Professional Documents

Culture Documents

Rheomac 707

Uploaded by

ulhas_nakasheCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rheomac 707

Uploaded by

ulhas_nakasheCopyright:

Available Formats

RHEOMAC 707

Low dosage, liquid, integral waterproofer

Description

A liquid admixture for concrete to give high water

resistance, based upon a blend of surface active

agents and refined lignosulphonate. Waterproof

concrete is the result of good concrete practice

coupled with the lowest w/c ratio compatible with

achieving full compaction.

The use of

RHEOMAC 707 enables all these criteria to be

met due to its strong plasticising and water

reducing properties.

Primary uses

RHEOMAC 707 should be used in all structural

concrete that is constantly or intermittently in

contact with water such as sea walls, tunnels,

basements, structural and pre-cast concrete in

exposed superstructures.

Advantages

Concrete containing RHEOMAC 707 is

resistant to water penetration either under

conditions of hydrostatic pressure or capillary

absorption.

Durability is increased due to a significant

reduction in w/c ratio.

Sulphate attack is reduced due to the sulphate

bearing ground water being resisted.

The cohesive properties of the concrete are

improved thus reducing segregation and

bleeding.

Concrete of similar workability to a control mix

produced with RHEOMAC 707, is easier to

place.

Pumpability of concrete is greatly improved.

The surface finish of the concrete is improved.

Packaging

RHEOMAC 707 is available in bulk or 210 litre

drums.

Action

RHEOMAC 707 assists in the production of

water resistant concrete by its two fold action:

I. It significantly reduces water demand to enable

production of good workability concrete with a

minimum water/cement ratio.

II. It disrupts the cellular network within the

concrete mass (capillaries), that are normally

inter-connected thereby reducing the concrete

permeability. Test results using Initial Surface

Absorption Tests (ISAT) in accordance with BS

1881: Part 5: 1970, on concrete with

RHEOMAC 707 show a decrease in surface

absorption of between 60-80% over a similar

concrete without RHEOMAC 707.

Composition

A blend of specially selected surface active agents

and refined lignosulphonates.

Typical properties

Properties listed are only for guidance and are not a

guarantee of performance

Colour:

Specific gravity:

Air entrainment:

Chloride content:

Nitrate content:

Freezing point::

Brown liquid.

1.185 at 25C.

2 1% according to grading of

sand and water content.

Nil to BS 5075.

Nil.

0C. Can be reconstituted if

stirred after thawing.

RHEOMAC 707

Standards

ASTM C494: Types A & D.

Directions for use

RHEOMAC 707 should be added with the mixing

water preferably via a dispenser. It should never

be added to the dry cement. No extension to

mixing times are required.

Points to remember

waterproof concrete:

when

producing

Ensure specified water / cement ratio is not

exceeded; work within the range of 0.4 to 0.6.

Keep water content as low as possible

compatible with achieving full compaction.

Place concrete quickly and ensure it is

thoroughly compacted.

Protect new concrete against rapid drying out

and ensure adequate and complete curing

with

BASF's

MASTERKURE

curing

compounds.

Dosage

320ml per 100kg of cement. Field trials should be

conducted to determine the effect of RHEOMAC

707 on the workability of the concrete.

Effects of over dosage

Slight set retardation. (No effect on striking

times).

Slight increase in air content.

Increase in workability.

Special features

Advantage of RHEOMAC 707s strong

plasticising action must be taken to reduce water

contents to a minimum. A reduction in w/c ratio

in the region of 10 to 15% can generally be

achieved.

Dispensing

RHEOMAC 707 should be dispensed through a

proprietary dispenser such as those available from

BASF. Details upon request.

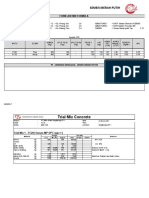

Typical test results

Table 1 - Water absorbency

Mix Proportions:

Series I

Series II

Cement

Sand

20mm-5mm aggregate

Workability

340kg

650kg

1280

50mm

400kg

585kg

1285

100mm

Series I

Series II

Admixture

None

RHEOMAC

707 at 320ml

/ 100kg

cement

None

RHEOMAC

707 at

320ml /

100kg

cement

Cement

SRC

Air %

SRC

OPC

OPC

W/C

0.5

0.44

0.43

5

0.37

Density kg/m

2.43

2.43

2.45

2.43

Water

absorbency

after 2 hours

4.6

2.0

4.1

1.8

Table 2 - Initial surface absorption test

Reference:

Initial surface absorption (ml/m/sec)

Control

10 min

30 min

1 hour

2 hour

1

2

3

2.04

2.58

2.33

1.15

1.77

1.61

0.87

1.44

1.35

0.73

1.28

1.23

Average

2.31

1.51

1.22

1.08

RHEOMAC 707

1

2

3

0.98

1.09

0.60

0.48

0.56

0.35

0.34

0.41

0.27

0.24

0.28

0.20

Average

0.89

0.46

0.34

0.24

RHEOMAC 707

Analysis of results

The typical results above show that RHEOMAC

707 is effective as a permeability reducing

admixture both under conditions of pressure and

capillary absorption. It can be used with complete

safety with OPC and SRC cements. That it

significantly lowers water cement ratio whilst

maintaining

workability

without

affecting

compressive strength.

Quality and care

All products originating from BASFs Dubai, UAE

facility are manufactured under a management

system independently certified to conform to the

requirements of the quality, environmental and

occupational health & safety standards ISO 9001,

ISO 14001 and OHSAS 18001.

05/94 BASF_CC-UAE revised 04/2004

All products should be used in accordance with

the manufacturer's instructions. No responsibility

can be taken by the manufacturer where

conditions of use are beyond our control.

Storage

Store under cover, out of direct sunlight and

protect from extremes of temperature.

Safety precautions

RHEOMAC 707 contains no hazardous

substances requiring labelling.

For further

information, refer to material safety data sheet.

Note

Field service, where provided, does not constitute

supervisory responsibility.

For additional

information

contact

your

local

BASF

representative.

BASF reserves the right to have the true cause of

any difficulty determined by accepted test

methods.

Whilst any information contained herein is true, accurate and represents our best knowledge and experience, no warranty is given or implied with

any recommendations made by us, our representatives or distributors, as the conditions of use and the competence of any labour involved in the

application are beyond our control.

As all BASF technical datasheets are updated on a regular basis it is the user's responsibility to obtain the most recent issue.

BASF Construction Chemicals UAE LLC

P.O. Box 37127, Dubai, UAE

Tel: +971 4 8090800

Fax: +971 4 8851002

www.basf-cc.ae

e-mail: marketingcc.mideast@basf.com

Certificate No.

963680

Certificate No.

945787

Certificate No.

772556

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Diet Plan in DetailedDocument6 pagesDiet Plan in Detailedulhas_nakasheNo ratings yet

- What Are The Main Responsibilities of Managers - TelegraphDocument5 pagesWhat Are The Main Responsibilities of Managers - Telegraphulhas_nakasheNo ratings yet

- Pt. Vilas Thuse: - Gruha Pravesh - Kalash Poojan Samagri (Material) ListDocument4 pagesPt. Vilas Thuse: - Gruha Pravesh - Kalash Poojan Samagri (Material) Listulhas_nakasheNo ratings yet

- Getting Started With The EOS 200DDocument21 pagesGetting Started With The EOS 200Dulhas_nakasheNo ratings yet

- Diaphragm Wall Method StatementDocument67 pagesDiaphragm Wall Method Statementulhas_nakashe100% (3)

- FIDIC Conditions of ContractDocument13 pagesFIDIC Conditions of Contractulhas_nakashe100% (2)

- Name of The Applicant, Home Address in Parent CountryDocument2 pagesName of The Applicant, Home Address in Parent Countryulhas_nakasheNo ratings yet

- Continuously Reinforced Concrete PavementDocument7 pagesContinuously Reinforced Concrete Pavementulhas_nakasheNo ratings yet

- Form 15g TaxguruDocument3 pagesForm 15g Taxguruulhas_nakasheNo ratings yet

- My Life ListDocument13 pagesMy Life Listulhas_nakasheNo ratings yet

- Secant Piles: What Are Secant Pile Walls?Document3 pagesSecant Piles: What Are Secant Pile Walls?ulhas_nakashe100% (2)

- Trip To Prayag - Varanasi and Gaya - Sept - Oct'09Document27 pagesTrip To Prayag - Varanasi and Gaya - Sept - Oct'09ulhas_nakasheNo ratings yet

- Sand Qnty SpreadsheetDocument1 pageSand Qnty Spreadsheetulhas_nakasheNo ratings yet

- Dream Is Not What U See in Sleep, It's The Thing Which Does Not Let U SL EepDocument1 pageDream Is Not What U See in Sleep, It's The Thing Which Does Not Let U SL Eepulhas_nakasheNo ratings yet

- Bridgestone Marine Fender Ver1.9Document73 pagesBridgestone Marine Fender Ver1.9matiasregis85% (20)

- Maharashtra Jeevan Pradhikaran Rate Analysis 2012 2013Document177 pagesMaharashtra Jeevan Pradhikaran Rate Analysis 2012 2013ulhas_nakasheNo ratings yet

- Handbook of Dredging ActivitiesDocument57 pagesHandbook of Dredging Activitiesulhas_nakashe0% (1)

- Bridgestone Marine Fender Ver1.9Document73 pagesBridgestone Marine Fender Ver1.9matiasregis85% (20)

- Design of Steel Structures (B.C.Punmia & Jain)Document14 pagesDesign of Steel Structures (B.C.Punmia & Jain)ulhas_nakashe38% (13)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Praveen SinghDocument24 pagesPraveen SinghAbhay Kumar PandeyNo ratings yet

- HSC ReportDocument53 pagesHSC ReportAless MarrticNo ratings yet

- JBR DCP - P.Q Log PDFDocument1 pageJBR DCP - P.Q Log PDFAL BASTAKI CONTRACTING L.L.C.No ratings yet

- CO2 Reduction Options in Cement IndustryDocument9 pagesCO2 Reduction Options in Cement IndustrySiddharth SinghNo ratings yet

- IHS Energy CatalogueDocument8 pagesIHS Energy CatalogueMzee Boydd Mkaka MwabutwaNo ratings yet

- Cement and Concrete Research: Amin Abrishambaf, Mário Pimentel, Sandra NunesDocument13 pagesCement and Concrete Research: Amin Abrishambaf, Mário Pimentel, Sandra NunesJoseluis Dejesus AnguloNo ratings yet

- Cement MENADocument60 pagesCement MENAazizelam11No ratings yet

- Earthworks SpecificationDocument18 pagesEarthworks SpecificationMohd Syaril Mohd Ali100% (1)

- TDS - Concresive 2020Document2 pagesTDS - Concresive 2020Venkata RaoNo ratings yet

- Araldite Klad XDocument1 pageAraldite Klad XakhanNo ratings yet

- 1 s2.0 S223878542300652X MainDocument14 pages1 s2.0 S223878542300652X MainFahra Aqilla AzzurahNo ratings yet

- Weber - Rep 370 PFDocument2 pagesWeber - Rep 370 PFPCWizNo ratings yet

- Sikagrout 3350Document4 pagesSikagrout 3350Mash-out VivA (www.VivA.com)No ratings yet

- Sediment BypassDocument310 pagesSediment BypassDavid RochaNo ratings yet

- Strap #1: Design AssumptionsDocument27 pagesStrap #1: Design AssumptionsLeanna Abdul Wahab100% (4)

- Gtu Project TitleDocument231 pagesGtu Project TitleMehul PaþelNo ratings yet

- RedGard Installation InstructionsDocument5 pagesRedGard Installation InstructionsAlex LongNo ratings yet

- Understanding CementDocument196 pagesUnderstanding Cementlcruz06100% (2)

- Bill of QuantityDocument35 pagesBill of QuantityJoshua LopezNo ratings yet

- Thermal Stresses and Movements in Bridges PDFDocument54 pagesThermal Stresses and Movements in Bridges PDFMaitrabarun KarjeeNo ratings yet

- Bridge 1 - Preliminary Bridge Design AASHTO LRFD 2017Document73 pagesBridge 1 - Preliminary Bridge Design AASHTO LRFD 2017Engr. Gazi Golam SarwarNo ratings yet

- Libro de Reforzamiento HORMIGON ARMADO 2022-9Document25 pagesLibro de Reforzamiento HORMIGON ARMADO 2022-9David Magne MamaniNo ratings yet

- Fitzpatrick Product Catalogue 2020 - Steel Doors-Frames (DS) (ITB)Document46 pagesFitzpatrick Product Catalogue 2020 - Steel Doors-Frames (DS) (ITB)Ramez Bou-RizkNo ratings yet

- Road Work QualityDocument508 pagesRoad Work QualityvivekNo ratings yet

- Repair Rehabilitation RetrofiitingDocument39 pagesRepair Rehabilitation RetrofiitingHina MalikNo ratings yet

- دراسة بعض خواص الخرسانة الحاوية على خبث الأفرانDocument7 pagesدراسة بعض خواص الخرسانة الحاوية على خبث الأفرانGandhi HammoudNo ratings yet

- Construction LogbookDocument2 pagesConstruction LogbookGerard BorbonNo ratings yet

- Hilti - Rebar For Engineers - Hit-Rebar MethodDocument20 pagesHilti - Rebar For Engineers - Hit-Rebar MethodMunduluNo ratings yet

- Semen Merah Putih: Form Job Mix FormulaDocument21 pagesSemen Merah Putih: Form Job Mix FormulaMochamad Abdul Mu'thiNo ratings yet