Professional Documents

Culture Documents

Erection Method Statement Royal Comision (Hollow Core)

Uploaded by

marckeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Erection Method Statement Royal Comision (Hollow Core)

Uploaded by

marckeCopyright:

Available Formats

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

EASTERN PRECAST CONCRETE

ERECTION PROCEDURE FOR CONCRETE

PRECAST HOLLOW CORE

Revision Record

Rev

No.

Date

Prepared by

08/04/2013

Engr. Alfred

Comendador

QA/QC

Dept.Supervisor

CLIENT:

Reviewed By:

Engr. Muzamil

Salih

Erection Manager

OWNER:

Approved By:

Engr. Luai

Shammat

General Manager

CONTRACTOR:

Remarks

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

1.0

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

Purpose

To introduce the methodology for erection of hollow core slab precast elements.

2.0

Scope

Design, production, delivery and erection for the following precast elements:

- Hollow core slabs

3.0

Personnel Responsible

3.1

3.2

3.3

4.0

Responsibility

4.1

4.2

4.3

5.0

Erection Manager: Overall in-charge for the project execution.

Erection Engineer: Over-all in-charge for the erection processes. Ensure that the

erection is done with accordance to the standard safe erection practices. Prepare

delivery schedule program.

Erection Foreman: Responsible for overall erection at site. Coordinate with the main

contractor with regards to the access for trailer and crane. The erection foreman is

available at site during erection.

Competent workers are to be provided, who are properly and well train to load,

deliver and erect all types of precast elements which required to achieved

completely satisfactory project.

The main contractor is responsible for providing proper access for the loaded trailers

to the position in the erection site premises.

Eastern Precast will provide all necessary erection accessories to complete the

erection works.

Preparation before the erection

5.1

Prior to commencing the handling and erection of precast concrete elements, the

following items should be considered by Site Contractor and EPC.

5.1.1

5.1.2

5.1.3

5.1.4

CLIENT:

Check the crane and trailer access in the site and ensure that it is leveled and

compacted.

Ensure that the dowels embedded in the foundation is in the right place or

location

Clear the site for truck and crane access ensuring room for crane outriggers,

counterweight tail swing, boomswing and under hook and overhead obstructions.

Ensure that sufficient space is available for precast propping or bracing.

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

6.0

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

Procedures for the Erection of Precast elements

6.1

Erection of Hollow-core slabs

6.1.1

6.1.2

6.1.3

6.1.4

6.1.5

6.1.6

6.1.7

6.1.8

CLIENT:

Hollow core slabs are transported to site on flatbed trailers.

Before erection of any slabs, the supporting structure should be checked to

determine if all pertinent dimensions correspond with those shown on the

approved drawings.

Prior to placing slabs the bearing surfaces should be checked to ensure that they

are smooth and level.

Leveling material should be placed if required.

The trailer carrying the hollow core slabs is brought close to the building, under

reachable crane radius where erection is to be carried out.

Precast HCS will be delivered at site with open cores, cores will be closed with

polystyrene core plugs or plastic end caps by main contractor either before lifting

the HCS form the trailer or after erection prior to place welded mess and prior for

casting/screeding to avoid concrete flow inside the core while casting.

Precast HCS will be lifted directly from the trailer by using lifting scissor or lifting

belt and place in proper location one by one, if the component lifted for at least 1

meter from the ground or from the trailer, safety chains underneath the HCS

should be placed and clamp it with lifting scissor and it should not be released

until the HCS is about 1.00 m from the support for safety reason.

Lifting area surrounding the trailer should be cordoned and barricaded by warning

tape with a safety signboards precaution.

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

6.1.9

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

Controlling the movement of precast HCS by using taglines (rope) to its final

location.

6.1.10 Upon completion of the erection of HCS, soffit of HCS will be check and

corrections will be carried out wherever necessary.

6.1.11 Final inspection form for erected HCS will be raised by EPC Engineer and after

the checking of HCS and approval by main contractor or consultant, welded mesh

to be place and MEP provision to fixed in proper location by main contractor

before screeding.

CLIENT:

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

6.1.12 Main contractor will cast the slab (screeding) and it will be cured 3 days at least

before starting the erection precast panel for succeeding level with same

procedure or methodology.

6.1.13 Care must be taken to ensure that each slab has at least the minimum bearing

shown on the drawing.

6.1.14 The screeding / topping for the slabs are done according to the design.

CLIENT:

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

SAFETY REQUIREMENTS

Personal safety:

>

Areas where overhead work is going will be treated as hard-hat areas. These areas

should be marked with safety signs. All personnels working there should wear hard-hat

(helmet) as protection against falling objects.

>

All personnel working at site must wear safety shoes with metal toecap to protect against

sharp objects. Rubber boots should be worn where work place is dirty or wet.

>

Personnel handling objects with sharp edges are required to wear hand gloves.

Personnel in loading and unloading section must wear gloves while at work.

>

Personnel handling grinding machines and power saws are required to wear safety

glasses to protect eyes from flying dust.

>

The persons working at height should wear safety harness.

>

Respiratory masks should be worn while spray painting, sand blasting, working with

cement & silica and during work which generates fine dust.

>

All persons should follow the safety rules set forward by the main contractor.

Cranes & Other lifting gear

>

The responsibility for maintaining the hired cranes is with the agencies. However it is the

responsibility of the site supervisor to ensure all hired cranes are tested / inspected as

per the statutory requirements and are having the valid certificate.

>

For EPC owned cranes, supervisor shall ensure that the crane is maintained as per the

statutory requirements.

>

Crane should be selected based on the load to be carried, height of the building and

distance of the crane fixing from the building.

CLIENT:

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

>

Crane should be positioned and fixed correctly such a way that it should not move from

its place during use. Area around the crane should be clear for free movement of the

crane boom so that no obstacle or hindrance is encountered while transporting the panel

from trailer to the spot.

>

Ensure ground conditions are good enough to receive delivery vehicles. Use a spotter to

direct the trucks and cranes.

>

Slings and ropes that have marked safe working load should be used.

>

When synthetic belts are used, sharp corners should be padded, as there is a chance for

the belt to get cut.

>

Do not put hands or fingers between the slings and its load while the sling is being

tightened around the load.

>

Ensure that shackle pins are screwed home.

>

Safety hooks will be fitted with latches to prevent displacement of load.

>

Ensure that edges of nylon belts and ropes are not damaged.

>

All lifting equipments should have valid test certificates.

>

Do not use a damaged or defective sling.

>

Do not shorten a sling with knots, bolts or other makeshift devices.

>

Do not load a sling from the sharp edges of its load.

>

Sharp corners of the load should be padded to prevent damage to the product and sling.

>

Shock loading should be avoided.

>

Do not pull a sling when load is resting on it.

>

Immediately remove a damaged or defective sling from service and destroy it to prevent

further use.

The following safety precautions should be followed during lifting & rigging

>

CLIENT:

Personnel used for signaling i.e. riggers, should be properly trained.

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

>

Crane operator should have a clear view of the signaller.

>

If loading and unloading is at two different points then different signaler should be used

at each location.

>

No one is allowed to ride the load, crane hook.

>

Position the boom at the highest possible boom angle, travel at slow speed and keep the

load as close as practical to the ground, avoid sudden stops and starts.

>

Before releasing the panels ensure that it is in proper position, has proper bearing and is

stable.

>

Check to ensure that necessary or temporary connections have been done.

The following things should be checked before performing any lifting operation.

>

The lifting shackle should be free of any defect or damage. If any damage is found it

must be reported and corrected before the operation.

>

The operator must have a good idea of the following things before lifting

-

Weight of load to be lifted

Load size & centre of gravity

Height to be lifted & final position of the load

Maximum radius at which load can be lifted

Restriction caused by plants, buildings, power lines etc.

The ground condition

The swing radius of the crane

>

Only trained and licensed persons are authorized to operate cranes.

>

Under no circumstances the crane shall be operated beyond its safe working load.

>

All safety devices fitted must be in good working condition.

>

All lifting machines, chains, ropes & lifting tackles etc. that has been altered shall be

adequately retested by a competent person / authority.

>

Make sure the load does not exceed the rated capacity.

>

There should not be any loose items on the load or the crane before lifting.

CLIENT:

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

>

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

Hoist line must be vertical prior to the lift.

While moving the load:

>

Do not pass the load over the workers.

>

Do not leave suspended loads unattended.

>

Do not attempt lifts beyond the rated load capacity of a crane or sling.

Inspection

Before each days use and at shift changes, the crane operator is responsible for visually

inspecting the crane to ensure that all operating and safety functions are working correctly. The

erection foreman shall ensure that these checks have been carried out.

The operator must visually inspect ropes before each day use. This inspection is done by

running the block to its lowest point, then slowly running it back up observing all parts of the

cable for signs of damage, including

-

Severe twists

Broken wires

Deformed, worn, or flattened wires and;

Corroded or pitted surfaces

Ensure that the fiber slings used for lifting HCS are inspected for any damage by removing their

protection covers before any lifting is being done.

Annual Inspection

Each crane must have its loading and boom hoists fully inspected at least once a year in order

to ensure the integrity of the wire rope and the maintenance supervisor should maintain a record

of the same.

WORKING AT HIGH ELEVATION

Scaffolds / Ladders / Guard Rails / Mid Rails / Toe Board

>

Scaffolding and working platforms used for working should be properly secured.

>

Dont overload the scaffolding or working platforms.

>

If scaffolding is provided by the main contractor, then it must be inspected in advance to

ensure that it meets the requirement.

CLIENT:

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

>

>

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

Do not alter a scaffold once it has been certified fit to use.

All scaffold erectors shall wear a full body harness with double lanyard and must be

100% tied off to an anchorage point.

>

When using a ladder to get to an elevated surface extend the ladder 3 rungs (36 in) past

the bearing point to provide a handhold for getting on & off. Ladder will be safe tied offv

and have protection against falls of men and materials.

>

Set the base of a straight or extension ladder back a safe distance from the vertical

approximately one-fourth the working height of the ladder to ensure stability.

>

Do not use broken or damage ladders.

>

Always secure straight or extension ladders at the top.

>

In addition to the above all standard safety precautions related to scaffolding has to be

followed.

Guard rails, mid rails and toe boards will be fitted at edges of decking to prevent men

from falling off. Guard rails will be 106 cm in height and toe boards not less than 15cm in

height. Both will be securely fixed.

The following safety precaution shall be followed while working under windy conditions

>

Extra caution should be taken while erection of hollow core slabs & panels under windy

conditions. High-speed winds cause swinging of the precast elements when lifted with

the crane. Under these conditions there is danger that the elements may swing

excessively and hit the nearby persons or building. Taglines used in these conditions

may not help.

>

When the wind speed is more than 20 knots stop erection of precast components.

>

Stop erection when it is unsafe to work.

The following safety precaution shall be followed while working around live electric lines.

>

While erecting precast components in the vicinity of high power electric lines, utmost

care is required. Any direct contact with the live power lines may lead to fatal accidents.

>

Work in the vicinity of electrical power lines is to be done under two conditions.

.

By disconnecting the power connection

.

Under charged lines

By disconnecting power lines

CLIENT:

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

>

If the power lines are to be disconnected, then ensure electrical authorities are informed

in advance. Make an arrangement with the electricity authority not to reconnect the

power unless it is confirmed.

>

Start crane operation only after ensuring that electricity is disconnected.

Working under charged lines

>

CLIENT:

If work is to be carried out under charged electrical lines, then minimum distances are to

be maintained between the nearest electrical line and any part of the crane or load.

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

>

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

Maintain a minimum gap of 5 m between the nearest electrical line and any part of the

crane or load if electrical ratings are not known provided you are not working in a

domestic area. In other cases, contact your supervisor.

Calculations for the use of 16mm dia. cables as a LIFELINE

RC REQUIREMENT :

1. Under the subject Fall Arrest & Work Restraint Systems, Nets & Rope Access

, Standard No. 218 dated May 30 2009.

2. Lifeline Systems : are points of attachment for the safety harness larnyard and

must be capable of supporting 5000 lbs (2268kgs) per employee. Lifelines may

be mounted either horizontally or vertically and are generally intended to

provide mobility to personnel.

COMPLIANCE :

16 mm dia. Wire Rope (Cable) shall be used as a Lifeline for Erecting Hollow Core Slab.

16mm = 5/8 ; ( Recommended safe working load of a 5/8 wire rope life line is 6,650 lbs.

or 3,022 kgs.)

Hence, 16mm dia. Lifeline can support the RC requirement of 5000 lbs (2268kgs) per

person.

Life line shall be attached at both ends with a pipe 1.2 meters away from the edge of the

building.

The length of the lifeline varies depending on the area where hollowcore slab or pre-cast

panels erection is being performed. Under normal circumstances, column to columns

distances is the precise location of the tie in points of the lifeline.

CLIENT:

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

To ensure that the rope will not slide, three (3) clips will be going to hold wire rope at each

end of the line.

It shall be ensured that all life line are so connected that 100 % tied off is maintained at all

time while moving on the working area.

7.0 HEALTH AND SAFETY

7.1. RISK ASSESMENT AND SAFETY MEASURES

Hazard

Plant and Machinery

Risks

Injury to personnel /

Damage to property

Control Measures

All plant and machinery to

be inspected and serviced

regularly as per ISO

9001:2008 QMS and KSA

Regulations

A maintenance and

service schedule is to be

established and

implemented.

Failure of lifting

equipment

Damage to

buildings/equipment and

injury/death to personnel

All lifting equipment is to

certificated and inspected

regularly

A copy of certification is to

be retained on site for

record keeping and

reference.

Slinger / Signaller to carry

out visual inspection prior

to use

CLIENT:

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

Falling Materials

Damage to

buildings/equipment and

injury/death to personnel

Free falling loads

Damage to

buildings/equipment and

injury/death to personnel

Heavy loads

Failure of lifting

equipment and machinery

/ Damage to equipment

and injury to personnel

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

All lifts are to be carried

out by competent trained

slinger/signallers

All lifts are to be carried

out as directed in the

lifting assessments and

schedule of common lifts

Daily inspections and

checks are to be made by

the crane operator to

ensure that the crane is

safe and operable

Visual assessments are to

be made by competent

personnel to ensure the

correct lifting equipment

is used for the lift and that

the crane is able to lift the

weight of the load at the

required radius

All lifts are to be carried

out as directed in the

lifting assessments and

schedule of common lifts

High Winds

Instability and loss of

control of lifting

operation / Damage to

equipment

Wind speeds within the

site area are to be

monitored and all lifting

operations are to be in

strict conditions of the

CLIENT:

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

wind speed allowances as

laid down for the

restrictions of safe use of

cranes in high wind and

wind conditions.

Unscheduled / Non

competent lifts

Damage to

buildings/equipment and

injury/death to personnel

No unauthorised persons

are to carry out any lifting

operations, all operatives

are to show proof of their

competency prior to

employment.

A lifting assessment is to

be carried out prior to any

unique or special lifts

being carried out.

Close proximity of

cranes/building/public

amenities

Entanglement leading to

loss of integrity of load /

Damage to Equipment /

Injury to Personnel

A safe system of work is

to be instigated ensuring

the risk of collision is

eradicated.

Environmental Safety & Health Contractor Requirements

Personal Protective Equipment

Protective & Safety Equipment

The following are the list of Personal Protective Equipment:

1. Hard hat

2. Safety shoes

3. Dust Mask

4. Safety goggles

5. Rubber gloves

6. Safety Vest

7. Safety built Ladder

CLIENT:

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

Contractual Requirements

Personal Protective Equipment shall be considered only as last resort of

defense against potential risk and hazards.

Contractor shall ensure that adequate stock of Personal Protective

Equipment are readily

either available on site or issued to personnel. PPE

shall be considered as consumable items.

All PPE utilized shall be manufactured to a recognized international

acceptable standard.

CLIENT:

OWNER:

CONTRACTOR:

METHOD STATEMENT FOR

ERECTION OF PRECAST

ELEMENTS

CLIENT:

OWNER:

File No.

: EPC- 003

Ref. No.

: EPC/SD/RAE-03

Rev.

:0

Date

: 08/04/2013

CONTRACTOR:

You might also like

- Container Installation-Method-StatementDocument9 pagesContainer Installation-Method-StatementMD AZHER ULLAH BAIGNo ratings yet

- Method Statement for New Petrol Filling Station DemolitionDocument15 pagesMethod Statement for New Petrol Filling Station DemolitionmuthunayakeNo ratings yet

- Example Method Statement For The Installation of Concrete Floor SlabsDocument8 pagesExample Method Statement For The Installation of Concrete Floor SlabsMohammad Ali ElhamNo ratings yet

- MS-CVL-009 Erection of Hollowcore Slabs 1Document12 pagesMS-CVL-009 Erection of Hollowcore Slabs 1Suju RajanNo ratings yet

- Alternative Proposal - Method Statement - Rev.0Document24 pagesAlternative Proposal - Method Statement - Rev.0Abdallah YounisNo ratings yet

- Method of Statement For Drywall-1Document15 pagesMethod of Statement For Drywall-1Mǻĥmöûd GěņdƴNo ratings yet

- Erect Pre-Cast Concrete Stairs MethodDocument2 pagesErect Pre-Cast Concrete Stairs MethodBaguma Grace Gariyo100% (3)

- 17 Kerb MethodologyDocument2 pages17 Kerb MethodologyAnish Panchal100% (2)

- 3) Method Statement For Formwork Steel & Concrete WorkDocument9 pages3) Method Statement For Formwork Steel & Concrete WorkMukesh PrajapatNo ratings yet

- Method Statements for Construction WorksDocument17 pagesMethod Statements for Construction Worksmangeshshinde124No ratings yet

- ERECTION METHOD STATEMENT Part 1Document8 pagesERECTION METHOD STATEMENT Part 1joseph chewNo ratings yet

- Method Statement for Pile and Pile Cap Treatment WorksDocument11 pagesMethod Statement for Pile and Pile Cap Treatment Workssalman khanNo ratings yet

- Method Statement Wet Areas (600) NDocument16 pagesMethod Statement Wet Areas (600) NmastercssiNo ratings yet

- Method Statement For Handling, Storage, Packaging, Preservation and Delivery1Document14 pagesMethod Statement For Handling, Storage, Packaging, Preservation and Delivery1Javed MA0% (1)

- Method Statement For Cement Board Dry Wall PartitionsDocument10 pagesMethod Statement For Cement Board Dry Wall PartitionsComet GroupNo ratings yet

- Steel Structures Erection Method Statement-DraftDocument43 pagesSteel Structures Erection Method Statement-DraftMahmoud Fakhereddin100% (1)

- Inspection Test Plan For Erection of Tower CraneDocument5 pagesInspection Test Plan For Erection of Tower CraneMarco AragonesNo ratings yet

- MOS of Installation Rise FloorDocument13 pagesMOS of Installation Rise FloorHussam WaleedNo ratings yet

- Efficient Framing and Sheeting ErectionDocument6 pagesEfficient Framing and Sheeting Erectionjoseph chewNo ratings yet

- MOD C MST 011 Precast Concrete WorksDocument9 pagesMOD C MST 011 Precast Concrete WorksArunKumar ChandrasekarNo ratings yet

- Method Statement For Precast Boundary Wall WorksDocument5 pagesMethod Statement For Precast Boundary Wall WorksRsjBugtongNo ratings yet

- Method Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامDocument20 pagesMethod Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامM.ZEKEBA0% (1)

- Work Procedure For Embedded Plate InstallationDocument10 pagesWork Procedure For Embedded Plate InstallationResearcherNo ratings yet

- Surface GI Conduit Installation Method StatementDocument4 pagesSurface GI Conduit Installation Method StatementJaneNo ratings yet

- Method Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01Document9 pagesMethod Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01hammad21100% (1)

- Method Statement: Construction CompanyDocument8 pagesMethod Statement: Construction CompanyDhimas Surya NegaraNo ratings yet

- Structural Steel ErectionDocument7 pagesStructural Steel ErectionVeronica De Jesus50% (4)

- Structure Work - Method StatementDocument8 pagesStructure Work - Method StatementTousif AhmedNo ratings yet

- Method Statement For Roofing WorksDocument4 pagesMethod Statement For Roofing WorksVeronica De JesusNo ratings yet

- Method Statement For Cranage & LiftingDocument6 pagesMethod Statement For Cranage & Liftingadeniyi abiolaNo ratings yet

- Kerbstones Installation GuidelinesDocument4 pagesKerbstones Installation Guidelinespartha_svnitNo ratings yet

- Method Statement For Wall Panels InstallationDocument11 pagesMethod Statement For Wall Panels InstallationChristos LoutrakisNo ratings yet

- Scaffolding Procedure CA 3913Document8 pagesScaffolding Procedure CA 3913Mohamed RizwanNo ratings yet

- Method of Statement Column and Access With Water MarkDocument11 pagesMethod of Statement Column and Access With Water MarkManu MohanNo ratings yet

- Method Statement For Precast Concrete WorksDocument21 pagesMethod Statement For Precast Concrete WorksBleep NewsNo ratings yet

- Method Statement-Fit-Out WorksDocument18 pagesMethod Statement-Fit-Out WorksВиссам АбдинNo ratings yet

- Tower Crane InstallationDocument6 pagesTower Crane Installationanon_177735386No ratings yet

- 12 - Method Statement For Steel Structure ErectionDocument5 pages12 - Method Statement For Steel Structure ErectionidzwanNo ratings yet

- Precast Boundary Wall ErectionDocument5 pagesPrecast Boundary Wall Erectioncprelator100% (2)

- 3.ITP For Erection of Precast - Rev-01Document3 pages3.ITP For Erection of Precast - Rev-01Suju Rajan100% (1)

- Method Statement For Block PavingDocument7 pagesMethod Statement For Block Pavingjohng5697No ratings yet

- Method of Statements - Precast WallDocument17 pagesMethod of Statements - Precast WallEd Salanga100% (3)

- Concrete Pre Pour Planning For Civil ProjectsDocument6 pagesConcrete Pre Pour Planning For Civil ProjectshemantrulzNo ratings yet

- Method Statement For Setting Up Anchor Bolts in Steel StructureDocument3 pagesMethod Statement For Setting Up Anchor Bolts in Steel StructureIbrahim AlrabibNo ratings yet

- Foundation Work Method Statement for 220kV Uganda Transmission ProjectDocument20 pagesFoundation Work Method Statement for 220kV Uganda Transmission ProjectAnonymous CPEha1db7UNo ratings yet

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Document10 pagesWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainNo ratings yet

- RCC Method StatementDocument10 pagesRCC Method StatementSagar AliasjackeyNo ratings yet

- Method Statement For Retaining Wall Work ExecutionDocument3 pagesMethod Statement For Retaining Wall Work ExecutionSujeet SarukNo ratings yet

- Block Work Method StatementDocument3 pagesBlock Work Method StatementPrashanth Cool100% (1)

- Casting of RC Slab MosDocument2 pagesCasting of RC Slab MosEngr Badz de DiosNo ratings yet

- Method Statement For General Concrete Work and Cutting Bending of Steel ReinforcementDocument4 pagesMethod Statement For General Concrete Work and Cutting Bending of Steel ReinforcementSandip PaulNo ratings yet

- Method Statement For Claustra Block Works.Document12 pagesMethod Statement For Claustra Block Works.sathiyaprasath80% (5)

- Method Statement For Earthwork Excavation & BackfillingDocument6 pagesMethod Statement For Earthwork Excavation & Backfillingjing aytonaNo ratings yet

- Install Insulated CladdingDocument16 pagesInstall Insulated CladdingfabinNo ratings yet

- 01 ITP TemplateDocument6 pages01 ITP TemplateHelsy FuentesNo ratings yet

- Hospital Raft Concrete WorksDocument13 pagesHospital Raft Concrete WorksHimanshu KumarNo ratings yet

- Method - Statement - For RCC in Beams and SlabsDocument15 pagesMethod - Statement - For RCC in Beams and Slabsirfan khan75% (4)

- Method Statement For Concrete WallDocument7 pagesMethod Statement For Concrete WallDeo100% (2)

- Erection Method Statement - Birla White (Gotan)Document15 pagesErection Method Statement - Birla White (Gotan)SEPL SEPLNo ratings yet

- Erection of DPC Clinker Silo Extraction-2Document7 pagesErection of DPC Clinker Silo Extraction-2RajuNo ratings yet

- Poultry Egg Production Business Plan and Management Guide: Deep Litter Housing and Battery Cage System ManagementDocument13 pagesPoultry Egg Production Business Plan and Management Guide: Deep Litter Housing and Battery Cage System ManagementCervancia Lianco Marc Raven50% (2)

- WWP Lifting Anchor Breakage PDFDocument5 pagesWWP Lifting Anchor Breakage PDFmarckeNo ratings yet

- WWP Lifting Anchor Breakage PDFDocument5 pagesWWP Lifting Anchor Breakage PDFmarckeNo ratings yet

- Report On Cement For Precast ConcreteDocument4 pagesReport On Cement For Precast ConcretemarckeNo ratings yet

- Travel Request FormDocument2 pagesTravel Request FormmarckeNo ratings yet

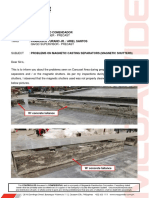

- Report On Magnetic Shutter and Other Forms PDFDocument6 pagesReport On Magnetic Shutter and Other Forms PDFmarckeNo ratings yet

- NCR BulacanDocument11 pagesNCR BulacanmarckeNo ratings yet

- CPD Certificate - 10Document1 pageCPD Certificate - 10marckeNo ratings yet

- Hotel Reservation Request Form: Personal Information Travelling Hotel Guest # 1Document2 pagesHotel Reservation Request Form: Personal Information Travelling Hotel Guest # 1marckeNo ratings yet

- Reynaldo Mamacos BPO SupervisorDocument3 pagesReynaldo Mamacos BPO SupervisormarckeNo ratings yet

- HCS OpeningDocument3 pagesHCS OpeningmarckeNo ratings yet

- Method Statement For CuttingDocument5 pagesMethod Statement For Cuttingmarcke0% (1)

- MS For Grouting ApplicationDocument20 pagesMS For Grouting ApplicationmarckeNo ratings yet

- Neutron Interactions - Week 2 Wednesday LectureDocument60 pagesNeutron Interactions - Week 2 Wednesday LectureFlorian Ananias ByarugabaNo ratings yet

- Physics in Airbags ExplainedDocument5 pagesPhysics in Airbags ExplainedNanda GopalNo ratings yet

- Merchant Shipping Act 2007Document189 pagesMerchant Shipping Act 2007twweettybirdNo ratings yet

- GR No 190022 February 15 2012Document2 pagesGR No 190022 February 15 2012Arellano AureNo ratings yet

- A320 MEMORY ITEMS FOR WINDSHEAR AND EMERGENCIESDocument1 pageA320 MEMORY ITEMS FOR WINDSHEAR AND EMERGENCIESDale Jordan67% (3)

- Safety AlertDocument1 pageSafety Alertjithin shankarNo ratings yet

- Analyze Poem by Anisah FauziyyahDocument4 pagesAnalyze Poem by Anisah FauziyyahAnisahNo ratings yet

- Essential PPE Guide for Welding SafetyDocument51 pagesEssential PPE Guide for Welding SafetyMarissa L BejerNo ratings yet

- Sight DistanceDocument2 pagesSight Distancenoor_osman_18100% (1)

- ATC Light Gun Signals PDFDocument1 pageATC Light Gun Signals PDFANVNo ratings yet

- Aircraft Accident Investigation: F-117A, SN 82-0801, 4 August 1992, 49 FW (416 FS), Holloman AFB NMDocument464 pagesAircraft Accident Investigation: F-117A, SN 82-0801, 4 August 1992, 49 FW (416 FS), Holloman AFB NMthatguy96100% (1)

- Wilton Plane CrashDocument3 pagesWilton Plane CrashEricNo ratings yet

- 7.6 Construction SafetyDocument32 pages7.6 Construction SafetyHtet Myet NeoNo ratings yet

- South Dakota Wing - Jul 2002Document10 pagesSouth Dakota Wing - Jul 2002CAP History LibraryNo ratings yet

- GSPC Asset Integrity Manual and Inspection RequirementsDocument109 pagesGSPC Asset Integrity Manual and Inspection Requirementsranjitpandey100% (2)

- Hell ScreenDocument19 pagesHell ScreenLj MirandaNo ratings yet

- ResumeDocument19 pagesResumeHonka VoxNo ratings yet

- LotusEliseS1 ServiceManualDocument626 pagesLotusEliseS1 ServiceManualClive BuckberryNo ratings yet

- Barangay Fire and Rescue SOPsDocument45 pagesBarangay Fire and Rescue SOPsSan Isidro LabradorNo ratings yet

- Raynera v. Hiceta Et. Al., G.R. No. 120027 (April 21, 1999)Document1 pageRaynera v. Hiceta Et. Al., G.R. No. 120027 (April 21, 1999)Lara YuloNo ratings yet

- Emergency Response On Conteiner ShipsDocument23 pagesEmergency Response On Conteiner ShipsRadu GeorgeNo ratings yet

- Chapter2 ModuleDocument133 pagesChapter2 ModulePauling ChiaNo ratings yet

- TrafficDocument5 pagesTrafficAli HusainNo ratings yet

- Anecdote TextDocument2 pagesAnecdote Textsusila10No ratings yet

- Integrating Process SafetyDocument25 pagesIntegrating Process Safetykanakarao1100% (1)

- Frida KahloDocument2 pagesFrida Kahlonatalia amayaNo ratings yet

- Consumer Cellular Envoy User Guide - FinalDocument36 pagesConsumer Cellular Envoy User Guide - FinalCree Dreams-of BearNo ratings yet

- 1 MomentumDocument15 pages1 Momentumcna_goldNo ratings yet

- Accident Analysis 1stAY201516Document13 pagesAccident Analysis 1stAY201516Clarence Clyde CarandangNo ratings yet

- Rehabilitation Project for Coalfield ResidentsDocument5 pagesRehabilitation Project for Coalfield ResidentsShailendra Kumar Roshan100% (2)