Professional Documents

Culture Documents

ZQZ 33

Uploaded by

harde2lahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZQZ 33

Uploaded by

harde2lahCopyright:

Available Formats

The length change or force induced by the piston effect is caused by pressure ch

anges inside the annulus and tubing at the packer, acting on different areas (Fi

g. 1). The length and force changes can be calculated as follows:

Fig. 1 Areas acted upon by pressure in the tubing and the annulus.

RTENOTITLE....................(1)

and RTENOTITLE....................(2)

where ?L1 = length change because of the piston effect, F1 = force change becaus

e of the piston effect, L = tubing length, E = modulus of elasticity (30,000,000

for steel), As = cross-sectional area of the tubing wall, Ap = area of the pack

er bore (values for common sizes can be found in Table 1), Ai = area of the tubi

ng ID, Ao = area of the tubing OD, ?pi = change in tubing pressure at the packer

, and ?po = change in annulus pressure at the packer.

Table 1-Area Of Packer Bores

Note that the length change ?L1 is a product of L/EA s and the piston force (F1)

. The piston force is the sum of two pressures acting on two areas one for the tub

ing and one for the annulus. The area acted upon by changes in pressure in the t

ubing is the cross-sectional area between the area of the packer bore and the ar

ea of the tubing ID in square inches (Ap Ai). The area acted upon by changes in p

ressure in the annulus is the cross-sectional area between the area of the packe

r bore and the area of the tubing OD in square inches (Ap Ao).

Fig. 1(a) shows a large-bore packer with a tubing string that has both a smaller

OD and ID than the packer bore. In this instance, annulus pressure causes downw

ard force, while tubing pressure causes an upward force. For a small-bore packer

, this situation is reversed (Fig. 1(b)). The force greatest in magnitude will d

etermine the resulting direction of action. An accurate schematic of the tubing

and packer bore for each case should be made for proper determination of areas,

forces, and the resulting direction of action.

It is possible to eliminate the forces generated on the tubing string by the pis

ton effect by anchoring the seals in the packer bore. In a string that is restra

ined at the packer from movement in either direction, the piston effect on the t

ubing string is zero. All the forces are now being absorbed or contained complet

ely within the packer.

Buckling Effects

Tubing strings tend to buckle only when the internal tubing pressure (pi) is gre

ater than the annulus pressure (po). The result is always a shortening of the tu

bing string, but the actual force exerted is negligible. The decrease in length

occurs because of the tubing string being in a spiral shape rather than straight

. The tubing-length change is calculated with the following:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- (Poultry Diseases Diagnosis and Aquaculture Lab) Ogere-Remo, Ogun State The M.D Nutridel Farms, Ogdl/0322/052/Ast AsipaDocument1 page(Poultry Diseases Diagnosis and Aquaculture Lab) Ogere-Remo, Ogun State The M.D Nutridel Farms, Ogdl/0322/052/Ast Asipaharde2lahNo ratings yet

- Reception Class Easter Holiday Homework Pack 2023Document12 pagesReception Class Easter Holiday Homework Pack 2023harde2lahNo ratings yet

- Name: - DateDocument8 pagesName: - Dateharde2lahNo ratings yet

- Blue WordsDocument1 pageBlue Wordsharde2lahNo ratings yet

- Broiler Vaccination GuideDocument1 pageBroiler Vaccination Guideharde2lahNo ratings yet

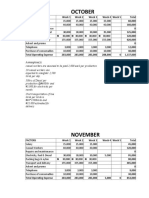

- Poultry Financial ProjectionsDocument28 pagesPoultry Financial Projectionsharde2lahNo ratings yet

- New Hope Agric and Tech Nig LTD - 20227283131579Document1 pageNew Hope Agric and Tech Nig LTD - 20227283131579harde2lahNo ratings yet

- ZQZ 32Document1 pageZQZ 32harde2lahNo ratings yet

- ZQZ 1Document2 pagesZQZ 1harde2lahNo ratings yet

- Exercise 8 Flow ImprovementDocument1 pageExercise 8 Flow Improvementharde2lahNo ratings yet

- ZQZ 3321Document2 pagesZQZ 3321harde2lahNo ratings yet

- ZQZ 332Document1 pageZQZ 332harde2lahNo ratings yet

- Jovan Petronic: 2012 FIDE World Youth Chess Champions in ActionDocument8 pagesJovan Petronic: 2012 FIDE World Youth Chess Champions in ActionKasparicoNo ratings yet

- DL Conversion TableDocument10 pagesDL Conversion Tableharde2lahNo ratings yet

- ZQZ 331Document2 pagesZQZ 331harde2lahNo ratings yet

- Reservoarfluider Og Strømning: Curtis Hays WhitsonDocument4 pagesReservoarfluider Og Strømning: Curtis Hays Whitsonharde2lahNo ratings yet

- ZQZ 31Document1 pageZQZ 31harde2lahNo ratings yet

- On Linear ProgrammingDocument49 pagesOn Linear Programmingh_badgujarNo ratings yet

- 600.0 Straight-Line (HCPV Const) Pot Aquifer: Cumulative Gas Recovery, GP/G, %Document3 pages600.0 Straight-Line (HCPV Const) Pot Aquifer: Cumulative Gas Recovery, GP/G, %harde2lahNo ratings yet

- Zqer 124 WDocument1 pageZqer 124 Wharde2lahNo ratings yet

- ZQZ 2Document1 pageZQZ 2harde2lahNo ratings yet

- ZQZ 3Document1 pageZQZ 3harde2lahNo ratings yet

- Zqer 124 W 1Document1 pageZqer 124 W 1harde2lahNo ratings yet

- Zqer 1 DDocument2 pagesZqer 1 Dharde2lahNo ratings yet

- ZQD 7211 GDocument2 pagesZQD 7211 Gharde2lahNo ratings yet

- Zqer 124Document1 pageZqer 124harde2lahNo ratings yet

- Zqer 12Document1 pageZqer 12harde2lahNo ratings yet

- Zqer 1 D 2Document1 pageZqer 1 D 2harde2lahNo ratings yet

- Zqer 1Document1 pageZqer 1harde2lahNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 192771712Document6 pages192771712alfredNo ratings yet

- Structural Mechanics Lab ReportDocument31 pagesStructural Mechanics Lab Reportmalicat alwroodNo ratings yet

- Soft CatenaryDocument13 pagesSoft CatenaryMarcos Garcia GarciaNo ratings yet

- 3-D Finite Element Modeling of Nanostructure Enhanced SAW SensorDocument6 pages3-D Finite Element Modeling of Nanostructure Enhanced SAW SensornitinsriniwasNo ratings yet

- 5000W ABS Taita TaiwanDocument1 page5000W ABS Taita TaiwanPhạm Thanh TùngNo ratings yet

- EC2 Shear Ultimate Limit StateDocument9 pagesEC2 Shear Ultimate Limit StateselinaNo ratings yet

- Certene L.A. LLBF-122D (Sustituto 11PG4) ActualizadaDocument1 pageCertene L.A. LLBF-122D (Sustituto 11PG4) ActualizadadianaNo ratings yet

- Optical MicrosDocument17 pagesOptical MicrosUmairSiddiqueSNo ratings yet

- Nptel PC Questions PDFDocument11 pagesNptel PC Questions PDFSanju KushwahaNo ratings yet

- Buenavista, Guimaras: Guimaras State College College of Engineering and Industrial TechnologyDocument7 pagesBuenavista, Guimaras: Guimaras State College College of Engineering and Industrial TechnologyJohn Kenneth VilchezNo ratings yet

- Engr. Vincent E. Malapo InstructorDocument23 pagesEngr. Vincent E. Malapo InstructorVincentNo ratings yet

- Gec223 Tutorial KitDocument5 pagesGec223 Tutorial KitDaniel AgbajeNo ratings yet

- Ground LossDocument11 pagesGround LossKam LauNo ratings yet

- Biomimicry Of' Bamboo Bast Fiber With Engineering Composite Materials PDFDocument6 pagesBiomimicry Of' Bamboo Bast Fiber With Engineering Composite Materials PDFaya1604No ratings yet

- Agglomerate Strength Measurement Using A Uniaxial Confined Compression TestDocument9 pagesAgglomerate Strength Measurement Using A Uniaxial Confined Compression TestshahzadyousafNo ratings yet

- 1969 - The Coupling of Shear WallsDocument462 pages1969 - The Coupling of Shear Wallssobah assidqiNo ratings yet

- Recitation 2Document11 pagesRecitation 2Theodore Teddy JNo ratings yet

- ENTC 376 Chapter 9 Lecture Notes-III-Stress TransformationDocument27 pagesENTC 376 Chapter 9 Lecture Notes-III-Stress TransformationYahia Raad Al-AniNo ratings yet

- CBD Csa S16 09Document195 pagesCBD Csa S16 09Edwin VizueteNo ratings yet

- Chapter 7 Capillary PressureDocument58 pagesChapter 7 Capillary PressurePugal100% (1)

- Astm C39 C39M-16Document7 pagesAstm C39 C39M-16Yao Leslie Armande MélissaNo ratings yet

- Prestressed Concrete Design Lecture NotesDocument52 pagesPrestressed Concrete Design Lecture NotesChristopher John Natividad100% (1)

- Bending Tests: 3-Point and 4-Point BendingDocument20 pagesBending Tests: 3-Point and 4-Point BendingTuấn NguyễnNo ratings yet

- 2shreyas - ResumeDocument2 pages2shreyas - ResumeAli SanadiNo ratings yet

- Hardness Test (For Materials)Document41 pagesHardness Test (For Materials)Rajan ChaudharyNo ratings yet

- Steel Design 4th - William T. SigueDocument4 pagesSteel Design 4th - William T. SigueKhale Kyrzhal RamirezNo ratings yet

- Analysis of Plate Straightening ApproachesDocument90 pagesAnalysis of Plate Straightening ApproachesPhạm Văn ĐảngNo ratings yet

- Chemical Composition: ASTM A36 Mild/Low Carbon SteelDocument2 pagesChemical Composition: ASTM A36 Mild/Low Carbon SteelrekyNo ratings yet

- Yield Criteria For MetalsDocument6 pagesYield Criteria For Metalsmahendran198111No ratings yet

- Principles of Polymer Chemistry by Paul J. FloryDocument687 pagesPrinciples of Polymer Chemistry by Paul J. FloryKatipot Inkong83% (6)