Professional Documents

Culture Documents

Ads Racksel

Uploaded by

maruc08Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ads Racksel

Uploaded by

maruc08Copyright:

Available Formats

Rack and Pinion Drive Calculation and Selection

Chapter

Racks Helical

m = 1.5

m=2

m=3

m=4

m=5

m=6

m=8

m = 10

m = 12

ZA-30

ZA-31

ZA-32

ZA-33

ZA-34

ZA-35

ZA-36

ZA-37

ZA-38

Racks Straight

m=1

m = 1.5

m=2

m = 2.5

m=3

m=4

m=5

m=6

m=8

m = 10

m = 12

ZB-36

ZB-37

ZB-38

ZB-39

ZB-40

ZB-41

ZB-42

ZB-43

ZB-44

ZB-45

ZB-46

Integrated Racks

m=2

m=3

m=4

p = 5 mm

p = 10 mm

p = 13.33 mm

ZC-15

ZC-16

ZC-17

ZC-18

ZC-19

ZC-20

Calculation, Instruction

Calculation Example

ZD-2

Travelling Operation

Lifting Operation

Actual size of modular gearing according to DIN 867

1/2012

Dimensions in mm

ZD-3

ZD-4

ZD-5

ZD 1

Rack and Pinion Drive Calculation and Selection

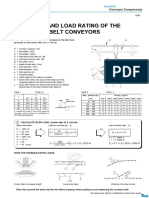

The values given in the load table are based upon uniform, smooth operation, KH=1.0 and reliable grease lubrication. Since,

in practice, the applications are very diverse, it is important to consider the given conditions by using appropriate factors SB,

KA, LKH and fn (see below).

Formulas for Determining the Tangential Force

a

= t

b

[m/s]

Fu

= m g + m a (for lifting axle)

1000

[kN]

= m g + m a (for driving axle) [kN]

1000

Fu Tab

Fu perm. =

[kN]

KA SB fn LKH

Fu

Formula dimensions see page ZD-3

The Condition Fu < Fu perm. Must be Fullled.

Load Factor KA

Drive

Type of load from the machines to be driven

Uniform

Medium Shocks Heavy Shocks

Uniform

1.00

1.25

1.75

Light Shocks

1.25

1.50

2.00

Medium Shocks

1.50

1.75

2.25

Safety Coefcient SB

The safety coefcient should be allowed for according to experience (SB = 1.1 to 1.4).

Life-Time Factor fn

considering of the peripheral speed of the pinion and lubrication.

Lubrication

Peripheral Speed

of Gearing

m/sec

m/min

0.5

30

1.0

60

1.5

90

2.0

120

3.0

180

5.0

300

Continuous Daily

0.85

0.95

1.00

1.05

1.10

1.25

0.95

1.10

1.20

1.30

1.50

1.90

Monthly

from

3

to

10

Linear Load Distribution Factor LKH

The linear load distribution factor considers the contact stress, while it describes unintegrated load distribution over the tooth

width (LKH = KH).

LKH = 1.1 for counter bearing, e.g. Torque Supporter

= 1.2 for preloaded bearings on the output shaft e.g. ATLANTA HT, HP and E servo-worm gear unit, BG bevel-gear unit

= 1.5 for unpreloaded bearings on the output shaft e.g. ATLANTA B servo-worm gear unit

ZD 2

Dimensions in mm

1/2012

Rack and Pinion Drive - Calculation and Selection

Calculation Example

Your Calculation

Values Given

Values Given

x Travelling Operation

x Travelling Operation

Mass to be Moved

= 820 kg

Mass to be Moved

kg

Speed

= 2 m/s

Speed

m/s

Acceleration Time

tb

= 1s

Acceleration Time

tb

Acceleration Due to Gravity g

= 9.81 m/s2

Acceleration Due to Gravity g

Coefcient of Friction

= 0.1

Coefcient of Friction

Load Factor

KA = 1.5

Load Factor

KA =

Life-Time Factor

fn

Life-Time Factor

fn

Safety Coefcient

SB = 1.2

Safety Coefcient

SB =

Linear Load

Distribution Factor

LKH = 1.5

Linear Load

Distribution Factor

LKH =

= 1.05 (cont. lubrication)

Calculation Process

a

Fu

tb

2

1

= 2 m/s2

tb

8209.810.1+8202

Fu zul./per. =

m/s2

kN

1000

Permissible Feed Force Fu Tab

Fu zul./per. =

KA SB fn LKH

= 2.44 kN

Assumed feed force: rack C45, ind. hardened, straight

tooth, module 3, pinion 16MnCr5, case hardened, 20 teeth,

page ZB-40 with Futab = 11.5 kN

Fu zul./per. =

a =

1000

1000

FuTab

Results

Fu = mg+ma ; Fu =

mg+ma

1000

Fu

Calculation Process

Results

a =

m/s2

9.81

11.5 kN

= 4.05 kN

1.51.21.051.5

Fu Tab

KA SB fn LKH

Fu zul. /per. =

kN

Condition

Fu zul./per. > Fu ; 4.05 kN > 2.44 kN

Condition

= > fullled

Fu zul./per. > Fu ;

Result:

1/2012

Rack

27 30 101

Page ZB-13

Pinion

24 35 220

Page ZB-23

case hardened

Dimensions in mm

kN >

kN

= > fullled

ZD 3

Rack and Pinion Drive - Calculation and Selection

Calculation Example

Your Calculation

Values Given

Values Given

x Lifting Operation

x Lifting Operation

Mass to be Moved

= 300 kg

Mass to be Moved

kg

Speed

= 1.08 m/s

Speed

m/s

Acceleration Time

tb

= 0.7 s

Acceleration Time

tb

= 9.81 m/s

Acceleration Due to Gravity g

Acceleration Due to Gravity g

Load Factor

KA =

Life-Time Factor

fn

SB = 1.2

Safety Coefcient

SB =

LKH = 1.2

Linear Load

Distribution Factor

LKH =

Load Factor

KA = 1.2

Life-Time Factor

fn

Safety Coefcient

Linear Load

Distribution Factor

= 1.1

(Cont. Lubrication)

Calculation Process

a

tb

a =

Fu = mg+ma

1000

Results

1.08

0.27

Fu = 3009.81+3004

9.81

Calculation Process

= 4 m/s

= 4.1 kN

=

tb

Fu

= mg+ma

Results

a =

Fu erf./req. =

m/s

kN

kN

1000

1000

1000

m/s

Assumed feed force: rack C45, ind. hardened, helical,

module 2, pinion 16MnCr5, case hardened, 20 teeth, page

Permissible Feed Force Fu tab

ZA-31 with Futab = 12 kN

Fu Tab

11.5 kN

Fu zul./per. =

; Fu zul./per. =

KA SB fn LKH

1.21.21.11.2

= 5.9 kN

Fu Tab

Fu zul./per. =

; Fu zul./per. =

KA SB fn LKH

Condition

Condition

Fu zul./per. > Fu ; 6.0 kN > 4.1 kN

Result:

ZD 4

=> fullled

Fu zul./per. > Fu ;

Rack

29 20 105

Page ZA-7

Pinion

24 29 520

Page ZA-24

Dimensions in mm

kN >

kN

=> fullled

1/2012

You might also like

- Design of Single Storey Residential BuildingDocument38 pagesDesign of Single Storey Residential Buildingsai thesis100% (2)

- Motor Selection CalculatorDocument5 pagesMotor Selection Calculatorjay100% (5)

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- App Dev Guide 1062Document770 pagesApp Dev Guide 1062khiladi2100% (3)

- Design of Gantry GirderDocument28 pagesDesign of Gantry Girders_bharathkumar75% (12)

- RHS Columnuns Embedded in RC ResearchDocument29 pagesRHS Columnuns Embedded in RC ResearchErnie Ernie100% (1)

- Databook Continental Agri 2006 PDFDocument0 pagesDatabook Continental Agri 2006 PDFdanilo3073No ratings yet

- Ads RackselDocument3 pagesAds RackselKiem TaNo ratings yet

- Engineering Reference: Sizing and Selection of Exlar Linear and Rotary ActuatorsDocument8 pagesEngineering Reference: Sizing and Selection of Exlar Linear and Rotary ActuatorsJelena BauerNo ratings yet

- 2 Stage GearboxDocument47 pages2 Stage GearboxSanad Shajahan0% (1)

- Example 2: Crane (Hoist Application) : Braking Calculation 03Document3 pagesExample 2: Crane (Hoist Application) : Braking Calculation 03A Tai TrieuNo ratings yet

- Exam Possible Questions: Velocity at HDocument31 pagesExam Possible Questions: Velocity at HJake FryNo ratings yet

- MINAS BLinfomationDocument7 pagesMINAS BLinfomationmashudi_fikriNo ratings yet

- Calculation of Torque For Selection of MotorDocument6 pagesCalculation of Torque For Selection of Motoratanughosh125100% (6)

- 1984Document46 pages1984Praveen Kumar85% (13)

- Machine-Design - Gear Shaft ProblemDocument51 pagesMachine-Design - Gear Shaft ProblemkidseismicNo ratings yet

- Selection PaP1 1Document32 pagesSelection PaP1 1RofochoNo ratings yet

- Difference Beetween Is 800-2007 & Is 800-1984Document96 pagesDifference Beetween Is 800-2007 & Is 800-1984ayazmadNo ratings yet

- Upgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectDocument14 pagesUpgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectkuttakhaoNo ratings yet

- Motor Selection, Inertia PDFDocument6 pagesMotor Selection, Inertia PDFIswar Rauf Aboo 'AqilahNo ratings yet

- Ball Screw Selection ExerciseDocument7 pagesBall Screw Selection ExercisemaddyaugNo ratings yet

- Philosophy of Limit State Design and Classification of SectionsDocument96 pagesPhilosophy of Limit State Design and Classification of Sectionsybm987100% (1)

- 200-Foot Simple Span Bridge Girder Design Using NU2000 V1Document50 pages200-Foot Simple Span Bridge Girder Design Using NU2000 V1Anthony GravagneNo ratings yet

- CalculationReport PDFDocument10 pagesCalculationReport PDFFikret DavudovNo ratings yet

- Process of Selection and Example of SelectionDocument8 pagesProcess of Selection and Example of Selectionarvi_vinNo ratings yet

- Chapter11 Prob01Document13 pagesChapter11 Prob01imranakhtarNo ratings yet

- 2 EngDocument26 pages2 EngMarg ConveyorsNo ratings yet

- ConvCalculation 140214Document7 pagesConvCalculation 140214Anup DoluiNo ratings yet

- Slab On GradeDocument105 pagesSlab On Gradevijaystructural100% (6)

- Loading On CanopyDocument1 pageLoading On CanopyUmesh ChamaraNo ratings yet

- Design of Steel Structure (Chapter 2) by DR R BaskarDocument57 pagesDesign of Steel Structure (Chapter 2) by DR R Baskarelect aksNo ratings yet

- Gantry GirderDocument25 pagesGantry GirderYash DhabaliaNo ratings yet

- Proiect Organe de Masini (Reductor)Document25 pagesProiect Organe de Masini (Reductor)SebiNo ratings yet

- Fms200806 Timing Belts Calc Methods 202 enDocument28 pagesFms200806 Timing Belts Calc Methods 202 enbrviraniNo ratings yet

- PTC MathcadDocument6 pagesPTC MathcadMuhammad Khaira AuliaNo ratings yet

- MMK1213 15Document6 pagesMMK1213 15S LubnaNo ratings yet

- Kanis Method of Frame AnalysisDocument20 pagesKanis Method of Frame AnalysisInemesit Ekop85% (20)

- Gantry GirderDocument48 pagesGantry GirderVishnu SamyNo ratings yet

- Ex3 LTBeamDocument27 pagesEx3 LTBeamYoussef AliNo ratings yet

- MBW Truss - Report PDFDocument11 pagesMBW Truss - Report PDFsolebNo ratings yet

- Estrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignDocument12 pagesEstrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignHannahNo ratings yet

- Proiect Om2Document20 pagesProiect Om2Gabriel CimpeanNo ratings yet

- AISC 360-10 Example 001Document7 pagesAISC 360-10 Example 001Bùi Văn HợpNo ratings yet

- Miscellaneous Calculations: 1 Sea Transport Forces On CargoDocument4 pagesMiscellaneous Calculations: 1 Sea Transport Forces On CargoAgarry EmmanuelNo ratings yet

- Design and Analysis of Rocker ArmDocument23 pagesDesign and Analysis of Rocker ArmAvt Shubhash25% (4)

- Tee Beam ProbDocument14 pagesTee Beam ProbSai GowthamNo ratings yet

- Team 3 ME 558 Final ReportDocument9 pagesTeam 3 ME 558 Final ReportingmecandresNo ratings yet

- Gear Box DesignDocument24 pagesGear Box DesignBada KimNo ratings yet

- Design of Gantry Girder and RCC Overhead WatertankDocument9 pagesDesign of Gantry Girder and RCC Overhead WatertankISFAQUL AHMEDNo ratings yet

- Helical Gear ProblemsDocument26 pagesHelical Gear ProblemsPrakash Joshi83% (6)

- DTS - Unit - 2 PDFDocument14 pagesDTS - Unit - 2 PDFmani100% (1)

- Servo Motor SelectionDocument11 pagesServo Motor Selectionanandparasu100% (1)

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Power Systems-On-Chip: Practical Aspects of DesignFrom EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardNo ratings yet

- Shape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationFrom EverandShape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Abbreviation DefinitionsDocument3 pagesAbbreviation DefinitionsrajeshNo ratings yet

- Api RP 5a3Document4 pagesApi RP 5a3maruc08100% (1)

- Separator Design MethodologyDocument19 pagesSeparator Design Methodologyromdhan88100% (1)

- DataBook Matrix - 60 (5-3T6 - 1,3M) (AM)Document1 pageDataBook Matrix - 60 (5-3T6 - 1,3M) (AM)maruc08No ratings yet

- CleanAgent XiDocument26 pagesCleanAgent XiMạnh NguyễnNo ratings yet

- CleanAgent SHPPRODocument21 pagesCleanAgent SHPPROmaruc08No ratings yet

- Air Cooled ExchangerDocument4 pagesAir Cooled Exchangermayurjannu100% (1)

- Er-56 01Document2 pagesEr-56 01maruc08No ratings yet

- Er-56 02Document3 pagesEr-56 02maruc08No ratings yet

- Er-56 01Document2 pagesEr-56 01maruc08No ratings yet

- Socotherm BrochureDocument9 pagesSocotherm Brochuremaruc08No ratings yet

- JLJJDocument1 pageJLJJmaruc08No ratings yet

- Corrected Log Mean Temperature Difference: ParametersDocument1 pageCorrected Log Mean Temperature Difference: Parametersprateek_bhoirNo ratings yet

- 4002Document3 pages4002maruc08No ratings yet

- JLJJDocument1 pageJLJJmaruc08No ratings yet

- Orlando PDFDocument2 pagesOrlando PDFmaruc08No ratings yet

- Free and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongDocument18 pagesFree and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongRajesh KachrooNo ratings yet

- Rainwater and Stormwater Harvesting Systems: Continuing Education From The American Society of Plumbing EngineersDocument8 pagesRainwater and Stormwater Harvesting Systems: Continuing Education From The American Society of Plumbing Engineers185412No ratings yet

- Technical Delivery Condition of S500MCDocument4 pagesTechnical Delivery Condition of S500MCdcevipin100% (1)

- Thermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsDocument39 pagesThermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsGregory MacLeodNo ratings yet

- FTNV-B FINAL - CatalogueDocument8 pagesFTNV-B FINAL - CatalogueAmodu Usman AdeyinkaNo ratings yet

- CI 1580A ENG User ManualDocument50 pagesCI 1580A ENG User ManualArdy KristianNo ratings yet

- CM6 Combined 2013Document154 pagesCM6 Combined 2013مسعد مرزوقىNo ratings yet

- Ac Repair Doha QatarDocument5 pagesAc Repair Doha QatarperfectsolutionqaseoNo ratings yet

- Module 4Document8 pagesModule 4ABIGAIL OLAJUMOKE JOSEPHNo ratings yet

- 1Z0 053 PDFDocument36 pages1Z0 053 PDFOscarRamirezNo ratings yet

- 3 3 3 Reverse Engineering Worksheet 1Document4 pages3 3 3 Reverse Engineering Worksheet 1api-275555576No ratings yet

- Tally Erp 9.0 Material Control Centre in Tally Erp 9.0Document27 pagesTally Erp 9.0 Material Control Centre in Tally Erp 9.0Raghavendra yadav KMNo ratings yet

- Automotive DevicesDocument152 pagesAutomotive DevicesLeticia PaesNo ratings yet

- Administration-Guide Open Bee OCSDocument7 pagesAdministration-Guide Open Bee OCSpeka76No ratings yet

- The Effects of Dissolved Sodium Chloride (Nacl) On Well Injectivity During Co2 Storage Into Saline AquifersDocument20 pagesThe Effects of Dissolved Sodium Chloride (Nacl) On Well Injectivity During Co2 Storage Into Saline AquifersMuhammad FatchurroziNo ratings yet

- Pds Microstran LTR en LRDocument2 pagesPds Microstran LTR en LRthaoNo ratings yet

- Euro Tempered Glass Industries Corp. - Company ProfileDocument18 pagesEuro Tempered Glass Industries Corp. - Company Profileunited harvest corpNo ratings yet

- Physical Mechanical and Flexural Properties of 3 Orthodontic Wires An in Vitro Study. DANIELA DLICANDocument8 pagesPhysical Mechanical and Flexural Properties of 3 Orthodontic Wires An in Vitro Study. DANIELA DLICANAlvaro ChacónNo ratings yet

- Chapter 4. FRC Manufacturing - Fundamental ConceptsDocument5 pagesChapter 4. FRC Manufacturing - Fundamental ConceptsNarendra GadkariNo ratings yet

- Boiling MechanismDocument16 pagesBoiling MechanismherawanadifNo ratings yet

- Item 103 Structure ExcavationDocument3 pagesItem 103 Structure ExcavationGerry Velicaria100% (1)

- Raymond Scott - Cindy ElectroniumDocument2 pagesRaymond Scott - Cindy ElectroniumJen HillNo ratings yet

- Appendix. 505 Program Mode Worksheets: 505 Digital Governor Manual 85017V1Document3 pagesAppendix. 505 Program Mode Worksheets: 505 Digital Governor Manual 85017V1gonzalesNo ratings yet

- Project: Tapis Eor Brownfield Modifications & RetrofitsDocument8 pagesProject: Tapis Eor Brownfield Modifications & RetrofitsMohamad Azizi AzizNo ratings yet

- High Efficiency Multijunction Solar Cells For Large Scale Solar Electricity Generation KurtzDocument29 pagesHigh Efficiency Multijunction Solar Cells For Large Scale Solar Electricity Generation Kurtzn1261984No ratings yet

- Calculating The Maximum Attenuation For Optical Fiber LinksDocument5 pagesCalculating The Maximum Attenuation For Optical Fiber LinksMiguel LiceagaNo ratings yet

- 07 Koolhaas Downtown Athletic ClubDocument10 pages07 Koolhaas Downtown Athletic ClubAndreea DituNo ratings yet