum long

sleeve shirts and pants (or coveralls) with a minimum arc rating of 8 cal/cm, cotton

underwear (conventional short sleeve T shirt and brief/shorts), leather EH rated safety

shoes/boots plus all the PPE required by table 2.

Employees engaged in performing the specific tasks shall wear the PPE described in the

paragraph immediately above when approaching within 20 feet of exposed energized

electrical conductors/equipment normally operating above 600 volts.

PPE for measuring/testing tasks not listed in table 2 and 3 shall be determined by

performing a flash hazard analysis.

PPE, voltage rated tools, and test instrument pre-use inspection:

All PPE and voltage rated tools shall be visually inspected prior to each days use and immediately

following any incident that can reasonably be suspected of having caused damage. Insulating rubber

goods shall be inspected as required. PPE and voltage rated tools found to have damage that could

affect its performance shall not be used on or near exposed energized conductors. Test instruments

and equipment and all associated test leads, cables, power cords, probes, and connectors shall be

visually inspected for external defects and damage before the equipment is used on any shift. If there

is a defect or evidence of damage that might expose an employee to injury, the defective or damaged

item shall be removed from service and not used until repairs necessary to render the equipment safe

have been made.

Test Instruments:

Test instruments, equipment, and their accessories shall be rated for circuits and equipment to which

they will be connected and designed for the environment to which they will be exposed, and for the

manner in which they will be used.

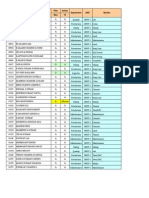

PPE Requirements for Specific Tasks:

6.6

6.7

6.8

6.9

Table2 in Appendix identifies minimum PPE requirements for specific asks(assuming exposed

equipment is energized, and work is within the flash protection boundary).

Underground Work:

Treat underground structures such as manholes and unvented vaults as confined spaces. Consult

confined space entry SOPs for safety procedures. All equipment inside an underground structure

(including manholes and vaults) operating at high voltage levels should be de-energized before

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 9 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

allowing entry into the underground structure. This includes insulated conductors. If the equipment

inside the manhole cannot be de-energized, apply the PPE requirements of table 3. Cables must not

be moved, adjusted or disturbed when energized. If a cable in an underground structure has one or

more abnormalities that could lead to or be an indication of an impending fault, the defective cable

must be de-energized before any employee can enter the manhole. Abnormalities such as oil or

compound leaking from cable or joints, broken cables sheaths or joint sleeves, hot localized surface

temperatures of cables or joints, or joints that are swollen beyond normal tolerance are presumed to

lead to or be an indication of an impending fault..

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 10 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

7.0

8.0

FORMATS

Format number

Title

NA

NA

RECORD

Record number

9.0

Title

REFERENCES

NA

10.0

ABBREVIATION

NA

11.0

12.0

ANNEXURE

Annexure number

Title

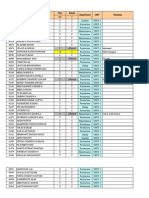

Table1 for approach boundary

Table2 for PPE requirements for different purposes.

REVISION HISTORY

Annexure-1

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 11 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

Table 1. Approach boundaries to live parts for shock prevention

Limited approach boundary

Restricted approach boundary

Nominal system voltage Exposed movable Exposed fixed(allowing for accidental

range, phase to phase conductor

circuit part

movement)

Prohibited

approach

boundary

0 to 50 volts

Not specified

Not specified

Not specified

Not specified

51 to 300 volts

10 ft. 0 in.

3 ft. 6 in.

Avoid contact

Avoid contact

301 to 750 volts

10 ft. 0 in.

3 ft. 6 in.

1 ft. 0 in.

0 ft. 1 in.

751 to 15,000 volts

10 ft. 0 in.

5 ft. 0 in.

2 ft. 2 in.

0 ft. 7 in.

Annexure-2

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 12 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

MASTER COPY

Page No.: 13 of 13

STANDARD OPERATING PROCEDURE

Mysore

Copy No

ENGINEERING

TITLE

WORK NEAR OR ON LIVE PARTS

SOP No

ENGG

00

REVIEW

DATE

EFFECTIVE DATE

CONTROLLED DOCUMENT-NOT TO BE PHOTOCOPIED WITHOUT AUTHORISATION

Name

Prepared by

Reviewed by

Approved by

F/QA/01

Aman Singh

Designation

Executive

Signature

Date

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- HW2 Om (1) 7Document4 pagesHW2 Om (1) 7Anonymous PN6h7s8hNo ratings yet

- List of SC/ST Under Govt. of NCT of DelhiDocument1 pageList of SC/ST Under Govt. of NCT of DelhiAnonymous PN6h7s8hNo ratings yet

- Julius Caesar (Translation) - CBSE Notes 2011-2012Document11 pagesJulius Caesar (Translation) - CBSE Notes 2011-2012Anonymous PN6h7s8hNo ratings yet

- Accident Investigation ReportDocument4 pagesAccident Investigation ReportAnonymous PN6h7s8hNo ratings yet

- 3 BHK Flat On RentDocument1 page3 BHK Flat On RentAnonymous PN6h7s8hNo ratings yet

- About Indian Institute of Management Ahmedabad (Iima) - 5Document32 pagesAbout Indian Institute of Management Ahmedabad (Iima) - 5Anonymous PN6h7s8hNo ratings yet

- C Shift 7 11 14Document1,890 pagesC Shift 7 11 14Anonymous PN6h7s8hNo ratings yet

- Description HARPIC ITC - Thermoform Tray - Double's Pack With Seal Rev 0.0 Prepared by Subir Ray Date 26.11.13Document1 pageDescription HARPIC ITC - Thermoform Tray - Double's Pack With Seal Rev 0.0 Prepared by Subir Ray Date 26.11.13Anonymous PN6h7s8hNo ratings yet

- A Attendance 19-05-14Document6 pagesA Attendance 19-05-14Anonymous PN6h7s8hNo ratings yet

- Ee 6103 - Power Systems AnalysisDocument1 pageEe 6103 - Power Systems AnalysisAnonymous PN6h7s8hNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- KWXTI5500 501 EngDocument6 pagesKWXTI5500 501 EngDaniel HallbergNo ratings yet

- AccuLoad III-D Operator Reference ManualDocument120 pagesAccuLoad III-D Operator Reference Manualpablobs100% (1)

- To Determine The V Curve of A Synchronous MotorDocument3 pagesTo Determine The V Curve of A Synchronous MotorAthay khanNo ratings yet

- Coupled Mode Theory of WaveguidesDocument18 pagesCoupled Mode Theory of WaveguidesKartikay5No ratings yet

- TDS 5450 Soft EN 20091127Document2 pagesTDS 5450 Soft EN 20091127Tim LeclerNo ratings yet

- Circuit Theory: DR Paul S SpencerDocument13 pagesCircuit Theory: DR Paul S SpencerMathew ClewlowNo ratings yet

- LM380 Power Audio AmplifierDocument8 pagesLM380 Power Audio AmplifierYonatan José Roche AndradeNo ratings yet

- AHB SlaveDocument18 pagesAHB SlaveRam VutaNo ratings yet

- EOBDII Fault Code Reader: With CAN Protocol. For Petrol Engines From 2001 Onwards and From 2004 For Diesel EnginesDocument78 pagesEOBDII Fault Code Reader: With CAN Protocol. For Petrol Engines From 2001 Onwards and From 2004 For Diesel EnginesAliNo ratings yet

- Instuments Types With ExamplesDocument9 pagesInstuments Types With ExamplesAmmar KhalidNo ratings yet

- Velomitor CT Transducer 125389-01 REV CDocument57 pagesVelomitor CT Transducer 125389-01 REV CHamid HannitNo ratings yet

- Basic Layout of OLTDocument3 pagesBasic Layout of OLTgulasbotNo ratings yet

- Data Sheet 3VM1110-3EE32-0AA0: ModelDocument4 pagesData Sheet 3VM1110-3EE32-0AA0: ModelJanaina SouzaNo ratings yet

- Lecture#7Document43 pagesLecture#720pwmct0739No ratings yet

- Understanding A Gas Sensor - Jaycon SystemsDocument1 pageUnderstanding A Gas Sensor - Jaycon SystemsSAN PEDRO IngenieríaNo ratings yet

- Energies: Design and Implementation of A Low-Power Low-Cost Digital Current-Sink Electronic LoadDocument14 pagesEnergies: Design and Implementation of A Low-Power Low-Cost Digital Current-Sink Electronic LoadciccioNo ratings yet

- AdrenaLinn Sync User GuideDocument1 pageAdrenaLinn Sync User GuidesNo ratings yet

- Level3 - Application Note Earth Leakage RelayDocument4 pagesLevel3 - Application Note Earth Leakage RelayChhinPidenNo ratings yet

- Technical Specsfor Energy MeterDocument32 pagesTechnical Specsfor Energy MeterbharatsinghNo ratings yet

- Railway Bridge Monitoring During Construction and Sliding: IMAC - Stress Analysis LaboratoryDocument7 pagesRailway Bridge Monitoring During Construction and Sliding: IMAC - Stress Analysis LaboratoryMariusHazaparuNo ratings yet

- RF Based Dual Mode RobotDocument17 pagesRF Based Dual Mode Robotshuhaibasharaf100% (2)

- Mit Lab 01Document6 pagesMit Lab 01api-247714257No ratings yet

- Assignment 21 EM WavesDocument10 pagesAssignment 21 EM Wavesbob jizzleNo ratings yet

- Transducers - 2.1 Sensors and Actuators - IOT2x Courseware - EdXDocument4 pagesTransducers - 2.1 Sensors and Actuators - IOT2x Courseware - EdXzaheeruddin_mohdNo ratings yet

- MisII Manual PageDocument21 pagesMisII Manual PageMorgan PeemanNo ratings yet

- L - 02 - Calibration of The Testing SystemDocument60 pagesL - 02 - Calibration of The Testing SystemSanjaya PereraNo ratings yet

- BrosurDocument68 pagesBrosurKiki Xhui7No ratings yet

- GR-SXM58 GR-SXM48 GR-FXM38 GR-SX24 GR-FX14: Compact Vhs CamcorderDocument2 pagesGR-SXM58 GR-SXM48 GR-FXM38 GR-SX24 GR-FX14: Compact Vhs CamcorderMaryNo ratings yet

- Circuit Breaker NTS Questions, Interview Questions and All About Circuit BreakerDocument46 pagesCircuit Breaker NTS Questions, Interview Questions and All About Circuit BreakerEngr Mubashar Ali50% (2)