Professional Documents

Culture Documents

Fortess Board Brochure PDF

Uploaded by

Ronald VictaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fortess Board Brochure PDF

Uploaded by

Ronald VictaCopyright:

Available Formats

Energy

Saving

Thermal Insulator

Durable

Fortress Lightweight Concrete Board

Lightweight

The Green Revolu-on Lightweight Concrete Panel

10

Advantages of using Fortress

Board

1.

Environmental

Friendly

The

Fortress

Board

does

not

contain

any

chemical

that

is

harmful

to

the

human

body

2.

Fire

Resistant

The

Fortress

Board

has

been

tested

to

withstand

re

within

4

hours

at

1000C.

And

during

the

burning

process,

it

will

not

emit

any

harmful

gas

3. Increase Useable Space

Compare to CHB which is about 6

inches thick (including plastering),

the Fortress Board occupies only

half of the walls thickness which is 3

inches, translaPng to more useable

space for the occupant

4.

Quick

Install

Since

Fortress

Board

is

manufactured

in

precast,

installaPon

is

a

lot

quicker,

and

saves

Pme

used

instead

for

hauling

sand

and

cement

5. Water and Moisture Resistant

Without any need for further

waterproong, Fortress Board can

resist water and moisture. It can

also be used on frequently wet areas

such as kitchen and bathroom

6. BeVer Sound InsulaPon

The Fortress Board has a good sound

insulaPon characterisPc. For a 90mm

thick wall, it can eecPvely reduce sound

travel from the other side of the room by

as much as 43 dB -assuming that the room

is enclosed

7.

Easy

to

Install

The

Fortress

Board

is

very

lightweight

that

it

can

be

carried

by

2

persons.

Installing

it

is

very

easy

and

the

working

area

is

relaPvely

clean

since

there

is

no

need

for

massive

mixing

of

sand

and

cement.

8.

Thermal

InsulaPon

The

pellets

inside

the

Fortress

Board

serves

as

good

thermal

insulators

thereby

reducing

energy

costs

parPcularly

on

air

condiPoning

units

9. Can be Nailed or Bolted thru

The Fortress Board is durable

enough to be nailed or bolted upon even

with the use of expansion bolt. It can

carry the weight of wall mounted

appliance such as LCD screens, and other

wall decoraPons

10.

Lightweight

The

weight

of

the

Fortress

Board

is

only

20%

of

that

of

tradiPonal

concrete

method,

and

will

translate

to

a

signicant

amount

of

savings

on

structural

costs

Background and Technical Specica4ons

DDue to the ever increasing demand for livable space, the construcPon industry is determined to

address it by providing fast and ecient living quarters. It is for this reason that our company has

invested a lot of eort on research and development on coming up with a product that will suitably

cater to that need. While adopPng the German technology and making some modicaPons, our

company was able to come up with our own lightweight concrete precast which can either be used

on walls, oors, or as roong material.

Installa4on Guidelines

1. InstallaPon markings

2. Cueng preparaPon

3. Joining applicaPon

4. Layout

Determining the proper verPcal

plumbness and alignment of the

wall is necessary prior to

installaPon. One piece of board

about 1.48 square meter can be

handled by 2 person

Hand tools with diamond blade

cuVer can be used to cut the

Fortress board for site eng

Wet both sides of the surface

where the board is going to be

joined together before applying

cement, sand, and adhesive

mixture

Bring the Fortress Board to its

designated area

5. AVachment

6. Fieng

7. Reinforcement

8. Slab/oor Reinforcement

Imbed a rebar to the adjacent

column and aVach it to the board.

Press the board to squeeze out the

excess cement mixture in between

the joint. As you lay-out the

remaining board on the wall, use

a temporary support to keep it

steady in place while it is being

cured. Then remove the squeezed

out excess cement mixture from

the walls surface

Use an L-type rebar to connect the

beam to the board

Use an L-type rebar to connect the

oor to the board

9. Board to Board connecPon

10. Electrical provision

11. Filling

12. PainPng and Finishing

Using a 45 degree angle, you can

nail both Fortress board using a

rebar

Cut a groove on the Fortress board

using cueng handtools to lay the

electrical pipe and the outlets as

well

Use Cement-Adhesive mixture to

ll up the grooves where the pipes

and outlets were imbedded.

Put a mesh tape on all the joints

where the Fortress board were

connected prior to painPng

Detail Drawings

Cement

mixture

Wall

thickness

Front View

Rebar imbed

Panel to panel connecPon

Beam

Wall panel

Wall to Beam connecPon

Side

View

Beam/

Slab

Rebar

imbed

One

imbed

for

every

2

panel

Wall panel

Cement

mix

Cement

mix

Rebar

imbed

Floor

One imbed for every 2 panel

Floor to wall connecPon detail

Wall thickness

Wall to Beam connecPon

Rebar imbed

Fortress Board

Baseboard

Rebar

imbed

Fortress Board

One imbed for every 2 panel

Removed support aler cured

Floor Finishing

Temporary triangular support

Floor

plastering

slab

Floor to wall connecPon

slab

Floor to wall connecPon

Detail Drawings

Rebar connecPon to Fortress Board

Cement mixture

rebar

Wall thickness

Structure

plastering

Corner

cement

plastering

Top view connecPon detail

Wall Panel to wall panel connecPon detail

4.5 Mtr and below

structure

45

rebar

imbed

Rebar

imbed

rebar

1

rebar

imbed

for

every

1.2Mtr

to

1.8Mtr

1 rebar imbed for every 1.2Mtr to 1.8Mtr

Wall panel front view with

Horizontal connecPon

Wall panel front view

45

rebar

imbed

200mm

rebar

length

Wall panel front view

200mm

rebar

length

Detail Drawings

6 or 8mm rebar imbed

Wall panel

Door opening

6 or 8mm rebar imbed

Door opening detail

Wall panel

Wall

panel

window

6 or 8mm rebar imbed

Window opening detail

Wall panel

Wall panel

Double door detail

Transport and Applica4on

Without the necessity of applying surface

plastering, a skilled worker can install 35

square meters a day. ComparaPvely to brick

laying or CHB method, the use of Fortress

Board is a lot quicker and cost saving

As shown on the picture on the lelmost,

the use of Fortress Board which is

lightweight material does not necessitate

it being laid directly on top of a beam

which gives the construcPon designers

greater exibility

Basing on the picture at the right, since

CHB installa-on is 5X heavier, it has to

be installed on top of a beam to support

its weight

Floor plan of a sample layout

Illustra4on on how addi4onal

space can be created

In this illustraPon, the tradiPonal CHB

laying method occupies 9.1% of the unit

area, while the Fortress Board occupies

only 4.26% of the area. Based on a 100

square meter area, an addi-onal 4.26

square meter of useable space is created

without adding cost

You might also like

- 200v MosfetDocument18 pages200v MosfetshivaramakrishnaNo ratings yet

- RRB NTPC 2019 Revised Notification PDFDocument79 pagesRRB NTPC 2019 Revised Notification PDFBapi SahooNo ratings yet

- Long Channel MOSFET 4Document27 pagesLong Channel MOSFET 4Cruise_IceNo ratings yet

- OTC - 5200 - Invoicing For Liner - LinerDocument37 pagesOTC - 5200 - Invoicing For Liner - LinerdeepakagarwallaNo ratings yet

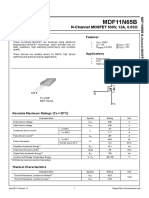

- MDF11N65BDocument6 pagesMDF11N65BElec FoNo ratings yet

- QUESTION PAPER PATTERNDocument1 pageQUESTION PAPER PATTERNபெரியகருப்பையாNo ratings yet

- How To Create GMS File in CorelDraw - TutorialDocument3 pagesHow To Create GMS File in CorelDraw - TutorialStillwithu StillNo ratings yet

- Time: 3 To 3 Hours Max. Marks: 80: Term 1 - Summative Assessment Mathematics Question Paper Set - 1Document7 pagesTime: 3 To 3 Hours Max. Marks: 80: Term 1 - Summative Assessment Mathematics Question Paper Set - 1raghavNo ratings yet

- Jabong BillDocument2 pagesJabong Biller_manish0350% (2)

- Document Purchase OrderDocument1 pageDocument Purchase OrderInvoiceNo ratings yet

- 206 PSycrometricDocument1 page206 PSycrometricAvinash GuptaNo ratings yet

- Gr11, T1, Math HL, P1, 2015 (QP)Document9 pagesGr11, T1, Math HL, P1, 2015 (QP)Theijan BaburajNo ratings yet

- Case Study British TelecomDocument2 pagesCase Study British TelecomAdvantec SrlNo ratings yet

- K 3918Document8 pagesK 3918Anderson DuarteNo ratings yet

- Gyrops 22 08 2016Document7 pagesGyrops 22 08 2016Desejo SozinandoNo ratings yet

- Chapter 4 - Analog Integrated Circuit Design by John ChomaDocument92 pagesChapter 4 - Analog Integrated Circuit Design by John ChomaAriana Ribeiro LameirinhasNo ratings yet

- GS20-SE-228 - Rev0-Proposal For AFAQ STEEL (BASED ON MTO) PDFDocument19 pagesGS20-SE-228 - Rev0-Proposal For AFAQ STEEL (BASED ON MTO) PDFதமிழ்மகன் ஜெகதீஷ் தாமோதரன்No ratings yet

- List of MinisterDocument4 pagesList of Ministershuvo134No ratings yet

- Is there hope for Ostrava's future amid industrial declineDocument1 pageIs there hope for Ostrava's future amid industrial declineMike B.No ratings yet

- Assignment Task 1 - 1.1 - 1.8Document3 pagesAssignment Task 1 - 1.1 - 1.8AzeemNo ratings yet

- AAI Junior Executive Syllabus For General KnowledgeDocument3 pagesAAI Junior Executive Syllabus For General Knowledgearvidkumar87060No ratings yet

- Chapter 1 Cement Civil Engineering MaterialDocument12 pagesChapter 1 Cement Civil Engineering MaterialAnonymous 59kjvq4OLB100% (1)

- SSC CGL Tier 1 Short Tricks and Formulas PDFDocument32 pagesSSC CGL Tier 1 Short Tricks and Formulas PDFAnuj TripathiNo ratings yet

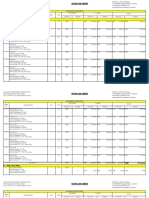

- Excel Sheet For Calculation Purpose - Web Uploading 1562 1449811938Document55 pagesExcel Sheet For Calculation Purpose - Web Uploading 1562 1449811938Civil GuyNo ratings yet

- Quantity Survey Methods in Buildings: by V.R.K.MurtyDocument101 pagesQuantity Survey Methods in Buildings: by V.R.K.MurtyRatnesh PatelNo ratings yet

- Ceiling Finishes BillDocument1 pageCeiling Finishes BillYing YiNo ratings yet

- SSC CGL Exam Syllabus: Tier I & II Exam DetailsDocument6 pagesSSC CGL Exam Syllabus: Tier I & II Exam DetailsharishmadavaramNo ratings yet

- Dimnna Escalona Nadales: Item # Description Qty Unit Price Discount Price Date of Deliver Received byDocument1 pageDimnna Escalona Nadales: Item # Description Qty Unit Price Discount Price Date of Deliver Received bydimnna nadalesNo ratings yet

- Build Hotel and Hotspot Solutions Using DG-LB1054Document7 pagesBuild Hotel and Hotspot Solutions Using DG-LB1054joy7825No ratings yet

- Mechanical Excavation MethodsDocument16 pagesMechanical Excavation MethodsKashyap GoradiaNo ratings yet

- Basic Shortcut KeysDocument52 pagesBasic Shortcut KeysSreenivas SunkaraNo ratings yet

- Estimation - Smoor Sadashivnagar 2602'22 - For VendorsDocument8 pagesEstimation - Smoor Sadashivnagar 2602'22 - For VendorsYashodhar SrbNo ratings yet

- Details of Demolition QuantityDocument92 pagesDetails of Demolition QuantityK. Mehedi HasanNo ratings yet

- Final BOQ Kisambi Piped Water SSDocument62 pagesFinal BOQ Kisambi Piped Water SSlutos2100% (1)

- Rah, Lah, RVH, LVHKDocument12 pagesRah, Lah, RVH, LVHKYuliana AtmayudhaNo ratings yet

- 1 Sep 9pm Upsssc Je Set-2Document47 pages1 Sep 9pm Upsssc Je Set-2Rana RafiqueNo ratings yet

- Health Statement (G-42) Form (Standard Employee)Document1 pageHealth Statement (G-42) Form (Standard Employee)Rahman AnisurNo ratings yet

- Design, construction and maintenance of bridges in BangladeshDocument21 pagesDesign, construction and maintenance of bridges in BangladeshBridge WingNo ratings yet

- Pavement Design for Road Upgrade ProjectDocument144 pagesPavement Design for Road Upgrade Projectsuleyman ahmedNo ratings yet

- HW 2 SolutionsDocument3 pagesHW 2 SolutionsssriraghavNo ratings yet

- LO - SCI 3530 Numerical Methods For Partial Differential EquationsDocument3 pagesLO - SCI 3530 Numerical Methods For Partial Differential Equationsa_minisoft2005No ratings yet

- Autocad 2009 2D Training ManualDocument342 pagesAutocad 2009 2D Training ManualFerdinand GarvidaNo ratings yet

- Prageeth Dhanushka Rathnasooriya: Curriculum VitaeDocument3 pagesPrageeth Dhanushka Rathnasooriya: Curriculum VitaeDhanushka RathnasooriyaNo ratings yet

- Garden DSR Civil 2016-17 FinalDocument218 pagesGarden DSR Civil 2016-17 FinalShruti DamgirNo ratings yet

- Bill of QuantitiesDocument7 pagesBill of Quantitieszaki_th008No ratings yet

- BBMP PreDCR HelpManualDocument23 pagesBBMP PreDCR HelpManualsmdiviNo ratings yet

- DOS - Steel Bridge - 4Document44 pagesDOS - Steel Bridge - 4Rana RafiqueNo ratings yet

- Cement and Gypsum Board Works - BOQ - STAGE BDocument1 pageCement and Gypsum Board Works - BOQ - STAGE BAhmed ElkhashabNo ratings yet

- Triangle Construction 4th R.A. Bill For Township IIDocument81 pagesTriangle Construction 4th R.A. Bill For Township IItriangle269No ratings yet

- Bid Document & SchedulesDocument229 pagesBid Document & Schedulesrahulchauhan7869No ratings yet

- Kartheek D N: ObjectiveDocument2 pagesKartheek D N: ObjectiveArun PeddiNo ratings yet

- Estimate for Renovation of Toilet Blocks at Gauhati Medical CollegeDocument7 pagesEstimate for Renovation of Toilet Blocks at Gauhati Medical Collegenilotpal borahNo ratings yet

- Estimate Sheet - Crs-tp2 BuildingDocument112 pagesEstimate Sheet - Crs-tp2 BuildingRhowelle TibayNo ratings yet

- Jacob ScottDocument2 pagesJacob ScottProject LangitRhkNo ratings yet

- Quantity & BOQ of PWDDocument11 pagesQuantity & BOQ of PWDMuhammad HamzaNo ratings yet

- Tidco Interior Renovation Tender Document Volume IDocument44 pagesTidco Interior Renovation Tender Document Volume IsureshNo ratings yet

- FORTHRESSDocument25 pagesFORTHRESSMaria Aiza Maniwang CalumbaNo ratings yet

- Housing Module 4Document11 pagesHousing Module 4Kyla TiangcoNo ratings yet

- Low Cost HousingDocument48 pagesLow Cost HousingManish Solanki71% (7)

- FPG Motor.247.benefit 150306Document1 pageFPG Motor.247.benefit 150306Ronald VictaNo ratings yet

- S CurveDocument3 pagesS CurveRonald VictaNo ratings yet

- Resignation Letter SBV62400 05.03.2018Document1 pageResignation Letter SBV62400 05.03.2018Ronald VictaNo ratings yet

- FPG Motor.247.benefit 150306Document1 pageFPG Motor.247.benefit 150306Ronald VictaNo ratings yet

- S CurveDocument3 pagesS CurveRonald VictaNo ratings yet

- Materials-Approval OcrDocument1 pageMaterials-Approval OcrRonald VictaNo ratings yet

- Auto Calculator FAO Dulhunty 2yrsDocument7 pagesAuto Calculator FAO Dulhunty 2yrsRonald VictaNo ratings yet

- List of Drivers in Manila PDFDocument75 pagesList of Drivers in Manila PDFerna molos100% (1)

- Auto Calculator FAO Dulhunty 2yrsDocument7 pagesAuto Calculator FAO Dulhunty 2yrsRonald VictaNo ratings yet

- TableofContents DocumentTitlesDocument12 pagesTableofContents DocumentTitlesAntoniette Samantha NacionNo ratings yet

- BDO Online Banking PDFDocument1 pageBDO Online Banking PDFRonald VictaNo ratings yet

- Door Lock Monitoring 4-8-18Document1 pageDoor Lock Monitoring 4-8-18Ronald VictaNo ratings yet

- Frequently Asked QuestionsDocument2 pagesFrequently Asked QuestionsRonald VictaNo ratings yet

- Materials-Approval OcrDocument1 pageMaterials-Approval OcrRonald VictaNo ratings yet

- Tle HWDocument20 pagesTle HWRonald VictaNo ratings yet

- Tle HWDocument20 pagesTle HWRonald VictaNo ratings yet

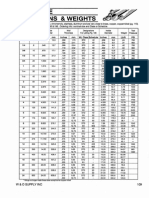

- ENGLISH Steel and Metals Catalog May 2015 PDFDocument63 pagesENGLISH Steel and Metals Catalog May 2015 PDFRonald VictaNo ratings yet

- ROJECT REQUEST APPROVAL FORM RevisedDocument3 pagesROJECT REQUEST APPROVAL FORM RevisedRonald VictaNo ratings yet

- Swimming Pool (SKIMMER)Document1 pageSwimming Pool (SKIMMER)Ronald VictaNo ratings yet

- Swimming Pool (SKIMMER)Document1 pageSwimming Pool (SKIMMER)Ronald VictaNo ratings yet

- Omega Platform StairliftDocument4 pagesOmega Platform StairliftRonald VictaNo ratings yet

- Installation of ExhaustDocument1 pageInstallation of ExhaustRonald VictaNo ratings yet

- ENGLISH Steel and Metals Catalog May 2015 PDFDocument63 pagesENGLISH Steel and Metals Catalog May 2015 PDFRonald VictaNo ratings yet

- OJT Exercise 1Document70 pagesOJT Exercise 1Ronald VictaNo ratings yet

- Transaction HistoryDocument7 pagesTransaction HistoryRonald VictaNo ratings yet

- Steel Bar MonitoringDocument23 pagesSteel Bar MonitoringRonald VictaNo ratings yet

- Schedule of LoadsDocument1 pageSchedule of LoadsRonald VictaNo ratings yet

- 1 General Products 82511 113Document1 page1 General Products 82511 113Fajr Al-FurqonNo ratings yet

- Equipment ListDocument5 pagesEquipment ListRonald VictaNo ratings yet

- Merrytown Properties Corporation: Transmittal FormDocument8 pagesMerrytown Properties Corporation: Transmittal FormRonald VictaNo ratings yet

- Chieftain 1800 SpecsDocument16 pagesChieftain 1800 SpecsPercy Luis Nima AlvaradoNo ratings yet

- Pce 3Document10 pagesPce 3Jovel LapidNo ratings yet

- Analytica Chimica Acta: Jacopo La Nasa, Francesca Modugno, Matteo Aloisi, Anna Lluveras-Tenorio, Ilaria BonaduceDocument8 pagesAnalytica Chimica Acta: Jacopo La Nasa, Francesca Modugno, Matteo Aloisi, Anna Lluveras-Tenorio, Ilaria Bonaducejuanda.scienceNo ratings yet

- Public Review Draft 2394Document82 pagesPublic Review Draft 2394Johan SetiawanNo ratings yet

- I-Series GC 600G36 GB WW 1016-3Document40 pagesI-Series GC 600G36 GB WW 1016-3Erick AvNo ratings yet

- pd10196 Tetra Alsafe PDFDocument2 pagespd10196 Tetra Alsafe PDFEusebio NavarroNo ratings yet

- 03 Vgasic PDFDocument8 pages03 Vgasic PDFAnonymous idBsC1No ratings yet

- Drying Shrinkage of ConcreteDocument6 pagesDrying Shrinkage of Concretecrownguard100% (1)

- Lean Manufacturing A1Document14 pagesLean Manufacturing A1Ankita SinhaNo ratings yet

- Catalogo Bepco Tractor PartsDocument266 pagesCatalogo Bepco Tractor PartsGabriel Escarcena Robles100% (5)

- Technical Data Sheet Baltoflake EcolifeDocument5 pagesTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadNo ratings yet

- Ch04Document20 pagesCh04nilesh0074313No ratings yet

- CabinetDocument2 pagesCabinet2267airportNo ratings yet

- Aesthetic FinishesDocument5 pagesAesthetic FinishesAnonymous dOdHWHg4No ratings yet

- Steel Coil AlignmentDocument1 pageSteel Coil AlignmentBalluff SensorsNo ratings yet

- D173 PDFDocument2 pagesD173 PDFArnold RojasNo ratings yet

- Legacy Product Catalog 2016 PDFDocument40 pagesLegacy Product Catalog 2016 PDFCamilo Andrés Abello RégeasseNo ratings yet

- M-DS31 Filcor Eps Data Sheet Cordek v1Document2 pagesM-DS31 Filcor Eps Data Sheet Cordek v1ShamaNo ratings yet

- Enzo Nicolai T. Teves High School 1st Periodical Test in Automotive ServicingDocument4 pagesEnzo Nicolai T. Teves High School 1st Periodical Test in Automotive ServicingSylvia Aguilar RizaldoNo ratings yet

- Naphthaplast F 707 UlDocument2 pagesNaphthaplast F 707 UlÖmer ErcanNo ratings yet

- Available in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BDocument32 pagesAvailable in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BHarikrishnanNo ratings yet

- Swatch Case AnalysisDocument3 pagesSwatch Case Analysisgunjanbihani100% (1)

- Tcsi Quality Plan: One Ayala Avenue Project Makati City, Metro ManilaDocument20 pagesTcsi Quality Plan: One Ayala Avenue Project Makati City, Metro ManilaEugene Santiago PadillaNo ratings yet

- Humidity Sensor SelectionDocument10 pagesHumidity Sensor Selectionmythri100% (1)

- VT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & CirculatorsDocument4 pagesVT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & Circulatorshamdi gshNo ratings yet

- As71164a CHECK LISTDocument9 pagesAs71164a CHECK LISTJulio HernandezNo ratings yet

- 12.4 Phase DiagramsDocument6 pages12.4 Phase DiagramsDr-SabaJamilNo ratings yet

- Trouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic BlisteringDocument10 pagesTrouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic Blisteringandreathome100% (1)

- Filtro Bacteriologico Puritan BennetDocument24 pagesFiltro Bacteriologico Puritan BennetRonald David ReyesNo ratings yet

- Chap 4 PDFDocument35 pagesChap 4 PDFKamarul Nizam100% (1)