Professional Documents

Culture Documents

Radome Test System

Uploaded by

Interogator5Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Radome Test System

Uploaded by

Interogator5Copyright:

Available Formats

Low Cost, Automated, RTCA/DO-213 Compliant - Radome Test System

John Wilber

MI Technologies

1125 Satellite Boulevard, Suite 100

Suwanee, GA 30024 USA

Abstract

The commercial aviation industry faces several

issues in regard to servicing and maintaining the

radomes that abound in the aircraft fleet flying

today. The first issue is the historically high cost

of radome test systems. As a result of this, there

are limited numbers of test systems in operation

today and some geographic regions have

insufficient radome test capacity. Advances in

weather radar and increased reliance on them for

turbulence avoidance and more efficient route

planning around storm systems will increase the

importance of ensuring that weather radar

systems are performing well and consequently

that weather radar radomes are in good condition

and have been adequately tested. Because of the

potential consequence of flying with a bad radome

and the demands of new radar systems, its more

important than ever to ensure test systems in use

adhere to requirements and to spread awareness

of these challenges within the aviation

community.

Recently, a design effort was conducted

specifically geared towards developing a system

concept for radome testing that would both

provide a robust test capability that fully meets

the RTCA-DO-213 after repair test requirements

and one that is much lower in cost than traditional

systems that are fielded today. This paper

describes the issues cited above and provides a

description of the low cost - compliant solution

Keywords: Low Cost Radome Measurement

System, Radome Measurements, RTCA/DO-213

1. Introduction

The term radome originated as a contraction of the

term radar dome the covering over a radar antenna

to protect it from environmental elements.

Presumably, the presence of the radome does not

prevent the radar from operating satisfactorily. The

Page 1 of 6

radome as part of the radar system is an

electromagnetic window, tuned to the operating

frequencies of the radar equipment within the radome.

When the radar is mounted on an aircraft the radome

surface typically serves additionally as an

aerodynamic surface, integrated into the design of the

airframe. Now that radar deployment has become

commonplace, the performance characteristics of

radomes have often been taken for granted by all but

the experts specialized in antenna design. [1]

Today, all commercial aircraft and many general

aviation aircraft carry weather avoidance radar

systems. The major parts of the aircraft weather radar

system

consist

of

the

radar

antenna,

transmitter/receiver, display, antenna positioning

system and critical to the operation of the aircraft and

weather system, the radome.

2. Commercial Weather Radome Testing

Testing of commercial weather radomes is controlled

by the Federal Aviation Administration (FAA) and is

documented in:

RTCA/DO-213,

Minimum

Operational

Performance Standards for Nose-Mounted

Radomes (commonly referred to as DO-213)

This specification was originally developed by the

Radio Technical Commission for Aeronautics (RTCA)

in response to the development of predictive

windshear weather radar systems. This document

specifies the tests to perform on both new and

repaired radomes. Testing for repaired radomes is

normally limited to Transmission Efficiency (TE) only.

New production radomes are additionally tested for

side lobe level and qualification testing further adds

requirements for incident reflection, beam width and

beam deflection.

Certain radar systems may require higher

performance from the radome to achieve the desired

system performance. Therefore, DO-213 defines

several radome classes as a function of TE to

accommodate system requirements in aircraft

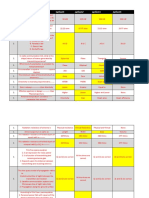

installations. The classes of radomes are shown in

Table 1.

Class A

Class B

Class C

Class D

Class E

Transmission Efficiency

Average

Minimum

90%

85%

87%

82%

84%

78%

80%

75%

70%

55%

facility because the local facilities do not have radome

test capability.

Alternatively, increasing spare

radomes in stock can be done, but this is expensive.

If there is no spare radome available, then the aircraft

remains grounded until the radome is repaired. If the

distance to a facility that can do the repair is

significant, then the amount of time the aircraft is

grounded increases. As air travel has become routine

and has permeated all areas of the world, the demand

for after repair radome test has outgrown current

capacity and there is a need for a low cost yet

accurate and compliant test solution.

3.2. An improperly repaired radome

degrades the radar performance

Table 1 DO-213 radome class by TE level

Design and manufacturing of radomes is done by a

specialized segment of the aviation industry and there

is a good understanding and test practice within that

segment. Repair of radomes is often performed by

organizations with less understanding of the function

and importance of the radome and with less skill to

repair and test it properly. Often these organizations

are aircraft composite and structural repair

organizations and their expertise is in repairing

aircraft. Thus they have a lot of mechanical and

aircraft expertise, but often do not have the requisite

RF or electromagnetic expertise.

The causes of degradation of a radomes electrical

performance that will result in a need to repair the

radome are rain erosion, impact damage (hail, bird

strikes, and ground equipment), lightning strike

damage and static burns. Especially during the

thunderstorm season, damage and the need for repair

is frequent and common. [2]

3. The importance of radome testing

A damaged or improperly repaired radome can cause

signal attenuation, refraction or distortion of the main

beam. As a result, the radar can have reduced range

from signal loss, underestimate the severity of

weather, paint false or inaccurate returns of weather

(i.e. a line of thunderstorms directly ahead may

appear to be off to the left or right), or have improper

windshear

avoidance

performance.

Proper

maintenance and repair of the radome is critical to

achieve maximum signal strength from the radar

transmitter. It is very important to avoid putting more

coatings on than are necessary. A large buildup of

coatings will cause a loss of radar signal strength

through the radome itself.

One reputable FAA repair station reports, that they

see a lot of improper repairs that have been made on

radomes. These can include: using incorrect

materials, applying the materials incorrectly, not

controlling the thickness correctly or allowing moisture

to remain in the radome. [3]

3.1. Lack of test capacity can ground an

aircraft

3.3. Modern radars transmit less power

and rely more on good radome TE

MI Technologies receives many requests per year

from companies that serve the aviation industry, most

of them in some sort of parts fabrication or repair

activity. A lot of them are composite repair houses

that repair any component of the aircraft made from

composite materials. Commonly, there is one notable

exception to their capability and that is the ability to

repair the composite radome for the weather radar

which is a high dollar value item for which there are

limited spares. Due to the historically high cost to

establish radome test capability, many facilities cannot

afford the investment.

Weather

radar

performance

has

improved

dramatically in the last decade with multiple suppliers

developing and producing new generation devices.

State-of-the-art

electronic

and

processing

technologies provide operational convenience and

features to the General Aviation community that was

previously available only to large air transport aircraft.

Now these new radars are both being installed on new

airframes and also being retrofitted onto older aircraft.

As a result of this, a common scenario is that an

aircraft can be grounded somewhere while the

radome has to be shipped to a more distant repair

Page 2 of 6

However, as the components and processing have

improved, another trend has been reduced transmit

power. While this is very beneficial for the airframe

and reduces the amount of power it has to supply to

the radar, it also means that the radar is more

susceptible to performance degradation due to

attenuation and the radome is a key source of

attenuation. Thus the radome TE test is more critical

with these newer systems. A recent incident as

reported in Aviation International News (AIN)

highlights the potential issue: a poor radome can

create. It was found that about 150 aircraft were fitted

with modern radar, but the radome performance was

not upgraded and its design dated to a time of higher

power weather radars. As a result, there were multiple

cases where experienced flight crews flew into

dangerous weather because it did not show up on the

radar screen. After investigation it was determined

that the radome TE was inadequate for the newer,

lower power radars. [4]

3.4. Turbulence avoidance and route

planning are increasing the importance

of

accurate

weather

radar

performance

Sudden and unexpected severe turbulence is not that

uncommon and has injured countless passengers and

flight crew including some fatalities. It is estimated that

airlines are facing greater that $100 million in

turbulence-related costs annually, according to the

U.S. Department of Transportation and the Federal

Aviation Administration (FAA). One key technology to

aid the situation is called the Enhanced Turbulence

(E-Turb) Mode Radar. This technology is a software

signal-processing upgrade to existing predictive

Doppler wind shear systems that are already on

airplanes. With it the aircrafts radar can provide flight

crews advance warning of turbulence, so that they

can avoid it altogether and keep themselves and their

passengers out of harms way. [5]

through gaps in storms, the importance of the weather

radar operating properly and thus having a good

radome is increased.

4. Key Requirements of RTCA/DO-213

The key requirements

summarized below:

Regions of adverse weather such as convective

activity, clear air turbulence, or mountain wave

activity, can effectively close off regions of airspace to

traffic. Without direct knowledge of the location and

severity of the turbulence, the restricted region may

be larger than necessary, placing an undue cost and

disruptive burden on controllers, operators, and the

traveling public. With forecasts of significant increases

in the demand for air travel over the next 20 years,

these capacity constraints appear likely only to

worsen with time. In such an environment, blocking

airspace in accordance with current practices on bad

weather days will not be a viable strategy. To keep the

system going, it is only natural that air traffic decision

makers will need to route more aircraft in closer

proximity to areas of weather currently deemed as

hazardous. Better tools to identify and pinpoint areas

of actual hazard will therefore be needed to safely

negotiate these weather systems. E-Turb will be a

contributor. [6]

As the industry relies more on the weather radar both

to avoid turbulence and to fly in closer to storms and

Page 3 of 6

of

RTCA/DO-213

are

Transmission efficiency is measured one way

through the radome. It is the amount of power

being passed completely through the radome

in the direction the radar main beam is

pointed compared to the amount of power

traveling the same path with the radome

removed.

The radome/antenna positioner must locate

the test antenna within the radome at the

same location as used in the aircraft

installation.

Gimbal sequence shall consider the order of

the actual antenna system in the aircraft

installation.

For indoor ranges, the minimum range

distance R, between the signal source and

2

receiving antenna shall be determined by D /2

where D is the diameter of the largest

antenna and is the free space wavelength at

the test frequency.

The test antenna must have the same size

and polarization with beamwidth and

sidelobes equal to or better than the antenna

for which the radome has been certified to

operate.

Good RF stability is required.

This is

established

by

measuring

the

RF

repeatability. DO-213 requires system level

repeatability of +/-2% power or less than +/0.08 dB throughout the span of a radome test.

Data is taken at the following antenna gimbal

angle orientations:

o For El Angles: 0, +/-10, and +/-20 or

+/-25 degrees

o For Az Angles 0, +/-20, +/-40, +/-60,

and +/-80 degrees

wave tuning is utilized and measurements

are taken at max power and min power.

These are then averaged together to minimize

the affects of standing waves between the test

and system antennas. [2]

Based on the current state of the radome test

environment in the commercial aircraft industry today

coupled with the increasing need for good radomes

and accurate test, as described above, MI

Technologies undertook an effort to develop a low

cost, high quality and accurate radome test system

that fully meets the requirements for DO-213 after

repair testing. The resulting solution is robust and

sets a new threshold in affordability.

5. Design Aspects

There are three fundamental approaches that could

be considered for the system, compact range, near

field and far field. The compact range can provide

excellent results and can be set up without requiring

as much facility space; however, you have the added

cost of the reflector to consider which is not required

for the far field system. The near field approach can

also provide excellent results, but because

significantly more data has to be taken to make the

necessary measurements, test time on a per radome

basis will be significantly longer than either compact

range or far field and this is not suitable for a large

aircraft repair facility that is handling significant

quantities or radomes. The far field range is very

affordable, provides excellent results and lends itself

to automation and ease of use. For this reason, a far

field approach was chosen.

5.1. Radome Test Range Design

The radome test range design is shown in Figure 1.

The size of the test room was determined by

considering the range length as well as providing

adequate room for the positioner and radome

handling space. The example shown below will test

radome up to and including the Boeing 747 radome.

The room dimensions are nominally 5.5 M height x 5.5

M width x 14.5M Length (18' H x 18'W x 48' L). The

range antenna and the system antenna are precisely

and permanently aligned with each other and do not

move during the measurements.

The range antenna is transmitting and all testing is

performed at the single frequency of operation of the

weather radar which is typically within 9.3 to 9.5 GHz.

A narrow band filter is used on the input of the

measurement device to filter out any out of band

signals.

Because the two directive antennas stay precisely

aligned to each other throughout the test and because

the filtering rejects any out of band signals, the

measurement is largely impervious to off axis or out of

band stray signals. As a result of this, the

requirements for the test room are significantly

reduced. Provided that there is not a significant

source of in band stray radiation near by, a full fledged

shielded anechoic chamber is not required. Eight (8)

inch absorber is only needed on the end walls to

knock down potential mutual coupling.

Figure 1 Radome Test Range Design

5.2. Positioning System

The overall positioning system is comprised of three

positioner subsystems; the radome test positioner, the

system antenna positioner and the range antenna

positioner. A transmit source antenna (range antenna

which illuminates the radome and system antenna) is

mounted to the range antenna positioner located at

the far end of the range. The radome test positioner

supports and rotates the radome about a fixed

antenna (system antenna) located inside the radome.

The system antenna receives the transmitted signal

and is supported by the system antenna positioner.

The individual positioner subsystems, and their

orientation to each other, are illustrated in Figure 1.

The range antenna is mounted on a fixed post that

does not move after it is precisely aligned with the

range axis. The range antenna positioner incorporates

a linear slide that allows the range length to be varied

between two predefined locations typically one quarter

wavelength apart. The system antenna is mounted on

a fixed boom over post and does not move after it is

precisely aligned with the range axis.

The radome positioner and system antenna positioner

are shown in Figure 2. The radome positioner is a roll

over azimuth configuration. This configuration can

simulate either the az over el or el over az gimbal

configuration of the radar system in a single

positioner. The antenna boom enters radome aperture

at an angle. This coupled with the roll over azimuth

configuration provides maximum azimuth travel to all

areas of the radome without interference with the

antenna boom. The antenna boom contains pressure

sensitive

collision

avoidance

features

that

automatically disconnect power to the motor is a

collision is imminent.

Both radome roll and az axes utilize tape encoders

and achieve the following specifications:

Page 4 of 6

Position accuracy

0.5

Repeatability 0.1

Velocity 0.75 RPM

Radome capacity 300 pounds

The overall layout is simple, inexpensive and yet very

rigid and accurate. There are no moving RF cables

which significantly reduces errors caused by flexing

cables. The large radome roll ring when coupled with

radome mounting adapters allows both very small and

very large radomes to be tested on the same

positioner. The large azimuth rail provides much

better stiffness and stability than a smaller azimuth

stage couple with an offset arm. Additionally, the

vertical load is transferred directly into the rail. Both

radome roll and lower az axes are implemented

without the use of large bearings significantly reducing

cost. The az axis is very low profile providing better

range RF performance and increased volume for

radome handling during load and unload operations.

The axis alignment and stability is such that the

roll/azimuth intersection is stable to within a sphere

of 0.64 cm (0.25) diameter

specific software modules include the MI-3047

Radome software coupled with the basic acquisition

and analysis software which provides capabilities to

perform radome acquisition and analysis. The

analysis functions available far exceed the TE

requirements of DO-213 and also include beam

deflection, boresight error and sidelobe levels. DO213 specifications and parameters can be easily

applied as thresholds to the measurement results.

Custom thresholds are also supported. Additionally,

measured radome results can be plotted over the

radome surface, see example in Figure 4, to help

repair personnel quickly isolate the damaged portion

of the radome.

Figure 3 Control and Instrumentation Diagram

Figure 2 Radome and System Antenna Positioner

5.3. Control and Instrumentation

The control and instrumentation approach are shown

in Figure 3. Control and instrumentation includes

position control, RF instrumentation and control and

processing software. The heart of the system is the

the MI-3003 Data Acquisition and Analysis

Workstation. The MI-3003 provides state of the art

control of antenna, microwave component, radome

and RCS measurement equipment. When coupled

with the MI-3000 Family of software packages it

supports highly efficient range operations, data

management, data presentation and analysis. The

Page 5 of 6

Figure 4 Radome Test Results Plotted over Radome

Surface

The RF system is based around a commercially

available precision dual channel power meter. Modern

power meters have excellent linearity and stability. To

this a narrow - band pass filter tuned to the weather

radar single frequency is added eliminating out of

band noise sources. One channel is used for the

radiated signal, the second channel is used as a

reference channel and is cabled directly to the source

so that drift can be eliminated by ratioing the radiatied

channel with the reference channel in post

processing. Use of the power meter is considerably

less expensive than a tradition VNA or Receiver

approach. The RF source is a single frequency

synthesized source module. To keep the cost low,

there is no control panel or display and control over

the module is provided through the MI-3003 Data

Acquisition and Analysis Workstation. The control

interface is limited to RF on and RF off commands.

Position Control functions are handled with the MI-710

Position Controller. This state of the art positioner

controller integrates all control functions and the

power amplifiers for the motors into a single package

that is significantly less expensive than the prior

generation of controllers that involved separate control

and power amplifier boxes and the associated cabling

between the units. Traditional data collection strategy

for measurements is to perform a step and scan

operation. This method moves a particular axis while

holding all other axes in a fixed location. The MI-710

allows coordinated motion where in the radome roll

and lower azimuth axes are moved together in a

synchronized arrangement during the measurement

so that a desired relationship among the axes

position is maintained while the axes are in motion.

This relationship is defined so that the radome passes

through the measurement points and the data is taken

during a continuous scan. This significantly reduces

test time and test expense. Further, if polarization

sensitive radomes are to be tested, the coordinated

motion feature allows an easy upgrade with range and

system antenna roll positioners to maintain

radome/antenna polarization orientation during scans.

The control and measurement system is greatly

simplified and designed specifically to do the TE

measurement. It has minimal components and the

cabling and all control is over robust and straight

forward Ethernet interfaces. The system has a built in

scripting function and testing can be fully automated.

With upgrade kits the system can easily be upgraded

to also do production and qualification testing.

6. Summary

Limited radome test capacity as a result of the

historically high cost of test systems can result in the

grounding of aircraft while a radome is shipped to a

remote site for repair and test. Additionally, the

importance of radome test is growing because

Page 6 of 6

modern weather radars often transmit lower power,

and good radar performance is becoming more

important as it is used increasingly for avoiding

turbulence and for more efficient route planning that

may take aircraft closer in to potentially severe

weather.

MI Technologies has developed a simple, cost

effective Radome test system that is fully compliant

with the after repair test requirements of RTCA/DO213 to address this need.

References:

[1] Electromagnetic Radome Measurements: A review

of Automated Systems, D. Hess, R. Luna, J.

McKenna. AMTA Proceedings

[2] RTCA/DO-213, RTCA Incorporated, Minimum

Operational Performance Standard for Nose-Mounted

Radomes (Authors: Many)

[3] Radome Repair, Atlanta Aerospace Composites

Web-site June 30, 2011

[4] Aviation International News, Flaws cited in Hawker

weather-radar radome, David A. Lombardo, August 1,

2003

[5] NASA, Office of the Chief Technologies, Steering

Aircraft Clear of Choppy Air, Spinoff 2006

[6] Using Airborne Turbulence Detection & Reporting

Technologies to Increase Airspace Utilization,

AeroTech Research, Inc., Paul A. Robinson, July

2005

You might also like

- Mil R 7705BDocument33 pagesMil R 7705BArmando CastellóNo ratings yet

- 03-2radar System Design ExampleDocument40 pages03-2radar System Design Exampleehsan1985No ratings yet

- FAA PS-ANM-25-17 Structural Certification Criteria For Antennas, Radomes Other External ModificationsDocument8 pagesFAA PS-ANM-25-17 Structural Certification Criteria For Antennas, Radomes Other External Modificationsayhun100% (1)

- Design and Analysis of Different Types of Aircraft Radome IJERTCONV3IS26038 PDFDocument5 pagesDesign and Analysis of Different Types of Aircraft Radome IJERTCONV3IS26038 PDFudaykumar8995No ratings yet

- Information Letter 205-03-33 212-03-53 UH-1H-II-03-16: A Subsidiary of Textron, IncDocument4 pagesInformation Letter 205-03-33 212-03-53 UH-1H-II-03-16: A Subsidiary of Textron, IncAli SyahbanaNo ratings yet

- DTA Guidelines For Antenna InstallationsDocument60 pagesDTA Guidelines For Antenna InstallationsivanfernandorodriguezNo ratings yet

- FMS Out-Of Cycle Update WMM 2019 Sl2896Document6 pagesFMS Out-Of Cycle Update WMM 2019 Sl2896Nerd Help.meNo ratings yet

- Sae Arp 5483-8 2002 (En) PDFDocument9 pagesSae Arp 5483-8 2002 (En) PDFWilliam LooNo ratings yet

- Australia AWB 34-008 PDFDocument11 pagesAustralia AWB 34-008 PDFdevriesenNo ratings yet

- Technical Publications UpdatedDocument26 pagesTechnical Publications UpdatedBruno100% (1)

- Ac 21-99Document399 pagesAc 21-99georgeclima4103100% (2)

- Good 5989-7575en - Radar MeasurementsDocument88 pagesGood 5989-7575en - Radar MeasurementspablocotanNo ratings yet

- How Electric Bonding WorksDocument10 pagesHow Electric Bonding WorksAMIYA SHANKAR PANDANo ratings yet

- FOIM 2019 03 Engine-Cool-down-time Issue 2Document8 pagesFOIM 2019 03 Engine-Cool-down-time Issue 2ralfair16No ratings yet

- PING-2020 ADS-B Transceiver: VerviewDocument2 pagesPING-2020 ADS-B Transceiver: VerviewshombisNo ratings yet

- 412 MM CH04Document16 pages412 MM CH04Hugo GonzalezNo ratings yet

- Avionics Question Bank and NotesDocument10 pagesAvionics Question Bank and NotesFaisal Muhammed MavathuNo ratings yet

- Aeroflex IFR6000 Test Set Operations Manual 6093Document258 pagesAeroflex IFR6000 Test Set Operations Manual 6093chrismosf100% (1)

- An Ultra-High Bypass Ratio Turbofan Engine For The Future PDFDocument40 pagesAn Ultra-High Bypass Ratio Turbofan Engine For The Future PDFFranzAnzuresFroitzheimNo ratings yet

- Makila - Sale Brochure PDFDocument2 pagesMakila - Sale Brochure PDFArisatya Patria TahtaNo ratings yet

- CT 196796 PDFDocument8 pagesCT 196796 PDFrsahu_36No ratings yet

- ASBAS350630009ENR2ERRDocument14 pagesASBAS350630009ENR2ERRBruno Alonso PachecoNo ratings yet

- Annex II AMC 20-136Document23 pagesAnnex II AMC 20-136philip00165No ratings yet

- WX 10 Stormscope ManualDocument3 pagesWX 10 Stormscope Manualalex castro0% (1)

- Aircraft Electric Equipment Selection and Installation StandardsDocument26 pagesAircraft Electric Equipment Selection and Installation StandardsqingtaoNo ratings yet

- Hoist GOODRICH 42325-R - Plaquette InfoDocument2 pagesHoist GOODRICH 42325-R - Plaquette InfoGmeweb GmeNo ratings yet

- Avidyne MFD Cirrus Transition CourseDocument83 pagesAvidyne MFD Cirrus Transition CourseEngr Rana Ali Safian100% (1)

- 2020 Price List Rev 1Document93 pages2020 Price List Rev 1Emc ComponentesNo ratings yet

- P-3 HF Antenna UpgradeDocument1 pageP-3 HF Antenna UpgradeLeon LellaNo ratings yet

- FASTprop Propeller De-Icers ASB-30-60-00-1Document6 pagesFASTprop Propeller De-Icers ASB-30-60-00-1Jetwill, C.A. Control de CalidadNo ratings yet

- Flutter TestDocument26 pagesFlutter TestYvessNo ratings yet

- Pneumatic Deicing BootsDocument160 pagesPneumatic Deicing BootsAlican AkkayaNo ratings yet

- DO-160G Section 21 1Document1 pageDO-160G Section 21 1JizzPontesNo ratings yet

- Tecnam P2008JC - 2000H NDT InspectionDocument4 pagesTecnam P2008JC - 2000H NDT Inspectionsaitoc marian saitoc100% (1)

- Bollettino Tecnico: The Technical Content of This Document Is Approved Under The Authority of DOA Nr. EASA.21J.005Document33 pagesBollettino Tecnico: The Technical Content of This Document Is Approved Under The Authority of DOA Nr. EASA.21J.005nandapassosNo ratings yet

- BOSE - Data Sheet For Model A20 - Aviation Headset - APAC - Email - 2019 PDFDocument16 pagesBOSE - Data Sheet For Model A20 - Aviation Headset - APAC - Email - 2019 PDFHanh Trung Nguyen DucNo ratings yet

- Model A-30 Altitude Digitizer Operation Manual Installation ManualDocument6 pagesModel A-30 Altitude Digitizer Operation Manual Installation ManualHeringerNo ratings yet

- Mil STD 1277bDocument242 pagesMil STD 1277bJ YNo ratings yet

- F-16 Wide Band RadomeDocument2 pagesF-16 Wide Band RadomebioineNo ratings yet

- FAA 8083 30 - Ch12 PDFDocument46 pagesFAA 8083 30 - Ch12 PDFhocimtmNo ratings yet

- Bell 212Document23 pagesBell 212Kittinan Mak-lonNo ratings yet

- Alert Service Bulletin: ASB EC135-62A-029Document10 pagesAlert Service Bulletin: ASB EC135-62A-029fredson mirandaNo ratings yet

- AW139 Supplement Provides Radar and TCAS DetailsDocument14 pagesAW139 Supplement Provides Radar and TCAS DetailsdugiNo ratings yet

- Reference: Issue Date: Last Check Date: Status: A/C Type/serie: Ata: Engine Manufacturer: Supplier: Purpose / Reason For Revision: StatusDocument11 pagesReference: Issue Date: Last Check Date: Status: A/C Type/serie: Ata: Engine Manufacturer: Supplier: Purpose / Reason For Revision: StatusNimesh Delan100% (1)

- 0013 Denis HoweDocument624 pages0013 Denis HoweHeidi WebbNo ratings yet

- KHF 1050 Feature ComparisonDocument8 pagesKHF 1050 Feature ComparisonMy Agung SuryadiNo ratings yet

- TM 9-4910-531-14 Cleaner Steam, High Pressure, Water Jet, Trailer MountedDocument448 pagesTM 9-4910-531-14 Cleaner Steam, High Pressure, Water Jet, Trailer MountedAdvocateNo ratings yet

- Integrated Avionics SystemsDocument13 pagesIntegrated Avionics SystemsTony GarrisonNo ratings yet

- Throttle Linkage CheckDocument4 pagesThrottle Linkage Checkjbert55No ratings yet

- At575 234W TNCF 000 RG 29.5 NMDocument3 pagesAt575 234W TNCF 000 RG 29.5 NMMarlene SalazarNo ratings yet

- Nigerian Aviation College Guide to Aircraft Avionics SystemsDocument32 pagesNigerian Aviation College Guide to Aircraft Avionics SystemsIdrisNo ratings yet

- ICS PlusDocument12 pagesICS PlusbbilledeauxNo ratings yet

- FM 55-450-2 Army Helicopter Internal Load Operations - CHPTR 6 Load Preparation, Loading, and Tie-DDocument26 pagesFM 55-450-2 Army Helicopter Internal Load Operations - CHPTR 6 Load Preparation, Loading, and Tie-DSebastian ZarzyckiNo ratings yet

- April 8/91: All GroupsDocument33 pagesApril 8/91: All Groupsreza mirzakhaniNo ratings yet

- CRU-73 Oxygen RegulatorDocument1 pageCRU-73 Oxygen Regulatorjesus diasNo ratings yet

- Storch Flight Manual - Eng Version 28 - 04 - 05 PDFDocument51 pagesStorch Flight Manual - Eng Version 28 - 04 - 05 PDFandre_jvcNo ratings yet

- Boeing 737-522 Fleet Specs and Avionics ListDocument3 pagesBoeing 737-522 Fleet Specs and Avionics ListcypNo ratings yet

- Blade Element Theory - Taimur Lec 4Document47 pagesBlade Element Theory - Taimur Lec 4Usman AheerNo ratings yet

- Module 9 (Human Factors) Sub Module 9.3 (Social Psychology)Document20 pagesModule 9 (Human Factors) Sub Module 9.3 (Social Psychology)Interogator5No ratings yet

- PIA B1.1 - Module 2 (PHYSICS) SubModule 2.4 (Optics) FinalDocument25 pagesPIA B1.1 - Module 2 (PHYSICS) SubModule 2.4 (Optics) FinalInterogator5No ratings yet

- Module 9 (Human Factors) Sub Module 9.7 (Communication) - RevDocument13 pagesModule 9 (Human Factors) Sub Module 9.7 (Communication) - RevInterogator5No ratings yet

- Module 9 (Human Factors) Sub Module 9.5 (Physical EnvironmeDocument13 pagesModule 9 (Human Factors) Sub Module 9.5 (Physical EnvironmeInterogator5No ratings yet

- PTC Thermodynamics ModuleDocument37 pagesPTC Thermodynamics ModuleInterogator5No ratings yet

- PIA B1.1 - Module 2 (PHYSICS) SubModule 2.4 (Optics) FinalDocument25 pagesPIA B1.1 - Module 2 (PHYSICS) SubModule 2.4 (Optics) FinalInterogator5No ratings yet

- PIA Training Module on Basic AerodynamicsDocument25 pagesPIA Training Module on Basic AerodynamicsAhsan Malik100% (1)

- Module 9 (Human Factors) Sub Module 9.2 (Human PerformanceDocument25 pagesModule 9 (Human Factors) Sub Module 9.2 (Human PerformanceInterogator5No ratings yet

- Module 9 (Human Factors) Sub Module 9.1 (INTRODUCTION TO HUDocument24 pagesModule 9 (Human Factors) Sub Module 9.1 (INTRODUCTION TO HUInterogator5No ratings yet

- PIA B2 - Module 2 (PHYSICS) SubModule 2.3 (Thermodynamics) FiDocument36 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.3 (Thermodynamics) FiInterogator5No ratings yet

- PIA B - Basic - Module 1.1 (MATHS) Arithmetic FinalDocument49 pagesPIA B - Basic - Module 1.1 (MATHS) Arithmetic Finalfaizan masoodNo ratings yet

- PTC Mechanics Module 2.2Document79 pagesPTC Mechanics Module 2.2Interogator5No ratings yet

- Module 4: Electronic Fundamentals: PIA Training Centre (PTC)Document48 pagesModule 4: Electronic Fundamentals: PIA Training Centre (PTC)KHAN SIDDIQUENo ratings yet

- PTC Wave Motion and SoundDocument17 pagesPTC Wave Motion and SoundInterogator5No ratings yet

- PIA B2 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) FinalDocument57 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) FinalInterogator5No ratings yet

- PIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) FinalDocument20 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) FinalInterogator5No ratings yet

- Sub Module 3.16 FiltersDocument16 pagesSub Module 3.16 FiltersInterogator5No ratings yet

- PTC Wave Motion and SoundDocument17 pagesPTC Wave Motion and SoundInterogator5No ratings yet

- Sub Module 3.13 AC THEORYDocument26 pagesSub Module 3.13 AC THEORYInterogator5No ratings yet

- Sub Module 3.15 TransformersDocument23 pagesSub Module 3.15 TransformersInterogator5No ratings yet

- AC Motors FundamentalsDocument22 pagesAC Motors FundamentalsInterogator5No ratings yet

- PTC PHYSICS MODULE 2 SUB-MODULESDocument20 pagesPTC PHYSICS MODULE 2 SUB-MODULESInterogator5No ratings yet

- Sub Module 3.17 AC GENDocument24 pagesSub Module 3.17 AC GENInterogator5No ratings yet

- DC Motor and Generator TheoryDocument51 pagesDC Motor and Generator TheoryInterogator5No ratings yet

- Magnetism FundamentalsDocument20 pagesMagnetism FundamentalsInterogator5No ratings yet

- Sub Module 3.11 Inductance FinalDocument17 pagesSub Module 3.11 Inductance FinalInterogator5No ratings yet

- Sub Module 3.9 Capacitance FinalDocument26 pagesSub Module 3.9 Capacitance FinalInterogator5No ratings yet

- Sub Module 3.7 (Resistance) Final2Document19 pagesSub Module 3.7 (Resistance) Final2Interogator5No ratings yet

- Sub Module 3.8 Power FinalDocument9 pagesSub Module 3.8 Power FinalInterogator5No ratings yet

- Generation of Electricity MethodsDocument8 pagesGeneration of Electricity MethodsInterogator5No ratings yet

- FHWA Noise Barrier Design HandbookDocument242 pagesFHWA Noise Barrier Design HandbookTampaMarkNo ratings yet

- Dale Hunt 80 MeterDocument7 pagesDale Hunt 80 MeterbuffeNo ratings yet

- Seminar ReportDocument26 pagesSeminar ReportAnsaf BIN MUHAMMEDNo ratings yet

- Antenna FundamentalsDocument45 pagesAntenna FundamentalsAllanki Sanyasi RaoNo ratings yet

- AAA Modulewise Question Bank UpdatedDocument3 pagesAAA Modulewise Question Bank UpdatedRohini JadhavNo ratings yet

- ECEPE3 - Lesson 1 AcousticsDocument42 pagesECEPE3 - Lesson 1 AcousticsGenesis AlquizarNo ratings yet

- Ec8701-Antennas and Microwave EngineeringDocument394 pagesEc8701-Antennas and Microwave EngineeringArjun GanesanNo ratings yet

- Architectural AcousticsDocument172 pagesArchitectural AcousticsMarnie B. Gutib100% (2)

- ANTENNA & PROPAGATION UNIT 4Document9 pagesANTENNA & PROPAGATION UNIT 4anilkumarpatil1988No ratings yet

- List of SymbolsDocument4 pagesList of Symbolsမိုး မိုးNo ratings yet

- Analysis of a Thin Wire Circular Loop AntennaDocument11 pagesAnalysis of a Thin Wire Circular Loop AntennaSon Nguyen100% (1)

- Presentation - Thesis On DamDocument36 pagesPresentation - Thesis On DamRavi Sharma BhandariNo ratings yet

- NSI Near Far PDFDocument12 pagesNSI Near Far PDFrajasekarkprNo ratings yet

- Discussion 1 - Intro To Lumerical and DVD TutorialDocument61 pagesDiscussion 1 - Intro To Lumerical and DVD TutorialBích Đỗ DanhNo ratings yet

- Ece Vi Antennas and Propagation (10ec64) NotesDocument112 pagesEce Vi Antennas and Propagation (10ec64) NotesMuhammad Ali ShoaibNo ratings yet

- Design Programmable MatterDocument119 pagesDesign Programmable MatterArjun Sagar.No ratings yet

- Sample RF Test ReportDocument11 pagesSample RF Test ReportSubramanian RNo ratings yet

- MCQ RMT Final Unit1,2,3Document14 pagesMCQ RMT Final Unit1,2,3Deven MaliNo ratings yet

- 29 Radiation Fundamentals and Infinitesimal Dipole AntennasDocument16 pages29 Radiation Fundamentals and Infinitesimal Dipole AntennasArmanul HaqueNo ratings yet

- Massive Blasting Trial at Los Colorados MineDocument7 pagesMassive Blasting Trial at Los Colorados Minealvaroaac4No ratings yet

- The "20dB per decadeDocument9 pagesThe "20dB per decadeLászló KovácsNo ratings yet

- Air Defense College Antenna Engineering CourseDocument410 pagesAir Defense College Antenna Engineering CourseOsama ElazabNo ratings yet

- Ece 422 IntroDocument36 pagesEce 422 Introabdessalem_tNo ratings yet

- Measuring External QiDocument13 pagesMeasuring External QiРэндом ДэнNo ratings yet

- Parameter-Parameter Antena: Fitri Yuli ZulkifliDocument49 pagesParameter-Parameter Antena: Fitri Yuli ZulkifliNurul MuhtadinNo ratings yet

- Loudspeaker Cabinet Diffraction: Tore Skogberg Acoustical Technology Ørsted DTU - 2006Document176 pagesLoudspeaker Cabinet Diffraction: Tore Skogberg Acoustical Technology Ørsted DTU - 2006Alexander ShivaNo ratings yet

- Understanding Antenna FundamentalsDocument5 pagesUnderstanding Antenna FundamentalsIsaiah Philip Alob MacamNo ratings yet

- Ec8701 Ame Unit-2 NotesDocument174 pagesEc8701 Ame Unit-2 Notesajaykarthicsp.ece2020No ratings yet

- Stradus User Manual B6Document111 pagesStradus User Manual B6Becherescu DanNo ratings yet

- A Symmetrically Stacked Planar Antenna Concept Exhibiting Quasi-Isotropic Radiation CoverageDocument5 pagesA Symmetrically Stacked Planar Antenna Concept Exhibiting Quasi-Isotropic Radiation CoverageSYED IMRAN HUSSAINNo ratings yet