Professional Documents

Culture Documents

Elevator C5000 Manual

Uploaded by

Alejandro Gonzalez GonzalezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elevator C5000 Manual

Uploaded by

Alejandro Gonzalez GonzalezCopyright:

Available Formats

ULF 2 Procter & Gamble Product Supply UK Ltd

Maintenance

INSPECTION & MAINTENANCE

RUNNING WARM

LUBRICATION

WEAR AND TEAR

FUNCTIONAL OPERATION

POSITIONING

I

L

6.19.

2.1

Lift wagon

I

C

I

L

6.19.

2.2

Centring unit

I

C

I

L

Drop lock

I

C

TENSION

TRACKING

I

C

PLAY

DIRT

OIL LEVEL

LEAK

FASTENING

Pallet lift

NOISES

DAMAGE

OPERATION

Every 3 months

Pallet lift

SEE

PAR.

A= ADJUST R= REFILL I= INSPECT

C= CLEANING L= LUBRICATION C= CHANGE

DA= DRAIN OFF WATER

I

A

6.19.

2.3

6.19.

2.4

10-7-15

Versie 1.0.0 - 2011-08-25 rev VV 2012-01-12

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

COMPONENT

FREQUENCY

MODULE

Tab. 6.5 Maintenance diagram C5000- Si / Ti

6.21

Elevator - changing chains and bearings lift shaft

See also drawing 0T.67.71A-2 (click to open)

6-26

CSi

October 7, 2015

ULF 2 Procter & Gamble Product Supply UK Ltd

Maintenance

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

Elevator or lift platform

10-7-15

Fig. 6.6 Overview Palletiser

6.21.1

Functional description

The lifting elevator function is integrated in the palletising function.

The lift function drive is designed for a specific maximum pallet weight of

1500 kg.

A pallet is positioned on a pallet roller conveyor.

This pallet roller conveyor is integrated on a lifting platform.

For optimal handling / energizing the unit is equipped with a guided

counterweight.

The pallet is lifted to a position under the loading platform (stripper table),

depending on the actual height of the pallet.

The loading platform opens and a layer is dropped on top of the pallet (or

pallet load).

Now the pallet(load) is lowered in high speed until the top of the pallet(load)

is under the loading platform.

October 7, 2015

CSi

6-27

ULF 2 Procter & Gamble Product Supply UK Ltd

Maintenance

Then it will raise the pallet(load) in slow speed back towards the platform

for the next layer to be accepted.

6.21.2

Description

Lift construction

See drawing drawing OT.67.71A-0

The lift construction consists of:

15 Geared motor with torque support.

16 Main shaft.

17 Two bearings for shaft support.

18 Two Sprockets on the main shaft for chain 1 duplex.

19 Two chains 1D.

20 Lift platform.

21 Counter weight.

Fig. 6.7 Safety blockage lift platform

23 Safety blockage counter weight See Fig. 6.8 Safety Blockage Positions

4/5 & 29/30 .

Blocking pin

Fig. 6.8 Safety Blockage Positions 4/5 & 29/30

6-28

CSi

October 7, 2015

10-7-15

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

22 Safety blockage lift platform See 2.1 or 7.1 or Fig 2 below

ULF 2 Procter & Gamble Product Supply UK Ltd

6.21.3

w

6.21.4

w

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

6.21.4.1

Maintenance

Safety

Warning

Improper use, faulty installation or operation, improper removal or

switching-off of safety devices and opening of protective covers without

taking safety precautions can result in serious injury or death as well as

major material damage.

Electrical installation

Warning

Work, of any nature, on the installation should be carried out by qualified

and authorised personnel only. Please read Chapter 1 ("Safety") and

take all necessary precautions.

Control cabinet

Please close the cabinet door properly always so that dust and moisture

cannot enter.

If the control cabinet is equipped with a ventilator, please check the filter

element for dirt and clean or replace when necessary. The air inlets and

outlets must remain easily accessible i.e. kept free of obstacles.

6.21.4.2

Proximity switches, limit switches and door switches

Please take particular care to check security switches and other switches

that are used now and again only.

6.21.4.3

Photo cells

Clean the lenses of photo cells and reflectors with a soft cloth.

10-7-15

The frequency of cleaning depends on environmental influences such as

dust, dirt, damp etc. You might therefore need to clean more often than

instructed.

6.21.4.4

Electrical cabling

Please ensure that cable duct do not become damaged. Please keep

cable work of the control current separate from cable work of the main

current. Loops in cables must be avoided.

6.21.4.5

Cable tracks

Depending on the application, cable tracks are used free-bearing or in

combination with cable ducts

October 7, 2015

CSi

6-29

ULF 2 Procter & Gamble Product Supply UK Ltd

Maintenance

Important when inspecting and carrying out maintenance work:

6.21.5

Cable ducts may not be damaged or dirty. Bulky rubbish such as

sticky tape, packaging and product remnants, glass fragments,

wood splinters etc. must be removed immediately .

Please shut cable tracks correctly and insure that connections and

internal sections are not damaged or loose.

Cables and pneumatic hoses (if applicable) must not become

twisted or jammed. Please also ensure that there is enough play for

lengthwise movement in the cable track.

Cables and hoses must be secured with a pull relief on outer ends

of cable tracks.

Replace the lift chains and/or lift shaft bearings

Warning

The counterweight must be blocked mechanically.

For that reason a blocking provision (See Fig. 6.8 Safety Blockage

Positions 4/5 & 29/30) has been fitted on each side of the frame.

Each blocking provision has two blocking pins. ( See Fig. 6.7 Safety

blockage lift platform positions 3) In total four counterweight blocking pins

have been fitted.

Check prior to works

1 Check that the platform is empty.

(No load allowed on the conveyor.)

2 Bring the lift platform up and the counter weight down (Using the manual

control on the main operator panel)

6.21.5.1

w

6.21.5.2

6-30

lift platform on high level for easier access.

10-7-15

Required:

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

General

Operation

Warning

The work must always be carried out by two persons.

Tools required:

-

Two padlocks.

Access to the lift drive motor.

Scaffolding and or a ladder.

Pulley wrench for motor drive removal.

CSi

October 7, 2015

ULF 2 Procter & Gamble Product Supply UK Ltd

6.21.5.3

Maintenance

Chain

Lift chain needs to be exchanged if the elongation is more than 3 %

1 Open the door

The safety cylinders will go out (on spring actuation) and at least one of the

cylinders will be captured in the safety profile. (See Fig. 6.7 Safety

blockage lift platform)

On each side of the elevator frame a blocking provision is mounted on the

outside (see Fig. 6.8 Safety Blockage Positions 4/5 & 29/30).

2 Remove the two dummy bolts M20 positioned in the provisions (one

each) side and approx 700 mm height. holes in the elevator frame will

occur.

3 The locking pin (See Fig. 6.9 Position 2 ) can now be taken from the

blockage provision. (see Fig. 6.8 Safety Blockage Positions 4/5 & 29/

30).

Keep the pins with you for further handling.

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

1 Place the dummy M20 into the (now) free slot (position) of the blocking

provision.

10-7-15

2 Remove the four (4) protection plates (See Fig. 6.9 Position 2) on the

lifting mechanism inside the palletiser.

Fig. 6.9 Position 2

w

October 7, 2015

Warning

The counterbalance weight must be secured!

CSi

6-31

ULF 2 Procter & Gamble Product Supply UK Ltd

Maintenance

Chains must be set slack on both sides

1 Switch to manual mode (using the manual control on the main operator

panel)

-

One person to Lower the lift platform and raise the counterweight in

manual operating of the elevator.

One person on the outside of the fencing to visually check when the

bolt slot(s) become free. The counter weight must be above the bolt

slots.

2 The operator can now stop moving the elevator.

3 Mount the locking pins in the blocking provision for the counterweight

from the outside.

(See Fig. 6.8 Safety Blockage Positions 4/5 & 29/30)

4 When all four pins are installed, the operator must raise the platform

shortly and lower the counterweight onto the pins. (using the manual

control on the main operator panel)

The chains to the counterweight now become slack.

5 Open the door.

The safety cylinders will go out (on spring) and at least one of the cylinders

will be captured in the safety profile.( See Fig. 6.6 Overview Palletiser

position 7.1)

Warning

Normally we will be needing some kind of slack of the chain

In order to work safely the strong hold of the lifting platform on the lifting

chain should be eliminated!

10-7-15

Create slack on the chains to the lifting platform.

Note

See Fig. 6.6 Overview Palletiser positions 7.1 and 7.2

1 Lift by hand the brakes of the elevator drive so that the platform will drop

downwards until the lift blockage system will stop the movement.

One of the safety cylinders is now against the bottom of the hole in the

safety catching profile.

Note

The chain is to be slack on both sides!

2 Switch off the air supply.

a Make sure surplus air is let off.

b Padlock the main air valve in order to work safely.

3 Switch off the entire system electrically.

a Padlock the main switch on the related panel.

4 Secure access around the drives on higher level.

6-32

CSi

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

The pin to enter into the profile of the moving area of the counterweight.

October 7, 2015

ULF 2 Procter & Gamble Product Supply UK Ltd

Maintenance

Scaffolding or ladders are needed for access.

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

Relevant safety ropes See Fig below position 22

Fig. 6.10 Position 22

5 Lift motor disconnect.

a Disconnect all cabling from the lift motor.

10-7-15

Note

The C5000 has one elevator drive.

6 Liftmotor removal/weight

a Expected weight 85 kg . Always check the actual indicated weight

on the available drive.

b Use sufficient lifting gear (hoist or crane) for safe handling of the

drive.

c Use sufficient and lifting rope(s) in combination with lifting gear .

d Only use equipment rated for the load required.

Note

Use tested and validated lifting equipment.

7 Lift rope(s)

October 7, 2015

CSi

6-33

ULF 2 Procter & Gamble Product Supply UK Ltd

Maintenance

For removal of the drive the lift a rope must be tightened in such a way that

it can be shifted to one side.

Note

Make sure the drive does not drop down when it comes off the shaft!

Torque arm

After the drive is secured we can now safely remove the torque arm

support.

Note

The drive still remains on the shaft.

If you only want to exchange the drive it is not required to use the

counterweight mechanical blockage system.

1 Lift drive motor and lift chains

a Lift drive motor is to be removed from the shaft before the lift

chains can be accessed.

b Pull the drive from the shaft (Use pulley wrench if necessary).

Note

See item 8 and make sure the drive is held properly by the lifting

equipment and rope(s)!

c Replace lift chain on the drive motor side.

2 Remove the bracket (16) from the top frame on the drive motor side.

This is one of the connections between the lift frame and top part.

Now the lifting chain on the drive motor side of the elevator is free.

Warning

Mind the weight of the chain!

3 Visually check the chain for wear and tear.

If necessary exchange the chain.

Note

If chains and or bearings need to be replaced always exchange both

bearings and or chains during the stop.

a Check the status of the chain sprockets.

When chain sprockets are worn (and or if there is play between the

key connections and the chain sprocket and drive shaft) and they

need to be replaced continue with item 18.

6-34

CSi

October 7, 2015

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

Note

The shaft will not start turning because the blocking mechanism prevents

the chains to move the shaft.

10-7-15

n

n

ULF 2 Procter & Gamble Product Supply UK Ltd

Maintenance

b Check the following for damages;

- The drive shaft ends.

- Drive shaft fixation key and the shaft key into the connection slot.

If so continue with item 18.

-

Bearing lift shaft drive side.

To access and remove the bearings the drive shaft must be supported.

4 Support the shaft from the top frame ( See Fig. 6.10 Position 22 using

ropes and ratchet belts.

n

n

Note

Only use equipment rated for the load required.

Note

Use tested and validated lifting equipment.

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

Bearing on drive side.

1 Untighten bearing and slide bearing sideways of the shaft.

2 Slide new bearing in position.

3 Tighten.

4 Loosen and remove ropes (etc) on this side.

5 On the driven side all checks are executed.

a Lift chain on the non-driven side.

Note

On the drive side the bracket is still not connected.

10-7-15

October 7, 2015

CSi

6-35

ULF 2 Procter & Gamble Product Supply UK Ltd

Maintenance

Fig. 6.11 Position 24

This bracket (24) is the second of the connections between the lift frame

and top part.

Now the lifting chain at the non-driven side is free.

Note

Mind the weight of the chain!

10-7-15

a Check the chain on visual damage and on the actual elongation.

If necessary exchange the chain.

Note

Reminder if to be exchanged always exchange the pair.

b Check the status of the chain sprocket.

- When chain sprocket is worn and needs to be replaced go to item

18.

c Bearing on non-driven side.

7 Untighten and slide sideways of the shaft.

8 Slide new bearing in position.

9 Tighten.

10 Loosen and remove ropes (etc) on this side.

11 Reassemble.

6-36

CSi

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

6 Remove the bracket ( See Fig. 6.11 Position 24) from the top frame at

the non- driven side.

October 7, 2015

ULF 2 Procter & Gamble Product Supply UK Ltd

Maintenance

a Install bracket 24.

b Install bracket 16.

12 In case of damage to the elevator shaft or chain wheels as under 10 or

1: call CSi service (LCSI) for exchanging the shaft.

In case of damage, stop this instruction from here.

13 Re-install the lift drive.

The shaft and bushings must be greased with correct lube prior to

assembly.

(For specification see drive. Normally to be expected is that the grease is

packed separately with the drive. If drive is re-installed check and apply

grease. )

a Carefully position the drive in front of the shaft and pay attention to

the key!

b Now slide over the shaft.

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

c If necessary lift the brake of the motor and turn the drive to its

position.

d Fix drive.

14 Re-install torque arm support .

a Loosen ropes etc from drive.

b Remove ropes etc from machine.

15 Connect drive.

a Connect cabling etc to the drive.

16 Power up.

17 Air up.

18 Check on safety.

10-7-15

19 Manual operation.

a Check that the installation is still in manual.

b Run lift platform down. The counterweight will now come off the

bolts.

c In this situation with all doors closed the lift platform blockage

system is now given free!

20 Stop the palletiser.

21 Remove blocking pins.

a From aside (you do not need to enter into the palletiser area)

remove the blocking pins (all 4).

b Exchange the 4 blocking pins with the 4 dummies.

c Seal the four dummies into position.

22 Back into manual.

a Run lift platform to highest position.

23 Re-install the protection plates.

a Stop palletiser. Open door (now the lift platform is automatically

blocked).

October 7, 2015

CSi

6-37

ULF 2 Procter & Gamble Product Supply UK Ltd

Maintenance

b Re-install protection plates items 2 to the lifting mechanism inside

the palletiser.

10-7-15

K:\Projects\22--\223100 P&G Manchester\Manual\C5000\2231-en06.fm

24 Reset and restart .

6-38

CSi

October 7, 2015

You might also like

- Iastar Door DriveDocument75 pagesIastar Door DriveSyed iliyasNo ratings yet

- Light Curtain Guide For ElevatorsDocument10 pagesLight Curtain Guide For ElevatorsFERNSNo ratings yet

- 3300ap Schindler Elevators in GhanaDocument16 pages3300ap Schindler Elevators in GhanaYILMA SEMUNo ratings yet

- Lifts-Opeartion Maintenance PDFDocument40 pagesLifts-Opeartion Maintenance PDFaung kokoNo ratings yet

- Fujitec Research Note 3Document2 pagesFujitec Research Note 3api-249461242No ratings yet

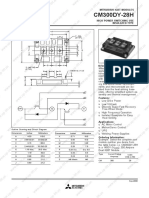

- Mitsubishi IGBT CM300DY-28HDocument4 pagesMitsubishi IGBT CM300DY-28HRaul Gutierrez100% (1)

- ELRV 450 - 10 - 10 - 01eDocument51 pagesELRV 450 - 10 - 10 - 01eabaelwalid01No ratings yet

- Ev100manual en PDFDocument13 pagesEv100manual en PDFdragishabl100% (1)

- Electrically Heated Utility Table With Boiler and Suction UnitDocument1 pageElectrically Heated Utility Table With Boiler and Suction UnitSami Moqbel100% (1)

- Icontrol DC Aug 08 Rel 42-02-7222 B7Document788 pagesIcontrol DC Aug 08 Rel 42-02-7222 B7ElputoAmo XDNo ratings yet

- S3300ap-Brochure Ascensor PDFDocument20 pagesS3300ap-Brochure Ascensor PDFStephanie García100% (1)

- Car Parking SP SystemDocument4 pagesCar Parking SP System61engineer61No ratings yet

- Elevator Control Card: User ManualDocument26 pagesElevator Control Card: User ManualГариб Мед100% (1)

- 100-173 ManualDocument65 pages100-173 ManualReza KühnNo ratings yet

- Start-Up Guide of LSLV-M100: Download ManualDocument8 pagesStart-Up Guide of LSLV-M100: Download ManualArief FibonacciNo ratings yet

- Soft Start ACS Digistart 3DS30 ManualDocument7 pagesSoft Start ACS Digistart 3DS30 ManualMohamedElsawi100% (1)

- Initialisation ProcedureDocument2 pagesInitialisation ProcedureDevas ShuklaNo ratings yet

- HSVF HSVF HSVF HSVF Adjustment Manual Adjustment Manual Adjustment Manual Adjustment ManualDocument20 pagesHSVF HSVF HSVF HSVF Adjustment Manual Adjustment Manual Adjustment Manual Adjustment ManualJesús David Diaz MontesNo ratings yet

- Synergy Element Brochure LowDocument16 pagesSynergy Element Brochure Lowangela1590No ratings yet

- Wittur Car Mechanism Fixing On Car Front PanelDocument4 pagesWittur Car Mechanism Fixing On Car Front PanelBhupiisterSinghNo ratings yet

- ElevatorDocument38 pagesElevatorÇisem Filiz100% (1)

- 3300 Version 2Document20 pages3300 Version 2ibiNo ratings yet

- Sword Elevator IndonesiaDocument24 pagesSword Elevator IndonesiaMohamad Ikhwan0% (2)

- Digital VVVF Synchronized Door Operator Installation InstructionDocument26 pagesDigital VVVF Synchronized Door Operator Installation InstructionYing Dang100% (1)

- Emesa CAR FRAMES 1Document2 pagesEmesa CAR FRAMES 1Ken LeeNo ratings yet

- Hidral RES540 enDocument1 pageHidral RES540 enpaul5791No ratings yet

- MUSE ED Elevator: Installation ManualDocument25 pagesMUSE ED Elevator: Installation ManualMoises PerelloNo ratings yet

- Z Type Escalator For USADocument10 pagesZ Type Escalator For USAa_salehiNo ratings yet

- Operating Manual ArdDocument13 pagesOperating Manual Ardkolwin .chindwinNo ratings yet

- Transformer-1 /75W Battery Group: 12V 12V 12V 12V 12VDocument1 pageTransformer-1 /75W Battery Group: 12V 12V 12V 12V 12VKen LeeNo ratings yet

- Appendix 2: System TroubleshootingDocument4 pagesAppendix 2: System Troubleshootingعلاء صقرNo ratings yet

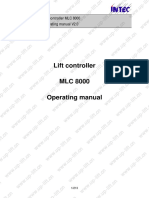

- MLC 8000 Manual EnglishDocument213 pagesMLC 8000 Manual EnglishRebecca DangNo ratings yet

- Programmable Logic Controller (PLC)Document41 pagesProgrammable Logic Controller (PLC)giriaj kokareNo ratings yet

- Primus Iron MachineDocument67 pagesPrimus Iron MachineKonstantinos Politis100% (1)

- Passenger Elevator (Compact Machine Room System) Series-IP/AP Version2 Series-IPDocument13 pagesPassenger Elevator (Compact Machine Room System) Series-IP/AP Version2 Series-IPyounesNo ratings yet

- Inspire 2.1 2500 Eng QSG Rev.ADocument2 pagesInspire 2.1 2500 Eng QSG Rev.AHaris SmansaNo ratings yet

- 7502.9041 MANUAL ES 5000 Escalator PDFDocument48 pages7502.9041 MANUAL ES 5000 Escalator PDFMohammed ansarNo ratings yet

- Maintenance and Service Manual For Elevator Control Valve: EV 100 BlainDocument13 pagesMaintenance and Service Manual For Elevator Control Valve: EV 100 Blainsuk2010No ratings yet

- Gma EDocument5 pagesGma EDull Rahim100% (1)

- Elevator Intercom Installation Guide 984 0012FS FULL SIZE R111407Document11 pagesElevator Intercom Installation Guide 984 0012FS FULL SIZE R111407asibrahimNo ratings yet

- FC 3000s PDFDocument60 pagesFC 3000s PDFAgnelo FernandesNo ratings yet

- India ElevatorDocument14 pagesIndia ElevatorNaren AnandNo ratings yet

- лифт арбат 2Document25 pagesлифт арбат 2Anton Lyakhov100% (1)

- Elex Door - Mitsubishi PLCDocument16 pagesElex Door - Mitsubishi PLCHiei_zoldyckNo ratings yet

- Operating Manual: Measuring Amplifier For Instrument Panel MountingDocument68 pagesOperating Manual: Measuring Amplifier For Instrument Panel Mountingrmdoucet100% (1)

- FRENIC Lift CatalogDocument20 pagesFRENIC Lift CatalogtejoNo ratings yet

- PM 7 000338 en 01Document30 pagesPM 7 000338 en 01Anonymous N57sCcpiNo ratings yet

- Fujitec Handrail MaintenanceDocument2 pagesFujitec Handrail Maintenancea_salehiNo ratings yet

- 0 - Roller Catalogue - EHC GlobalDocument21 pages0 - Roller Catalogue - EHC GlobalManuel Hernandez0% (1)

- 00f4lebk300 PDFDocument108 pages00f4lebk300 PDFDull RahimNo ratings yet

- Data Sheet: 品 名:Power Supply SupervisorDocument9 pagesData Sheet: 品 名:Power Supply SupervisoranjgarNo ratings yet

- Hyundai Elevator Preventive Maintenance ProcedureDocument19 pagesHyundai Elevator Preventive Maintenance ProcedureTrebor Santos100% (2)

- DokumenDocument14 pagesDokumenTroubleshootingNo ratings yet

- Manuale IV5 (Inglese)Document223 pagesManuale IV5 (Inglese)bmonaandaNo ratings yet

- PLC Based Elevator Control System-1Document26 pagesPLC Based Elevator Control System-1Belete GetachewNo ratings yet

- Mitsubishi V3F Advance PDFDocument4 pagesMitsubishi V3F Advance PDFFERNSNo ratings yet

- Elevator Mechanic's Helper: Passbooks Study GuideFrom EverandElevator Mechanic's Helper: Passbooks Study GuideNo ratings yet

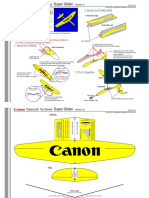

- Planeur Tres Simple PDFDocument3 pagesPlaneur Tres Simple PDFAhmedNo ratings yet

- MBD Asrock Imb150n ManualDocument39 pagesMBD Asrock Imb150n ManualLaur IriNo ratings yet

- Subitec Info Industrial CultivationDocument4 pagesSubitec Info Industrial CultivationUsamah ZakiNo ratings yet

- 80312A-ENUS Error LogDocument10 pages80312A-ENUS Error LogSafdar HussainNo ratings yet

- Dating Torrential ProcessesDocument29 pagesDating Torrential ProcessesJulio Montenegro GambiniNo ratings yet

- Datasheet Joint Isolant 4'' #300 PDFDocument1 pageDatasheet Joint Isolant 4'' #300 PDFseifNo ratings yet

- This Worksheet Is Due by The Deadline Posted On Blackboard. This Is An Individual SubmissionDocument2 pagesThis Worksheet Is Due by The Deadline Posted On Blackboard. This Is An Individual SubmissionAhsan AliNo ratings yet

- Valtra Tractor All Model Diagnostics and Programming ManualDocument22 pagesValtra Tractor All Model Diagnostics and Programming Manualpicax1879100% (17)

- K.analysis of The Articulated Robotic Arm (TITLE DEFENCE)Document22 pagesK.analysis of The Articulated Robotic Arm (TITLE DEFENCE)sky4sterNo ratings yet

- Fastening SystemsDocument74 pagesFastening SystemsskyvaneNo ratings yet

- Ntu IgpDocument6 pagesNtu IgpRobertCallaghanNo ratings yet

- Guide To Petrophysical Interpretation PDFDocument147 pagesGuide To Petrophysical Interpretation PDFDwiandaru DarmawanNo ratings yet

- Precio Por Escala Dosyu Efectiva HasDocument4 pagesPrecio Por Escala Dosyu Efectiva HasAliss SanchezNo ratings yet

- Commander SE - Advanced User Guide PDFDocument195 pagesCommander SE - Advanced User Guide PDFJuan David Ardila TorresNo ratings yet

- PeltonDocument7 pagesPeltonKunal Kumar DasNo ratings yet

- Overview of Ultrasound Detection Technologies For Photoacoustic ImagingDocument24 pagesOverview of Ultrasound Detection Technologies For Photoacoustic ImagingShuvam5 GuptaNo ratings yet

- FTB - Fire Alarm Boq Take Off - 10-08-2022Document4 pagesFTB - Fire Alarm Boq Take Off - 10-08-2022Thai ChheanghourtNo ratings yet

- Bricks ComparisonDocument13 pagesBricks ComparisonMd. Numan HossainNo ratings yet

- Conformity Assessment For The Execution of Steel & Aluminium StructuresDocument14 pagesConformity Assessment For The Execution of Steel & Aluminium StructuresJevgenijsKolupajevsNo ratings yet

- I - Introduction To ErgoDocument39 pagesI - Introduction To ErgoNeknek Diwa De GuzmanNo ratings yet

- Greenstar Cdi Installation ManualDocument60 pagesGreenstar Cdi Installation Manualkb1856No ratings yet

- Motorized Hydraulic PressDocument4 pagesMotorized Hydraulic PressDhiraj Shinde100% (2)

- Heydar Aliyev Cultural Centre: StructureDocument3 pagesHeydar Aliyev Cultural Centre: Structurenusha rakheNo ratings yet

- Instruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 ADocument32 pagesInstruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 AYunisNo ratings yet

- 130195mitsubishi ManualDocument16 pages130195mitsubishi ManualAbdul Noor KhanNo ratings yet

- A Review On Water ElectrolysisDocument18 pagesA Review On Water ElectrolysisSilvester KolicNo ratings yet

- Potable Water Tank Calculation PDFDocument37 pagesPotable Water Tank Calculation PDFboysitumeangNo ratings yet

- Ram Structural SystemDocument234 pagesRam Structural Systemlavy100% (1)

- A N Engineering Report On Unit 8: Engineering Design, Assignment 2 - Use of Computer Based Technology in Engineering DesignDocument14 pagesA N Engineering Report On Unit 8: Engineering Design, Assignment 2 - Use of Computer Based Technology in Engineering DesignTop Engineering SolutionsNo ratings yet

- Shaper Gear CuttingDocument4 pagesShaper Gear Cuttingnevadablue100% (4)