Professional Documents

Culture Documents

PTK1

Uploaded by

hagg0 ratings0% found this document useful (0 votes)

80 views2 pagesHypro

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHypro

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

80 views2 pagesPTK1

Uploaded by

haggHypro

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

HY-PRO FILTRATION

PTK-1 Test Kit

PTK1 Oil Analysis Patch Test Kit

A valuable tool for visually

analyzing contamination levels

and contaminate types in

hydraulic and lubrication systems

in the field when you need results

now.

Applications

Complete PTK-1 Kit Includes

Monitoring fluid cleanliness in hydraulic and

lubrication systems is a common practice. When

the pressure is on waiting weeks for bottle samples

from an independent lab might not be an option. Oil

analysis practices vary from lab to lab and once the

sample is shipped off you no longer have control of

the sample or how it is processed.

Complete PTK-1 Kit Includes

100x magnification field microscope

1.2m filter test patches

Funnel assembly with ml fill line for accuracy

Vacuum pump to extract fluid samples from the system

and process 25ml sample through filter patch

See The Difference, Control The Process

Sample bottles

With PTK-1 oil cleanliness can be visually

analyzed in the field without waiting for lab results

and losing control of the analyzing process. The

PTK-1 kit provides the opportunity to see the

type, concentration, and actual size of particulate

contamination inside the system. The kit includes

reference photos so that the patch sample can be

correlated to an approximate ISO Fluid Cleanliness

Code. When used in conjunction with the PM-1

on-line particle counting equipment exact fluid

cleanliness and visual analysis are at your fingertips.

When you need results now the PTK-1 is great

alternative to off-site oil analysis laboratories.

Forceps for filter patch handling

Solvent dispenser with dispensing filters

Instruction manual

Visual correlation chart to determine

approximate ISO Cleanliness Code of patch test kit

sample

Visual correlation chart to determine type of particles

captured on the patch

Patch mounting cards and adhesive covers to protect

samples from ambient contamination and to preserve

samples for future reference

www.hyprofiltration.com

PTK-1 Test Kit

Draw the sample fluid through the

patch by pulling on the vacuum

pump handle. Confirm that the waste

bottle and funnel-patch assembly

are sealed.

Once the entire sample has passed

through the patch rinse the funnel

with filtered solvent and draw

through the patch. Then separate

the funnel from the patch supporter

and remove the patch with forceps.

Place the sample (ink/dirty side up)

on a clean index card and cover it

immediately with a plastic laminate

patch cover.

Analyze the sample with the 100x

magnification field microscope. For

best results it might be necessary

to hold the light source closer to the

sample

Analyze the sample with the 100x

magnification field microscope. For

best results hold the light source

closer to the sample

Use the reference manual photos

to make approximate ISO code

correlation and identify contaminant

types.

Bright metal particle typically from

internal contaminant generation.

Combination bright metal, silica,

rust, gel and fiber materials.

Rust or gel

www.hyprofiltration.com

AT-PTK1-0812

You might also like

- PTK1 Oil Analysis Patch Test KitDocument2 pagesPTK1 Oil Analysis Patch Test KitВалерия КорнееваNo ratings yet

- Oil Analysis Patch Test KitDocument1 pageOil Analysis Patch Test KitOscar Navarro100% (1)

- Handout BioPlexDocument6 pagesHandout BioPlexGeorge ValiakosNo ratings yet

- Usp 788Document3 pagesUsp 788Wesley OliveiraNo ratings yet

- FINAL Ink Jet Lab 021207Document13 pagesFINAL Ink Jet Lab 021207Emma SNo ratings yet

- Sop of Disinfection, CoatingDocument27 pagesSop of Disinfection, CoatingAhmed Quadri0% (1)

- Usp 203 High-Performance Thin-Layer Chromatography Procedure For Identification of Articles of Botanical OriginDocument3 pagesUsp 203 High-Performance Thin-Layer Chromatography Procedure For Identification of Articles of Botanical OriginLexxie85100% (1)

- APR SORT B 04 Color Sortation ProtocolDocument13 pagesAPR SORT B 04 Color Sortation ProtocolnomsyNo ratings yet

- Guidance on Testing Fire Fighting FoamDocument21 pagesGuidance on Testing Fire Fighting Foamluckystrike9008No ratings yet

- Prueba de RefractometroDocument7 pagesPrueba de RefractometroPaulina Andrea Jiménez VarasNo ratings yet

- Headspace Oxygen Measurement in Vials and AmpoulesDocument4 pagesHeadspace Oxygen Measurement in Vials and AmpoulesGhanta Ranjith KumarNo ratings yet

- Talc OSHA 2121Document15 pagesTalc OSHA 2121Zenal AbidinNo ratings yet

- Landwind Biomedical Technology Mass Spectrometer Reagents ConsumablesDocument3 pagesLandwind Biomedical Technology Mass Spectrometer Reagents ConsumablesMohammed Kahla'aNo ratings yet

- Penetrant Testing-III March 2009Document51 pagesPenetrant Testing-III March 2009DanielNo ratings yet

- USD2301 Integrity Testing Filter Presterilized Single Use Bag System An enDocument8 pagesUSD2301 Integrity Testing Filter Presterilized Single Use Bag System An enMarcelo García FacalNo ratings yet

- Qualification of Manufacturing EquipmentDocument44 pagesQualification of Manufacturing Equipmentinnovativejayesh27No ratings yet

- 203 High-Performance Thin-Layer Chromatography Procedure For Identification of Articles of Botanical OriginDocument4 pages203 High-Performance Thin-Layer Chromatography Procedure For Identification of Articles of Botanical OriginRonak PatelNo ratings yet

- MICLAB 060 SampleDocument7 pagesMICLAB 060 SampleVizit31No ratings yet

- Hach 8009 Zinc Ed 08Document6 pagesHach 8009 Zinc Ed 08Beth AlvaradoNo ratings yet

- 788 - Particulate Material - Usp MonographDocument6 pages788 - Particulate Material - Usp MonographVanessa CarreraNo ratings yet

- Catalogo Control ContaminantesDocument132 pagesCatalogo Control ContaminantesJose Jaramillo50% (2)

- Framework For Testing The Performance of All-Purpose Cleaners, Window Cleaners and Sanitary Cleaners Version 1.3 of Sep 2012Document4 pagesFramework For Testing The Performance of All-Purpose Cleaners, Window Cleaners and Sanitary Cleaners Version 1.3 of Sep 2012Shaun RimosNo ratings yet

- HPX 87c ManualDocument22 pagesHPX 87c ManualSharini_Mu_oz_137No ratings yet

- FO1081-01A MaxSignal® Oxytetracycline ELISA Test Kit Manual 07052014Document12 pagesFO1081-01A MaxSignal® Oxytetracycline ELISA Test Kit Manual 07052014phucongchiNo ratings yet

- Cleaning Validation GuidlinesDocument8 pagesCleaning Validation GuidlinesswanandkulNo ratings yet

- PhosphateDocument8 pagesPhosphateUmi NazaliaNo ratings yet

- Cleaning Validation Practices Using A Single Pot ProcessorDocument9 pagesCleaning Validation Practices Using A Single Pot Processorjljimenez1969No ratings yet

- 463 PHT Quality Control of Pharmaceutical AerosolsDocument16 pages463 PHT Quality Control of Pharmaceutical AerosolsPavani RamNo ratings yet

- Endotoxin Test Protocol PTSDocument5 pagesEndotoxin Test Protocol PTSSebastián SalazarNo ratings yet

- Cleaning & Monitoring: ProceduresDocument6 pagesCleaning & Monitoring: Proceduresumi_hayyatNo ratings yet

- Disposable Syringe Project ProfileDocument17 pagesDisposable Syringe Project Profileskype2121No ratings yet

- Opthalmic PreparationsDocument8 pagesOpthalmic PreparationsprasanthiNo ratings yet

- Revital-Ox Step 3 High Level Disinfecting Wall ChartDocument1 pageRevital-Ox Step 3 High Level Disinfecting Wall ChartLizethNo ratings yet

- Visual Inspection of Inject Able Products More Than Just Sorting Good From BadDocument44 pagesVisual Inspection of Inject Able Products More Than Just Sorting Good From BadEngy Hany Moustafa50% (2)

- Validation of Membrane FiltrationDocument32 pagesValidation of Membrane Filtrationruby100% (1)

- Swabbing technique and active residue limitsDocument3 pagesSwabbing technique and active residue limitsAGANo ratings yet

- PDFDocument39 pagesPDFEdna Lip AnerNo ratings yet

- Destructive TestingDocument17 pagesDestructive Testingసురేంద్ర కారంపూడిNo ratings yet

- Hy Lite InstructionDocument4 pagesHy Lite InstructionArluky NovandyNo ratings yet

- Specific Gravity by Density Meter - 6657759 - 01Document9 pagesSpecific Gravity by Density Meter - 6657759 - 01Joe LavaNo ratings yet

- Experiment No: 13 Solubility of Bituminous Material: (Aashto Designation: T 44-93 Astm Designation: D 2042-81)Document5 pagesExperiment No: 13 Solubility of Bituminous Material: (Aashto Designation: T 44-93 Astm Designation: D 2042-81)Tanvir Rajib 191-47-234No ratings yet

- Environmental Swabbing PDFDocument10 pagesEnvironmental Swabbing PDFnilebhalNo ratings yet

- Dissertation On Cleaning ValidationDocument8 pagesDissertation On Cleaning ValidationPapersHelpUK100% (1)

- Testing and Quality ControlDocument51 pagesTesting and Quality ControlVishal PoddarNo ratings yet

- Filter ManualDocument53 pagesFilter ManualHazem DiabNo ratings yet

- SOP For Serial Dilutions of Microbial CultureDocument5 pagesSOP For Serial Dilutions of Microbial CultureranerxNo ratings yet

- 2017 07531 Milliflex Rapid Autospray Station Data Sheet MRK Web MKDocument4 pages2017 07531 Milliflex Rapid Autospray Station Data Sheet MRK Web MKTHIEBAUDNo ratings yet

- AflaCup COKAC1020 Package InsertDocument1 pageAflaCup COKAC1020 Package InsertEmrullah CemiloğluNo ratings yet

- Qualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesDocument1 pageQualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesAli Goutas50% (2)

- 1 TabletDocument45 pages1 TabletkjghlkdfjgNo ratings yet

- Particulate Matter in Injections StandardsDocument4 pagesParticulate Matter in Injections StandardsQC MahakamNo ratings yet

- Purgeable Aromatics by GC MethodDocument22 pagesPurgeable Aromatics by GC MethodSyedahmadraza BokhariNo ratings yet

- Solid-Liquid Filtration: Practical Guides in Chemical EngineeringFrom EverandSolid-Liquid Filtration: Practical Guides in Chemical EngineeringRating: 5 out of 5 stars5/5 (1)

- Flow charts of pharmaceutical quality control tests for different dosage formsFrom EverandFlow charts of pharmaceutical quality control tests for different dosage formsNo ratings yet

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingFrom EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingRating: 5 out of 5 stars5/5 (9)

- Adiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringFrom EverandAdiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringNo ratings yet

- Solid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityFrom EverandSolid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityRating: 5 out of 5 stars5/5 (2)

- How to Scale-Up a Wet Granulation End Point ScientificallyFrom EverandHow to Scale-Up a Wet Granulation End Point ScientificallyRating: 4 out of 5 stars4/5 (1)

- Servo Actuator POS 100Document2 pagesServo Actuator POS 100haggNo ratings yet

- STEP 7 - Working With STEP 7Document108 pagesSTEP 7 - Working With STEP 7saranjit1No ratings yet

- Accumulator PDFDocument25 pagesAccumulator PDFJuan Alejandro Cañas ColoradoNo ratings yet

- Pressure SwitchesDocument4 pagesPressure SwitcheshaggNo ratings yet

- ITI - Sim: SimulationDocument13 pagesITI - Sim: SimulationhaggNo ratings yet

- Abe33 22 2001 08 27Document12 pagesAbe33 22 2001 08 27haggNo ratings yet

- ITI - Sim: Simulation ApplicationDocument5 pagesITI - Sim: Simulation ApplicationhaggNo ratings yet

- Pooyan Hydraulics: Description Symbol ApplicationDocument20 pagesPooyan Hydraulics: Description Symbol Applicationrmajdi2000100% (2)

- ITI - Sim: Simulation ApplicationDocument3 pagesITI - Sim: Simulation ApplicationhaggNo ratings yet

- E Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievingDocument30 pagesE Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievinghaggNo ratings yet

- Pressure Switch For Panel Mounting: Cutout in The Panel Section A-ADocument4 pagesPressure Switch For Panel Mounting: Cutout in The Panel Section A-AhaggNo ratings yet

- Catalogo de AcumuladoresDocument65 pagesCatalogo de Acumuladoresingenioso23No ratings yet

- Abe32 10 2002 11 14Document4 pagesAbe32 10 2002 11 14haggNo ratings yet

- Piston Pressure Switch Hydraulic-ElectricDocument2 pagesPiston Pressure Switch Hydraulic-ElectrichaggNo ratings yet

- Oil Level Indicator AB-E 31-21: ND3 Sheet 1Document5 pagesOil Level Indicator AB-E 31-21: ND3 Sheet 1hagg0% (1)

- Thermostat AB-E 31-32: Adjustment Range 5 To 100°CDocument2 pagesThermostat AB-E 31-32: Adjustment Range 5 To 100°ChaggNo ratings yet

- Resistance Thermometer AB-E 31-17: 1 Area of ApplicationDocument3 pagesResistance Thermometer AB-E 31-17: 1 Area of Applicationhagg0% (1)

- Heat Exchanger AB-E 32-09: Oil / Water System: Single TubeDocument7 pagesHeat Exchanger AB-E 32-09: Oil / Water System: Single TubehaggNo ratings yet

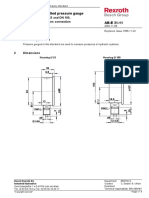

- Glycerine Filled Pressure Gauge AB-E 31-11: DN 63 and DN 100, Bottom ConnectionDocument4 pagesGlycerine Filled Pressure Gauge AB-E 31-11: DN 63 and DN 100, Bottom ConnectionhaggNo ratings yet

- Float Switches AB-E 31-06: Without Protective Tube, With One or Two Switching Contacts Sheet 1Document6 pagesFloat Switches AB-E 31-06: Without Protective Tube, With One or Two Switching Contacts Sheet 1haggNo ratings yet

- SolenoidsDocument12 pagesSolenoidshaggNo ratings yet

- Abe21 14 2002 11 06Document2 pagesAbe21 14 2002 11 06haggNo ratings yet

- Technical Catalogue FPDocument100 pagesTechnical Catalogue FPhaggNo ratings yet

- Hydraulic piston pressure switches with electrical outputsDocument2 pagesHydraulic piston pressure switches with electrical outputshagg100% (1)

- 2-Conceptos y Principios GeneralesDocument65 pages2-Conceptos y Principios GeneralesMichael Mejia MoraNo ratings yet

- D O Cetop 3/Ng6: Irectional Control Valves Ther Operator IDocument3 pagesD O Cetop 3/Ng6: Irectional Control Valves Ther Operator IhaggNo ratings yet

- The Oil Level Switch With Technical and Economical Advantages!Document2 pagesThe Oil Level Switch With Technical and Economical Advantages!haggNo ratings yet

- IGCDocument10 pagesIGChaggNo ratings yet

- Catalogo VL Cepto3 y Cepto4Document274 pagesCatalogo VL Cepto3 y Cepto4paula vergaraNo ratings yet

- Technical Catalogue: June JuneDocument9 pagesTechnical Catalogue: June JunehaggNo ratings yet

- Principles of Cost Accounting 1Document6 pagesPrinciples of Cost Accounting 1Alimamy KamaraNo ratings yet

- Delhi Public School: Class: XI Subject: Assignment No. 3Document1 pageDelhi Public School: Class: XI Subject: Assignment No. 3Aman Kumar BhagatNo ratings yet

- HU675FE ManualDocument44 pagesHU675FE ManualMar VeroNo ratings yet

- 4 - Complex IntegralsDocument89 pages4 - Complex IntegralsryuzackyNo ratings yet

- Module 4-Answer KeyDocument100 pagesModule 4-Answer KeyAna Marie Suganob82% (22)

- Chapter 1 - IntroductionDocument42 pagesChapter 1 - IntroductionShola ayipNo ratings yet

- UT Dallas Syllabus For Ee3311.002.07f Taught by Gil Lee (Gslee)Document3 pagesUT Dallas Syllabus For Ee3311.002.07f Taught by Gil Lee (Gslee)UT Dallas Provost's Technology GroupNo ratings yet

- 3.2 Probability DistributionDocument38 pages3.2 Probability Distributionyouservezeropurpose113No ratings yet

- Legal Principles and The Limits of The Law Raz PDFDocument33 pagesLegal Principles and The Limits of The Law Raz PDFlpakgpwj100% (2)

- ChE 135 Peer Evaluation PagulongDocument3 pagesChE 135 Peer Evaluation PagulongJoshua Emmanuel PagulongNo ratings yet

- ThesisDocument250 pagesThesislax mediaNo ratings yet

- CHEM206 Answers 1Document3 pagesCHEM206 Answers 1Shiro UchihaNo ratings yet

- English Skills BookDocument49 pagesEnglish Skills BookAngela SpadeNo ratings yet

- Linguistics: Chapter 1 - 10Document41 pagesLinguistics: Chapter 1 - 10Ahmad A. JawadNo ratings yet

- 9 - NCP Computer Science PGDocument19 pages9 - NCP Computer Science PGM AmbreenNo ratings yet

- Little Book of Effective WritingDocument44 pagesLittle Book of Effective Writingshalashvili100% (1)

- Marksmanship: Subject: III. Definition of TermsDocument16 pagesMarksmanship: Subject: III. Definition of TermsAmber EbayaNo ratings yet

- Lesson Plan 2018-2019 Term 1Document205 pagesLesson Plan 2018-2019 Term 1Athlyn DurandNo ratings yet

- Future Design of Accessibility in Games - A Design Vocabulary - ScienceDirectDocument16 pagesFuture Design of Accessibility in Games - A Design Vocabulary - ScienceDirectsulaNo ratings yet

- Drypro832 PreInstallGude 0921YH220B 070627 FixDocument23 pagesDrypro832 PreInstallGude 0921YH220B 070627 FixRicardoNo ratings yet

- D257272 1200 FDD 002 R1 PDFDocument420 pagesD257272 1200 FDD 002 R1 PDFTap Toan100% (1)

- MKT-case StudyDocument7 pagesMKT-case StudyJoe Thampi KuruppumadhomNo ratings yet

- Chemical Cleaning Products Are Destroying The Ecosystem and Your Septic Tank - Organica BiotechDocument14 pagesChemical Cleaning Products Are Destroying The Ecosystem and Your Septic Tank - Organica BiotechKrispin FongNo ratings yet

- The Graduation Commencement Speech You Will Never HearDocument4 pagesThe Graduation Commencement Speech You Will Never HearBernie Lutchman Jr.No ratings yet

- City of Brescia - Map - WWW - Bresciatourism.itDocument1 pageCity of Brescia - Map - WWW - Bresciatourism.itBrescia TourismNo ratings yet

- IE399 Summer Training ReportDocument17 pagesIE399 Summer Training ReportgokanayazNo ratings yet

- Front Cover Short Report BDA27501Document1 pageFront Cover Short Report BDA27501saperuddinNo ratings yet

- April 3rd - Asynchronous Class - Questions-4Document3 pagesApril 3rd - Asynchronous Class - Questions-4alidrissiNo ratings yet

- Using Snapchat For OSINT - Save Videos Without OverlaysDocument12 pagesUsing Snapchat For OSINT - Save Videos Without OverlaysVo TinhNo ratings yet

- Ilham Bahasa InggrisDocument12 pagesIlham Bahasa Inggrisilhamwicaksono835No ratings yet