Professional Documents

Culture Documents

Mod

Uploaded by

skchavanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mod

Uploaded by

skchavanCopyright:

Available Formats

Tribology

Module2: Friction

Q.1.

Instead of providing lubrication between two rubbing surfaces, is it advisable to

improve the surface finish of the two surfaces to reduce friction?

Ans: Friction occurs due to ploughing (due to surface roughness) and adhesion (due to

surface smoothness). This means improving surface finish would definitely help in

reducing the friction caused by ploughing and micro-cutting, but increase friction

caused by molecular attraction between tribo-pair. Lubricant reduces molecular

attraction between tribo-surfaces, therefore lubrication (in form of solid / liquid /

gaseous) is essential to reduce friction. In addition liquid lubricant has some other

advantages also like cooling, transferring of wear debris etc. Also achieving high

surface finish would be very costly as compared to providing lubrication.

Q.2.

Since coefficient of friction is dependent on various parameters such as

temperature, surface roughness and hardness how can we quantify the coefficient

for a particular material in general?

Ans: Coefficient of friction is a system property. It may be defined for a pair of materials,

for particular environment condition. In other words coefficient of friction cannot be

defined for a may vary significantly.

Q.3.

Is there any other alternative to reduce the adhesion component of friction without

lubrication?

Ans: No. Lubrication is a generic term. Reducing chemical activities between tribo-surface

may be treated as lubrication. In other words, choosing appropriate surface coating

or surface treatment, which reduces chemical affinity between tribo-material and

provides wear-resistant surface, is part of lubrication mechanisms.

Q.4.

What is friction instability and how it is related to stick slip process?

Ans: Friction instability generally occurs due to large difference in the value of static and

kinetic coefficients of friction. Similarly stick-slip phenomenon occurs due to huge

variation in static and kinetic coefficient of friction. Ideally lubricated condition having

kinetic coefficient of friction equal to 0.00025 shall be preferred, but there is a

possibility of high value of static coefficient of frictions. If we assume that static

coefficient of friction under lubricated conditions is equal to 0.01 and kinetic

coefficient of friction is equal to 0.00025, then this lubricated contact may not be

preferred. This huge difference between static and kinetic friction coefficients provide

negative damping and initiate a stick-slip process. Instantaneous sliding speed of

an object does not remain close to the average sliding speed and friction coefficient

decreases as velocity increases.

Q.5.

What is the difference between static and kinetic coefficients of friction and what is

the practical significance of these two terms?

Ans: Static friction: Static frictional force will increase to prevent any relative motion up

until some limit where motion occurs. It is that threshold of motion which is

characterized by the coefficient of static friction. The coefficient of static friction is

typically (but not necessary) larger than the coefficient of kinetic friction.

Kinetic friction: Kinetic friction force acts at interface of two relatively moving

surfaces. The kinetic frictional resistance is almost constant over a wide range of

sliding speeds. The kinetic coefficient is typically less than the coefficient of static

friction, reflecting the common experience that it is easier to keep something in

motion across a horizontal surface than to start it in motion from rest. Often starting

force is calculated based on static friction while energy loss is calculated based on

kinetic friction force.

Q.6.

Why are junctions formed at the region of contact between two surfaces?

Ans: All surfaces are made of atoms. All atoms attract one another by attractive force. For

examples, if we press steel piece over indium piece they will bind across the region

of contact. This process is sometimes called "cold welding or junction" since the

surfaces stick together without the application of heat. It requires some force to

separate the two surfaces. If we now apply a sideways force to one of surfaces, the

junctions formed at the regions of real contact will have to be sheared if sliding is to

take place. The force to do this is the frictional force. Due to high stress those

asperities suffer plastic deformation, which permits strong adhesive bonds among

asperities. Such cold formed junctions are responsible for the adhesive friction.

Q.7.

What is ploughing effect?

Ans: When two bodies in contact have different hardness the asperities on the harder

surface may penetrate into the softer surface and produce grooves on it, if there is

relative motion. This is called ploughing effect.

Q.8.

Out of spherical asperity and conical asperity which is more significant for increase

in the coefficient of friction and why?

Ans: Conical asperities are much more severe than spherical asperity for increase in

coefficient of friction. Conical asperity has comparatively more ploughing effect. The

tip of the conical asperities may break, further adding to the debris which would

further add to the friction.

Q.9.

How does lubrication help in reducing the coefficient of friction?

Ans: Lubricants reduce the friction between sliding surfaces by reducing shear strength of

interface. The interface shear strength in the presence of lubricant is generally very

low compared to shear strength of any of material in tribo-contact. In addition

lubricant fills the surface cavities and making the surfaces smoother, which help one

surface to slide over another easily and thus reducing friction.

Q.10. What are various methods to reduce friction instability?

Ans: The best alternative to reduce friction instability is to choose the appropriate

lubrication mechanism that maintains negligible difference in values of static and

kinetic coefficients of friction.

Q.11. While designing a mechanical system should the selection of material for a

tribological pair be based on the coefficient of friction or on the basis of functional

requirement?

Ans: Functional importance of material is the primary requirement. It plays the most

crucial role in the material selection. Friction can be handled by choosing pairing

materials, surface treatment, coating, lubricant, etc. Right choice is "overall

economic solution", which may require few practical trails, before finalizing complete

design.

Q.12. In a tribological pair wear of softer material takes place much faster rate,S0 is it

advisable to use materials of same hardness?

Ans: Choosing same hardness of tribo-pair shall reduce abrasive wear, but adhesive,

corrosion, fatigue and fretting wear may continue. Therefore material and

corresponding lubricant selection must be able to minimize all kinds of wear

phenomena.

You might also like

- Industrial Designs 1Document10 pagesIndustrial Designs 1skchavanNo ratings yet

- Creep DescriptionDocument14 pagesCreep DescriptionskchavanNo ratings yet

- T Code&tablesDocument1 pageT Code&tablesskchavanNo ratings yet

- Wipo Ip HCM 03 4-Related1Document6 pagesWipo Ip HCM 03 4-Related1pranit1234No ratings yet

- Titanium and Titanium AlloysDocument4 pagesTitanium and Titanium AlloysskchavanNo ratings yet

- Crystal Structures MSMDocument21 pagesCrystal Structures MSMskchavanNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentskchavanNo ratings yet

- Industrial Designs 1Document10 pagesIndustrial Designs 1skchavanNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentskchavanNo ratings yet

- Creep Part 1Document53 pagesCreep Part 1skchavanNo ratings yet

- 10au834 QPDocument1 page10au834 QPskchavanNo ratings yet

- LetterDocument1 pageLetterskchavanNo ratings yet

- Time Table Even Sem 2017-18Document5 pagesTime Table Even Sem 2017-18skchavanNo ratings yet

- Alloys SheetDocument11 pagesAlloys SheetskchavanNo ratings yet

- Creep DescriptionDocument14 pagesCreep DescriptionskchavanNo ratings yet

- Creep DescriptionDocument14 pagesCreep DescriptionskchavanNo ratings yet

- Composite QPDocument3 pagesComposite QPskchavanNo ratings yet

- Weekly syllabus completion report by deptDocument4 pagesWeekly syllabus completion report by deptskchavanNo ratings yet

- Technical Specs WeldingDocument8 pagesTechnical Specs WeldingSUKhanNo ratings yet

- Emi HTMLDocument12 pagesEmi HTMLskchavanNo ratings yet

- Creep DescriptionDocument14 pagesCreep DescriptionskchavanNo ratings yet

- HodDocument2 pagesHodskchavanNo ratings yet

- Emi HTMLDocument12 pagesEmi HTMLskchavanNo ratings yet

- Section 2 Listening B AnswersDocument1 pageSection 2 Listening B AnswersSoumya DasNo ratings yet

- M.tech PG AUTOMOTIVE SyllabusDocument17 pagesM.tech PG AUTOMOTIVE SyllabusskchavanNo ratings yet

- CPMDocument1 pageCPMskchavanNo ratings yet

- The Assignment Problem The Hungarian MethodDocument31 pagesThe Assignment Problem The Hungarian MethodYinghui LiuNo ratings yet

- Deterministic vs. Stochastic ModelsDocument12 pagesDeterministic vs. Stochastic ModelsskchavanNo ratings yet

- Optimal Assignment of Repairmen to Jobs in Automobile Engineering DepartmentDocument3 pagesOptimal Assignment of Repairmen to Jobs in Automobile Engineering DepartmentskchavanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Determination of The Diffraction Intensity at Slit and Double Slit SystemsDocument5 pagesDetermination of The Diffraction Intensity at Slit and Double Slit SystemsJose Galvan100% (1)

- CNC CONTOUR VALIDATION WITH LASER BALL BARDocument15 pagesCNC CONTOUR VALIDATION WITH LASER BALL BARNitin DaduNo ratings yet

- Engineering Structures: SciencedirectDocument12 pagesEngineering Structures: Sciencedirectyasemin bürüngüzNo ratings yet

- PCAB List of Licensed Contractors For CFY 2017-2018 As of 19 Sep 2017 - Web2Document175 pagesPCAB List of Licensed Contractors For CFY 2017-2018 As of 19 Sep 2017 - Web2Paige Lim76% (21)

- Revision Notes Grade 11Document3 pagesRevision Notes Grade 11anuelisajoseNo ratings yet

- Cluster Level Question Bank (Ahmedabad & Gandhinagar Cluster)Document33 pagesCluster Level Question Bank (Ahmedabad & Gandhinagar Cluster)manpreetsingh3458417No ratings yet

- Name: Teacher: Date: Score:: Identify The Properties of MathematicsDocument2 pagesName: Teacher: Date: Score:: Identify The Properties of MathematicsMacPapitaNo ratings yet

- PID - From Theory To ImplementationDocument5 pagesPID - From Theory To Implementationvictor-cabral3433No ratings yet

- ASTM STP1385 Durability 2000 Accelerated and Outdoor Weathering TestingDocument186 pagesASTM STP1385 Durability 2000 Accelerated and Outdoor Weathering TestingKYAW SOENo ratings yet

- Geogrids in Walls and SlopesDocument6 pagesGeogrids in Walls and SlopesYong Cheng Hung100% (1)

- Chapter 2 1 - Linear EquationsDocument23 pagesChapter 2 1 - Linear Equationsapi-263209117No ratings yet

- Vacita Integrated ServicesDocument21 pagesVacita Integrated ServicesNwosu AugustineNo ratings yet

- Hiad 2Document15 pagesHiad 2Hrishikesh JoshiNo ratings yet

- CGN 3421 - Numerical Methods Lecture 3Document15 pagesCGN 3421 - Numerical Methods Lecture 3sori1386No ratings yet

- Design Steel Compression MembersDocument42 pagesDesign Steel Compression MembersFayyazAhmadNo ratings yet

- 1konsep Dasar TermodinamikaDocument39 pages1konsep Dasar TermodinamikamisrakandiNo ratings yet

- A Simple Lamina Flow Engine PDFDocument2 pagesA Simple Lamina Flow Engine PDFSelva KumarNo ratings yet

- DeoxofluorDocument2 pagesDeoxofluorleda_prandiNo ratings yet

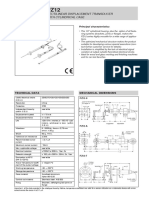

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionsl561926No ratings yet

- Assignment MetrologyDocument8 pagesAssignment MetrologyPratama sudibyo0% (1)

- Metalic AsDocument16 pagesMetalic AsKarencita Genesis LapibaNo ratings yet

- Vibration assignment on 3DOF cantilever beam systemDocument5 pagesVibration assignment on 3DOF cantilever beam systemIzzah 'AtirahNo ratings yet

- Review of Literature On Probability of Detection For Liquid Penetrant Nondestructive TestingDocument51 pagesReview of Literature On Probability of Detection For Liquid Penetrant Nondestructive TestingVicky GautamNo ratings yet

- How To Design R.C. Flat Slabs Using Finite Element AnalysisDocument16 pagesHow To Design R.C. Flat Slabs Using Finite Element Analysisocenkt100% (10)

- Motion of Particles in FluidDocument26 pagesMotion of Particles in FluidSubakti HungNo ratings yet

- Review Beer AgeingDocument25 pagesReview Beer AgeingTimothy WestNo ratings yet

- 9702 w04 QP 4Document16 pages9702 w04 QP 4api-3706826No ratings yet

- KIT-DISSOLVED OXYGEN CHEMets® Refills, ULR CHEMets®-KITDocument2 pagesKIT-DISSOLVED OXYGEN CHEMets® Refills, ULR CHEMets®-KITSorinNo ratings yet

- Electrical Conductivity of Carbon Blacks Under CompressionDocument7 pagesElectrical Conductivity of Carbon Blacks Under CompressionМирослав Кузишин100% (1)

- Modeling Mantle Convection CurrentsDocument3 pagesModeling Mantle Convection Currentsapi-217451187No ratings yet