Professional Documents

Culture Documents

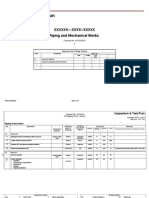

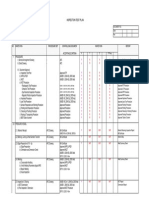

Inspection and Test Plan For Pipe Line Works Rev 0

Uploaded by

CrstnScribidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection and Test Plan For Pipe Line Works Rev 0

Uploaded by

CrstnScribidCopyright:

Available Formats

LOGO

INSPECTION AND TEST PLAN FOR PIPE LINE WORKS

REV 0

Project Name

ACTIVITY

1.0

Procedure Approval

1.1

1.2

Approve engineering procedures

Approve welding procedures

Review

Approved procedures

Review WPS & PQR

Approved procedures

1.3

Approve NDT procedures

Review

Approved procedures

1.4

Approve field joint coating procedure

Review

Approved procedures

Check shipping Docs-100%

Cargo Manifest

Quantitative inspection

MRR

2.0

2.1

2.2

3.0

Arrival at Warehouse

Handling / Storage

4.1

Welding equipment

Confirm Identification-100%

Visual Inspection-100%

Review certification

Verify Handling

Verify Storage conditions

Verify material condition

WELDER QUALIFICATION

Verify pipe length - 100%

pipe tally sheet

Check anode Yes / No

pipe tally sheet

Inspect and approve

Equipment list

Check Calibration

calibration certificates

Review welder qualification records

WQT records

Qualified welders list

(Stores records)

CONSUMABLE STORAGE AND

Check storage conditions

HANDLING

Check batch identification

Review certificates

4.4

4.5

4.7

4.8

CTR

Traceability

Welding

4.3

DOCUMENTATION

Material

4.0

4.2

CONTROL DESCRIPTION

CHECKPOINTS

ITEM

PREPARATION

Alignment / fit up

BEFORE JOINT WELD OUT

DURING JOINT WELD OUT

4.9

AFTER JOINT WELD OUT

4.10

REPAIRS

5.0

NDT

5.1

EQUIPMENT

H

Quality certificates

Visualy inspect preparation for damage

Hi / Lo + root gap

Check WPS to be used is correct

H

H

H

H

Identify and mark weld ID

Weld log

Identify and mark welder ID

Weld log

Check root pass

Check welding parameters

Visually inspect weld

Perform required RT

Confirm defect location

H

Visual report/inspection log

RT report

H

H

H

H

Grind to bright Metal

Confirm defect removal

Perform MT to excavation

check as per 4.7

Perform RT

Inspect and approve

Equipment list

Check calibration certificates

Calibration certificates

5.2

5.3

OPERATORS ( UT, RT, MT )

NDT AFTER JOINT WELD OUT

Review operator qualification

RT

Qualification certificates

RT report

H

H

RT

RT report

Equipment list

5.4

NDT AFTER REPAIR

6.0

FIELD JOINT COATING

6.1

EQUIPMENT & MATERIALS

Inspect and approve

6.2

PREPARATION

Check preparation of each joint

6.3

JOINT COATING

Confirm coating material requirements

Material certificates

6.4

COATING INSPECTION

Inspect coating quality

Coating inspect report

7.0

PRESSURE TESTING

7.1

EQUIPMENT

Inspect and approve

Equipment list

Check calibration certificates

Calibration certificates

Review test package

Test package

Confirm conformity to Dwg.

Pretest check list

Confirm pressuring up time

Chart and certificate

Confirm test pressure

Chart and certificate

Check for leaks

Chart and certificate

Confirm test duration

Chart and certificate

Confirm depressurization rate

Chart and certificate

Confirm reinstatement of removed items

Post test check list

7.2

5.3

5.4

BEFORE TEST

DURING TEST

AFTER TEST

Client

PROC.

You might also like

- Inspection and Test Plan: On-Shore Pipeline CertificationDocument2 pagesInspection and Test Plan: On-Shore Pipeline CertificationKayra Riri Chirul100% (1)

- ITP For Piping WorksDocument3 pagesITP For Piping WorksOrlando1949100% (3)

- Itp VesselDocument4 pagesItp VesselHakim BaihaqiNo ratings yet

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankAhmed100% (5)

- Itp For Pipeline at SiteDocument3 pagesItp For Pipeline at Siteanang_pri100% (2)

- ITP For Pipeline Construction Table 1Document3 pagesITP For Pipeline Construction Table 1wahyu100% (2)

- Inspection & Test Plan For 16 Inch Pipeline (R0)Document13 pagesInspection & Test Plan For 16 Inch Pipeline (R0)Nilesh Kabade100% (1)

- Itp For Tank Fabrication & Installation Work1 - Rev02Document22 pagesItp For Tank Fabrication & Installation Work1 - Rev02mister pogi100% (3)

- To Commissioning Manual: Appendix No. 1Document7 pagesTo Commissioning Manual: Appendix No. 1Bassem BalghouthiNo ratings yet

- Hydrotest Procedure For PipelineDocument12 pagesHydrotest Procedure For Pipelineaike_577% (13)

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument9 pages5 - Tank Itp - Inspection & Test Plan For Tanksmandi100% (1)

- Underground Piping Pressure Test RecordDocument1 pageUnderground Piping Pressure Test RecordPaulSwinbankNo ratings yet

- Piping Release Report (Spool For Paint)Document2 pagesPiping Release Report (Spool For Paint)Siddiqui Abdul Khaliq100% (1)

- 5 Form Test Piping Package Data SheetDocument1 page5 Form Test Piping Package Data Sheetmashudi_fikriNo ratings yet

- Tie in Procedure Rev. BDocument8 pagesTie in Procedure Rev. BgenjiNo ratings yet

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- Ag Test Package FormatDocument25 pagesAg Test Package FormatoparoystNo ratings yet

- Itp PipingDocument4 pagesItp Pipingerdemlix100% (2)

- Piping Inspect & Testing ProcedureDocument11 pagesPiping Inspect & Testing ProcedureErlanggaBonaparteNo ratings yet

- 20-11 - Installation of Swamp PipelinesDocument47 pages20-11 - Installation of Swamp PipelinesFolayemi100% (2)

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuNo ratings yet

- Itp For Piping Fabrication and Erection CorrectionDocument4 pagesItp For Piping Fabrication and Erection CorrectionAnand Ramachandran67% (3)

- Sample - Template - Itp For Piping Fabrication and InstallationDocument2 pagesSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriNo ratings yet

- Form Welding Summary and Material Traceability Record - Piping TuhupDocument6 pagesForm Welding Summary and Material Traceability Record - Piping TuhupYuwantoniAlNo ratings yet

- Piping Hydrostatic Test Procedure Rev0Document8 pagesPiping Hydrostatic Test Procedure Rev0smsunil12345No ratings yet

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument10 pages5 - Tank Itp - Inspection & Test Plan For TanksAhmed Hassan100% (2)

- ITP - PipingDocument7 pagesITP - PipingRiaz Rasool100% (2)

- Installtion of Lact Unit, Gas Metering Skid and Their Interconnecting Piping. CostDocument2 pagesInstalltion of Lact Unit, Gas Metering Skid and Their Interconnecting Piping. CostAtty AttyNo ratings yet

- Above Ground Piping ProcedureDocument4 pagesAbove Ground Piping Proceduremusthafa_11No ratings yet

- Contractor Quality Control Plan For Storage Tank ErectionDocument2 pagesContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (4)

- Hydrotest Check ListDocument1 pageHydrotest Check ListSaut Maruli Tua SamosirNo ratings yet

- Sample Work Activities For Process Tank FabricationDocument4 pagesSample Work Activities For Process Tank FabricationMuhammad ZubairNo ratings yet

- Piping Tie in Procedure Rev ADocument15 pagesPiping Tie in Procedure Rev AAnh Võ95% (19)

- Inspection Test Plan For Pipeline JobsDocument6 pagesInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينNo ratings yet

- 30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingDocument21 pages30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingkilioNo ratings yet

- JIMT Fire Fighting System Pre Commissioning Punch List (Piping)Document9 pagesJIMT Fire Fighting System Pre Commissioning Punch List (Piping)Gomathyselvi100% (1)

- Daily Welding Progress ReportDocument1 pageDaily Welding Progress ReportManoj KumarNo ratings yet

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Document24 pagesItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- 10) Itp - Tank Fabrication PDFDocument6 pages10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- MS-24 Hydrotest Pipeline ProcedureDocument13 pagesMS-24 Hydrotest Pipeline Proceduresosi2020100% (13)

- Line History SheetDocument46 pagesLine History SheetBhanu Pratap Choudhury33% (3)

- Inspection and Test Plan For Pressure VesselDocument4 pagesInspection and Test Plan For Pressure VesselNurul Amirah Princesza100% (3)

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Piping Hydrotest Procedure - Oil - Gas - WorldDocument3 pagesPiping Hydrotest Procedure - Oil - Gas - WorldFrank100% (6)

- Access LadderDocument1 pageAccess LadderglenNo ratings yet

- Tiling PDFDocument2 pagesTiling PDFglen100% (2)

- Case Composite System Audit Training 2016Document85 pagesCase Composite System Audit Training 2016Kenton CharlesNo ratings yet

- Inspection and Test Plan For Fin Tube Heat ExchangerDocument4 pagesInspection and Test Plan For Fin Tube Heat ExchangerSenthil Kumar100% (2)

- ITP-000 Piping Fabrication (Exemple)Document5 pagesITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- H Quality and Certification Requirements-SPDocument3 pagesH Quality and Certification Requirements-SPEl_memitoNo ratings yet

- ITP - Fabrication of Structural SteelDocument2 pagesITP - Fabrication of Structural Steelsahad100% (6)

- Inspection Test Plan Equipment - AFC Header Plug Seal Weld 1Document4 pagesInspection Test Plan Equipment - AFC Header Plug Seal Weld 1Mohd Shafuaaz KassimNo ratings yet

- ITP Format For New PVDocument8 pagesITP Format For New PVDavid LambertNo ratings yet

- ITP New Pressure VesselDocument2 pagesITP New Pressure Vesselyosafateden60% (5)

- 102-V-5 QipDocument8 pages102-V-5 QipSaleemSahabNo ratings yet

- Inspection Test PlanDocument3 pagesInspection Test PlanMohd Shafuaaz Kassim100% (2)

- Checlist Kelompok Pressure VesselDocument8 pagesCheclist Kelompok Pressure VesselerniNo ratings yet

- Attach. D Itp Induction BendDocument1 pageAttach. D Itp Induction BendAdvisNo ratings yet

- Template For Process Validation ProtocolDocument3 pagesTemplate For Process Validation Protocolreflectprakash361083% (6)

- Sample ITP BoilerDocument6 pagesSample ITP Boilerintolscrib100% (1)

- Aluminium Window and Door Hardware FittingsDocument76 pagesAluminium Window and Door Hardware FittingsLaborioso GeneralNo ratings yet

- PVC Water StopDocument2 pagesPVC Water StopBassemM100% (1)

- Ultra Thin WhitetoppingDocument36 pagesUltra Thin WhitetoppingAnil Kumsr T B100% (1)

- List of Garment Factory Accidents in Bangladesh 2013-2017Document10 pagesList of Garment Factory Accidents in Bangladesh 2013-2017Jashim UddinNo ratings yet

- ConvexDocument12 pagesConvexPraveen KumarNo ratings yet

- F701 SDocument2 pagesF701 SSubin AnandanNo ratings yet

- Cross Laminated Timber CEUDocument12 pagesCross Laminated Timber CEUHasan Žera TalićNo ratings yet

- Torque SpecsDocument2 pagesTorque SpecsMirnal MungraNo ratings yet

- 3020 - 001 Foam Pigs TDWDocument2 pages3020 - 001 Foam Pigs TDWIKKYHD100% (1)

- Milk Supply Chain of Visakha DairyDocument30 pagesMilk Supply Chain of Visakha DairyHavish SrinivasulaNo ratings yet

- Imerys Mica in PP 2010Document2 pagesImerys Mica in PP 2010Jedsan LiangphapaipunNo ratings yet

- UOP CCR Catalysts Target A Range of Objectives Tech Paper1Document5 pagesUOP CCR Catalysts Target A Range of Objectives Tech Paper1Humberto AgmNo ratings yet

- Galbon S-HB - Jan En-ThDocument2 pagesGalbon S-HB - Jan En-ThRenalyn TorioNo ratings yet

- Foundry Hand ToolsDocument83 pagesFoundry Hand ToolsKiran MunavalliNo ratings yet

- Fastener Industry and Boeing White PaperDocument28 pagesFastener Industry and Boeing White Papermasrit123No ratings yet

- Preventing Mechanical FailuresDocument15 pagesPreventing Mechanical Failuresmarcalasan0% (1)

- Philippine Agribusiness: An Introduction: Vicky GuiebDocument21 pagesPhilippine Agribusiness: An Introduction: Vicky GuiebMaria Charlene Grace AringoNo ratings yet

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- Welding Metalwork Fabrication Services Sample ProposalDocument9 pagesWelding Metalwork Fabrication Services Sample ProposalDouglas OngomNo ratings yet

- Pdf1610 TMPDocument12 pagesPdf1610 TMPTimmyJuriNo ratings yet

- 3D Printing Seminar REPORT-srijanDocument26 pages3D Printing Seminar REPORT-srijanSrijan UpadhyayNo ratings yet

- Irizar Technical BrochureDocument84 pagesIrizar Technical BrochureJuarez LeiteNo ratings yet

- Thermowell MaterialsDocument2 pagesThermowell Materialswhite9013No ratings yet

- 12 PressroomDocument58 pages12 PressroomilliteratewhinoNo ratings yet

- Oracle Master Scheduling and Material Requirements Planning: Manufacturing Functional FoundationDocument28 pagesOracle Master Scheduling and Material Requirements Planning: Manufacturing Functional FoundationwellawellawellaNo ratings yet

- Mechanical Design Manual FastenerDocument68 pagesMechanical Design Manual FastenerRuben VidalNo ratings yet

- Site Visit ReportDocument17 pagesSite Visit ReportAlphaNo ratings yet

- Consumables Catalogue EngDocument719 pagesConsumables Catalogue Engpaulon9271No ratings yet

- Manufacturing Process Assignment 1Document10 pagesManufacturing Process Assignment 1abhishek chibNo ratings yet

- MC LANAHAN ScrubbersDocument4 pagesMC LANAHAN ScrubbersTsakalakis G. KonstantinosNo ratings yet