Professional Documents

Culture Documents

14-2 Data Forms

Uploaded by

Mohammed Abdul NaseerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14-2 Data Forms

Uploaded by

Mohammed Abdul NaseerCopyright:

Available Formats

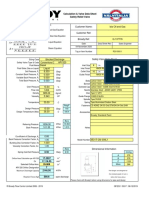

APPENDIX A MQPS 14-2

CHOPPED STRAND GLASS MATDATA FORM CMA/1R

!"#$

Word 97 Version

Mat reference number or grade:

Manufacturer:

Address:

Standards complied with:

Keying agent type:

Binder type:

Applications:

Part 1-FIBRE AND MAT PROPERTIES

PROPERTY

Nominal

Value

Filament alkali content (as Na2O) (%)

m)

Average filament diameter (

Strand length (mm)

Strand count

Binder content (as % ignition loss)

Mass per unit area (g/mm2)

Variation in mass per unit area (%)

Moisture content (%)

Density of the glass (g/cm3)

Dimensions of standard rolls:

Weight of standard rolls:

Packaging details:

Storage life:

Recommended storage temperature:

Lloyds Register Group Limited 2013

Tolerance

Test Method

!"#$

APPENDIX A MQPS 14-2

CHOPPED STRAND GLASS MATDATA FORM CMA/1R

Part 2- TEST LAMINATE PROPERTIES

Tests to be conducted on a laminate containing a nominal 1800 g/m2 of

reinforcement with a 30-35% glass content using an approved resin. The laminate

is to be cured initially for not less than 24 hours at room temperature (18- 21C)

and postcured for 16 hours at 40C . Laminates subjected to more intensive

postcuring schedules will not be considered.

One copy of the Test House report and load extension curves must accompany

this data summary form.

LAMINATE PREPARATION

Polyester resin employed:

Manufacturer:

Mat nominal weight:

Number of plies:

Laminate thickness (mm):

Actual weight of resin used (kg):

Actual weight of mat used (kg):

Lloyds Register Group Limited 2013

APPENDIX A MQPS 14-2

CHOPPED STRAND GLASS MATDATA FORM CMA/1R

!"#$

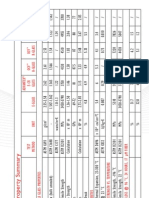

Part 3

QUALITY CONTROL SCHEDULE

List below the tests carried out for routine Quality Control purposes and the frequency of

these tests.

Test

Frequency

Signature .

(on behalf of manufacturer)

Position

Date

Lloyds Register Group Limited 2013

APPENDIX B MQPS 14-2

FIBRE ROVINGS DATA FORM GRA/1R

!"#$

Word 97 version

Product reference number or grade:

Manufacturer:

Address:

Standards complied with:

Keying agent type:

Approvals sought

For spray-up and local reinforcement

For local reinforcement

Part 1-ROVING PROPERTIES (where applicable)

PROPERTY

Nominal

Value

Filament alkali content (as Na2O) (%)

m)

Average filament diameter (

Strand count

Roving yield (tex)

Size content (%)

Moisture content (%)

Density of the fibre material (g/cm3)

Standard windings:

Weight of standard package:

Packaging details:

Storage life

Recommended storage temperature:

Lloyds Register Group Limited 2013

Tolerance

Test Method

!"#$

APPENDIX B MQPS 14-2

FIBRE ROVINGS DATA FORM GRA/1R

Part 2- TEST LAMINATE PROPERTIES

(Applicable only to spray-up roving approvals)

Tests to be conducted on a laminate containing a nominal 1800 g/m2 of

reinforcement and 30-35% glass content produced by a glass/resin depositor

using an approved resin. The laminate is to be cured initially for not less than 24

hours at room temperature (18- 21C) and postcured for 16 hours at 40C .

Laminates subjected to more intensive postcuring schedules will not be

considered.

One copy of the Test House report and load extension curves must accompany

this data summary form.

LAMINATE PREPARATION

Resin employed:

Manufacturer:

Resin fibre depositor employed:

(Manufacturer and Model No.)

Number of roving packages in

Simultaneous use during spray-up:

Sprayed fibre length (mm):

Reinforcement weight

(deposited):

Laminate thickness (mm):

Lloyds Register Group Limited 2013

APPENDIX B MQPS 14-2

FIBRE ROVINGS DATA FORM GRA/1R

!"#$

Part 3

QUALITY CONTROL SCHEDULE

List below the tests carried out for routine Quality Control purposes and the frequency of

these tests.

Test

Frequency

Signature .

(on behalf of manufacturer)

Position

Date

Lloyds Register Group Limited 2013

APPENDIX C MQPS 14-2

WOVEN ROVINGS DATA FORM WRA/1R

!"#$

Word 97 version

Product reference number or grade:

Manufacturer:

Address:

Standards complied with:

Keying agent type:

Part 1-FIBRE AND WOVEN ROVING PROPERTIES (where applicable)

Nominal

Value

PROPERTY

Filament alkali content (as Na2O) (%)

m)

Average filament diameter (

Roving ends per 100 mm

Warp:

Weft:

Linear density of rovings (tex)

Warp:

Weft:

Residual size content (%)

Mass per unit area (g/m2)

Moisture content (%)

Density of the fibre material (g/cm3)

Weave type:

Standard roll width and length:

Standard roll weight:

Packaging details:

Storage life:

Recommended storage temperature:

Lloyds Register Group Limited 2013

Tolerance

Test Method

!"#$

APPENDIX C MQPS 14-2

WOVEN ROVINGS DATA FORM WRA/1R

Part 2- TEST LAMINATE PROPERTIES

Tests to be conducted on a laminate containing a nominal 50% glass content and

2800 g/m2 of reinforcement produced by the hand lay-up process, using an

approved resin. The laminate is to be cured initially for not less than 24 hours at

room temperature (18- 21C) and postcured for 16 hours at 40C . Laminates

subjected to more intensive postcuring schedules will not be considered.

All reinforcements are to be parallel plied during laminate construction.

One copy of the Test House report and load extension curves must accompany

this data summary form.

LAMINATE PREPARATION

Resin employed:

Manufacturer:

Weight of resin used:

Weight of reinforcement used

Laminate thickness (mm):

Number of plies:

Note If the reinforcement has a specific moulded surface (e.g. the surface of the

laminate to be on the outside of the hull), flexural tests must be conducted with this

surface in tension.

Lloyds Register Group Limited 2013

!"#$

Part 3

APPENDIX C MQPS 14-2

WOVEN ROVINGS DATA FORM WRA/1R

QUALITY CONTROL SCHEDULE

List below the tests carried out for routine Quality Control purposes and the frequency of

these tests.

Test

Frequency

Signature .

(on behalf of manufacturer)

Position

Date

Lloyds Register Group Limited 2013

!"#$

APPENDIX D MQPS 14-2

COMPOSITE FIBRE REINFORCEMENTSDATA FORM CGR/2

Product reference number or grade:

Manufacturer:

Address:

Word 97 version

Part 1-FIBRE AND COMPOSITE COMPONENT PROPERTIES

Method of bonding roving

and mat components:

Where stitching is used to secure the mat please provide full details

Yarn type:

Stitch:

Direction:

Count :

Keying agent on roving:

Keying agent on mat:

Mat binder type:

MAT

PROPERTY

Mean

Value

Tolerance

Filament alkali content (as Na2O) (%)

m)

Average filament diameter (

Roving ends per 100 mm

Warp:

Weft:

Linear density of rovings (tex)

Warp:

Weft:

Residual size content of rovings(%)

Mass per unit area (g/m2)

Moisture content as supplied (%):

Density of the fibre material (g/cm3)

Roving weave type:

Standard roll width and length:

Standard roll weight:

Packaging details:

Storage life

Recommended storage temperature:

Lloyds Register Group Limited 2013

ROVING

Mean

Value

Tolerance

Test Methods

!"#$

APPENDIX D MQPS 14-2

COMPOSITE FIBRE REINFORCEMENTSDATA FORM CGR/2

Part 2- TEST LAMINATE PROPERTIES

(Applicable only to spray-up roving approvals)

Tests to be conducted on a laminate containing a nominal 2800 g/m2 of

reinforcement ,but consisting of not less than two plies, produced by the hand

lay-up process, using an approved resin. The laminate is to be cured initially for

not less than 24 hours at room temperature (18- 21C) and postcured for 16 hours

at 40C . Laminates subjected to more intensive postcuring schedules will not be

considered.

All reinforcements are to be parallel plied mat face downward during laminate

construction.

One copy of the Test House report and load extension curves must accompany

this data summary form.

LAMINATE PREPARATION

Resin employed:

Manufacturer:

Weight of resin used:

Weight of reinforcement used:

Laminate thickness (mm):

Number of plies

Recommended range of fibre content

In use for hand lay-up:

Lloyds Register Group Limited 2013

% to

!"#$

Part 3

APPENDIX D MQPS 14-2

COMPOSITE FIBRE REINFORCEMENTSDATA FORM CGR/2

QUALITY CONTROL SCHEDULE

List below the tests carried out for routine Quality Control purposes and the frequency of

these tests.

Test

Frequency

Signature .

(on behalf of manufacturer)

Position

Date

Lloyds Register Group Limited 2013

You might also like

- E1 Technical Data Sheet - ShortDocument2 pagesE1 Technical Data Sheet - ShortOmaiyio M. SaginiNo ratings yet

- Earthing of Gas PipelinesDocument5 pagesEarthing of Gas PipelinesAnonymous YPpAb2KNo ratings yet

- KOC Gasket Selection and Installation GuideDocument39 pagesKOC Gasket Selection and Installation GuidePraveen BabuNo ratings yet

- Connectorsubsea 20502 0210 CSS Split Sleeve Repair ClampsDocument2 pagesConnectorsubsea 20502 0210 CSS Split Sleeve Repair ClampsTTNo ratings yet

- DD - 046973 - Clearances Between Underground ServicesDocument2 pagesDD - 046973 - Clearances Between Underground ServicesvincentNo ratings yet

- Mechanical Engineering News BulletinDocument16 pagesMechanical Engineering News BulletinAshok KumarNo ratings yet

- Mitered Bend DesignDocument8 pagesMitered Bend Designkamranishfaq0% (1)

- Oil & Gas Pipeline Design, Maintenance & Repairs CourseDocument27 pagesOil & Gas Pipeline Design, Maintenance & Repairs CourseernmrajaNo ratings yet

- Tutorial - IsO 14692 FRPDocument36 pagesTutorial - IsO 14692 FRPEugene DerkachNo ratings yet

- Properties of AirDocument4 pagesProperties of AirRhea FayeNo ratings yet

- Stress Analysis of GRPDocument4 pagesStress Analysis of GRPSuthan SelvarajNo ratings yet

- NORSOKDocument35 pagesNORSOKSasa ZivkovicNo ratings yet

- Cable Tray 27Document37 pagesCable Tray 27Sri Ravindra Yadav PattapogulaNo ratings yet

- Recent Developments in Piping Vibration Screening LimitsDocument15 pagesRecent Developments in Piping Vibration Screening Limitstgpg7fk758No ratings yet

- Resolving Piping and Instrumentation Diagram CommentsDocument16 pagesResolving Piping and Instrumentation Diagram CommentsBurhan Ayub100% (1)

- COADE Friction StiffnessDocument1 pageCOADE Friction Stiffnessniteshk_45No ratings yet

- Caesar Newsletter Timehistory AnalysisDocument16 pagesCaesar Newsletter Timehistory AnalysisNixonNo ratings yet

- EQT Welding Procedure Qualification RequirementsDocument101 pagesEQT Welding Procedure Qualification RequirementsCeki CeriaNo ratings yet

- Estudo de Caso - Asme 2398Document6 pagesEstudo de Caso - Asme 2398biancogallazziNo ratings yet

- Computational Analysis of Parallel Flow of Hot and Cold Fluid Through A PipeDocument6 pagesComputational Analysis of Parallel Flow of Hot and Cold Fluid Through A PipeVIGNESH PNo ratings yet

- Chief Engineer Directive No 50Document7 pagesChief Engineer Directive No 50rize1159No ratings yet

- v1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterDocument4 pagesv1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterJasonChong212No ratings yet

- 9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesDocument12 pages9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesAnjani Prabhakar100% (1)

- Guardian - Lightning Protection SystemDocument8 pagesGuardian - Lightning Protection SystemAdhy GunaNo ratings yet

- Stress Analysis Course Description Image GrafixDocument2 pagesStress Analysis Course Description Image GrafixPrakhar Deep Kulshreshtha100% (1)

- Pressure and Volume Relationship of A Gas - Boyle's Law - Pass My Exams - Easy Exam Revision Notes For GSCE Physics PDFDocument4 pagesPressure and Volume Relationship of A Gas - Boyle's Law - Pass My Exams - Easy Exam Revision Notes For GSCE Physics PDFDorwinNeroNo ratings yet

- Mechanical Engineering: Merger Turns To Collaboration - COADE Remains IndependentDocument24 pagesMechanical Engineering: Merger Turns To Collaboration - COADE Remains IndependentfileseekerNo ratings yet

- GRP and HDPE PipeDocument1 pageGRP and HDPE PipeRashid KayumNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- CS Pipe Wall Thickness CalculationDocument16 pagesCS Pipe Wall Thickness CalculationunnicyriacNo ratings yet

- DSM Chemical Guide 2007 03.qDocument17 pagesDSM Chemical Guide 2007 03.qABHISEK BHATTACHARYANo ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- 4 Commentary On Standard Practice For Design and Conbstruction of Concrete Silos and Stacking Tubes For Storing Granular Materials ACI 313-97Document20 pages4 Commentary On Standard Practice For Design and Conbstruction of Concrete Silos and Stacking Tubes For Storing Granular Materials ACI 313-97Nikki Marlo CruzNo ratings yet

- USB - Ole Gjerstad - SUT - Manifolds and Connections May 2014Document76 pagesUSB - Ole Gjerstad - SUT - Manifolds and Connections May 2014solicoco100% (1)

- MS 01 168Document12 pagesMS 01 168Rawn BushNo ratings yet

- Mew R6 2016Document33 pagesMew R6 2016MujtabaNo ratings yet

- H1M0011503-CO4D3-MD16012 - Rev 2 PIPINGDocument100 pagesH1M0011503-CO4D3-MD16012 - Rev 2 PIPINGhoke-14No ratings yet

- MEPG - Repurposing Existing Pipeline For CO2 TransportDocument33 pagesMEPG - Repurposing Existing Pipeline For CO2 TransportAmmarul NafikNo ratings yet

- Properties of Pure SubstancesDocument12 pagesProperties of Pure SubstancesDSNo ratings yet

- Pipe Wall Thickness Calculations and Allowable StressesDocument21 pagesPipe Wall Thickness Calculations and Allowable StressesYehia HassanNo ratings yet

- Free Span Design According To The DNV-RP-F105 For Free Spanning PipelinesDocument24 pagesFree Span Design According To The DNV-RP-F105 For Free Spanning PipelinesconanbhNo ratings yet

- Guidelines For The Conduct of AISSEE - 2021: Date of Exam: 07 February 2021Document101 pagesGuidelines For The Conduct of AISSEE - 2021: Date of Exam: 07 February 2021DrAjay SinghNo ratings yet

- Thermowell Calculation Guide V1.3Document19 pagesThermowell Calculation Guide V1.3AymanelorbanyNo ratings yet

- JHF 610-Xgat-Mm (2006 Ac)Document1 pageJHF 610-Xgat-Mm (2006 Ac)Arya Bayu WibisonoNo ratings yet

- Creep of Metals and Polymers Lab ReportDocument6 pagesCreep of Metals and Polymers Lab ReportamokhtaNo ratings yet

- Hydraulic Analysis Report for Mogas Project Phase II Machike Terminal StationDocument16 pagesHydraulic Analysis Report for Mogas Project Phase II Machike Terminal StationBILAL ILYASNo ratings yet

- Rock Shield Material Data SheetDocument1 pageRock Shield Material Data SheetR.S.No ratings yet

- MS Data Sheet TanqueDocument2 pagesMS Data Sheet TanqueLION_FIRENo ratings yet

- Caesar Ii: Training SyllabusDocument1 pageCaesar Ii: Training SyllabusJason ChongNo ratings yet

- Design and Optimization of Weld Neck Flange For Pressure VesselDocument5 pagesDesign and Optimization of Weld Neck Flange For Pressure Vesselcat arroNo ratings yet

- R P RP O501 E W P S: Ecommended RacticeDocument43 pagesR P RP O501 E W P S: Ecommended RacticepaulortsNo ratings yet

- Specification - For - Erection - Static EquipmentDocument10 pagesSpecification - For - Erection - Static EquipmentOctavian IonescuNo ratings yet

- Lecture Note 4 (Metallic & Non-Metallic Pipes) PDFDocument20 pagesLecture Note 4 (Metallic & Non-Metallic Pipes) PDFhkaqlqNo ratings yet

- CCP Graphs (2e) PDFDocument152 pagesCCP Graphs (2e) PDFRajat KaliaNo ratings yet

- Flange Isolation Kits PDFDocument4 pagesFlange Isolation Kits PDFVILLANUEVA_DANIEL2064No ratings yet

- ASTM F1545 Plastic Lined Pipe 0803Document6 pagesASTM F1545 Plastic Lined Pipe 0803JabranYounasNo ratings yet

- Appendix E1 Ages SP 09 002Document13 pagesAppendix E1 Ages SP 09 002SandeepNBabuNo ratings yet

- Graphite Vademecum E-HDocument27 pagesGraphite Vademecum E-Hdroessaert_stijnNo ratings yet

- Spray-Up 687 NewDocument2 pagesSpray-Up 687 NewMohammed Abdul NaseerNo ratings yet

- Product Data Sheet: Direct Roving - Multi CompatibleDocument2 pagesProduct Data Sheet: Direct Roving - Multi CompatibleMohammed Abdul NaseerNo ratings yet

- Chop Roving 605 NewDocument2 pagesChop Roving 605 NewMohammed Abdul NaseerNo ratings yet

- Guide To Using MinitabDocument14 pagesGuide To Using MinitabMohammed Abdul Naseer0% (1)

- MicroscopeDocument6 pagesMicroscopeMohammed Abdul NaseerNo ratings yet

- Corrective Action Process Flow ChartDocument3 pagesCorrective Action Process Flow ChartMohammed Abdul NaseerNo ratings yet

- Guide To Using MinitabDocument14 pagesGuide To Using MinitabMohammed Abdul Naseer0% (1)

- Sample Control of Nonconformances R1Document2 pagesSample Control of Nonconformances R1Mohammed Abdul NaseerNo ratings yet

- Fiberex 408 DataSheetDocument1 pageFiberex 408 DataSheetMohammed Abdul NaseerNo ratings yet

- Bushing OperationDocument2 pagesBushing OperationMohammed Abdul NaseerNo ratings yet

- SIBOR Oxidation ProtectionDocument5 pagesSIBOR Oxidation ProtectionMohammed Abdul NaseerNo ratings yet

- Glass Fibers - PropertiesDocument2 pagesGlass Fibers - PropertiesMohammed Abdul NaseerNo ratings yet

- Oxyfuel BurnersDocument31 pagesOxyfuel BurnersMohammed Abdul NaseerNo ratings yet

- Greenhouse Arid Regions IIMADocument11 pagesGreenhouse Arid Regions IIMATheScienceOfTimeNo ratings yet

- Low Cost Green Houses For Vegetable ProductionDocument19 pagesLow Cost Green Houses For Vegetable Productionqfarms100% (2)

- Boc G Oct04 QKDocument3 pagesBoc G Oct04 QKMohammed Abdul NaseerNo ratings yet

- AF Animals Poultry IntroDocument10 pagesAF Animals Poultry IntroMamta KabraNo ratings yet

- Performance Appraisal Form From IndustryDocument2 pagesPerformance Appraisal Form From IndustryJaspal SinghNo ratings yet

- TC 1265Document8 pagesTC 1265Sameh El-SabbaghNo ratings yet

- X-Arcade Tankstick Manual USADocument13 pagesX-Arcade Tankstick Manual USAmight69No ratings yet

- ICMT Valve With ICAD Motor Control Using A Pressure Input SignalDocument2 pagesICMT Valve With ICAD Motor Control Using A Pressure Input SignalvickersNo ratings yet

- DehumidificationDocument9 pagesDehumidificationRafael Echano AcederaNo ratings yet

- THE PASSION AND GLOBAL APPROACH DRIVING HONDA MOTORCYCLES TO SUCCESSDocument11 pagesTHE PASSION AND GLOBAL APPROACH DRIVING HONDA MOTORCYCLES TO SUCCESSjatinag990No ratings yet

- Motor Protection Principles: Arijit Banerjee, Arvind Tiwari-GE Global Research Jakov Vico, Craig Wester - GE MultilinDocument35 pagesMotor Protection Principles: Arijit Banerjee, Arvind Tiwari-GE Global Research Jakov Vico, Craig Wester - GE Multilinvaradarajanrengasamy100% (1)

- Convolutional Neural Networks (LeNet) - DeepLearning 0.1 DocumentationDocument12 pagesConvolutional Neural Networks (LeNet) - DeepLearning 0.1 DocumentationSumit PatelNo ratings yet

- MASTERSEAL 755 SPF v1 PDFDocument2 pagesMASTERSEAL 755 SPF v1 PDFJaga Nath100% (1)

- EY Tax Administration Is Going DigitalDocument12 pagesEY Tax Administration Is Going DigitalVahidin QerimiNo ratings yet

- Right ShipDocument25 pagesRight ShipEmmNo ratings yet

- 1st Term Exam Part 2 - QSDocument10 pages1st Term Exam Part 2 - QSMark Anthony TajonNo ratings yet

- Mahindra and Mahindra PPT LibreDocument11 pagesMahindra and Mahindra PPT LibreMeet DevganiaNo ratings yet

- Abb CatDocument9 pagesAbb CatMukesh Kumar MeenaNo ratings yet

- Nano Particle Characterization MethodsDocument32 pagesNano Particle Characterization MethodsVignesh Raja PNo ratings yet

- Why Geomechanical Reservoir KpiDocument43 pagesWhy Geomechanical Reservoir KpiKevin MusterNo ratings yet

- GLARE - History of The Development of A New Aircraft MaterialDocument229 pagesGLARE - History of The Development of A New Aircraft MaterialklausoshoNo ratings yet

- Cable Diagram: Technical Data SheetDocument1 pageCable Diagram: Technical Data SheetCharlie MendozaNo ratings yet

- Carrier LDU ManualDocument123 pagesCarrier LDU Manualdafrie rimbaNo ratings yet

- Fortigate Ipv6 54Document64 pagesFortigate Ipv6 54Fredy Gualdron VargasNo ratings yet

- TM 1001 AVEVA Plant 12 1 PDMS Foundations Rev 3 0 PDFDocument153 pagesTM 1001 AVEVA Plant 12 1 PDMS Foundations Rev 3 0 PDFPolarogramaNo ratings yet

- What Is A Project in Project ManagementDocument3 pagesWhat Is A Project in Project ManagementSamuel AntobamNo ratings yet

- Mikom Remote Unit Software ManualDocument35 pagesMikom Remote Unit Software ManualealforaNo ratings yet

- Evaluating SWOT's Value in Creating Actionable, Strategic IntelligenceDocument94 pagesEvaluating SWOT's Value in Creating Actionable, Strategic IntelligenceMJFinnegan4100% (4)

- AT-8600 Series Switch: Hardware ReferenceDocument30 pagesAT-8600 Series Switch: Hardware ReferenceSubbuNo ratings yet

- Whirlpool ADP 6600 WH Service ManualDocument15 pagesWhirlpool ADP 6600 WH Service ManualMarcelo Sergio HamerNo ratings yet

- MS 1472-2017Document65 pagesMS 1472-2017Thinagaran100% (2)

- 0751 VICTAULIC in Mechanical PipingDocument17 pages0751 VICTAULIC in Mechanical PipingsyafiqNo ratings yet

- Online Ticket Reservation SystemDocument100 pagesOnline Ticket Reservation SystemPiya SharmaNo ratings yet

- Clear IM Inventory DifferencesDocument11 pagesClear IM Inventory DifferencesnguyencaohuygmailNo ratings yet