Professional Documents

Culture Documents

Quality Assurance Plan for Hydraulic Buffer

Uploaded by

aniketkadekarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Assurance Plan for Hydraulic Buffer

Uploaded by

aniketkadekarCopyright:

Available Formats

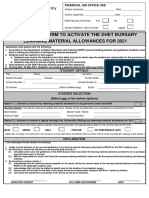

DOC. No.

QUALITY ASSURANCE PLAN

KOBA Co.,Ltd.

HYDRAULIC BUFFER

REV. No.

PAGE

ISO 9001 : 2008 / KS Q ISO 9001 : 2009

BS / EN / ISO 9001 : 2008

ThyssenKrupp Industries India Private Limited.

CUSTOMER

PROJECT NAME

SEW

VIZAG

COAL

TERMINAL PVT LTD

MANUFACTURER

KOBA Co.,Ltd.

PROJECT No.

ITEMS

Hydraulic Buffer

Rev.No

DATE

DESCRINTION

27 Dec. 2012

Issued

KB-QAP-01

REV. 0

DESIGNED CHECKED APPRVED

C.S.BAEK

KOBA Co.,Ltd.

H.K.SHIM

J.H.KIM

A4

DOC. No.

QUALITY ASSURANCE PLAN

KOBA Co.,Ltd.

HISTORY OF KOBA

REV. No.

PAGE

1993 _ 2000

Established PYUNGWON in Bucheon (1993.10)

Moved to company to Incheon(1995.04)

The headquarter moved to Seoul(1996.06)

Changed Company name as KOREA BUFFER INDUSTRY(1998.10)

Changed Company name as KOBA Co., Ltd. (1999.12)

Participated in Korea Factory Automation(2000.03)

Participated in Intl Factory Automation Show(2000.09)

Acquired ISO9001 Quality System certificate(2000.09)

Participated in Korea Intl machinery Expo(2000.10)

2001 _ 2004

Selected as Clean Production line by Korean Government(2001_2004)

Carried out a project as a member of consortium (Industry niversity Research Cooperation)(2001_2002)

Acquired the utility model for the Shock Absorber test Equipment (2002.09)

Registered as Subcontractor of Defense Industry for the national defense (2002.09)

Applied for two patens and one utility model (2003.01)

Moved to Head quarter and Factory (2003.04)

Registered as KOBA Co., Ltd. (2003.11)

2005 _ 2010

Registered 1 trademark (2005.01)

Registered as official vender of USS-POSCO INDUSTRIES(UPI)

(2006.09)

Registered 1 patent and 1 design (2007.)

Registered 2 patents and obtained 1(2008.)

Participated in Hannover Fair (2008.04)

Renewal ISO9001 (2009.05)

Selected as INNO-BIZ(Innovation Business Company) (2010.03)

Selected as Venture Business Company(2010.04)

2011~

Registered as Official partner of Siemens(Germany) (2011.03)

Registered as official partner of MUKAND LTD(India)(2011.04)

Acquired CE certificate (2012.09)

KB-QAP-01

REV. 0

KOBA Co.,Ltd.

A4

DOC. No.

QUALITY ASSURANCE PLAN

KOBA Co.,Ltd.

PRODUCT OF KOBA

REV. No.

PAGE

KMA Series is small-sized units that can be adjusted by Adjustment Dial (up to180) according to

collision speed. With using Bumper Head Type, it provides a positive stop to prevent damage

caused by the piston "bottoming out" in stage of stoke without Stop Collar.

KMS Series is self-adjustable and small sized units. It is specially designed with multiple orifice to

smoothly stop moving loads. With using Bumper Head Type, it provides a positive stop to prevent

damage caused by the piston "bottoming out" in stage of stoke without Stop Collar.

KHA Series is mid-sized units for the medium and heavy moving loads.

It is adjusting type by

Adjustment Dial (up to180) according to collision speed.

KHG Series is self-adjustable units designed for heavy industries. It absorbs larger shock energy by

using special oil and Nitrogen gas and uses compressed Nitrogen gas to return piston rod.

KHS Series is self-adjustable and mid sized units designed for heavy industries. It is specially

designed with multiple orifice to smoothly stop moving loads.

KCS series is used usually in stacker crane of Automatic distributing system. KCSC has wide range of

capacity and stroke (Stroke 1500mm, Capacity 930 kJ). It is possible to design and manufacture for

special purpose as customers request. KOBA hydraulic buffer is met the Global industrial safety

standards like OSHA, AISE, CMMA, DIN, and FEM.

KGL Series (Free Lock Gas Spring) have all advantage of general Gas Spring with the Free Lock

feature that allows you to set the stroke anywhere you want by pressing Lock Pin.

KG, KGP Series (Gas Spring) have various strengths, including small Spring Constant, Long Stroke,

Speed Control at compression and Stable Strength compared to general plate spring or coil spring

and is widely used across the industries. May be customized into various type, e.g, Stroke, Speed

Force or Mount Type according to customer needs.

KB-QAP-01

REV. 0

KOBA Co.,Ltd.

A4

DOC. No.

QUALITY ASSURANCE PLAN

KOBA Co.,Ltd.

QUALITY POLICY

REV. No.

PAGE

QUALITY POLICY

Customer Satisfaction, Best Quality Product, Human Respect

To reach this Quality Policy, we set up below mentioned as Quality Goal.

Technology Creation

Value Innovation

0% of fraction defective

Best Delivery

Jan. 02, 2014

KOBA Co., LTD.

President

KB-QAP-01

REV. 0

Seog-pil Yong

KOBA Co.,Ltd.

A4

DOC. No.

QUALITY ASSURANCE PLAN

KOBA Co.,Ltd.

REV. No.

PAGE

Scope of Application

This document applies to the quality assurance plan for the products produced by our company.

2. Purpose

This document aims to assure you that the quality of the products produced and supplied by our company

meets the requisites and requirements of the enterprise.

3. Responsibility and Authority

3.1 Sales headquarters

1) Determination and documentation of the orders related to contracts

The sales headquarters shall document the contract documents, customer requirements documents or orally

ordered matters, and grasp the customer requirements(product, inspection method, delivery method, etc.).

2) Review of customer requirements

The sales headquarters shall grasp the orders related to contracts, review the determined contents, and then

let the wrong matters be corrected.

3) Conclusion of a contract

When the unclear matters on the contract are solved and it is judged to have an ability to achieve the

customer requirements, the sales headquarters shall conclude a contract and inform the related responsible

persons thereof

4) Modification of a contract

When the customer requirements should be modified after concluding a contract, the sales headquarters shall

review its contents and then inform the related responsible persons of the modified contents

KB-QAP-01

REV. 0

KOBA Co.,Ltd.

A4

DOC. No.

QUALITY ASSURANCE PLAN

KOBA Co.,Ltd.

REV. No.

PAGE

5) Discussion with customers

When the contract conditions and customer requirements based on the review result are not exactly defined,

the sales headquarters shall agree on or determine it through a discussion with customers.

3.2 Administration headquarters

1) Evaluation, registration and post-management of suppliers

The administration headquarters shall select, register and then continuously post-manage(evaluate and classify)

a supplier that meets the designated requirements(product kind, enterprise result and ability).

2) Recording and control of procurement information

The administration headquarters shall continuously record and manage the quality and information required for

the procured items.

3.3 Production headquarters

1) Identification and control of materials and products

The production headquarters shall attach and manage a tag to a designated place to facilitate the

identification of raw/sub materials and products.

2) Tracking and control of products

The production headquarters shall record the delivered product when delivery a complete product, and let all

the processes of production be tracked to facilitate its tracking when there happens a complaint or claim from

customers.

3.4 Quality headquarters

1) Verification of purchases(raw/sub material)

The quality headquarters shall execute, record and control a conformity inspection for all the materials

affecting the quality.

2) Process inspection and test

The quality headquarters shall execute, record and control the inspection and test for the items affecting the

products while the a process is carried out.

3) Verification of complete products

The quality headquarters shall execute, record and control the final inspection and test to verify that the

completed products meet the prescribed requirements.

4) Data analysis for improvement

The quality headquarters shall collect, analyze and control the data(defects and nonconforming items) to

enhance the quality continuously.

3.5 R&D Center

1) Product design

The R&D Center shall collect and record the necessary data(customer specification, application material,

product standard, technical standard, etc.) enough so that the customer requirements may be reflected.

2) Drawing control

The R&D Center shall give a drawing number to the approved drawings, and register, keep and control it on

the drawing control register.

4. Education and Training

The reasonable operation of a quality system shall be sought by providing education and training to all the

employees who execute the work affecting the quality.

KB-QAP-01

REV. 0

KOBA Co.,Ltd.

A4

DOC. No.

QUALITY ASSURANCE PLAN

KOBA Co.,Ltd.

REV. No.

PAGE

4.1 Division of education/training

4.2 Education/training procedure

1) Each department manager shall prepare an annual education/training plan and inform the administration

department manager thereof, and the administration department manager shall review this and execute annual

education/training.

2) For the education/training results, a personal education/training record shall be prepared and controlled.

5. Inspection

5.1 Warehousing inspection

1) Warehousing inspection procedure

The warehousing inspection shall comply with the following procedure.

KB-QAP-01

REV. 0

KOBA Co.,Ltd.

A4

DOC. No.

QUALITY ASSURANCE PLAN

KOBA Co.,Ltd.

REV. No.

PAGE

2) Inspection item

The warehousing inspection shall comply with the warehousing inspection standard(Appendix 1).

5.2 Process inspection and complete product inspection

1) Process inspection and complete product inspection procedure

The process inspection and complete product inspection shall comply with the following procedure.

2) Inspection item

The process inspection and complete product inspection shall comply with the inspection standard(Appendix 2).

5-3. Recording

The inspection and test results shall be recorded so that its pass or failure may clearly appear depending on

the prescribed criterion.

6. Nonconformity Control

This prevents the use of a product unsuitable for the prescribed requirements from the warehousing inspection

to the complete product inspection.

KB-QAP-01

REV. 0

KOBA Co.,Ltd.

A4

DOC. No.

QUALITY ASSURANCE PLAN

KOBA Co.,Ltd.

REV. No.

PAGE

6.1 Identification and disposal

1) When there happens a product unsuitable for the prescribed requirements, attach a nonconformity judgment

document, record the contents of nonconformity, separate it in a designated place, and then control

it.

2) The

nonconforming items shall be handled as repair, rework, sorting, use change, abolition or return depending on

their contents.

3) The items determined as rework shall be reworked and then reinspected.

4) All the contents related to nonconformity shall be recorded and controlled.

6.2 Corrective and preventive measure

1) For the nonconforming items found during an inspection that are judged to be a serious quality problem,

prepare a corrective and preventive measure document and inform the corresponding departments and

subcontractors thereof.

2) The corresponding department and subcontractor shall execute correction and prevention and then inform the

quality headquarters of the result.

3) The quality headquarters shall check the corrective and preventive measure results and then record and keep

its contents.

7. Meter Control

Calibrate and manage the equipment used for the inspection, measurement and test of a product to verify the

conformity of the product.

7.1 Equipment overview

1) The equipment overview of the quality headquarters shall comply with the overview table(Appendix 3).

7.2 Verification and calibration

1) The verification and calibration period of the equipment in the quality headquarters shall be 1 year (based on

the national verification and calibration institution).

2) Establish a verification and calibration plan at the beginning of every year, and then execute verification and

calibration according to it.

3) Attach a verification and calibration certificate to the verified and calibrated equipment, and then record and

keep its contents.

4) The contents of verification and calibration at the corresponding year are shown in Appendix 3.

KB-QAP-01

REV. 0

KOBA Co.,Ltd.

A4

You might also like

- ISO 9000/9001 and CMMDocument19 pagesISO 9000/9001 and CMMAnkur SinghNo ratings yet

- Quality ManualDocument38 pagesQuality ManualsathyabalaramanNo ratings yet

- ABC QualityManualDocument46 pagesABC QualityManualSuresh PantNo ratings yet

- AS9100 Rev C Transition DeadlineDocument10 pagesAS9100 Rev C Transition DeadlineGaneshkumar Krishna ShettyNo ratings yet

- Frequently Asked Questions (FAQ's) : International Aerospace Quality GroupDocument6 pagesFrequently Asked Questions (FAQ's) : International Aerospace Quality GroupMassimiliano MelisNo ratings yet

- STS Profile Rev-04Document19 pagesSTS Profile Rev-04Walid BdeirNo ratings yet

- "Creative Enginnering Solution ": Industrial OperationsDocument15 pages"Creative Enginnering Solution ": Industrial OperationsAshwini ShettyNo ratings yet

- QUALITY MANAGEMENT PLAN Excavator Boom ADocument89 pagesQUALITY MANAGEMENT PLAN Excavator Boom ARomally Antonette TagnipezNo ratings yet

- Management of Fabrication Quality - bk206Document7 pagesManagement of Fabrication Quality - bk206Nithish KuttanNo ratings yet

- METHOD STATEMENT For Roll-Up Doors InstallationDocument16 pagesMETHOD STATEMENT For Roll-Up Doors Installationmoytabura96100% (2)

- SRWF Quality ManualDocument22 pagesSRWF Quality ManualSRWFdicerNo ratings yet

- Iqcm 2019 PDFDocument151 pagesIqcm 2019 PDFshivam johri100% (1)

- ASME Conformity Assessment BenefitsDocument31 pagesASME Conformity Assessment BenefitsGTpianomanNo ratings yet

- SCM Manual - KSCDocument19 pagesSCM Manual - KSCSathishkumar DhamodaranNo ratings yet

- But I've Always Done It This Way .. ": Do You Really Know What Is The Right WayDocument43 pagesBut I've Always Done It This Way .. ": Do You Really Know What Is The Right Wayshashiv74No ratings yet

- Plan GCDocument18 pagesPlan GCLuis Zavala0% (1)

- Cpi Quality ProceduresDocument18 pagesCpi Quality ProceduresAdrian RogersNo ratings yet

- ABC Group Checking and Gauge Standard 80-STD-D-01Document53 pagesABC Group Checking and Gauge Standard 80-STD-D-01Quy HoangNo ratings yet

- Kundel Industries-Crane Division-Quality Assurance ManualDocument20 pagesKundel Industries-Crane Division-Quality Assurance ManualYasir JamilNo ratings yet

- DNVGL CP 01401Document9 pagesDNVGL CP 01401danekox9623No ratings yet

- Obtained From SQA Difference Between Iso 9001 and As 9100Document44 pagesObtained From SQA Difference Between Iso 9001 and As 9100Kristian GarcidueñasNo ratings yet

- IPC IntroductionDocument41 pagesIPC Introductionram salunkheNo ratings yet

- Cold Forging Process For The Manufacturing of Nuts&boltDocument35 pagesCold Forging Process For The Manufacturing of Nuts&boltaseemk1No ratings yet

- Click To Edit Master Subtitle StyleDocument30 pagesClick To Edit Master Subtitle StyleNico AmicoNo ratings yet

- Section 8 - Quality Assurance/Quality Control PlanDocument3 pagesSection 8 - Quality Assurance/Quality Control PlanJoemon T JoyNo ratings yet

- 9 QualityDocument14 pages9 QualitySSE DEMUNo ratings yet

- 1.QSMl - BVQI - NUMBERINGDocument49 pages1.QSMl - BVQI - NUMBERINGtruongthi100508No ratings yet

- ASSENT Prequalification DocumentDocument95 pagesASSENT Prequalification DocumentMostafaAdelMaghrabyNo ratings yet

- Site QAQC PlanDocument9 pagesSite QAQC PlanP SHANKAR BABU100% (1)

- Home Catalog Business Employee Form Leave Form Sample Leave Form FormatDocument17 pagesHome Catalog Business Employee Form Leave Form Sample Leave Form FormatSATISH SONDHINo ratings yet

- Best Engineering PumpsDocument62 pagesBest Engineering PumpsVivek Us83% (6)

- Welding Manual for Boiler ComponentsDocument19 pagesWelding Manual for Boiler ComponentsRajesh ThakurNo ratings yet

- Ravindra Mhaske CV - QualityDocument4 pagesRavindra Mhaske CV - QualityRavi MhaskeNo ratings yet

- A Summer Training ProjectDocument130 pagesA Summer Training Projectmukesh007dwivedi100% (1)

- 1.1 General Functions in BHEL-HPVP Plant: 1.1.1 Marketing DepartmentDocument36 pages1.1 General Functions in BHEL-HPVP Plant: 1.1.1 Marketing DepartmentYash RayuduNo ratings yet

- Alstom: Supplier Quality Manual Quality RequirementsDocument48 pagesAlstom: Supplier Quality Manual Quality Requirementspnagarajj67% (3)

- Loler Competent Person Competence Assessment Valid From 01032016 PDFDocument22 pagesLoler Competent Person Competence Assessment Valid From 01032016 PDFAndrew LiddellNo ratings yet

- Quality Function Deployment (QFD) Quality Function DeploymentDocument5 pagesQuality Function Deployment (QFD) Quality Function DeploymentApril Rose BaquerosNo ratings yet

- IMS 2nd ModuleDocument21 pagesIMS 2nd Modulesreejith KBNo ratings yet

- Supplier Quality ManualDocument24 pagesSupplier Quality Manualshobhit2310100% (1)

- WBIFR Systems GuideDocument27 pagesWBIFR Systems GuideneerajtrvNo ratings yet

- F0389 Deliverable Quality Plan TemplateDocument6 pagesF0389 Deliverable Quality Plan TemplatefarhansidraNo ratings yet

- QA Manual Ensures Quality StandardsDocument18 pagesQA Manual Ensures Quality StandardsMohanad GanemNo ratings yet

- BCA ISO 9000 Certification Scheme GuideDocument5 pagesBCA ISO 9000 Certification Scheme GuideGordon NicolasNo ratings yet

- STD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureDocument27 pagesSTD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureNikunj KNo ratings yet

- ReportDocument18 pagesReportKrishna KKNo ratings yet

- QMS 32 - 2009Document4 pagesQMS 32 - 2009Prasenjit PuriNo ratings yet

- COMP-OPP-01 Procedure For Control and Validation of ProductionDocument4 pagesCOMP-OPP-01 Procedure For Control and Validation of ProductionISODCC DSPINo ratings yet

- Quality Assurance in Fabrication of Boilers and Pressure VesselsDocument18 pagesQuality Assurance in Fabrication of Boilers and Pressure Vesselsمحمد اظهرNo ratings yet

- 1 Product Development ProcessDocument100 pages1 Product Development Processzaid zainol100% (1)

- IAQG 9120:2009 Revision Overview: Prepared by IAQG 9120 TeamDocument24 pagesIAQG 9120:2009 Revision Overview: Prepared by IAQG 9120 TeamYogita NarangNo ratings yet

- 00-10-001 - F - Nov.2000Document0 pages00-10-001 - F - Nov.2000Levi MurdokNo ratings yet

- BDK CatalogDocument344 pagesBDK CatalogloucifNo ratings yet

- Cover Letter: Home AddressDocument4 pagesCover Letter: Home AddressVenkates WaranNo ratings yet

- Quality Control ManualDocument50 pagesQuality Control ManualKhairul Azri100% (1)

- Elaborated By: Arturo LlanosDocument59 pagesElaborated By: Arturo LlanosSuryaprakashNo ratings yet

- V4s46A Cement Quality AssuranceDocument22 pagesV4s46A Cement Quality AssuranceDilnesa EjiguNo ratings yet

- AS9000 Standard for Aerospace QualityDocument2 pagesAS9000 Standard for Aerospace QualityJean CarloNo ratings yet

- Ankit Satsangi - Co-OpDocument14 pagesAnkit Satsangi - Co-OpGaurav SinghNo ratings yet

- Iso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailFrom EverandIso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailRating: 5 out of 5 stars5/5 (3)

- Learn essential Tamil phrases in English and informal TamilDocument6 pagesLearn essential Tamil phrases in English and informal TamilaniketkadekarNo ratings yet

- H.R. Flat Bar: Astm-Aisi Thickness Tolerance RangesDocument1 pageH.R. Flat Bar: Astm-Aisi Thickness Tolerance RangesMaria Eliza Renee DominguezNo ratings yet

- Shahcement TranslatedDocument9 pagesShahcement TranslatedaniketkadekarNo ratings yet

- List of Items / Equipments For Fire Truck / Fire Engine: Sr. No. Description Items IncludedDocument1 pageList of Items / Equipments For Fire Truck / Fire Engine: Sr. No. Description Items IncludedaniketkadekarNo ratings yet

- Cross Reference of Steel StandardsDocument4 pagesCross Reference of Steel StandardsNugroho Adhi SaputroNo ratings yet

- Flow Diagram - Milling Section in SugarDocument1 pageFlow Diagram - Milling Section in SugaraniketkadekarNo ratings yet

- Star15012 Gusset XLSX - Calculation WeldingDocument4 pagesStar15012 Gusset XLSX - Calculation WeldinganiketkadekarNo ratings yet

- Cross Reference of Steel StandardsDocument4 pagesCross Reference of Steel StandardsNugroho Adhi SaputroNo ratings yet

- Babcox BoilerDocument14 pagesBabcox BoilertoanbtdNo ratings yet

- Spectrum Analysis - PlotsDocument3 pagesSpectrum Analysis - PlotsaniketkadekarNo ratings yet

- Dynamic Balancing-Randall FoxDocument33 pagesDynamic Balancing-Randall FoxRicardo Zevallos CruzNo ratings yet

- Friction Loss in Pipes & ValvesDocument1 pageFriction Loss in Pipes & ValvesaniketkadekarNo ratings yet

- Surface Preparation - Write-UpDocument3 pagesSurface Preparation - Write-UpaniketkadekarNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Sound Power Determination With or Without IS09614-1: by Erik Cletus Petersen, Bruei&Kjser, DenmarkDocument2 pagesSound Power Determination With or Without IS09614-1: by Erik Cletus Petersen, Bruei&Kjser, Denmarkeng13No ratings yet

- Moment Balnce Method of BalancingDocument16 pagesMoment Balnce Method of BalancinganiketkadekarNo ratings yet

- Wheatstone BridgeDocument6 pagesWheatstone BridgeaniketkadekarNo ratings yet

- Helicopter ModelDocument1 pageHelicopter ModelaniketkadekarNo ratings yet

- Sony's Evolving HR ChallengeDocument23 pagesSony's Evolving HR ChallengeaniketkadekarNo ratings yet

- Vidhayak - 2015Document1 pageVidhayak - 2015aniketkadekarNo ratings yet

- Surface Preparation - Write-UpDocument3 pagesSurface Preparation - Write-UpaniketkadekarNo ratings yet

- 8 Tools - LeanDocument1 page8 Tools - LeananiketkadekarNo ratings yet

- H.R. Flat Bar: Astm-Aisi Thickness Tolerance RangesDocument1 pageH.R. Flat Bar: Astm-Aisi Thickness Tolerance RangesMaria Eliza Renee DominguezNo ratings yet

- NSFAS Laptop FormDocument2 pagesNSFAS Laptop FormKagiso China'män NtsaneNo ratings yet

- Orbit 60 Series System Datasheet 137M5182 PDFDocument35 pagesOrbit 60 Series System Datasheet 137M5182 PDFJuan Antonio MarinNo ratings yet

- Web Lab FileDocument34 pagesWeb Lab Filesaloniaggarwal0304No ratings yet

- Manual Skoda Octavia 1,4 55kWDocument118 pagesManual Skoda Octavia 1,4 55kWCornea Horatiu SebastianNo ratings yet

- Test Logic Insertion For Optimization of Testing Parameters On Lower Technology NodeDocument6 pagesTest Logic Insertion For Optimization of Testing Parameters On Lower Technology NodeshaguftaNo ratings yet

- Assurance Digest BCS PreliminaryDocument1,090 pagesAssurance Digest BCS Preliminaryshaheen alamNo ratings yet

- Atif CV (Architect) PKDocument2 pagesAtif CV (Architect) PKFahad0% (1)

- Dsb19 0003. 30rb Xa XW Exv Board ChangesDocument4 pagesDsb19 0003. 30rb Xa XW Exv Board Changesชัยณรงค์ เทียนบุตรNo ratings yet

- Advertising Strategies of Bajaj International Pvt. LtdDocument4 pagesAdvertising Strategies of Bajaj International Pvt. LtdFathima LibaNo ratings yet

- SCHEDULINGDocument29 pagesSCHEDULINGkishoreNo ratings yet

- Vector 750 v08 Ent m75Document262 pagesVector 750 v08 Ent m75jvega_534120No ratings yet

- Code of Ethics - UPDocument5 pagesCode of Ethics - UPhannah marvillaNo ratings yet

- STB B860HDocument17 pagesSTB B860HHardiyantoNo ratings yet

- WLC D1Document2 pagesWLC D1jvtamilanbanNo ratings yet

- Engine Driven Welders PDFDocument13 pagesEngine Driven Welders PDFLazzarus Az GunawanNo ratings yet

- Technische Daten D 2840 LE 20x-Eng4Document1 pageTechnische Daten D 2840 LE 20x-Eng4Daniel GraterolNo ratings yet

- Ipc Hdbw3841r Zas Datasheet 20210330Document4 pagesIpc Hdbw3841r Zas Datasheet 20210330gustavo saucedoNo ratings yet

- Framework Integrated IT Risk ManagementDocument8 pagesFramework Integrated IT Risk Managementluisbmwm6No ratings yet

- Solved Board Problems - Geothermal Power PlantDocument6 pagesSolved Board Problems - Geothermal Power PlantFAMY Vazzim Soriano100% (1)

- BEEE101 Basic Electrical EngineeringDocument3 pagesBEEE101 Basic Electrical EngineeringRupam KunduNo ratings yet

- Document Tracking SystemDocument13 pagesDocument Tracking SystemjertinNo ratings yet

- Monoprice Delta Mini Manual, Version 1Document20 pagesMonoprice Delta Mini Manual, Version 1Ted ThompsonNo ratings yet

- Master Architecture Thesis TopicsDocument5 pagesMaster Architecture Thesis Topicsveronicasulaimannewyork67% (3)

- Computer SecurityDocument20 pagesComputer SecurityVaiBhav AroraNo ratings yet

- SPD39T 39B6X Service Manual-01-0226 PDFDocument63 pagesSPD39T 39B6X Service Manual-01-0226 PDFAlejandroVCMXNo ratings yet

- Udyam Registration Certificate - The Lord's Family SpaDocument2 pagesUdyam Registration Certificate - The Lord's Family SpaNeekhil PareekNo ratings yet

- Encode or Decode File As MIME Base64 (RFC 1341)Document17 pagesEncode or Decode File As MIME Base64 (RFC 1341)Predrag DamnjanovićNo ratings yet

- Design and Costing of 3kW Home Solar PlantDocument2 pagesDesign and Costing of 3kW Home Solar Plant002Pradeep002No ratings yet

- PDF Service Manual Ge Healthcare Dash 2500 DLDocument71 pagesPDF Service Manual Ge Healthcare Dash 2500 DLWidassNo ratings yet

- Digitalization in HealthcareDocument2 pagesDigitalization in HealthcareAlamNo ratings yet