Professional Documents

Culture Documents

Minor Friction Losses in Pipe Fittings

Uploaded by

Edward RazorhandsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Minor Friction Losses in Pipe Fittings

Uploaded by

Edward RazorhandsCopyright:

Available Formats

Running Head: EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

FLUID MECHANICS LABORATORY

Abstract

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

The objective of this lab was to calculate minor friction losses in pipe fittings. Globe

valve, gate valve, miter, constriction, expansion and bend were used for minor losses. The

head loss calculation was done for may pipe fitting, it can be seen that nature of flow in

all fitting is turbulent as Reynolds numbers were higher than 2000. The head loss

calculations were done and it was noted that values of measured head loss are comparable

with calculated values of head loss.

Data, Theory and Results

1 | Page

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

Table 1: Dark Blue

Dark Blue

Trial

time

55.3

55.24

54.64

T avg=55.06

57.14

56.69

55.71

T avg=56.52

58.76

61.75

60.26

T avg=60.25

66.16

64.51

67.07

Tavg=65.92

74.93

73.55

75.33

T avg=74.60

Mass Flow

rate (kg/s)

U Tube mm Hg

Gate Valve

Globe Valve

0.327

0.318

0.299

0.273

Piezom.

Readings

10

370

815

10

340

750

10

305

670

10

265

565

210

450

10

0.241

Table 2. Light Blue

Trial

time

Mass

Flow rate

(kg/s)

Light Blue

U Tube mm Hg

Gate Valve

Globe Valve

Piezom. Readings

7-9--10 11--12

8

2 | Page

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

71.57

73.32

74.02

T avg=72.97

70.38

68.51

68.05

T avg=68.98

62.96

62.83

61.76

T avg=62.52

57.41

57.54

55.69

T avg=56.88

53.42

53.22

52.14

T avg=52.93

0.247

220

50

165

215

0.261

250

50

185

240

0.288

275

50

215

275

0.316

355

50

265

330

0.340

405

50

310

380

Type

5-6

8-9

11-12

Length (mm)

870

914.4

850

trail 1: Gate valve open and globe valve is closed

trail 2: Gate valve closed and globe valve is open

trail 3: Gate valve half open and globe valve fully open

Table 3: Conversion from mm-Hg to Pa

Dark Blue

U Tube mm Hg

Piezom. Readings

Gate Valve

Globe Valve

5--6

1334.16

49363.92

108734.04

1334.16

45361.44

100062

1334.16

40691.88

89388.72

3 | Page

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

1334.16

35355.24

75380.04

1334.16

28017.36

60037.2

Light Blue

Gate Valve

Globe Valve

7--8

9--10

11--12

29351.52

6670.80

0.00

22013.64

28684.44

33354.00

6670.80

0.00

24681.96

32019.84

36689.40

6670.80

0.00

28684.44

36689.40

47362.68

6670.80

0.00

35355.24

44027.28

54033.48

6670.80

0.00

41358.96

50698.08

Results:

With D = 17 mm and m1 = 0.327 kg/s,

V1 =

m1

A

m1

V1 =

D

)

4

4 | Page

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

V1 =

0.327

( 0.017 )2

1000 (

)

4

V1 = 1.44 m/s

Reynolds Number

VD

Re =

Re=

10001.440.017

1 x 103

Re = 24480

With D = 17 mm and m2 = 0.318 kg/s,

V2 =

m2

A

m2

2

V2 =

D

(

)

4

V2 =

0.318

( 0.017 )2

1000 (

)

4

V2 = 1.4 m/s

Reynolds Number

Re =

VD

Re=

10001.40.017

3

1 x 10

Re = 23800

5 | Page

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

Dark Blue Circuit

At Gate Valve with KL = 0.2

Pressure Drop @ Gate Valve

PD =

1333.16 =

KLV2

2

0.2V 21000

2

V = 0.73m/s

Reynolds Number

Re =

Re =

VD

10000.730.00919

3

1 x 10

Re = 6714

Head Loss

HL =

K LV 2

2g

2

HL =

0.2(0.73)

(29.81)

1000 mm

1m

HL = 54.4 mm

At Miter Bend with KL = 1.1

Pressure Drop @ Gate Valve

PD =

49363.92=

KLV2

2

1.1 V 21000

2

V = 9.48 m/s

Reynolds Number

Re =

Re =

VD

100014.26950.00445

1 x 103

6 | Page

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

Re = 42159

Head Loss

K LV 2

2g

HL =

HL =

1.1(9.48)

(29.81)

1000 mm

1m

= 5032 mm

Light Blue Circuit

At Globe Valve with KL = 10

Pressure Drop @ Globe Valve

PD =

KLV2

2

10 V 21000

2

29351.52 =

V = 2.43 m/s

Reynolds Number

VD

Re =

=

10002.430.01836

1 x 103

Re = 44484

Head Loss

K LV

2g

HL =

2

HL =

10 (2.43)

(29.81)

1000 mm

1m

HL = 2992 mm

At Expansion with m = 0.327 kg/s and 13.7 mm radius to 26.4 mm radius

7 | Page

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

V1 =

m

A

V2 =

m

A

m

D2

(

)

4

m

D2

(

)

4

0.327

(0.0137)2 , V1 = 2.25 m/s

1000 (

)

4

0.327

(0.0264)2 , V2 = 0.6 m/s

1000 (

)

4

Reynolds Number

V 2 D2

Re =

Re =

10000.600.0264

, Re = 15970

1 x 103

Head Loss for Expansion

V 1V 2

He =

2

2.250.60

He =

x

2

1000 mm

1m

He = 170.6 mm

At Contraction with m = 0.327kg/s and 26. 4 mm radius to 13.7 mm radius

0.327

m

m

2

2

V1 = A = ( D ) = 1000 ( (0.0264) ) , V2 = 0.6 m/s

4

4

V2 =

m

A

m

D2

(

)

4

0.327

(0.0137)2 , V1 = 2.25 m/s

1000 (

)

4

Head Loss for Contraction HL with KL = 0.23,

HL =

V2

2

KL

8 | Page

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

2.25

HL =

x

2

0.23

1000 mm

1m

HL = 59.34 mm

o

At Smooth 90 Bend with KL = 0.75

KLV2

Pressure Drop @ Smooth Bend =

2

0.75V 21000

2

51995.74 =

V = 11.78 m/s

Reynolds Number

Re =

=

VD

100011.780.017

1 x 103

Re = 200,181

Head Loss

HL =

K LV

2g

0.75(11.782)

(29.81)

HL =

1000 mm

1m

HL = 5321 mm

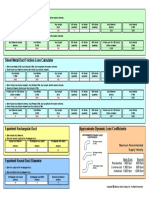

Table 4: Head loss summary

Fitting

Gate Valve

Globe Valve

Miter Bend

Sudden Expansion

Sudden Contraction

90o Smooth 152.4 mm

radius Bend

Measured Head Rise or

Loss (mm)

54.4

2992

5032

170.6

59.34

Calculated( Theoretical)

Head Rise or Loss (mm)

53.28

2968

5031.6

173.2

60.28

5321

5358.6

9 | Page

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

Table 5: Error

Fitting

Error

Gate Valve

.048%

Globe Valve

.028%

Miter Bend

0.052%

Sudden Expansion

0.01%

90 smooth

0.083%

Figure 1: Measured Head Loss vs Calculated Head Loss (mm)

f(x) = - 0x^5 + 0x^4 - 0x^3 + 0x^2 + 1.11x - 19.57

Analysis and Discussion

It can be seen that the values of measured head loss are comparable with calculated

values of head loss.

Analysis and Discussion

Conclusion

The head loss calculation was done for may pipe fitting, it can be seen that nature of flow

in all fitting is turbulent as Reynolds numbers were higher than 2000. The head loss

10 | P a g e

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

calculations were done and it was noted that values of measured head loss are comparable

with calculated values of head loss. The objective of lab was met successfully

Practical Application

Most of practical application of minor loss in fitting comes into civil engineering

and mechanical engineering. As an engineer, we must account of these losses while

designing any system where flow of fluid takes place. The miner loss calculation helps in

deciding flow capacity and pressure rating of pump used in fluid system

References

1 - lab manual

Appendix

Equations

h L=

K LV2

2g

(1)

Where, KL is the loss coefficient and is dimensionless.

For sudden contraction, the value of KL is calculated by,

K L=

(V 1 V 2)2

2g

(2)

11 | P a g e

EXPERMINT #5 MINOR FRICTION LOSSES IN PIPE FITTINGS

Reynolds Number

Re =

VD

(3)

V1 =

m1

A

(4)

12 | P a g e

You might also like

- Losses in Pipe Bends: ME 337 Fluid Mechanics LabDocument20 pagesLosses in Pipe Bends: ME 337 Fluid Mechanics LabOk SokNo ratings yet

- Experiment 9Document8 pagesExperiment 9saad_arif_10No ratings yet

- DAELIM TOYO Batangas - BONNA Technical Note 1#00 Intake HydraulicsDocument7 pagesDAELIM TOYO Batangas - BONNA Technical Note 1#00 Intake HydraulicsFerdie TolosaNo ratings yet

- Department of Petrochemical EngineeringDocument5 pagesDepartment of Petrochemical Engineeringsamir hussenNo ratings yet

- Losses in Pipe Systems and FittingsDocument15 pagesLosses in Pipe Systems and FittingsMUHAMMAD AKRAMNo ratings yet

- Flat SlabDocument19 pagesFlat SlabParamveer SinghNo ratings yet

- 32.0 M Dia Roof Design ReportDocument124 pages32.0 M Dia Roof Design ReportsndpinNo ratings yet

- Experiment 2: Internal Pipe FlowDocument13 pagesExperiment 2: Internal Pipe FlowDhanush MahendranNo ratings yet

- Friction Head Loss in PipesDocument9 pagesFriction Head Loss in PipesnattydreadfathelahNo ratings yet

- Discharge Capacity CheckDocument14 pagesDischarge Capacity CheckkolioskiNo ratings yet

- Orifice CalculationsDocument23 pagesOrifice CalculationsYatish Kumar Jain0% (1)

- Parafusos PT SemblexDocument10 pagesParafusos PT SemblexSBonderNo ratings yet

- 13 API Power-Law ModelDocument44 pages13 API Power-Law Modeltotos20No ratings yet

- Elbow and Bend Fluid Mechanics ReportDocument13 pagesElbow and Bend Fluid Mechanics ReportPira CsonNo ratings yet

- Case Study To Find Tank Bulging, Radial Growth and Tank Settlement Using API 650Document15 pagesCase Study To Find Tank Bulging, Radial Growth and Tank Settlement Using API 650Jafer SayedNo ratings yet

- Mold Engineering - How To Calculate The Pressure Drop Through An OrificeDocument3 pagesMold Engineering - How To Calculate The Pressure Drop Through An OrificeCicel JaimaniNo ratings yet

- Calculations For Rectangular Storage TankDocument44 pagesCalculations For Rectangular Storage TankSiva ShankarNo ratings yet

- Head Loss in PipeDocument14 pagesHead Loss in PipeMoontarij JahanNo ratings yet

- Duct Static Loss CalculationDocument8 pagesDuct Static Loss CalculationYe Thiha Min100% (2)

- Design of Steel I-Section (BS5950)Document6 pagesDesign of Steel I-Section (BS5950)Rachelle C. Abanes50% (4)

- 6000m3 VST DesignDocument17 pages6000m3 VST Designjohney2No ratings yet

- DMK RP 3 - 4 - 2Document6 pagesDMK RP 3 - 4 - 2Vlad Stefan CristianNo ratings yet

- Lab Report 1 Major and Minor LossDocument10 pagesLab Report 1 Major and Minor LossEskiasNo ratings yet

- External Metal LouvresDocument28 pagesExternal Metal LouvresQuitzs QuitzsNo ratings yet

- Design of Heat ExchangerDocument26 pagesDesign of Heat ExchangerSatish YadavNo ratings yet

- Losses in Pipe FittingDocument8 pagesLosses in Pipe FittingjhalakNo ratings yet

- Ductulator May 2010Document10 pagesDuctulator May 2010Arshavin Watashi WaNo ratings yet

- Lab Report Fluid 2Document15 pagesLab Report Fluid 2Mariam DalloulNo ratings yet

- Barringer Corrosion With Gumbel Lower PDFDocument22 pagesBarringer Corrosion With Gumbel Lower PDFRaman AuarNo ratings yet

- Thumb Rules Xls For Chemical EngineerDocument44 pagesThumb Rules Xls For Chemical EngineershashibagewadiNo ratings yet

- 8645 enDocument2 pages8645 enhoangmy0106No ratings yet

- Thumb Rules For Chemical EngineerDocument44 pagesThumb Rules For Chemical EngineerNallathambiNo ratings yet

- Ductulator May 2010Document8 pagesDuctulator May 2010haroub_nasNo ratings yet

- Group-2: Che F312 Chemical Engineering Lab Experiment-5Document8 pagesGroup-2: Che F312 Chemical Engineering Lab Experiment-5Prateek MantriNo ratings yet

- FLOWDocument7 pagesFLOWKaren AtallahNo ratings yet

- Fluid Friction (AHMAD OLIMAT)Document7 pagesFluid Friction (AHMAD OLIMAT)saleem tuhaimerNo ratings yet

- UGNA3023 Report 1Document12 pagesUGNA3023 Report 1Shawn OngNo ratings yet

- Merlin Gerin Medium VoltageDocument10 pagesMerlin Gerin Medium VoltagekjfenNo ratings yet

- G Pluvinage, J.Capelle, C. Schmitt and M. MouwakehDocument8 pagesG Pluvinage, J.Capelle, C. Schmitt and M. MouwakehPeter IyereNo ratings yet

- Drilling HydraulicDocument52 pagesDrilling HydraulicHeris Sitompul100% (1)

- Piping Design Quick Reference CardDocument3 pagesPiping Design Quick Reference CardPiping_SpecialistNo ratings yet

- 13 - Pipe Sizing Example 10Document4 pages13 - Pipe Sizing Example 10staryklt100% (1)

- Case Study To Find Tank Nozzle Stiffness, Flexibility and Allowable Loads by API650 Using PASS START PROFDocument15 pagesCase Study To Find Tank Nozzle Stiffness, Flexibility and Allowable Loads by API650 Using PASS START PROFJafer SayedNo ratings yet

- 1n21 25 Microwave Mixer DiodesDocument8 pages1n21 25 Microwave Mixer DiodesCristian PaitasNo ratings yet

- Pipe Sizing Tabulation Sheet EdtDocument9 pagesPipe Sizing Tabulation Sheet EdtmaxmorekNo ratings yet

- LAB 3.1 - Determination of Headloss in PipesDocument7 pagesLAB 3.1 - Determination of Headloss in PipesNur QuraishaNo ratings yet

- DruckluftkesselDocument3 pagesDruckluftkesselVictor Hugo Rodriguez CelyNo ratings yet

- 08 Roof Hoods Ads PDFDocument34 pages08 Roof Hoods Ads PDFkasztakatikaNo ratings yet

- Viscous Flow in Pipes: CEE 331 Fluid Mechanics March 11, 2014Document40 pagesViscous Flow in Pipes: CEE 331 Fluid Mechanics March 11, 2014Paulo BuenoNo ratings yet

- EN6114Document14 pagesEN6114akayirNo ratings yet

- Pipes For Civi and Industrial Installations OK PDFDocument24 pagesPipes For Civi and Industrial Installations OK PDFBruno ReisNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Air Ducting CompleteDocument133 pagesAir Ducting CompleteEdward RazorhandsNo ratings yet

- AllenDocument2 pagesAllenEdward RazorhandsNo ratings yet

- LECTURE 1-Centroids and The Moment of InertiaDocument4 pagesLECTURE 1-Centroids and The Moment of InertiaKent PicatoNo ratings yet

- Entropy ChangeDocument13 pagesEntropy ChangeAhmedAmer1No ratings yet

- Pipe Sizing FinalDocument2 pagesPipe Sizing FinalEdward RazorhandsNo ratings yet

- Energy Conservation GuidelinesDocument102 pagesEnergy Conservation GuidelinesEdward RazorhandsNo ratings yet

- Ahu Supermrket and Dept Store ClculationsfinalDocument50 pagesAhu Supermrket and Dept Store ClculationsfinalEdward RazorhandsNo ratings yet

- Thermodynamics Homework FinalDocument4 pagesThermodynamics Homework FinalEdward RazorhandsNo ratings yet

- Analytical Fundamentals2Document6 pagesAnalytical Fundamentals2Eric JohnsonNo ratings yet

- Entropy ChangeDocument13 pagesEntropy ChangeAhmedAmer1No ratings yet

- Chapter 1Document5 pagesChapter 1Edward RazorhandsNo ratings yet

- Machine FoundationDocument12 pagesMachine FoundationEdward Razorhands100% (1)

- EnergyDocument11 pagesEnergyEdward RazorhandsNo ratings yet

- Ahu Supermrket and Dept Store ClculationsfinalDocument50 pagesAhu Supermrket and Dept Store ClculationsfinalEdward RazorhandsNo ratings yet

- Hardness-Test Lab FinaDocument5 pagesHardness-Test Lab FinaEdward RazorhandsNo ratings yet

- AHU Calculations 3rd FloorDocument14 pagesAHU Calculations 3rd FloorEdward RazorhandsNo ratings yet

- Fan Horse Power Computation From: Trane Air Conditioning Manual Brake PowerDocument2 pagesFan Horse Power Computation From: Trane Air Conditioning Manual Brake PowerEdward RazorhandsNo ratings yet

- 16 - WavesDocument15 pages16 - WavesEdward RazorhandsNo ratings yet

- Ahu CalculationsDocument16 pagesAhu CalculationsEdward RazorhandsNo ratings yet

- Pipe Sizing FinalDocument2 pagesPipe Sizing FinalEdward RazorhandsNo ratings yet

- Power TheoremDocument14 pagesPower TheoremEdward RazorhandsNo ratings yet

- Tangent and SecantsDocument6 pagesTangent and SecantsEdward RazorhandsNo ratings yet

- Air Ducting CompleteDocument133 pagesAir Ducting CompleteEdward RazorhandsNo ratings yet

- ME 556 Solar Energy Conversion Lecture 1Document19 pagesME 556 Solar Energy Conversion Lecture 1Edward Razorhands100% (1)

- Lab Mechanical and DataDocument7 pagesLab Mechanical and DataEdward RazorhandsNo ratings yet

- CH 16Document15 pagesCH 16Khasan MustofaNo ratings yet

- Lecture3 Cir AnalysisDocument11 pagesLecture3 Cir AnalysisDani SomiNo ratings yet

- Review ProblemsDocument3 pagesReview ProblemsEdward RazorhandsNo ratings yet

- Thermal Spray ProcessDocument11 pagesThermal Spray ProcessAshok Kumar100% (1)

- Demand of Pharmaceutical Facility Functionality - Validation and Qualification of HVAC SystemDocument17 pagesDemand of Pharmaceutical Facility Functionality - Validation and Qualification of HVAC Systemraju1559405No ratings yet

- Fluid Mechanics and Hydraulics 4th EditionDocument285 pagesFluid Mechanics and Hydraulics 4th EditionZachary Angelo Gustav100% (1)

- EtaNorm Curva SDocument174 pagesEtaNorm Curva Sseht94No ratings yet

- Mechanics of Materials - Poisson's RatioDocument11 pagesMechanics of Materials - Poisson's RatioDavid Clark100% (5)

- Abstract-This Experiment Is To Examine The Time DomainDocument1 pageAbstract-This Experiment Is To Examine The Time DomainSajjad AhmedNo ratings yet

- Duct CalculationDocument1 pageDuct CalculationDan Nugraha100% (1)

- Design of - ESR (200KL)Document33 pagesDesign of - ESR (200KL)sanju middya100% (1)

- Numerical Unit1Document3 pagesNumerical Unit1Ayush DubeyNo ratings yet

- Sound Energy and Doppler EffectDocument2 pagesSound Energy and Doppler EffectVera MaureenNo ratings yet

- Reflections On Magnetohydrodynamics: WWW - Moffatt.tcDocument45 pagesReflections On Magnetohydrodynamics: WWW - Moffatt.tcbasharatNo ratings yet

- Reservoir Eng Labsheet - 2019Document39 pagesReservoir Eng Labsheet - 2019Albert ChongNo ratings yet

- Turbulent Zero Pressure Gradient Flat Plate - simpleFOAMDocument11 pagesTurbulent Zero Pressure Gradient Flat Plate - simpleFOAMPAVAN KUMARNo ratings yet

- Definitions - Topic 4 Mechanics and Materials - AQA Physics A-LevelDocument3 pagesDefinitions - Topic 4 Mechanics and Materials - AQA Physics A-LevelLaud FumhandaNo ratings yet

- Bolted Connections LectureDocument65 pagesBolted Connections Lecturerghazzaoui1793100% (1)

- Gas - in - Place - A - Volumetrics - I. KocabasDocument31 pagesGas - in - Place - A - Volumetrics - I. KocabasTadeo ChoqueNo ratings yet

- The Siphon: Physics EducationDocument6 pagesThe Siphon: Physics EducationJuan Sebastian MartínezNo ratings yet

- 5 CorrosionDocument67 pages5 CorrosiongnanasekarNo ratings yet

- Utkarshgupta Class 11a Physics Ch9 PresentationDocument46 pagesUtkarshgupta Class 11a Physics Ch9 PresentationRishabh GuptaNo ratings yet

- BS en Iso 13503-1-2011Document32 pagesBS en Iso 13503-1-2011Олег СоловьевNo ratings yet

- Lec-34,35-36 Effectiveness NTU MethodDocument33 pagesLec-34,35-36 Effectiveness NTU MethodMazhar aliNo ratings yet

- Heat Exchanger DesignDocument15 pagesHeat Exchanger DesignCharito Sollera AlbaricoNo ratings yet

- Yang 2019Document11 pagesYang 2019Djaouadi amirNo ratings yet

- Experiment Number 2 Coffee Cup CalorimetryDocument7 pagesExperiment Number 2 Coffee Cup Calorimetryapi-529605052No ratings yet

- Manual Ast 24uw4sdbtg10 1Document96 pagesManual Ast 24uw4sdbtg10 1pacoNo ratings yet

- CBB 2024 Chapter 4-Second Law of Thermo V2Document90 pagesCBB 2024 Chapter 4-Second Law of Thermo V2Ameer Muhammad100% (1)

- Answerkey FullTest2 SankalpEducationDocument16 pagesAnswerkey FullTest2 SankalpEducationDkNo ratings yet

- Shear Force and Bending MomentDocument3 pagesShear Force and Bending MomentDej AdmasuNo ratings yet

- Ch.1-Matter in Our Surroundings 9th SolvedDocument50 pagesCh.1-Matter in Our Surroundings 9th SolvedVikash SharmaNo ratings yet

- James Clerk Maxwell - Theory of HeatDocument351 pagesJames Clerk Maxwell - Theory of HeatpajorocNo ratings yet