Professional Documents

Culture Documents

Wps - Rev 4 First Page Print

Uploaded by

Alam MD SazidCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wps - Rev 4 First Page Print

Uploaded by

Alam MD SazidCopyright:

Available Formats

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 2 of 16

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

Rev. date

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 3 of 16

CONTENTS

ITEM

DESCRIPTION

PAG

E

QUALIFICATION OF WELDING PROCEDURE

SPECIFICATION (WPS).

1.1

General

1.2

Proposed Welding Procedure Specification (PWPS)

1.3

Grouping of

Materials

1.4

..

Welding Procedure Qualification Record (PQR)

1.5

.

Testing of Qualification

Welds

1.6

Qualification of Repair Welding

1.7

Procedures.

Re-

Tests

1.8

..

Procedure Qualification Records (PQR's) and final approval of

WPS's..

PROCEDURE TO ESTABLISH WPS FOR PROJECT PIPELINE

WELD JOINTS..

2.1

WPS Grade X-56, Diameter 36 and WT 7.93mm, WT 9.53, 12.7mm,

2.2

15.88mm Pipes weld joint.

WPS Grade X-65, Diameter 36 and WT 7.93mm, WT 9.53, 12.7mm,

2.3

15.88mm Pipes weld joint.

Types of tests & certificates for

2.4

PQR..

Certificates for Filler Metals & Base

Materials

WPS for API 5L, 36, Grade X56, Pipe Joint Weld with Internal

Clamp.

WPS for API 5L, 36, Grade X56, Pipe Joint Weld with External

Clamp

WPS for API 5L, 36, Grade X56, Pipe Joint Weld Full Penetration

Appendix1

Appendix2

Appendix3

Repair

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

Appendix4

Appendix5

Appendix6

Appendix7

Appendix8

Appendix9

Appendix10

Appendix11

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 4 of 16

WPS for API 5L, 36, Grade X56, Pipe Joint Weld Partial

10

Repair

WPS for API 5L, 36, Grade X56, Pipe Tie-in

11

Weld

WPS for API 5L, 36, Grade X65, Pipe Joint Weld with Internal

12

Clamp

WPS for API 5L, 36, Grade X65, Pipe Joint Weld with External

13

Clamp

WPS for API 5L, 36, Grade X65, Pipe Joint Weld Full Penetration

14

Repair

WPS for API 5L, 36, Grade X65, Pipe Joint Weld Partial

15

Repair

WPS for API 5L, 36, Grade X65, Pipe Tie-in

16

Weld..

Coupon Test Report.

16a

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

1.

i.

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 5 of 16

QUALIFICATION OF WELDING PROCEDURE SPECIFICATION

(WPS)

General

Accredited and experienced test laboratory has to be nominated to perform all

necessary destructive testing (DT) and non-destructive testing (NDT) as per

requirements of specification of Standard API 1104, Sept 2013 Welding pipeline

and related facilities or ASME Sec.IX Qualification for welding and brazing. Further,

WPS shall be and follow according to the contract specifications.

ii.

Proposed Welding Procedure Specification (PWPS)

Proposed (PWPS) submit for review and approval prior to the beginning of welding

procedure qualification. The proposed (WPS) shall be in accordance with the

requirements of the applicable standard API 1104, Sept 2013 or ASME section- IX.

iii.

Grouping of Materials

The applicable welding standards API 1104, Sept 2013 and ASME Section IX allow a

wide range of materials to be grouped for the qualification of welding procedures.

This can be considered sufficient for most applications in pipeline construction.

iv.

Welding Procedure Qualification Record (PQR)

The qualification test welds will be performed simulating production like clamping,

lifting and lowering. All welding parameters and conditions influencing the

essential variables will be recorded using calibrated equipment. All welding for

procedure qualification and for production will do by using calibrated welding

machines.

The quality of the qualification welds will be determined by non-destructive testing

(NDT) and destructive testing (DT) as per applicable standards.

v.

Testing of Qualification Welds

Preparation of test samples and testing will be performed at an approved test

laboratory. All qualifications welds will be subjected to (NDT) after completion of

welding, if post - weld heat treatment is necessary (NDT) will be performed after

treatment. Non-destructive testing consists of the following.

Visual Exam

Radiographic/ Ultrasonic Test.

As applicable to the design and specification requirement by using approved

equipment and procedures that will be employed for production.

The (NDT) acceptance criteria are defined in the applicable standards and any

welds failing to meet the acceptance criteria not be subjected to destructive

testing. For destructive testing as a minimum all qualification welds subjected to

hardness test. Supplemented by further tests and required in applicable standards.

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 6 of 16

vi. Qualification of Repair Welding Procedures: All repairs welding shall be

performed in accordance with an approved repair welding WPS and shall be

executed by qualified welders. The repair welding WPS is separate from the

original welding procedure with the addition of the following:

Method of defect removal

NDT requirements to determine complete removal of detect

To qualify a repair welding procedure, a production weld shall be produced in

accordance with the approved WPS and shall be non-destructive tested after

completion. If acceptable, a section within the allowable limits has to be removed

and re-welded in accordance with the proposed repair procedure. Finally this repair

weld has to pass all required test described in the relevant sections of the

applicable standards and this specification.

vii.

Re-Tests

General

If the mechanical test fails for whatever reason, it should investigate the cause of

the failure, and re-test or re-evaluation of PQR parameters.

If after re-testing the qualification weld finally fails to meet the minimum

requirements, a new WPS proposal shall be established and qualification welding

and testing repeated.

Tensile and Bend Tests

If one tensile test or bend specimens does not meet the acceptance criteria, two

additional specimens shall be tested and both have to meet the acceptance

criteria.

Hardness Tests

If only one hardness result exceeds the specified maximum then three further

impressions shall be made in close proximity to that which failed such that they do

not mutually interfere. If all of the further tests are below the specified maximum

then the test shall be accepted.

viii.

Procedure Qualification Records (PQR's) and final approval of WPS's

During procedure qualification all the parameters used shall be recorded. After

complication of the welding procedure qualification a procedure qualification

record shall be complied, containing the following information:

Revised WPS based on "as-run" parameters

Printout or datasheet of the "as-run" parameters and welding details

Summary of the welding parameters

Certificates of base materials

Certificates of filler metals and other welding consumables

Calibration certificates of equipment

Pre-heated treatment records

PWHT (Post Weld Heat Treatment) records

Visual inspection report of NDT

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 7 of 16

Radiographic and Ultrasonic Reports.

Result of destructive testing

Coupon Test Reports

Certificate of Welders

Certificate of NDT Inspectors

The final WPS, accompanied by the PQR, shall be submitted for review and

approval. Based on satisfactory results the WPS will be stamped and signed as

"APPROVED FOR CONSTRUCTION".

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

2.

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 8 of 16

PROCEDURE TO ESTABLISH WPS FOR PROJECT PIPELINE

WELD JOINTS

1. WPS Grade X-56, Diameter 36 and WT 7.93mm, WT 9.53, 12.7mm,

15.88mm Pipes weld

joints

Prepare WPS for following weld joints for API 5 L, X-56 grade and wall thickness

from 4.8mm to 19.1 mm; Pipe outside diameter > 12.750 inch as per API 1104,

Sept 2013

2.1.1

For: Transmission & distribution line. Standard: API 1104, Welding

process: SMAW + FCAW; Type of clamp: External, Direction of welding: Uphill/

Downhill, Position:5 G fixed, min 2 welders

2.1.2

For: Transmission & distribution line. Standard: API 1104, Welding

process: SMAW + FCAW; Type of clamp: Internal Clamp. Position: 5G Fixed.

Direction of welding: Downhill

2.1.3

For: Full Penetration Repair, Standard: API 1104, Welding process:

SMAW; Direction of welding: Uphill/ Downhill, Position: 5G Fixed

2.1.4

For Partial Repair, Welding process: SMAW, Direction of welding:

Downhill.

2.1.5

For: Tie-In Weld. Welding Process: SMAW, External clamp. Uphill/

Downhill. No. of Welders: min 2 welders.

Note: WPS & PQR for weldolet & Fillet-welding for branch-connection with main

pipeline based on ASME Boiler & Pressure Vessel Code- IX will be submitted later

for base material API 5L, X-56 grade.

2. WPS Grade X-65, Diameter 36 and WT 7.93mm, WT 9.53, 12.7mm,

15.88mm Pipes weld

joint

Prepare WPS for following weld joints for API 5 L, X-65 grade and wall thickness

from 4.8mm to 19.1 mm; Pipe outside diameter > 12.750 in as per API Standard

1104 21st Edition, Sept 2013.

2.2.1

For: Transmission & distribution line. Standard: API 1104, Welding

process: SMAW + FCAW; Type

of clamp: External, Direction of welding:

Uphill/ Downhill, Position:5 G fixed, min 2 welders

2.2.2

For: Transmission & distribution line. Standard: API 1104, Welding

process: SMAW + FCAW; Type

of clamp: Internal Clamp. Position: 5G Fixed.

Direction of welding: Downhill

2.2.3

For: Full Penetration Repair, Standard: API 1104, Welding process:

SMAW; Direction of welding: Uphill/ Downhill, Position: 5G Fixed

2.2.4

For Partial Repair, Welding process: SMAW, Direction of welding:

Downhill.

2.2.5

For: Tie-In Weld. Welding Process: SMAW, External clamp. Uphill/

Downhill. No. of

Welders: min 2 welders.

Note: Base Material (API 1104 Sept.2013; 5.4.2.2) group b: Specified Minimum

Yield Strength greater than 42,000 psi but less than 65,000 psi. Group c: For

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 9 of 16

material with a SMYS great or equal to 65,000 psi, each grade shall receive a

separate qualification test.

Note: WPS & PQR for weldolet & Fillet-welding for branch-connection with main

pipeline based on ASME Boiler & Pressure Vessel Code- IX will be submitted later

for base material API 5L, X-65 grade.

3. Types of tests & certificates for PQR

Following Types of tests & certificates are required for establishing Procedure

Qualification Record (PQR) as per API Standard 1104 21st Edition, Sept 2013

from approved laboratory.

2.3.1 Destructive Test of weld joint of API 5L PSL2, X-56 grade and wall thickness

of pipe less than or equal to 12.7 mm for pipe outside diameter > 12.75

inches.

Tensile strength . 4 no.

Nick-Break.. 4 no.

Root Bend 4 no.

Face Bend... 4 no. Total 16 no. (Table 2)

Radiographic Test (RT) and 16 destructive tests are require for following

weld joints of pipe

sample of same material grade API 5L, PSL2, X-56 of

Transmission & Distribution pipeline.

Weld joint of pipeline produced from Internal or External clamp pipe

aligning device. (16 tests) Table 2. For Table 2 & Table 5 refer API

standard 1104, 21st Edition, Sept 2013.

Weld joint of Tie-in.(16 tests). Refer Table 2.

Root Repair of weld joint/ full penetration repair. (5 tests). Refer Table 5.

Partial Repair of weld joint.(4 tests) Refer Table 5.

2.3.2 Destructive Test of weld joint of API 5L PSL2, X-56 grade and wall thickness

of pipe > 12.7 mm for pipe outside diameter > 12.75 inches.

Tensile strength 4 no.

Nick-Break.. 4 no.

Side Bend. 8 no. Total 16 no. (Refer Table 2)

Radiographic Test (RT) and 16 destructive tests are require for following

weld joints of pipe

sample of same material grade API 5L, PSL2, X-56 of

Transmission & Distribution pipeline.

Weld joint of pipeline produced from Internal or External clamp pipe

aligning device. (16 tests). Refer Table 2.

Weld joint of Tie-in.(16 tests). Refer Table 2

Root Repair of weld joint/ full penetration repair. (5 tests) Refer Table 5.

Partial Repair of weld joint.(4 tests)Refer Table 5.

2.3.3

Destructive Test of weld joint of API 5L PSL2, X-65 grade and wall

thickness of pipe > 12.7 mm for pipe outside diameter > 12.75 inches.

Tensile strength . 4 no.

Nick-Break.. 4 no.

Side Bend. 8 no. Total 16 no. (Refer Table 2)

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 10 of

16

Radiographic Test (RT) and 16 destructive tests are require for following

weld joints of pipe sample of same material grade API 5L, PSL2, X-56 of

Transmission & Distribution pipeline.

Weld joint of pipeline produced from Internal or External clamp pipe

aligning device. (16 tests). Refer Table 2.

Weld joint of Tie-in.(16 tests) Refer Table 2.

Root Repair of weld joint/ full penetration repair. (5 tests) Refer Table 5.

Partial Repair of weld joint.(4 tests). Refer Table 5.

4. Certificates for Filler Metals & Base Materials

Following certificates are required for Filler metal group (Electrode & FCAW wire) &

base material:

Inspection certificate of Filler metal group (All electrodes and FCAW wire) issued by

manufacturer covering chemical analysis & classification (EN#, AWS & ISO #).

2.4.1 Certificate of compliance of base material (pipe) supplied for Testing.

2.4.1.1 Mill Inspection & Test certificate:

Nondestructive Testing

Destructive Testing

Hydrostatic Testing. D) Dimensional

Inspection.

2.4.1.2 Pipe Manufacturers QA Report: Chemical Composition, Tensile,

Charpy Impact Test, Guided Bend Test, Viker Hardness Test.

2.4.1.3 Packing list of Pipe Manufacturer.

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 11 of

16

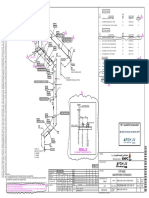

APPENDIX-1: WPS FOR API 5L, 36, Grade X56, PIPE JOINT WELD WITH INTERNAL CLAMP

Project / Contract No

WTS-PH1-CPL-MECREV 3

WPS-001

WTS-PH1-CPL-MECPAGE 1

PQR-001

WELDING PRECEDURE

SPECIFICATION

Standard

For

Welding process

Material

Diameter & Wall thickness

Joint design

Filler metal

Position

Direction of welding

Number of welders

Time lapse between

welding

Type and removal of lineup

clamp

Cleaning & or grinding

Preheat temperature

Temperature between

passes

Shielding gas & flow rate

Shielding flux

Plasma gas composition

Plasma gas orifice size

Plasma gas flow rate

:

:

:

:

:

:

:

:

:

:

:

API 1104, Sept 2013

Transmission and Distribution Line

SMAW+FCAW

API-5L , Grade X-56

OD>12.75" & from 4.8 to 19.1 mm thickness

V Groove

AWS, A-5.1 E6010 /A-5.29 E71T8

5G Fixed

Downhill

Min.2 welders

Between root & hot pass 15 min;

weld interruption after finishing 70% of welding only

: Internal Clamp, removal of clamp after finishing root pass

: Mechanical Brushing & Grinding

: 50 C

: 300 C max

:

:

:

:

:

NA

NA

NA

NA

NA

Joint Design Sketch

CAP

FILL

HP

3035

R

P

2

(0.5)

2 (0.5)

Electrical

Characteristics and Travel Speed

LAYER

ROOT

HOT

PROCESS

2

SMAW

(0.5)

FCAW

FILLER MATERIAL

AWS No

(mm)

2

(0.5)

VOLTAGE

(V)

CURRENT

A

POLARITY

E6010

3.2 4

25 30

100 110

DC ( - )

E71T8

2.0

17 - 21

160 - 260

DC ( + )

DIRECTIO

N

OF

WELD

DOWNHIL

L

DOWNHIL

TRAVEL

SPEED

cm/min

12 15

15 - 26

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

FILL

FCAW

E71T8

2.0

17 - 21

160 - 260

DC ( + )

CAP

FCAW

E71T8

2.0

17 - 21

160 - 260

DC ( + )

CONTRACTOR

THIRD PARTY NDT/WELDING

INSPECTOR

Page

Page 12 of

16

L

DOWNHIL

L

DOWNHIL

L

CONSULTANT

15 26

15 26

APPENDIX-2: WPS FOR API 5L, 36, Grade X56, PIPE JOINT WELD WITH EXTERNAL CLAMP

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Project / Contract No

WTS-PH1-CPL-MECREV 3

WPS-002

WTS-PH1-CPL-MECPAGE 1

PQR-002

WELDING PRECEDURE

SPECIFICATION

Standard

For

Welding process

Material

Diameter & Wall thickness

Joint design

Filler metal

Position

Direction of welding

Number of welders

Time lapse between

welding

Type and removal of lineup

clamp

Cleaning & or grinding

Preheat temperature

Temperature between

passes

Shielding gas & flow rate

Shielding flux

Plasma gas composition

Plasma gas orifice size

Plasma gas flow rate

:

:

:

:

:

:

:

:

:

:

:

API 1104, Sept 2013

Transmission and Distribution Line

SMAW+FCAW

API-5L , Grade X-56

OD>12.75" & from 4.8 to 19.1 mm thickness

V Groove

AWS, A-5.1 E6010 /A-5.29 E71T8

5G Fixed

Uphill / Downhill

Min.2 welders

Between root & hot pass 15 min;

weld interruption after finishing 70% of welding only

: External Clamp, removal of clamp after finishing 50% of

root pass

: Mechanical Brushing & Grinding

: 50 C

: 300 C max

:

:

:

:

:

NA

NA

NA

NA

NA

Joint Design Sketch

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 13 of

16

CAP

FILL

HP

3035

R

P

2

(0.5)

2 (0.5)

Electrical

Characteristics and Travel Speed

LAYER

PROCES

S

FILLER MATERIAL

CURRENT

VOLTAGE

(V)

E6010

3.2- 4

25 30

100 110

POLARIT

Y

DC ( - )

FCAW

E71T8

2.0

17 - 21

160 - 260

DC ( + )

FILL

FCAW

E71T8

2.0

17 - 21

160 - 260

DC ( + )

CAP

FCAW

E71T8

2.0

17 - 21

160 - 260

DC ( + )

ROOT

HOT

2

SMAW

(0.5)

2 (mm)

(0.5)

AWS No

CONTRACTOR

DIRECTI

ON

OF

WELD

UPHILL

DOWNHIL

L

DOWNHIL

L

DOWNHIL

L

TRAVEL

SPEED

cm/min

12 15

15 - 26

15 26

15 26

CLIENT

APPENDIX-3: WPS FOR API 5L, 36, Grade X56, PIPE JOINT WELD FULL PENETRATION REPAIR

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Project / Contract No

WTS-PH1-CPL-MECREV 3

WPS-003

WTS-PH1-CPL-MECPAGE 1

PQR-003

WELDING PRECEDURE

SPECIFICATION

Standard

For

Welding process

Material

Diameter & Wall thickness

Joint design

Filler metal

Position

Direction of welding

Number of welders

Time lapse between

welding

Type and removal of lineup

clamp

Cleaning & or grinding

Preheat temperature

:

:

:

:

:

:

:

:

:

:

API 1104, Sept 2013

Full Penetration Repair

SMAW

API-5L , Grade X-56

OD>12.75" & from 4.8 to 19.1 mm thickness

V Groove

AWS, A-5.1 E6010 /A-5.5 E7010

5G Fixed

Uphill / Downhill

1 welders

: NA

: NA

: Mechanical Brushing & Grinding

: 100 C

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

Rev. date

1

08 Dec

2013

Temperature between

passes

Shielding gas & flow rate

Shielding flux

Plasma gas composition

Plasma gas orifice size

Plasma gas flow rate

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 14 of

16

: 300 C max

:

:

:

:

:

NA

NA

NA

NA

NA

Joint Design Sketch

Weld Preparation;

40

DL CAP

40

FILL

HP

R

P

50

50

Repair Area

DL : Defect

Length

LAYER

Electrical Characteristics and Travel Speed

PROCES

S

FILLER MATERIAL

AWS No

(mm)

ROOT

SMAW

E6010

3.2 4.0

HOT

SMAW

E7010

4.0 5.0

FILL

SMAW

E7010

4.0 5.0

CAP

SMAW

E7010

4.0 5.0

CONTRACTOR

VOLTAGE

(V)

24 28

24 28

24 28

24 28

CURRENT

90 100

POLARIT

Y

DC ( - )

100 - 110

DC ( + )

135 145

DC ( + )

130 - 140

DC ( + )

CLIENT

DIRECTI

ON

OF

WELD

UPHILL

DOWNHIL

L

DOWNHIL

L

DOWNHIL

L

TRAVEL

SPEED

Cm/min

7 - 13

10 - 15

13 - 15

13 - 15

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

APPENDIX-4: WPS FOR API 5L, 36, Grade X56, PIPE JOINT WELD PARTIAL REPAIR

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Project / Contract No

WTS-PH1-CPL-MECWPS-004

WTS-PH1-CPL-MECPQR-004

WELDING PRECEDURE

SPECIFICATION

Standard

For

Welding process

Material

Diameter & Wall thickness

Joint design

Filler metal

Position

Direction of welding

Number of welders

Time lapse between

welding

Type and removal of lineup

clamp

Cleaning & or grinding

Preheat temperature

Temperature between

passes

Shielding gas & flow rate

Shielding flux

Plasma gas composition

Plasma gas orifice size

Plasma gas flow rate

:

:

:

:

:

:

:

:

:

:

Page

Page 15 of

16

REV 3

PAGE 1

API 1104, Sept 2013

Partial Repair

SMAW

API-5L , Grade X-56

OD>12.75" & from 4.8 to 19.1 mm thickness

V Groove

AWS, A-5.5 E7010

5G Fixed

Downhill

1 welders

: NA

: NA

: Mechanical Brushing & Grinding

: 100 C

: 300 C max

:

:

:

:

:

NA

NA

NA

NA

NA

Joint Design Sketch

CAP

FILL

HP

Electrical Characteristics

and Travel Speed

LAYER

FILL

PROCESS

SMAW

FILLER MATERIAL

AWS No

(mm)

E7010

4.0 5.0

P

VOLTAGE

(V)

26 28

CURRENT

A

POLARITY

120 - 130

DC ( + )

DIRECTIO

N

OF

WELD

DOWNHIL

L

TRAVEL

SPEED

cm/min

10 15

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

CAP

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

SMAW

1

08 Dec

2013

E7010

CONTRACTOR

2

12 May

2014

4.0 5.0

3

15 June

2014

26 - 28

Document No

WTS-PH1-CPL-MEC-QAC002

115 - 125

DC ( + )

CLIENT

DOWNHIL

L

Page

Page 16 of

16

7 13

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

APPENDIX-5: WPS FOR API 5L, 36, Grade X56, PIPE TIE-IN WELD

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Project / Contract No

WTS-PH1-CPL-MECWPS-005

WTS-PH1-CPL-MECPQR-005

WELDING PRECEDURE

SPECIFICATION

Standard

For

Welding process

Material

Diameter & Wall thickness

Joint design

Filler metal

Position

Direction of welding

Number of welders

Time lapse between

welding

Type and removal of lineup

clamp

Cleaning & or grinding

Preheat temperature

Temperature between

passes

Shielding gas & flow rate

Shielding flux

Plasma gas composition

Plasma gas orifice size

Plasma gas flow rate

Page

Page 17 of

16

REV 3

PAGE 1

:

:

:

:

:

:

:

:

:

:

:

API 1104, Sept 2013

Tie-in Weld

SMAW

API-5L , Grade X-56

OD>12.75" & from 4.8 to 19.1 mm thickness

V Groove

AWS, A-5.1 E6010 /A-5.5 E7010

5G Fixed

Uphill / Downhill

1 welders

Between root & hot pass 15 min;

weld interruption after finishing 70% of welding only

: External Clamp, removal of clamp after finishing 50% of

root pass

: Mechanical Brushing & Grinding

: 50 C

: 300 C max

:

:

:

:

:

NA

NA

NA

NA

NA

Joint Design Sketch

CAP

FILL

HP

3035

R

P

2

(0.5)

2 (0.5)

Electrical

Characteristics and Travel Speed

LAYER

ROOT

HOT

PROCESS

2SMAW

(0.5)

SMAW

FILLER MATERIAL

AWS No

E6010

E7010

(mm)

2

(0.5)

3.2 4.0

4.0 5.0

VOLTAGE

(V)

27 35

25 32

CURRENT

A

POLARITY

80 95

130 - 150

DC ( - )

DC ( + )

DIRECTIO

N

OF

WELD

UPHILL

DOWNHIL

TRAVEL

SPEED

cm/min

12 - 15

15 - 26

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

FILL

CAP

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

SMAW

E7010

SMAW

E7010

2

12 May

2014

4.0 5.0

4.0 5.0

3

15 June

2014

25 30

25 30

Document No

WTS-PH1-CPL-MEC-QAC002

120 140

DC ( + )

130 - 140

DC ( + )

CONTRACTOR

L

DOWNHIL

L

DOWNHIL

L

Page

Page 18 of

16

15 - 26

15 - 26

CLIENT

APPENDIX-6: WPS FOR API 5L, 36, Grade X65, PIPE JOINT WELD WITH INTERNAL CLAMP

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Project / Contract No

WTS-PH1-CPL-MECREV 3

WPS-006

WTS-PH1-CPL-MECPAGE 1

PQR-006

WELDING PRECEDURE

SPECIFICATION

Standard

For

Welding process

Material

Diameter & Wall thickness

Joint design

Filler metal

Position

Direction of welding

Number of welders

Time lapse between

welding

Type and removal of lineup

clamp

Cleaning & or grinding

Preheat temperature

Temperature between

passes

Shielding gas & flow rate

Shielding flux

Plasma gas composition

Plasma gas orifice size

Plasma gas flow rate

:

:

:

:

:

:

:

:

:

:

:

API 1104, Sept 2013

Transmission and Distribution Line

SMAW+FCAW

API-5L , Grade X-65

OD>12.75" & from 4.8 to 19.1 mm thickness

V Groove

AWS, A-5.1 E6010 /A-5.29 E71T8

5G Fixed

Downhill

Min.2 welders

Between root & hot pass 15 min;

weld interruption after finishing 70% of welding only

: Internal Clamp, removal of clamp after finishing root pass

: Mechanical Brushing & Grinding

: 50 C

: 300 C max

:

:

:

:

:

NA

NA

NA

NA

NA

Joint Design Sketch

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 19 of

16

CAP

FILL

HP

3035

R

P

2

(0.5)

2 (0.5)

Electrical

Characteristics and Travel Speed

LAYER

ROOT

PROCES

S

2

SMAW

(0.5)

FILLER MATERIAL

CURRENT

VOLTAGE

(V)

2 (mm)

(0.5)

AWS No

POLARIT

Y

E6010

3.2 4.0

25 30

100 110

DC ( - )

HOT

FCAW

E71T8

2.0

17 - 21

160 - 260

DC ( + )

FILL

FCAW

E71T8

2.0

17 - 21

160 - 260

DC ( + )

CAP

FCAW

E71T8

2.0

17 - 21

160 - 260

DC ( + )

CONTRACTOR

DIRECTI

ON

OF

WELD

DOWNHIL

L

DOWNHIL

L

DOWNHIL

L

DOWNHIL

L

TRAVEL

SPEED

cm/min

12 15

15 - 26

15 26

15 26

CLIENT

APPENDIX-7: WPS FOR API 5L, 36, Grade X65, PIPE JOINT WELD WITH EXTERNAL CLAMP

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Project / Contract No

WTS-PH1-CPL-MECREV 3

WPS-007

WTS-PH1-CPL-MECPAGE 1

PQR-007

WELDING PRECEDURE

SPECIFICATION

Standard

For

Welding process

Material

Diameter & Wall thickness

Joint design

Filler metal

Position

Direction of welding

Number of welders

Time lapse between

welding

Type and removal of lineup

clamp

Cleaning & or grinding

:

:

:

:

:

:

:

:

:

:

:

API 1104, Sept 2013

Transmission and Distribution Line

SMAW+FCAW

API-5L , Grade X-65

OD>12.75" & from 4.8 to 19.1 mm thickness

V Groove

AWS, A-5.1 E6010 /A-5.29 E71T8

5G Fixed

Uphill / Downhill

Min.2 welders

Between root & hot pass 15 min;

weld interruption after finishing 70% of welding only

: External Clamp, removal of clamp after finishing 50% of

root pass

: Mechanical Brushing & Grinding

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

Preheat temperature

Temperature between

passes

Shielding gas & flow rate

Shielding flux

Plasma gas composition

Plasma gas orifice size

Plasma gas flow rate

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 20 of

16

: 50 C

: 300 C max

:

:

:

:

:

NA

NA

NA

NA

NA

Joint Design Sketch

CAP

FILL

HP

3035

R

P

2

(0.5)

2 (0.5)

Electrical

Characteristics and Travel Speed

LAYER

PROCES

S

FILLER MATERIAL

CURRENT

VOLTAGE

(V)

E6010

3.2 4.0

25 30

100 110

POLARIT

Y

DC ( - )

FCAW

E71T8

2.0

17 - 21

160 - 260

DC ( + )

FILL

FCAW

E71T8

2.0

17 - 21

160 - 260

DC ( + )

CAP

FCAW

E71T8

2.0

17 - 21

160 - 260

DC ( + )

ROOT

HOT

2

SMAW

(0.5)

2 (mm)

(0.5)

AWS No

CONTRACTOR

DIRECTI

ON

OF

WELD

UPHILL

DOWNHIL

L

DOWNHIL

L

DOWNHIL

L

TRAVEL

SPEED

cm/min

12 15

15 - 26

15 26

15 26

CLIENT

APPENDIX-8: WPS FOR API 5L, 36, Grade X65, PIPE JOINT WELD FULL PENETRATION REPAIR

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Project / Contract No

WTS-PH1-CPL-MECREV 3

WPS-003

WTS-PH1-CPL-MECPAGE 1

PQR-003

WELDING PRECEDURE

SPECIFICATION

Standard

For

Welding process

Material

Diameter & Wall thickness

Joint design

Filler metal

:

:

:

:

:

:

:

API 1104, Sept 2013

Full Penetration Repair

SMAW

API-5L , Grade X-65

OD>12.75" & from 4.8 to 19.1 mm thickness

V Groove

AWS, A-5.1 E6010 /A-5.5 E8010

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

Rev. date

1

08 Dec

2013

Position

Direction of welding

Number of welders

Time lapse between

welding

Type and removal of lineup

clamp

Cleaning & or grinding

Preheat temperature

Temperature between

passes

Shielding gas & flow rate

Shielding flux

Plasma gas composition

Plasma gas orifice size

Plasma gas flow rate

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 21 of

16

: 5G Fixed

: Uphill / Downhill

: 1 welders

: NA

: NA

: Mechanical Brushing & Grinding

: 100 C

: 300 C max

:

:

:

:

:

NA

NA

NA

NA

NA

Joint Design Sketch

Weld Preparation;

40

DL CAP

40

FILL

HP

R

P

50

50

Repair Area

DL : Defect

Length

LAYER

Electrical Characteristics and Travel Speed

PROCES

S

FILLER MATERIAL

AWS No

(mm)

ROOT

SMAW

E6010

3.2 - 4.0

HOT

SMAW

E8010

4.0 - 5.0

FILL

SMAW

E8010

4.0 5.0

CAP

SMAW

E8010

4.0 5.0

CONTRACTOR

VOLTAGE

(V)

24 28

24 28

24 28

24 28

CURRENT

90 100

POLARIT

Y

DC ( - )

100 - 110

DC ( + )

135 145

DC ( + )

130 - 140

DC ( + )

CLIENT

DIRECTI

ON

OF

WELD

UPHILL

DOWNHIL

L

DOWNHIL

L

DOWNHIL

L

TRAVEL

SPEED

cm/min

7 - 13

10 - 15

13 - 15

13 - 15

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

APPENDIX-9: WPS FOR API 5L, 36, Grade X65, PIPE JOINT WELD PARTIAL REPAIR

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Project / Contract No

WTS-PH1-CPL-MECWPS-004

WTS-PH1-CPL-MECPQR-004

WELDING PRECEDURE

SPECIFICATION

Standard

For

Welding process

Material

Diameter & Wall thickness

Joint design

Filler metal

Position

Direction of welding

Number of welders

Time lapse between

welding

Type and removal of lineup

clamp

Cleaning & or grinding

Preheat temperature

Temperature between

passes

Shielding gas & flow rate

Shielding flux

Plasma gas composition

Plasma gas orifice size

Plasma gas flow rate

:

:

:

:

:

:

:

:

:

:

Page

Page 22 of

16

REV 3

PAGE 1

API 1104, Sept 2013

Partial Repair Procedure

SMAW

API-5L , Grade X-65

OD>12.75" & from 4.8 to 19.1 mm thickness

V Groove

AWS, A-5.5 E8010

5G Fixed

Downhill

1 welders

: NA

: NA

: Mechanical Brushing & Grinding

: 100 C

: 300 C max

:

:

:

:

:

NA

NA

NA

NA

NA

Joint Design Sketch

CAP

FILL

HP

Electrical Characteristics

and Travel Speed

LAYER

FILL

PROCES

S

SMAW

FILLER MATERIAL

AWS No

(mm)

E8010

4.0 5.0

R

P

VOLTAGE

(V)

26 28

CURRENT

A

POLARIT

Y

120 - 130

DC ( + )

DIRECTI

ON

OF

WELD

DOWNHIL

L

TRAVEL

SPEED

cm/min

10 15

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

CAP

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

SMAW

1

08 Dec

2013

E8010

CONTRACTOR

2

12 May

2014

4.0 5.0

3

15 June

2014

26 - 28

Document No

WTS-PH1-CPL-MEC-QAC002

115 - 125

DC ( + )

CLIENT

DOWNHIL

L

Page

Page 23 of

16

7 13

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

APPENDIX-10: WPS FOR API 5L, 36, Grade X65, PIPE TIE-IN WELD

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Project / Contract No

WTS-PH1-CPL-MECWPS-005

WTS-PH1-CPL-MECPQR-005

WELDING PRECEDURE

SPECIFICATION

Standard

For

Welding process

Material

Diameter & Wall thickness

Joint design

Filler metal

Position

Direction of welding

Number of welders

Time lapse between

welding

Type and removal of lineup

clamp

Cleaning & or grinding

Preheat temperature

Temperature between

passes

Shielding gas & flow rate

Shielding flux

Plasma gas composition

Plasma gas orifice size

Plasma gas flow rate

Page

Page 24 of

16

REV 3

PAGE 1

:

:

:

:

:

:

:

:

:

:

:

API 1104, Sept 2013

Tie-in Weld

SMAW

API-5L , Grade X-65

OD>12.75" & from 4.8 to 19.1 mm thickness

V Groove

AWS, A-5.1 E6010 /A-5.5 E8010

5G Fixed

Uphill / Downhill

1 welders

Between root & hot pass 15 min;

weld interruption after finishing 70% of welding only

: External Clamp, removal of clamp after finishing 50% of

root pass

: Mechanical Brushing & Grinding

: 50 C

: 300 C max

:

:

:

:

:

NA

NA

NA

NA

NA

Joint Design Sketch

CAP

FILL

HP

3035

R

P

2

(0.5)

2 (0.5)

Electrical

Characteristics and Travel Speed

LAYER

ROOT

HOT

PROCES

S

2

SMAW

(0.5)

SMAW

FILLER MATERIAL

AWS No

E6010

E8010

VOLTAGE

(V)

2 (mm)

(0.5)

3.2 4.0

4.0 5.0

27 35

25 32

CURRENT

A

80 95

130 - 150

POLARIT

Y

DC ( - )

DC ( + )

DIRECTI

ON

OF

WELD

UPHILL

DOWNHIL

TRAVEL

SPEED

cm/min

12 - 15

15 - 26

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

Rev. date

FILL

CAP

1

08 Dec

2013

SMAW

E8010

SMAW

E8010

2

12 May

2014

4.0 5.0

4.0 5.0

3

15 June

2014

25 30

25 30

Document No

WTS-PH1-CPL-MEC-QAC002

120 140

DC ( + )

130 - 140

DC ( + )

L

DOWNHIL

L

DOWNHIL

L

Page

Page 25 of

16

15 - 26

15 - 26

COUPON TEST REPORT

Date______________________________________________

Test No_____________________________________

_

Location____________________________________________________________________________________________

_

State______________________________________________

Weld Position:

Roll

_

Fixed

Welder____________________________________________

Mark_______________________________________

_

Welding

Time of

Time________________________________________

day__________________________________

Mean

Wind break

Temperature___________________________________

used______________________________

Weather

conditions____________________________________________________________________________________

Voltage___________________________________________

Amperage__________________________________

__

_

Welding machine

Welding machine

type_________________________________

size__________________________

Filler

metal___________________________________________________________________________________________

Reinforcement______________________________________________________________________________________

__

Pipe type and

grade____________________________________________________________________________________

Wall

Outside

thickness_______________________________________

diameter_____________________________

Coupon stenciled

Original specimen

dimension

Original specimen

area

Maximum load

Tensile strength

Fracture location

Procedure

Welder

Qualified test

Line test

Qualified

Disqualified

Maximum

tensile___________________

Minimum tensile

Average tensile

Project

EXTENSION OF PHASE-1 WATER SUPPLY PROJECT TO VILLAGES AT HAIL

Client

MINISTRY OF WATER AND ELECTRICITY (MOWE)

Consultant

OTAISHAN CONSULTING ENGINEERS

Contractor

Document

Name

Rev. No

BIN SAMMAR CO.

Rev. date

WELDING PROCEDURE SPECIFICATION (WPS)

0

07 Nov

2013

1

08 Dec

2013

2

12 May

2014

3

15 June

2014

Document No

WTS-PH1-CPL-MEC-QAC002

Page

Page 26 of

16

Remarks on tensile-strength

test__________________________________________________________________________

1.

__________________________________________________________________________________________________

2.

__________________________________________________________________________________________________

3.

__________________________________________________________________________________________________

4.

__________________________________________________________________________________________________

Remarks on bend

test___________________________________________________________________________________

1.

__________________________________________________________________________________________________

2.

__________________________________________________________________________________________________

3.

__________________________________________________________________________________________________

4.

__________________________________________________________________________________________________

Remarks on nick-break

test______________________________________________________________________________

1.

__________________________________________________________________________________________________

2.

__________________________________________________________________________________________________

3.

__________________________________________________________________________________________________

4.

__________________________________________________________________________________________________

Test made at

__________________________________________

Tested by

____________________________________________

Date

_________________________________________

Supervised by

__________________________________

You might also like

- CV Faisal ZAFAR SHAHIDDocument6 pagesCV Faisal ZAFAR SHAHIDAlam MD SazidNo ratings yet

- QD62-H-103 DocumentationDocument16 pagesQD62-H-103 DocumentationAlam MD SazidNo ratings yet

- R016611Document4 pagesR016611Alam MD SazidNo ratings yet

- Peneterant Testing For NDT - Procedure Details - Latest FinalDocument8 pagesPeneterant Testing For NDT - Procedure Details - Latest FinalAlam MD Sazid100% (1)

- Third Party QC For SWCC Man IndiaDocument1 pageThird Party QC For SWCC Man IndiaAlam MD SazidNo ratings yet

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- Sawaed PT Report No. 02 For SWCC Jubail Emergency LineDocument1 pageSawaed PT Report No. 02 For SWCC Jubail Emergency LineAlam MD SazidNo ratings yet

- DPT Test Report FormatDocument1 pageDPT Test Report FormatAlam MD SazidNo ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- ISO 9001, 14001, 45001 certified companyDocument1 pageISO 9001, 14001, 45001 certified companyAlam MD SazidNo ratings yet

- Request for Welding Procedure ApprovalDocument10 pagesRequest for Welding Procedure ApprovalAlam MD SazidNo ratings yet

- Cathodic ProtectionDocument52 pagesCathodic Protectionredback666100% (2)

- List of WPS (Jerp) PDFDocument2 pagesList of WPS (Jerp) PDFAlam MD SazidNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- Prime Minister Employment Generation Programme DetailsDocument1 pagePrime Minister Employment Generation Programme DetailsAlam MD SazidNo ratings yet

- Accoutnt Statement PDFDocument3 pagesAccoutnt Statement PDFAlam MD SazidNo ratings yet

- SAWAED'S LIQUID PENETRANT TEST PROCEDUREDocument7 pagesSAWAED'S LIQUID PENETRANT TEST PROCEDUREAlam MD SazidNo ratings yet

- P6022mab Amd 128 11541 01 - S4Document1 pageP6022mab Amd 128 11541 01 - S4Alam MD SazidNo ratings yet

- Mowe Letter For Aico Approval For Pipeline Inspection PDFDocument1 pageMowe Letter For Aico Approval For Pipeline Inspection PDFAlam MD SazidNo ratings yet

- Understanding Process DrawingsDocument25 pagesUnderstanding Process Drawingspippo2378793No ratings yet

- PID SymbolsDocument18 pagesPID SymbolsAnonymous f9EEXptHCNo ratings yet

- ISO 9001, 14001, 45001 certified companyDocument1 pageISO 9001, 14001, 45001 certified companyAlam MD SazidNo ratings yet

- Shop Materials Confidential Use OnlyDocument1 pageShop Materials Confidential Use OnlyAlam MD SazidNo ratings yet

- Signed Acceptance of Job OfferDocument2 pagesSigned Acceptance of Job OfferAlam MD Sazid0% (1)

- Experience LetterDocument1 pageExperience LetterAlam MD Sazid0% (1)

- ch9 1Document38 pagesch9 1Karam AlmasriNo ratings yet

- Piping Isometric Drawings GuideDocument857 pagesPiping Isometric Drawings GuideHugo Ruiz67% (3)

- Seed License Documents NewDocument8 pagesSeed License Documents NewAlam MD SazidNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Rebar Orderlist (Revision)Document3 pagesRebar Orderlist (Revision)alnoel tordillaNo ratings yet

- Amoeba Sisters Video Select Recap: Properties of Water: Solvent Is Important For Living OrganismsDocument2 pagesAmoeba Sisters Video Select Recap: Properties of Water: Solvent Is Important For Living Organismsnoor100% (2)

- Ecc SF 80Document1 pageEcc SF 80longyiequipmentNo ratings yet

- PDS - Sikasil-111 MultiPurpose PDFDocument3 pagesPDS - Sikasil-111 MultiPurpose PDFcahyo hutomoNo ratings yet

- Binding Systems: Catalog Switzerland Pricelist 2016Document6 pagesBinding Systems: Catalog Switzerland Pricelist 2016Gennadiy BondarenkoNo ratings yet

- EPAPROOF FPCS 08.EN - Rev.11.060917Document8 pagesEPAPROOF FPCS 08.EN - Rev.11.060917Ali HashemiNo ratings yet

- Casting Material Carbon Steel A27 GR 65 35Document8 pagesCasting Material Carbon Steel A27 GR 65 35Abdul RozaqNo ratings yet

- Joint Free Slabs On Grade An Innovative Approach WorkingDocument6 pagesJoint Free Slabs On Grade An Innovative Approach Workingmehdi_hoseineeNo ratings yet

- Daftar Pustaka KilnDocument2 pagesDaftar Pustaka Kilnazzahra ghina fadillahNo ratings yet

- PT. Ispat Indo Company ProfileDocument2 pagesPT. Ispat Indo Company Profileputri rianiNo ratings yet

- Restol BrochureDocument2 pagesRestol BrochureAndrei PopNo ratings yet

- Building Materials Module 1 PPT NotesDocument20 pagesBuilding Materials Module 1 PPT NotesmanojNo ratings yet

- Moulding Sand Tesying - 11Document17 pagesMoulding Sand Tesying - 11firdoshansariNo ratings yet

- PENETRON ADMIX Data Sheet PDFDocument2 pagesPENETRON ADMIX Data Sheet PDFakositeodoroNo ratings yet

- Study of The Thermal Cracking During The Vacuum Distillation of Atmospheric Residue of Crude OilDocument11 pagesStudy of The Thermal Cracking During The Vacuum Distillation of Atmospheric Residue of Crude OilPhạm QuânNo ratings yet

- Byk-360n TDS (En)Document4 pagesByk-360n TDS (En)GİZEM D.No ratings yet

- Astm B 138 - B 138M - 06Document4 pagesAstm B 138 - B 138M - 06Ramsi AnkziNo ratings yet

- EnamelingDocument10 pagesEnamelingLavanya NagpalNo ratings yet

- Silcone Glass Cloth Tech SheetDocument1 pageSilcone Glass Cloth Tech SheetOdo AsuNo ratings yet

- Glass: A Versatile MaterialDocument34 pagesGlass: A Versatile MaterialRUSHALI SRIVASTAVANo ratings yet

- 649 1 PDFDocument239 pages649 1 PDFZainul AbideenNo ratings yet

- Writing and Naming Ionic and Covalent Compounds (39Document3 pagesWriting and Naming Ionic and Covalent Compounds (39Chennille Ann Bleu GundayaoNo ratings yet

- Ejb EnclosuresDocument8 pagesEjb EnclosuresMarito VallejitosNo ratings yet

- Journal of Membrane Science: SciencedirectDocument13 pagesJournal of Membrane Science: SciencedirectGonzalo BenavidesNo ratings yet

- 2011 04 11 Biomass GasificationDocument48 pages2011 04 11 Biomass GasificationHotib PerwiraNo ratings yet

- Splice WashDocument4 pagesSplice WashJosue ToribioNo ratings yet

- IGCSE Unit 10 ExtractionDocument17 pagesIGCSE Unit 10 ExtractionIsuriy AdasuriyaNo ratings yet

- Shrinkage Control MethodsDocument26 pagesShrinkage Control MethodsSwapniel PatilNo ratings yet

- Nas1352 Rev 11Document6 pagesNas1352 Rev 11staedtlerpNo ratings yet

- Pennzoil GT Performance SAE 20W-50: Motor OilDocument2 pagesPennzoil GT Performance SAE 20W-50: Motor OilAkmal ShauqyNo ratings yet