Professional Documents

Culture Documents

15 0 8 - Pilot Box Specs

Uploaded by

daniel.cabasa2577Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15 0 8 - Pilot Box Specs

Uploaded by

daniel.cabasa2577Copyright:

Available Formats

SAUDI CONSOLIDATED ELECTRIC COMPANY

CENTRAL REGION

SPECIFICATION NO: 15-0-8

PILOT TERMINATION, ISOLATION & SUPERVISION

BOX WIT 5 kV INSULATION

APPROVED:

DIVISION

MANAGER

REVISION

Original

DATE

25/11/1987

04/04/1402

ENDORSED

Director for Distribution Engineering

DATE 15/07/1408H

03/03/1988G

APPROVED

Vice President for Consumers Services

012/74350/04.9/RET-mza.

DATE

Specification No: SC/TS - 16

Rev. No:

REVISIONS

Issue 1

(November-1987)

Original

012/74350/04.9/RET-mza.

26-3-1408(17-11-1987)

Page 2 of 8

R.Awwal-1408

Specification No: SC/TS - 16

Rev. No:

CONTENTS

1.

Scope

2.

General

3.

Enclosure

4.

Construction

5.

Cable Gland Plates

6.

Pilot Supervision Equipment

7.

Pilot Isolation Equipment

8.

Terminal Blocks and Wiring

9.

Earthing

10.

Labelling

ASSOCIATED SPECIFICATIONS SCECO Spec.

TPD-4/3

15-0-1

15-0-2

15-0-5

15-0-6

15-1-1(F3)

15-2-1 33kV

Nomenclature of Protective Relays

Testing and Commissioning

Protection Policy and Application Standards

Intertripping

13.8kV Underground Cable Feeder -Unit Protection

Underground Feeder Protection

Rationalisation of Protection Equipment

Page 3 of 8

Specification No: SC/TS - 16

Rev. No:

Pilot Termination, Isolation & Supervision Box with 5kV Insulation .

1.

SCOPE

This specification details the basic requirements for terminating one or two twelve-pair pilot

cables and up to 10 outgoing multicore cables with facilities for pilot isolation, 5kV pilot

insulation and send or receive end pilot supervision.

2.

GENERAL

2.1

The pilot boxes covered by this specification are for use with pilot wire protection and possible

emergency tripping schemes in the case of consumer's feeders, on either 13.8kV or 33kV power

cables where a 5kV pilot insulation level is required.

2.2

Two main types of boxes are required, one with send end pilot supervision and one with receive

end pilot supervision.

2.3

In the case of multiple installations required for a turnkey contract, it is permissible for one box to

contain all the equipment required for two cable circuits. In such cases, the double circuit box

could be equipped with two send ends, two receive ends or one send end and one receive end pilot

supervision. The exact requirements shall be specified at the time of ordering.

3.

ENCLOSURE

3.1

The box shall be made out of polyester reinforced with fibreglass and shall be self-extinguishing.

3.2

The box shall be fitted with four external brackets to facilitate wall mounting of boxes side-byside if necessary.

3.3

The front of the box shall comprise a door which is hinged on the left. The door shall be fitted

with two closing handles which do not have any integral key locking arrangement. A suitable

bracket shall be fitted to J the centre of the right side of the door to allow locking with a padlock

having a hasp diameter of 6 mm with 25 mm clearance. The door shall be suitably sealed to

prevent the ingress of dust to class IPSO of IEC 529.

3.4

The top and bottom of the box shall each have a suitable cut-out for mounting a cable gland plate

for the outgoing multicore cables and pilot cables respectively.

3.5

When pilot box is associated with two cable feeders, the necessary equipment shall be mounted to

the left for one cable feeder and to the right for the other cable-feeder. A barrier of insulating

material not less than 100mm deep shall be fixed in the centre to segregate the 2 sets of

equipment.

3.6

The box and door shall be finished in shade RAL-7033 -Grey.

Page 4 of 8

Specification No: SC/TS - 16

Rev. No:

4.

CONSTRUCTION

4.1

All the internal components of the box shall be mounted on a mild-steel backplate with fixing

brackets and rails as appropriate.

4.2

The exact layout and dimensions are left to the manufacturer.

5.

CABLE GLAND PLATES

5.1

Two mild-steel cable gland plates shall be provided. These shall not be drilled to accept cables

unless specifically requested at the time of order. All gland plates shall be of sufficient strength to

prevent distortion in use.

5.2

The top gland plate shall be of sufficient size to accommodate the maximum number of multicore

cable glands depending on the type of box as follows:

For pilot box with SEND END pilot supervision:

1 Cable gland for 7 core 2.5 mm2 PVC/PVC/SWA/PVC cable for protection.

2 Cable glands for 4 core 2.5 mm2 PVC/PVC/SWA/PVC cables for supplies.

For pilot box with RECEIVE END pilot supervision:

1 Cable gland for 7 core 2.5 mm2 PVC/PVC/SWA/PVC cable for protection.

In addition to the above, for each consumers feeder which requires emergency tripping facilities,

the top gland plate shall also accommodate one cable gland for 4 core 2.5 mm2

PVC/PVC/SWA/PVC 5kV insulated cable for the emergency tripping push button or receive relay

as appropriate.

5.3

The bottom gland plate shall be of sufficient size to accommodate one cable gland for the 12 core

0.9 mm diameter PVC/PVC/SWA/PVC 5kV insulated pilot cable.

5.4

For a pilot box which is associated with two cable feeders, each gland plate shall be of sufficient

size to accommodate all the necessary cables for both feeders in line with 5.2 and 5.3 above.

5.5

For a pilot box associated with a turnkey contract where all the cables are accommodated in

trunking requiring bottom entry, the requirement for the top gland plate may be deleted. The

bottom gland plate shall then be suitable for all the cable entries with the pilot cables on the right

and the multicore cables on the left.

5.6

Adequate cable glands to suit the application shall be supplied as loose equipment inside the box.

Page 5 of 8

Specification No: SC/TS - 16

Rev. No:

6.

PILOT SUPERVISION EQUIPMENT

6.1

Pilot wire supervision equipment shall be installed in the box for either send end or receive end

functions. The equipment shall be fully compatible with the pilot wire protection relays which

shall be specified at the time of ordering. The pilot supervision equipment shall detect open

circuit, short-circuit or crossed pilots and loss of supervision supply.

6.2

For send end pilot supervision, the required pilot injection transformer shall be suitable for a 127V

60 Hz input and 30V output. The auxiliary relays shall be suitable for operation from 50 V DC

and 125V DC for which a DC/DC converter is preferred. However, a suitable dropping resistor

may be acceptable.

7.

PILOT ISOLATION EQUIPMENT

7.1

For each pilot wire protection, a suitable pilot isolation transformer shall be supplied and fitted in

the send or receive end box if required in order to achieve a 5kV insulation level between the pilot

wires and the protection equipment. The ratio of the transformer shall be as recommended by the

pilot wire protection manufacturer.

7.2

An additional suitable pilot isolation transformer shall be supplied and fitted in the send end box

in order to achieve a 5kV insulation level between the pilot wires and the pilot wire supervision

equipment as covered in Section 6.1 above.

8.

TERMINAL BLOCKS ANO WIRING

8.1

For each pilot wire protection, a vertically mounted group of 13 terminal blocks shall be provided

which have a 5kV insulation level. Each terminal block shall be fitted with an isolating plug link.

A shorting bar shall be fitted on the equipment side of the terminal blocks.

8.2

The group of 5kV terminals shall be mounted towards the bottom right of the box and the lowest

two terminal blocks shall be used for the pilot wire protection pair. The 11 terminal blocks above

shall be used for the spare pairs of the pilot cable.

8.3

For each pilot wire protection a vertically-mounted group of 15 or 7 terminal blocks shall be

provided for send end or receive end supervision respectively. These terminal blocks shall be

insulated to 2kV. The group of 2kV terminals shall be mounted towards the top left of the box.

8.4

All terminals which are insulated to the 5kV or 2kV levels shall be suitably shrouded.

8.5

All wiring which is directly connected to the pilot wires shall be insulated to at least 5kV.

8.6

All other wiring shall be insulated to at least 2kV.

8.7

The 5kV insulated wiring shall be segregated from all other wiring.

Page 6 of 8

Specification No: SC/TS - 16

Rev. No:

8.8

For send end pilot supervision, 8 of the 2kV terminals shall be for AC and DC auxiliary supplies.

For send or receive end pilot supervision, 7 of the 2kV terminals shall be for protection and alarm.

9.

EARTHING

9.1

The main earth connection to the box shall be via an M10 brass earth stud which protrudes

through the base of the box. The earth stud shall be supplied with washers and locking nuts etc., to

permit an earth bond to be made to the substation main earth.

9.2

All internal exposed metallic parts shall be effectively earthed to the earth stud via a removable

link which is mounted on a barrel insulator rated at least 5kV. A small earthing strip shall

facilitate multiple connections.

9.3

Two wandering earth leads 6 mm2 multi-strand PVC cable colour green/ yellow shall be provided.

Each shall be long enough to earth any pilot cable core.

9.4

The cable gland plates shall be effectively earthed to the earthing strip by 35 mm2 copper

connections with 5kV insulation.

10.

LABELLING

10.1

All labels shall be made out of laminated plastic which, unless otherwise specified, shall be

suitable for black letters on a white background.

10.2

All labels shall be fixed to the appropriate surface using self-tapping, screws and labels shall not

be fixed to removable shrouds.

10.3

A label shall be fixed near the top of the door, which shall be at least 180mm x 50mm. The top

line of text shall read 'PILOT WIRE PROTECTION'. The second line of text shall read as

appropriate:

or

or

10.4

A label shall be fixed near the bottom of the door having red letters on a white background and at

least 190mm x 50mm. The text shall read:

CAUTION:

10.5

PILOT ISOLATION SEND END BOX

PILOT ISOLATION RECEIVE END BOX

PILOT-ISOLATION SEND AND RECEIVE END BOX

CONNECTIONS SUBJECT TO HIGH VOLTAGES

EARTH PILOT CORES BEFORE HANDLING

On the centre of the door shall be fixed a label 150mm x 50mm. This label shall be left blank so

that it can be engraved by SCECO after erection on site to indicate the feeder number. In the case

of a box for two cable circuits, two labels as above shall be fixed on the door, one on the left and

one on the right.

Page 7 of 8

Specification No: SC/TS - 16

Rev. No:

10.6

Two further blank labels 75mm x 25mm shall be fixed to the internal backplate, one on the left

and one on the right, for engraving by SCECO following erection on site to indicate the feeder

numbers. The location of each label shall be chosen to maximise legibility and access, having due

regard to the layout of all the components on the back plate and the necessary wiring.

10.7

Suitable labels shall be fixed adjacent to each group of terminal blocks to identify their use.

Page 8 of 8

You might also like

- 48 TMSS 04 R0Document0 pages48 TMSS 04 R0renjithas2005100% (1)

- Communications Backbone CablingDocument3 pagesCommunications Backbone CablingHumaid ShaikhNo ratings yet

- Mew SpecsDocument2 pagesMew SpecsMohammed Abdul HakeemNo ratings yet

- 1212.03 15kV Submersible Transformer SpecificationDocument8 pages1212.03 15kV Submersible Transformer SpecificationurramarianiNo ratings yet

- Controllogix Chassis-Series B: Installation InstructionsDocument16 pagesControllogix Chassis-Series B: Installation InstructionsneoflashNo ratings yet

- M26 Anti FoulingDocument33 pagesM26 Anti FoulingVinay Kumar NeelamNo ratings yet

- Junction Box and Bay Marshalling Kiosk Technical SpecificationDocument8 pagesJunction Box and Bay Marshalling Kiosk Technical SpecificationShaswat JhaNo ratings yet

- Junction Box & Bay Marshalling Box PDFDocument8 pagesJunction Box & Bay Marshalling Box PDFshaswatNo ratings yet

- Document No PCPL-0532-4-407-04-06 Contol & Relay Panel Section - 4 PAGE: 1 of 6 ScopeDocument6 pagesDocument No PCPL-0532-4-407-04-06 Contol & Relay Panel Section - 4 PAGE: 1 of 6 ScopetceterexNo ratings yet

- Pipelines, Cathodic Protection Systems 670.840 : Rocess Ystems Ngineering Fabrication and Erection SpecificationDocument9 pagesPipelines, Cathodic Protection Systems 670.840 : Rocess Ystems Ngineering Fabrication and Erection Specificationpuwarin najaNo ratings yet

- LT Switchgear Technical SpecificationDocument28 pagesLT Switchgear Technical SpecificationUday Sankar YadavNo ratings yet

- 11kv and 33KVDocument43 pages11kv and 33KVArun KumarNo ratings yet

- 06-POWER AND CONTROL CABLE - Rev5 PDFDocument14 pages06-POWER AND CONTROL CABLE - Rev5 PDFSanjay RoutNo ratings yet

- 5-Power & Control Cables PDFDocument11 pages5-Power & Control Cables PDFAnonymous ufMAGXcskMNo ratings yet

- Activity Performance Worksheet: Computer TechnologyDocument13 pagesActivity Performance Worksheet: Computer TechnologyJefferson CanalejaNo ratings yet

- Busbar Trunking System 800A Sandwich ConstructionDocument3 pagesBusbar Trunking System 800A Sandwich Constructionsajeevi piumikaNo ratings yet

- 11kV GIS Specification PDFDocument44 pages11kV GIS Specification PDFRiyazNo ratings yet

- Installation Guide For Instrument Cables, Conduits and Cable TraysDocument35 pagesInstallation Guide For Instrument Cables, Conduits and Cable TraysImran Mohiuddin100% (1)

- 6.8.6 Ground Bus Safety Ground Bus Bar: CE/416/NPCIL/24VDC/TR Rev 00 Page 13 of 20Document1 page6.8.6 Ground Bus Safety Ground Bus Bar: CE/416/NPCIL/24VDC/TR Rev 00 Page 13 of 20Satyasrinivas PulavarthiNo ratings yet

- Link Boxes in Ehv CablesDocument7 pagesLink Boxes in Ehv CablesRavi Kumar100% (1)

- Engineering Specification for Electrical Control Gear NM 100-2006-4Document6 pagesEngineering Specification for Electrical Control Gear NM 100-2006-4augustinAugNo ratings yet

- Aac Spec 543005Document19 pagesAac Spec 543005custro_mohaleNo ratings yet

- 41.R2 - DC EOP Specification SheetDocument9 pages41.R2 - DC EOP Specification SheetsuperthambiNo ratings yet

- Service Manual SONY LCD klv32bx350Document44 pagesService Manual SONY LCD klv32bx350elec104No ratings yet

- Switchgear SpecificationsDocument29 pagesSwitchgear SpecificationsNandkumar ChinaiNo ratings yet

- Automation Specn - 220kVDocument88 pagesAutomation Specn - 220kVkiran100% (1)

- 15 Sec Technical Rev 0Document13 pages15 Sec Technical Rev 0mohanksebNo ratings yet

- 33& 11kv Terminations. KitsDocument9 pages33& 11kv Terminations. Kitsnvinodn06No ratings yet

- Screened SUBCAB Cable Connection Recommendations and EMC Guideline PDFDocument12 pagesScreened SUBCAB Cable Connection Recommendations and EMC Guideline PDFEduardo Mendoza SanchezNo ratings yet

- Copper Bus Duct SpecDocument135 pagesCopper Bus Duct SpecChilamkurti Siva Sankara Rao100% (2)

- 01 Appd SPSCLT Piller Drawings 28-04-2010Document41 pages01 Appd SPSCLT Piller Drawings 28-04-2010cayunk7145No ratings yet

- Specification for LV Distribution Fuse Board (Feeder PillarDocument29 pagesSpecification for LV Distribution Fuse Board (Feeder PillarRaison Mukkath100% (5)

- 11kV - 3-C - 300 - AL - Cable - Specification Final PDFDocument18 pages11kV - 3-C - 300 - AL - Cable - Specification Final PDFShubham BaderiyaNo ratings yet

- In313 PR1Document35 pagesIn313 PR1wellbr123No ratings yet

- HV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601Document9 pagesHV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601AnilNo ratings yet

- Electrical Plan Layout GuideDocument65 pagesElectrical Plan Layout Guidehahadu0% (1)

- Raychem Heat Shrink Terminations HVTDocument18 pagesRaychem Heat Shrink Terminations HVTgerardoNo ratings yet

- Lighting SystemDocument10 pagesLighting SystemJyoti ShekharNo ratings yet

- Alpha Fix SL CompactDocument6 pagesAlpha Fix SL CompactgarysNo ratings yet

- ACDBDocument88 pagesACDBuvilasNo ratings yet

- Panelboards and circuit breakersDocument1 pagePanelboards and circuit breakersAhmad Ramin AbasyNo ratings yet

- 1.25MVA Transformer Specs for 9MW Solar ProjectDocument10 pages1.25MVA Transformer Specs for 9MW Solar ProjectHeather CarterNo ratings yet

- Relay TS Latest R8Document46 pagesRelay TS Latest R8Mere Thakur JiNo ratings yet

- 11KV CT TECH SPECDocument11 pages11KV CT TECH SPECBknboy Pali60% (5)

- Cap Ngam 24KV-1x500mm2Document10 pagesCap Ngam 24KV-1x500mm2Minh VienNo ratings yet

- Sony KDL-40R485A Chassis ITC2Document70 pagesSony KDL-40R485A Chassis ITC2Nico50% (4)

- Is 2551Document44 pagesIs 2551sankaractecheeeNo ratings yet

- Spec 11kV 3 Core CablesDocument5 pagesSpec 11kV 3 Core CablessasikalaNo ratings yet

- FOC Specs (Figure 8) - FTTHDocument4 pagesFOC Specs (Figure 8) - FTTHLuis OdictaNo ratings yet

- AC 21-99 Aircraft Wiring Installation ProceduresDocument38 pagesAC 21-99 Aircraft Wiring Installation Proceduressteve.rodowicz1011100% (2)

- Cabling SystemDocument162 pagesCabling Systemstefan998877No ratings yet

- Cap Ngam 240mm2 Cach Dien Xlpe Hay EprDocument7 pagesCap Ngam 240mm2 Cach Dien Xlpe Hay EprMinh VienNo ratings yet

- 2178CL-S Series F/O Splice Case: InstructionDocument13 pages2178CL-S Series F/O Splice Case: InstructionHữu Khánh NguyễnNo ratings yet

- Type Tested LV Panel For Industry (IEC 61439)Document19 pagesType Tested LV Panel For Industry (IEC 61439)nihar039255No ratings yet

- Cable Tray InstallationDocument10 pagesCable Tray Installationalrwin_b2yNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Industrial Solutions: Paralleling SwitchgearDocument1 pageIndustrial Solutions: Paralleling Switchgeardaniel.cabasa2577No ratings yet

- Electrical Characteristics: Aluminium Conductors Steel Reinforced (Acsr) To Astm B:232-86 SpecificationDocument1 pageElectrical Characteristics: Aluminium Conductors Steel Reinforced (Acsr) To Astm B:232-86 Specificationdaniel.cabasa2577No ratings yet

- Technical Specification for 17.5kV Metal-Clad SwitchgearDocument5 pagesTechnical Specification for 17.5kV Metal-Clad Switchgeardaniel.cabasa2577No ratings yet

- Mirat PV Plant RMU Installation ScheduleDocument1 pageMirat PV Plant RMU Installation Scheduledaniel.cabasa2577No ratings yet

- Relay SettingDocument7 pagesRelay Settingdaniel.cabasa2577No ratings yet

- UPEEP 1st General Assembly 2018Document1 pageUPEEP 1st General Assembly 2018daniel.cabasa2577No ratings yet

- Single Line Diagram - High Voltage Power Distribution Rev ADocument1 pageSingle Line Diagram - High Voltage Power Distribution Rev Adaniel.cabasa2577No ratings yet

- HV Intake 1 Mark Up - 071218Document1 pageHV Intake 1 Mark Up - 071218daniel.cabasa2577No ratings yet

- HV Intake 2 Mark Up - 071218Document1 pageHV Intake 2 Mark Up - 071218daniel.cabasa2577No ratings yet

- Mission Vision SCEDocument5 pagesMission Vision SCEdaniel.cabasa2577No ratings yet

- Ayban Scope of WorkDocument38 pagesAyban Scope of Workdaniel.cabasa25770% (1)

- PRC Application GuideDocument2 pagesPRC Application Guidedaniel.cabasa2577100% (1)

- Remote RelaysDocument1 pageRemote Relaysdaniel.cabasa2577No ratings yet

- Transformer Electrical Connection SCLB 1250-22-0.415 ModelDocument1 pageTransformer Electrical Connection SCLB 1250-22-0.415 Modeldaniel.cabasa2577No ratings yet

- Annual Safety Summary Report for Central Region Operations SectionDocument2 pagesAnnual Safety Summary Report for Central Region Operations Sectiondaniel.cabasa2577No ratings yet

- Revised National Plumbing Code of The Philippines 1Document225 pagesRevised National Plumbing Code of The Philippines 1daniel.cabasa2577No ratings yet

- Electrical Characteristics: Aluminium Conductors Steel Reinforced (Acsr) To Astm B:232-86 SpecificationDocument1 pageElectrical Characteristics: Aluminium Conductors Steel Reinforced (Acsr) To Astm B:232-86 Specificationdaniel.cabasa2577No ratings yet

- 3-Phase Fault AnalysisDocument11 pages3-Phase Fault Analysisdaniel.cabasa25770% (1)

- Busbar Sizing Calculation-2Document7 pagesBusbar Sizing Calculation-2daniel.cabasa2577No ratings yet

- ABB CT and VT Application Guide Ed3Document128 pagesABB CT and VT Application Guide Ed3Andrej Černe100% (4)

- ETAP Report (Modified - 4pages) PDFDocument4 pagesETAP Report (Modified - 4pages) PDFdaniel.cabasa2577No ratings yet

- Tower Details Double CKTDocument1 pageTower Details Double CKTdaniel.cabasa2577No ratings yet

- RX DiagramDocument1 pageRX Diagramdaniel.cabasa2577No ratings yet

- PUTT SchemeDocument1 pagePUTT Schemedaniel.cabasa2577No ratings yet

- ETAP Short-Circuit Report AnalysisDocument4 pagesETAP Short-Circuit Report Analysisdaniel.cabasa2577No ratings yet

- Acceleration FinalDocument1 pageAcceleration Finaldaniel.cabasa2577No ratings yet

- Logic Diagram for Acceleration Trip Coordination SchemeDocument1 pageLogic Diagram for Acceleration Trip Coordination Schemedaniel.cabasa2577No ratings yet

- SLD Updtd Hail ProjectDocument1 pageSLD Updtd Hail Projectdaniel.cabasa2577No ratings yet

- Room Layout 7701-ModelDocument1 pageRoom Layout 7701-Modeldaniel.cabasa2577No ratings yet

- Ad Dayir - LayoutDocument1 pageAd Dayir - Layoutdaniel.cabasa2577No ratings yet

- Apcjab Fmi C10adhoc A en 220301Document27 pagesApcjab Fmi C10adhoc A en 220301M. AZIZINo ratings yet

- Electrical Formulas: General InformationDocument1 pageElectrical Formulas: General InformationalbertoNo ratings yet

- Cabinas MT UNIMIX-JTI PDFDocument26 pagesCabinas MT UNIMIX-JTI PDFpedrommm2No ratings yet

- Circuit Symbols: Wires and Connections Compone NT Circuit Symbol Function of ComponentDocument7 pagesCircuit Symbols: Wires and Connections Compone NT Circuit Symbol Function of ComponentRalph MedinaNo ratings yet

- MODEL 6505S Control Head (Mighty Mariner System)Document3 pagesMODEL 6505S Control Head (Mighty Mariner System)pan - panNo ratings yet

- SB07 Quantity Take Off Details 04Document20 pagesSB07 Quantity Take Off Details 04Praveen SalindaNo ratings yet

- Vision BrochureDocument28 pagesVision BrochuresvmrNo ratings yet

- Figure 1 A Typical Starting System Converts Electrical Energy Into Mechanical Energy To Turn The EngineDocument8 pagesFigure 1 A Typical Starting System Converts Electrical Energy Into Mechanical Energy To Turn The EngineAniruddh TrivediNo ratings yet

- Scope Tests ToolboxDocument38 pagesScope Tests ToolboxsupljinaNo ratings yet

- ETD1000 Instruction ManualDocument28 pagesETD1000 Instruction ManualrgunasekaranNo ratings yet

- Arcing Test 61641Document25 pagesArcing Test 61641Sergio Aldo Enriquez Loria100% (1)

- JS200 Excavator Electrical Parts CatalogDocument3 pagesJS200 Excavator Electrical Parts CatalogLiliana GarciaNo ratings yet

- Low Voltage ATS GuideDocument50 pagesLow Voltage ATS GuideAnom Pletot Badoger100% (1)

- Roof Deck Floor Plan: Bureau of DesignDocument1 pageRoof Deck Floor Plan: Bureau of DesignJule LobresNo ratings yet

- Electronic Components GuideDocument11 pagesElectronic Components GuideVinay SinghNo ratings yet

- TAPROOT COMPLETE MAT LIST (Grand Stand)Document1 pageTAPROOT COMPLETE MAT LIST (Grand Stand)Abdul HameedNo ratings yet

- A100K10760 DAK48 Installation GuideDocument4 pagesA100K10760 DAK48 Installation Guideshaji10173No ratings yet

- Ruger 10-22 ManualDocument43 pagesRuger 10-22 Manualapi-3840428100% (3)

- Government of Rajasthan Project Report on Pradhan Mantri Awas Yojana Housing SchemeDocument23 pagesGovernment of Rajasthan Project Report on Pradhan Mantri Awas Yojana Housing SchemeSANDEEP KUMAR VYASNo ratings yet

- Section 3.3.4 Neutral Earthing Resistors R1Document7 pagesSection 3.3.4 Neutral Earthing Resistors R1waelabouelelaNo ratings yet

- E30 Speedometer Repairs - F.Document4 pagesE30 Speedometer Repairs - F.Aloisio MelloNo ratings yet

- PVL Quick Reference PDFDocument2 pagesPVL Quick Reference PDFJoel Cazalla PuyolNo ratings yet

- MobileDart Evolution MX8cDocument16 pagesMobileDart Evolution MX8cAbel Chaiña Gonzales100% (1)

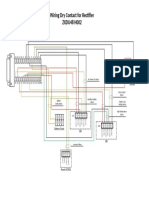

- Wiring Dry Contact ZXDU48 H002Document1 pageWiring Dry Contact ZXDU48 H002Donny Sulistyo NugrohoNo ratings yet

- NXS Series Cable Fitting GuideDocument10 pagesNXS Series Cable Fitting GuideFalsoNo ratings yet

- Micro InverterDocument4 pagesMicro InverterRadhika PriyadarshiniNo ratings yet

- DZ158 CatalogueDocument4 pagesDZ158 CatalogueThinura SamarawickramaNo ratings yet

- Zinc Oxide Surge Arrester PEXLIM P-X Technical DataDocument7 pagesZinc Oxide Surge Arrester PEXLIM P-X Technical DataRaharjo YakinNo ratings yet

- Sienna Electrical Wiring DiagramDocument95 pagesSienna Electrical Wiring DiagramVargas Lara JonathanNo ratings yet

- Lab 3 Three Phase Motor Rev For 10102023 014430pmDocument7 pagesLab 3 Three Phase Motor Rev For 10102023 014430pmSYED ALIYYAN IMRAN ALINo ratings yet