Professional Documents

Culture Documents

Multilube Pumping Unit MLP Advantages and Features: Compact and Flexible Centralised Lubrication System

Uploaded by

MachineryengOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multilube Pumping Unit MLP Advantages and Features: Compact and Flexible Centralised Lubrication System

Uploaded by

MachineryengCopyright:

Available Formats

MultiLube Pumping Unit MLP

Advantages and Features

Compact all-in-one structure

Can be vertically or horizontally installed

Modular and durable design

Visual and electric low level monitoring in

reservoir

Easy to install and start-up

Pumping centre is equipped with heating

resistor

Enables use of various doser types

Filling connection equipped with safety valve

Suitable for all pumpable lubricants

Two reservoir sizes

Pumping centre is equipped with internal

pressure relief valve

Clear and versatile user interface

Field data can be read externally

Wide operation temperature range

(-30 - +70C / -22F- +158F)

ST-103 User interfaces

The MultiLube lubrication system is controlled from an user interface installed in the vehicle

cabin. This makes it easy and simple to use and monitor the system. The monitoring and

adjusting of the system can also be realised with the user interface IF-103 that is integrated in

the pumping centre.

Max. output

Reservoir

Max. pressure

Operation temperature range

Lubrication line connections

Lubricant

Operating voltage

Power consumption

Protection classification

Weight, (full reservoir)

Height of pump

Width of pump

Depth of pump

Material

5 min - 120 min

Pressurisation time

1 min - 10 min

Functions

Setting lubrication cycle

Setting max. pressurisation time

Extra lubrication and alarm

acknowledgement

Indicator lights

Line pressurisation

Low level alarm on lubricant level

Line pressure alarm

13g/min

4l

250 bar / 3626 psi

-30C - +70C / -22F - +158F

R1/4

up to NLGI 2

12/24 V DC

150W

IP65

16 kg / 35.3 lb

448 mm / 17.64

230 mm / 9.06

235 mm / 9.25

Aluminium

13g/min

10 l

250 bar / 3626 psi

-30C - +70C / -22F - +158F

R1/4

up to NLGI 2

12/24 V DC

150W

IP65

24 kg / 52.9 lb

688 mm / 27.09

230 mm / 9.06

235 mm / 9.25

Aluminium

Abbreviation

Description

MLP

A

MLP

4

10

1

2

12

24

JB-103

IF-103

PS

PSE

MultiLube Pump

Reservoir size, 4 litres

Reservoir size, 10 litres

Number of main lines, single line system

Number of main lines, dual line system

Operating Voltage 12 V

Operating Voltage 24 V

User interface, JB-103

User interface, IF-103

Pressure control, pressure switches in pump

Pressure control, pressure sensors in pump

Lubrication cycle

10 l reservoir

MLP-A-B-C-D-E

User interface JB-103

4 l reservoir

D

E

Example: MLP-4-2-24-JB103-PSE

Europe

Slough, UK

Latin America

So Paulo, Brazil

Middle East, Africa, Asia

Dubai, United Arab Emirates

North America

Morton Grove, Illinois USA

Tel: 44-1753-224000

Fax: 44-1753-224224

Tel: 55-11-3371-2500

Fax: 55-11-3371-2599

Tel: 971-4-3438940

Fax: 971-4-3438970

1-800-SEALING

Tel: 1-847-967-2400

Fax: 1-847-967-3915

Compact and Flexible Centralised

Lubrication System

For your nearest John Crane facility, please contact one of the locations above.

If the products featured will be used in a potentially dangerous and/or hazardous process, your John Crane representative should be consulted prior to their selection and use.

In the interest of continuous development, John Crane Companies reserve the right to alter designs and specifications without prior notice. It is dangerous to smoke while

handling products made from PTFE. Old and new PTFE products must not be incinerated.

2002 John Crane Print 08/02

www.johncrane.com

ISO 9001, ISO 14001, ISO/TS 16949 Certified. Details available on request.

B-MultilubeHeavy/Eng

Safematic MultiLube Centralised

Lubrication System

Safematic MultiLube Systems

Heavy - Single line centralised lubrication system

Safematic MultiLube centralised lubrication systems are superior solutions for lubrication

maintenance of heavy vehicles. Since the systems are easy to install, the pumping centre

has a compact structure, the dosers' operate reliably and the system is simple to use,

the operation in machine- and vehicle-specific applications can be guaranteed even in

harsh conditions.

Twinheavy - Dual line centralised lubrication systems

Lubricant: greases NLGI 000 NLGI 1 and oils

Lubricant: Greases NLGI 000 NLGI 2

Centralised Lubrication Improves Runnability

The high-quality MultiLube centralised lubrication system prevents bearing failures and

improves the runnability of machines and equipment. Due to a centralised lubrication

system the lubrication result is always optimal, consequently reducing energy

and lubricant consumption.

The MultiLube is a financially justified solution for centralised

lubrication in order to improve runnability of heavy vehicles.

14

B dosers

SMG dosers

13

10

1

SUPPORTING BLOCK

PRESSURE CONTROL UNIT

LUBRICANT OUTLETS

PUMPING ELEMENT

LOW LEVEL SWITCH

HEATING ELEMENT

LINE VALVE

CONTROL UNIT

ELECTRICAL MOTOR

10 OVERFILL RELIEF VALVE

2

12

3

11

max

Dosage [g] (grease thickness 0,88g/cm3)

3

6

7

11 FILLING CONNECTOR WITH FILTER

min

12 PRESSURE RELIEF VALVE

13 VISUAL LEVEL INDICATOR

ADJUSTING SCREW TURNS /L

mm/turn

14 FOLLOWER PISTON

Main applications for the Heavy system are heavy trucks and their auxiliary equipment, earth

moving machinery, forwarders, harvesters, material handling and property service machines.

Main applications for the Twinheavy system are heavy earth moving machines,

forwarders and harvesters, material handling machines and special vehicles.

You might also like

- Ford EEC IV TesterDocument96 pagesFord EEC IV TesterTorney Benedict60% (10)

- PC1250Document16 pagesPC1250Gavin Li100% (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- bw141 151 154 Ac Ad-4 Service TrainingDocument231 pagesbw141 151 154 Ac Ad-4 Service Trainingjosue100% (1)

- Lifts and Hoists Maintenance Tasks PDFDocument19 pagesLifts and Hoists Maintenance Tasks PDFMachineryengNo ratings yet

- End-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesDocument6 pagesEnd-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesMuhammad MustafaNo ratings yet

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- PurifierDocument4 pagesPurifierRizal Falevy100% (1)

- Design and Construct A 3 KVA Micro Controller Based Pure Sine Wave Inverter With Controlled OutputDocument70 pagesDesign and Construct A 3 KVA Micro Controller Based Pure Sine Wave Inverter With Controlled OutputMcCurtis Akpojaro100% (1)

- Initial Start Up Procedure g3516bDocument16 pagesInitial Start Up Procedure g3516bmuhammad arifNo ratings yet

- Introduction To Storage TanksDocument49 pagesIntroduction To Storage TanksMachineryeng100% (2)

- Triveni Offer - 17.1 MWDocument52 pagesTriveni Offer - 17.1 MWPrasanna kumar subudhi100% (1)

- Wheel ExcavatorDocument32 pagesWheel Excavatorpricopdaniel100% (1)

- Volvo EW145B Wheeled ExcavatorDocument48 pagesVolvo EW145B Wheeled ExcavatorHai Van100% (9)

- 70ZV 2 BrochureDocument12 pages70ZV 2 BrochurepedrofalfanNo ratings yet

- T4078 Techical Sheet and Manual CAT 320E LDocument36 pagesT4078 Techical Sheet and Manual CAT 320E Lricktmg100% (1)

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDocument25 pagesHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- Cat 988FDocument46 pagesCat 988FFilipe Gomes100% (3)

- Wa480-5 PDFDocument12 pagesWa480-5 PDFMhd Hanafi LubisNo ratings yet

- Volvo TAD1250VE Spec SheetDocument2 pagesVolvo TAD1250VE Spec SheetEngine Tuning UpNo ratings yet

- SE SL 9 30 KW DatasheetGB 0412Document100 pagesSE SL 9 30 KW DatasheetGB 0412GrundfosEgyptNo ratings yet

- Technology Working For You.: Approved PrecisionDocument11 pagesTechnology Working For You.: Approved PrecisionDavid Alejandro TellezNo ratings yet

- Hydraulic Excavator: Engine WeightDocument36 pagesHydraulic Excavator: Engine WeightAngel Puntaca QuispeNo ratings yet

- MFL Compendium 002Document59 pagesMFL Compendium 002kingston67% (3)

- Alfa Laval PurifiersDocument4 pagesAlfa Laval PurifiersNasim AbbasNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

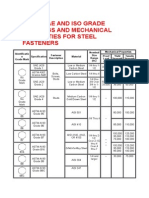

- Bolts GradesDocument9 pagesBolts GradesMachineryengNo ratings yet

- BORSIG Valve PresentationDocument18 pagesBORSIG Valve PresentationMachineryengNo ratings yet

- D7C Ta: Volvo Penta Inboard DieselDocument2 pagesD7C Ta: Volvo Penta Inboard DieselAhmet GelisliNo ratings yet

- AQA AS Physics A Chapter 4 Textbook AnswersDocument4 pagesAQA AS Physics A Chapter 4 Textbook AnswerscathylisterNo ratings yet

- Compressor MountingDocument41 pagesCompressor MountingjmacarroNo ratings yet

- Bornemann Subsea BrochureDocument5 pagesBornemann Subsea BrochureMartike KharmagasNo ratings yet

- Doosan 340Document16 pagesDoosan 340Victor VillarrealNo ratings yet

- 2 Competitor Product Guide LG936L - LiugongCLG836 - XCMG LW300F 10183Document40 pages2 Competitor Product Guide LG936L - LiugongCLG836 - XCMG LW300F 10183George Jhonson100% (3)

- Linde Hydraulics - HPV-02Document0 pagesLinde Hydraulics - HPV-021antonio100% (1)

- BP Hydraulik Pum Mot EnGB 144026Document44 pagesBP Hydraulik Pum Mot EnGB 144026Jasmin Kahrimanovic100% (3)

- Sgt-600 GT Mechdrive enDocument4 pagesSgt-600 GT Mechdrive enRoozbeh PNo ratings yet

- Compressor Performance Test Procedure Shaybah Rev.2 BorsigDocument23 pagesCompressor Performance Test Procedure Shaybah Rev.2 BorsigMachineryengNo ratings yet

- Hydro Turbine Speed Governing SystemDocument12 pagesHydro Turbine Speed Governing SystemNaveen Kumar100% (1)

- Api 617 CameronDocument31 pagesApi 617 CameronMachineryengNo ratings yet

- Komatsu PC160LC 7Document20 pagesKomatsu PC160LC 7Virgil Cenariu100% (3)

- BZM Centrifugal CompressorDocument16 pagesBZM Centrifugal CompressorMachineryengNo ratings yet

- Mcmurdo E-5 Service ManualDocument42 pagesMcmurdo E-5 Service Manualsathish kumar100% (4)

- FlowServe InLine PumpDocument8 pagesFlowServe InLine PumpchadvillelaNo ratings yet

- Teikoku Pump BrochureDocument16 pagesTeikoku Pump BrochureAndrew MaverickNo ratings yet

- Voith Turbo BasicsDocument49 pagesVoith Turbo BasicsSamir Benabdallah100% (1)

- Burgmann Quick Guide To Identifying Mechanical Seal FailuresDocument1 pageBurgmann Quick Guide To Identifying Mechanical Seal FailuresakabbaraNo ratings yet

- Hygk307 ManualDocument16 pagesHygk307 Manualkenlavie1No ratings yet

- KCBDocument10 pagesKCBMarcos CarvalhoNo ratings yet

- Safematic Greasing ManualDocument50 pagesSafematic Greasing ManualDenis VieiraNo ratings yet

- Grundfos Apa Uzata Multilift PDFDocument88 pagesGrundfos Apa Uzata Multilift PDFAldea CatalinNo ratings yet

- Catalog 01 Single LineDocument24 pagesCatalog 01 Single Lineangela draguNo ratings yet

- Hiteam Fluid Control Company ProfileDocument13 pagesHiteam Fluid Control Company ProfileSen VanNo ratings yet

- SureFire-PDI Pumps 8-10Document7 pagesSureFire-PDI Pumps 8-10Joel Muñoz BernalNo ratings yet

- 290UG - Catalogue Reject PumpDocument22 pages290UG - Catalogue Reject PumpMuhammad Ashraf KadabaNo ratings yet

- Wood Group SPS Surface Pumping SystemsDocument7 pagesWood Group SPS Surface Pumping Systemssafy2005150% (1)

- Sude Mining CatalogDocument15 pagesSude Mining CatalogAwanNo ratings yet

- Oil Miss Fan PDFDocument61 pagesOil Miss Fan PDFsutta111No ratings yet

- Unitati Externe LG Multi V Mini Pliant Prezentare Limba EnglezaDocument8 pagesUnitati Externe LG Multi V Mini Pliant Prezentare Limba EnglezaIon VasileNo ratings yet

- 895988engDocument12 pages895988engavalbuena_82No ratings yet

- Memolub Triptyque en 140402 LRA4Document6 pagesMemolub Triptyque en 140402 LRA4Diego Felipe Gavilán RetamalesNo ratings yet

- M 315 CspecalogDocument28 pagesM 315 CspecalogNemanja Subic0% (1)

- Rotare Vane PumpsDocument10 pagesRotare Vane PumpsZoran DjurdjevicNo ratings yet

- en Piston Pump Unit - Product Series KFGDocument20 pagesen Piston Pump Unit - Product Series KFGJurun_BidanshiNo ratings yet

- REFCOMPDocument20 pagesREFCOMPsibar.eirlNo ratings yet

- Sivam Powerlift: Technical DataDocument4 pagesSivam Powerlift: Technical Dataafdal ridhaNo ratings yet

- Smedegaard ECO GaardPress Pressurisation Sets Low ResDocument6 pagesSmedegaard ECO GaardPress Pressurisation Sets Low ResAnonymous CRQ100No ratings yet

- Maintenance of Circuit-Breaker Drive Mechanism ELK SN / BBC: SF Gas-Insulated SwitchgearDocument2 pagesMaintenance of Circuit-Breaker Drive Mechanism ELK SN / BBC: SF Gas-Insulated SwitchgearMuthuraj74No ratings yet

- BE SG RWF Frick II RotaryDocument8 pagesBE SG RWF Frick II RotarygamunozdNo ratings yet

- F240 LeafletDocument4 pagesF240 LeafletSelviana Niwar Fuad Part IINo ratings yet

- Tad 1242Document2 pagesTad 1242Essam SelimNo ratings yet

- Mantenimiento Lek 3500Document4 pagesMantenimiento Lek 3500Ana María AcostaNo ratings yet

- Power Is Intermittently Low or Power Cutout Is Intermittent 320DDocument4 pagesPower Is Intermittently Low or Power Cutout Is Intermittent 320DfalahNo ratings yet

- Danfoss VLT Hvac 1Document20 pagesDanfoss VLT Hvac 1Syed Noman AhmedNo ratings yet

- D1-170 Ecosmart en PDFDocument8 pagesD1-170 Ecosmart en PDFrakacyuNo ratings yet

- Tech Booster 0312Document4 pagesTech Booster 0312Luis VilelaNo ratings yet

- JC Gasket CranfoilDocument2 pagesJC Gasket CranfoilMachineryengNo ratings yet

- Lip Seal Installation PDFDocument11 pagesLip Seal Installation PDFMachineryengNo ratings yet

- Seal Design For High Pressure Offshore-Morton & EvansDocument10 pagesSeal Design For High Pressure Offshore-Morton & EvansMachineryengNo ratings yet

- Borsig BZM - 2016 - EngDocument84 pagesBorsig BZM - 2016 - EngMachineryengNo ratings yet

- Compressor Turbo-Air API a4-IRDocument12 pagesCompressor Turbo-Air API a4-IRMachineryengNo ratings yet

- Thread Terms: External Standard Thread ProfileDocument2 pagesThread Terms: External Standard Thread ProfileMachineryengNo ratings yet

- 713 SYS LubeSite-Systems BR-R5Document36 pages713 SYS LubeSite-Systems BR-R5Jas SumNo ratings yet

- SVS.435 Steam Turbine Control UpgradesDocument4 pagesSVS.435 Steam Turbine Control UpgradesMachineryengNo ratings yet

- Recommended Radial Clearance For Cast Bronze BearingDocument1 pageRecommended Radial Clearance For Cast Bronze BearingMachineryengNo ratings yet

- Bolting Guide LineDocument2 pagesBolting Guide LineMachineryengNo ratings yet

- Technical Data of ThreadedDocument4 pagesTechnical Data of ThreadedMachineryengNo ratings yet

- Embedded Systems and Its ScopeDocument81 pagesEmbedded Systems and Its Scopenanobala15No ratings yet

- PA0FBK Antenna DemystifiedDocument25 pagesPA0FBK Antenna DemystifiedEnero A. SaisNo ratings yet

- Chapter 10: Vibration Isolation of The SourceDocument12 pagesChapter 10: Vibration Isolation of The SourceAshokNo ratings yet

- The Electromagnetic Spectrum by Cindy GriggDocument2 pagesThe Electromagnetic Spectrum by Cindy GriggMae Dil G. Tirariray - PaladNo ratings yet

- EV Charger Price ListDocument5 pagesEV Charger Price ListSoud AbdallahNo ratings yet

- Week 1 Part I Capacitors June 05Document41 pagesWeek 1 Part I Capacitors June 05Marty J. SmithNo ratings yet

- ESA PPT For UNIT-IDocument37 pagesESA PPT For UNIT-IAeronaughtycs HamdanNo ratings yet

- RC Infant Flow Sipap Operator Manual UG enDocument80 pagesRC Infant Flow Sipap Operator Manual UG enpericopepeNo ratings yet

- To Determine The V Curve of A Synchronous MotorDocument3 pagesTo Determine The V Curve of A Synchronous MotorAthay khanNo ratings yet

- 3GPP TR 29.998-05-1: Technical ReportDocument25 pages3GPP TR 29.998-05-1: Technical Reportdzo007No ratings yet

- 74LS145Document6 pages74LS145Deepesh MishraNo ratings yet

- CP4014 0 1Document3 pagesCP4014 0 1Jou PowerNo ratings yet

- Calibration of Linear Displacement Sensor Systems Used To Measure MicromotionDocument4 pagesCalibration of Linear Displacement Sensor Systems Used To Measure MicromotionAhmad Zubair RasulyNo ratings yet

- Bose Designmax DM3CDocument4 pagesBose Designmax DM3CAmit KidechaNo ratings yet

- Health Index Monitoring Assessment of A TransformerDocument6 pagesHealth Index Monitoring Assessment of A TransformerOmkar WaghNo ratings yet

- AHB SlaveDocument18 pagesAHB SlaveRam VutaNo ratings yet

- Blues30Nv: User ManualDocument36 pagesBlues30Nv: User Manualrsojos19544No ratings yet

- Powerware 9 Prestige UPS: Power Management Software Technical SpecificationsDocument6 pagesPowerware 9 Prestige UPS: Power Management Software Technical Specificationsandy175No ratings yet

- Using The DHT11 Sensor With Raspberry Pi To Measure Temperature and HumidityDocument3 pagesUsing The DHT11 Sensor With Raspberry Pi To Measure Temperature and HumidityVimalNo ratings yet

- Power System Protection: Noornabi ShaikhDocument10 pagesPower System Protection: Noornabi ShaikhSadam MemonNo ratings yet

- TP of AutomobileDocument20 pagesTP of AutomobileHicham Salahdine100% (1)

- Tech. (sEM" SEM.) Examination,: TLL) IlDocument4 pagesTech. (sEM" SEM.) Examination,: TLL) IlAbhimanyu YadavNo ratings yet

- PNTC Colleges: Activity SheetDocument6 pagesPNTC Colleges: Activity SheetMarianne Jubille CataquisNo ratings yet