Professional Documents

Culture Documents

1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15

Uploaded by

NirmalKumarSelvarajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15

Uploaded by

NirmalKumarSelvarajCopyright:

Available Formats

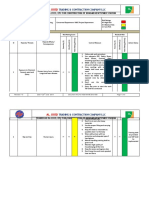

Risk Assessment Title:

Risk Assessment Installation of Electrical Equipment and Panels

JHRA 1760 - 010

JHRA NO. / Revision:

Item

Task (Steps)

Preparation and

hauling of tools and

equipment prior to

start of work.

Potential Hazard

HSE-001 Risk Assessment

1

Current Risk

Prob. Risk

Cons.

Sharp edges of tools and equipment that

are not easily spotted.

Secure approve and appropriate

work permit prior to start of work.

Provide guards to sharp edges of all

equipment.

Tie barricade tapes to provide

warning signs on sharp materials to

make it visible for all employees

present in the worksite.

Safe access and walk ways shall be

provide and free from any

obstruction.

Provide proper personal protective

equipment to all employees as per

project requirement assigned for the

activity.

Hot and humid weather resulting to heat

stress and dehydration.

Provision of cool drinking water

and shaded rest place.

Supervisor shall monitor their work

force by looking for signs of

dehydration.

Heat Stress management plan shall

be establish and communicated to

all employees at site.

Improper manual lifting technique.

Maintain proper back posture and

body position during manual lifting

of materials.

Position the body where less effort

is exerted and less strain.

Divide load weight between

coworkers.

All Employees must be aware about

the site plan and safe access routes

inside the project including ongoing

activities.

Use proper personal protective

equipment.

Approved and appropriate work

permit with all required attachment

shall be posted or carry at site prior

for work execution.

Only designated operator or driver

must operate to their assigned

equipment.

Follow safe and defensive driving

practices.

Check the equipment prior to

operate.

Equipment must be inspected and

received the inspection pass

sticker from Samsung C&T prior to

mobilize at site.

Incompetent / poor maneuvering of

equipment.

Positioning of

equipment:

Trailer trucks,

Boom truck and

Cranes.

Existing Control

Additional Control

All employees that will be mobilize/assign at site must be inducted by

SAMSUNG C&T HSE Dept.

Good housekeeping must be maintained at the work area.

Sharp and pointed edged materials and equipment will be segregated and

stored properly.

Adequate lighting will be provided during night time works and in low

visibility areas.

Directional signboards shall be provided and appropriate access

illumination shall maintain at dark areas or during night works.

Sharp and pointed edges of equipment that are not possible to remove

shall be provided with softener, protection or to be barricaded.

Impose staggered working hours. Include substitution n of workforce to

allow sufficient rest in between employees.

Provision of secured sun shades for direct sunlight works during hot

season.

Supplied Drinking water at site will be mixed with glucose with the

assistance of the project nurse during hot season.

Heat Stress awareness banners, alert and bulletins will be posted at site

during hot season.

Use lifting equipment if the load to be carried is too heavy for manual

lifting.

Follow manual lifting procedures; use the leg not the back. Seek for

assistance if the load is too heavy for you.

Never carry too much of your tools at the same time.

Proper communication must be maintained between working groups and

discipline.

Access ways and walk ways must be free from any obstruction and

spills.

Material management and housekeeping shall be maintained on, before

and during the execution of work.

Use mechanical aid (e.g. forklift, wheelbarrow, pallet truck, cranes, etc.)

when the load exceeds on body capacity.

Assigned competent flagman during transportation.

Assigned flagman shall be equipped with color green/red flags during

day hours and color green/red stick lights during night works. .

Equipment shall be maintained in a regular basis with the update

appropriate checklist.

Equipment shall be equipped with reverse tail light and back horn.

Ensure all side and rear mirrors of equipments are in good condition and

proper position.

Cons.

Final Risk

Prob. Risk

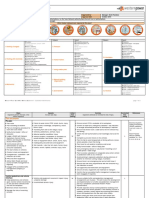

Risk Assessment Title:

Risk Assessment Installation of Electrical Equipment and Panels

JHRA 1760 - 010

JHRA NO. / Revision:

Item

Task (Steps)

Potential Hazard

Existing Control

Current Risk

Prob. Risk

Cons.

Additional Control

Cons.

Final Risk

Prob. Risk

Adequate lightings shall be

provided during night works.

Over speeding.

Observed and maintain imposed

speed limit of: a.) 20 kph inside R2IPP Project site and b.) 60 kph from

outside Samsung C&T project site

to Rabigh2 main road.

Driver / operator should have

undergone training on defensive

driving and aware of the Samsung

C&T project traffic rules and

regulations.

Improper lashing of load.

Only certified operator will operate

boom truck with valid third party

certification.

Apply wheel chokers when boom

truck is on full stop.

Only competent person (rigger)

shall do the rigging works and give

signal to operator during lifting of

load using boom truck or crane.

Incompetent operator.

Boom truck operator shall possess

with valid third party certification

and SAG license.

Trailer operators shall possess with

their valid Sag license.

Do not exceed the capacity of load

High wind velocity.

HSE-001 Risk Assessment

2

Unsecured load.

Transport of

Electrical Equipment:

Power Transformer

Switchgear

Motor control

center

Other control panel

Power capacitor

Grounding resistors

Uninterrupted

power supply

Battery,

and Battery charger

installation.

Crane outrigger pads shall be in

good condition,

standard/appropriate dimensions as

per crane capacity.

Crane outriggers must be fullextend prior to operate.

Crane to be leveled horizontally

'before commencing lifting

operations.

Secured the equipment with binder

and straps before transportation.

Ensure competency of employees

assigned in securing the load.

Poor stability of crane.

Lifts shall not be made in winds

that exceeds that manufacturers

recommendation of the equipment

or greater without approval from

the ARCC Rigging Supervisor.

Provide additional softener for sharp edged materials prior for securing

the load.

All tools must be inspected, color coded and in good condition prior to

use.

No one shall pass or stay underneath of suspended load.

Assigned competent flagman for mobile equipment during transportation

inside project site and ensure the provision of escort vehicle during

transportation of long or oversized loads.

Ensure the provision of enough speed limit signboards along the access

roads for the awareness of all vehicle and equipment at site.

Ensure working radius of Boom truck is clear of any obstruction during

loading and off-loading of materials.

Appropriate rigging tackles and equipment shall be used in lifting,

loading and off-loading of loads.

Provide and use softener for sharp edged materials or equipment.

Observed double choke for long loads to prevent slip.

Operator must aware with the appropriate rigging hardware and chain

blocks or pullers to be use.

Operators must conduct visual inspection with their respective units prior

to operate.

Issues regarding unauthorized operating of equipment shall be discuss

during tool box meeting with the corresponding disciplinary rules/action.

Wind speed monitoring shall be log or posted on site for the awareness

of other equipments without anemometer or wind meter device.

Use minimum of two (2) taglines to control load movement.

Ensure all cranes are retracted every end of shift and to be park in a

designated equipment parking area.\

Crane outriggers shall be position for at least 2 meters away from the

edge of excavation.

Underground utilities/facilities shall be identified and mark with

necessary additional protection when positioning the crane.

Locking pins for outriggers shall be utilized during crane operations.

Risk Assessment Title:

Risk Assessment Installation of Electrical Equipment and Panels

JHRA 1760 - 010

JHRA NO. / Revision:

Item

Task (Steps)

Potential Hazard

Unsecured tools, materials

Installation of

Electrical equipment:

Power Transformer

Switchgear

Motor control

center

Other control panel

Power capacitor

Grounding resistors

Uninterrupted

power supply

Battery,

and Battery charger

installation.

.

Unsafe working practices.

Damaged / defective electrical tools,

cables and outlets.

As per Samsung C&T lifting rules,

up to 40 km/h wind velocity, the

relevant the competent lifting

supervisor responsible shall

determine the level of risk for each

load and act accordingly.

Hand tools used at elevated areas

shall be secured with a retaining

string.

Observed proper material

management and housekeeping at

elevated work platforms.

Elevated working platforms shall be

free from bolts, nuts and stockpiled

materials

Workers assigned on elevated area

with a height of 1.8 m. (6 ft) or

greater shall be equipped with an

inspected and color coded bull body

harness.

Maintain 3-point contact when

descending or ascending on a

ladder.

All tools to be used must be

inspected and color coded.

Use required personal protective

equipment.

Secure work permit and complete

the required checklist prior to work.

Ensure electrical tools must be

inspected and color coded.

Handles and guard in place.

Do not alter the design of the

equipment.

Only trained personnel will use

power tools.

Defective electrical facilities.

Do not dilapidated electrical cables

and tampered outlet.

Use outlet or electric source with

GFCI or ground fault circuit

interrupter.

Do not use dilapidated extension

cables and tampered outlets.

Do not alter engineering design of

equipment.

Improper manual lifting technique.

Maintain proper back posture and

body position during manual lifting

of materials. Position body where

Termination works

and Cable pulling.

HSE-001 Risk Assessment

3

Existing Control

Current Risk

Prob. Risk

Additional Control

Cons.

Cons.

Final Risk

Prob. Risk

Rigging in charge shall be responsible to disseminate the winds velocity

monitoring to all lifting equipment.

Provide bolt bags for small materials to be use at elevated area.

Secure materials and tools by means of retaining string when working on

elevated areas.

Use the appropriate tools for the job.

Ensure all elevated areas and plat forms are free from any loose

materials.

All materials at elevated areas are properly stock or piled that prevent

from rolling.

Barricade and warning signs are provided.

Avoid holding any materials when descending or ascending a ladder.

No one shall pass beneath the suspended load.

Responsible supervision must discuss the JSA to all involved personnel

prior to job execution.

Keep body parts out of pinch points.

Only competent or qualified persons are allowed to perform the activity.

Do not remove guarding and replace the dead man switch of grinders.

Defective tools must be immediately surrendered at tool room for repair.

Do not alter the design of the equipment.

Do not coiled the cable direct on the steel structure or scaffold pipes to

prevent from damaged.

Install cables properly so as not to pose obstruction to any work location.

Only approved electrical hardware shall be used.

Wear the correct type of hand protection.

Damaged electrical outlets shall be replaced immediately.

Use lifting equipment if the load to be carried is too heavy for manual

lifting.

Risk Assessment Title:

Risk Assessment Installation of Electrical Equipment and Panels

JHRA 1760 - 010

JHRA NO. / Revision:

Item

Task (Steps)

Potential Hazard

Existing Control

Current Risk

Prob. Risk

less effort is exerted and less strain.

Apply buddy system when the load

is heavy.

Divide load weight between coworkers.

Use proper personal protective

equipment.

Follow manual lifting procedures;

use the leg not the back. Seek for

assistance if the load is too heavy

for you.

Never carry too much of your tools

at the same time.

All cable roller to be used must be

free from any damaged.

Apply buddy system when pulling a

cable.

Wear complete PPEs such as hand

gloves, safety glass, safety shoes,

etc.

Unsecured tools and materials

Maintained proper housekeeping on

the work area.

Only workable materials must be

present on the work area.

Proper material management and

storage should be done.

Only qualified/competent

electricians to inspect all electrical

system prior to work.

Damaged equipment shall be

immediately removed at work area.

Wear appropriate PPEs for the job.

Unsafe condition.

Ensure all equipment is properly

secure with grounding.

Only workable materials shall be

present on the work area.

Provide proper storage area for all

materials.

Fall of personnel and materials from elevated

work areas.

Secure approve and appropriate

work permit for scaffold works

prior to start of work.

Required attachments shall be

complied as required by Samsung

C&T or AL Morjan.

Scaffold erectors and personnels

going down thru the straight access

electrical

or

Testing of electrical

equipment and

panels.

6

Installation of scaffold

structure.

HSE-001 Risk Assessment

4

Cons.

Final Risk

Prob. Risk

Proper communication must be maintained between working groups and

discipline.

Access ways and walk ways must be free from any obstruction and

spills.

Material management and housekeeping shall be maintained on, before

and during the execution of work.

Use mechanical aid (e.g. forklift, wheelbarrow, pallet truck, cranes, etc.)

when the load exceeds on body capacity.

Unsafe practices

Faulty / exposed

connections.

Additional Control

Cons.

Correct body positioning during cable pulling works.

All tools or equipment to be used are inspected and color coded.

Responsible supervision must discuss the JSA to all involved personnel

prior to job execution.

Use mechanical aid: (cable puller machine, etc) when the cable is too

heavy for manual pulling.

Homemade tools are strictly not allowed at site.

Provision of barricades and warning signs to prevent unauthorized

personnel for the job.

Wear complete PPEs for the job.

Ensure all tools are in good condition with updated inspection color

code.

All tools or equipment to be used are inspected and color coded.

Only approved electrical hardware shall be used.

Electrical cable gladding shall be in-place and in good condition.

Standard splicing procedures shall be practiced and checked by the

assigned supervisor prior and subjected for testing.

Conduct housekeeping before and after work.

Provide sufficient lighting during night time.

Electrical facilities must be free from any water leakages and flammable

liquids.

Access ways and walk ways must be identified inside electrical rooms.

Adequately lightings shall be provided near the manhole entrance.

Adequate working pat form shall be provided as per activity

requirements.

Maintain 3-point contact when descending or ascending on a ladder.

Avoid carrying materials when descending and ascending the access

ladder.

Risk Assessment Title:

Risk Assessment Installation of Electrical Equipment and Panels

JHRA 1760 - 010

JHRA NO. / Revision:

Item

Task (Steps)

Potential Hazard

Unsecured scaffold tubes, accessories and

other.

Unsafe acts and poor working practices.

High intensity noise.

Cutting using:

Oxygen-acetylene,

grinder, speed

cutter, etc.

Grinding works

and

Welding works.

Damaged electrical cables and outlets

HSE-001 Risk Assessment

5

Existing Control

Current Risk

Prob. Risk

Cons.

Additional Control

Cons.

Final Risk

Prob. Risk

ladder more than (7) seven meters,

shall provide retractable lanyards

hooked on to the rigid tubular

structure.

Only trained and certified

scaffolders are allowed to erect and

dismantle scaffolds.

Use pulley and material bucket or

bolt bags in transporting materials

at the top of scaffold.

Throwing scaffold accessories are

not allowed when dismantling.

Scaffold shall have a top rail, mid

rail and toe board installed in

standard heights.

Scaffold erector, supervisor and

inspector must observe the use of

chin strap, full body harness and

observe 100% tie-off while

working.

Inspect scaffold before climbing.

Check for the scaffold tag.

Provide sufficient access on the

scaffold. Laid cables on ladder

rungs are prohibited.

Scaffolds must have a safe distance

from electrical / power source.

Barricade the working area and

install corresponding warning signs.

Use fall protection equipment while

working on the top of scaffold or

working platforms with a height

above of 1.8m (6 ft.). Observed 100

% tie-off in using full body harness.

Approved hot work permit

shall be posted or carry by the

working group at work site

prior to execute the

task/activity.

Wear ear protection (ear plugs,

earmuffs) when using or

assisting in grinding and

cutting works or any activity

with noise intensity more than

85 dB.

Ensure grinders are inspected

and color coded in a monthly

basis.

Handles and guard in place.

Use only the correct type of

Scaffolder hand tools should have retaining string to prevent from

falling.

In case of special scaffold, an engineered design shall be secured and

analyzed prior to erection.

Observed proper housekeeping and material management when the

work is done.

Entry exit point shall provide with sufficient illumination.

Wearing of clear safety glasses on dark or covered areas is required.

Scaffold platform should be free of oil, bolts and nuts, gravels and other

materials that can cause slip, trip or fall.

Refrain storing materials that could slip from the top of scaffold platform

to the ground.

Required attachment for PTW shall be provided.

Noise monitoring shall be conducted and communicated to all working

personnel involve in the task with expected high intensity of noise.

Use of double hearing protection is highly recommended dB level

monitored is highly extreme.

Barricades and safety signboards shall be provided for high noise areas.

Employees to practice visual daily inspection of tools and equipments to

be use.

Use correct PPE for cutting and grinding works such as leather gloves,

face respirator, safety glass and face shield for double eye protection.

Risk Assessment Title:

Risk Assessment Installation of Electrical Equipment and Panels

JHRA 1760 - 010

JHRA NO. / Revision:

Item

Task (Steps)

Potential Hazard

Existing Control

Current Risk

Prob. Risk

Cons.

cutting and grinding discs.

Ensure rpm on disc is not less

than rpm on grinders.

Only trained personnel will use

power tools.

Additional Control

Cons.

Final Risk

Prob. Risk

Bend or provide protective caps on vertically protruding bars.

Ensure no flammable materials or liquids are present or near the welding

vicinity.

Have a post welding inspection to ensure that the activity is safely

completed.

Unsafe behavior and practices.

Flammable materials at the welding

areas.

Arching

Fire Explosion

HSE-001 Risk Assessment

6

Secure hot work area with fire

blankets and have a stand by

fire extinguisher.

Assign competent fire watcher

during work execution.

Welding shall not be done in

wet area.

Plate welders shall undergo

specific training with

certificate and competent for

the job.

Ensure hot work checklist is

completed.

Keep cylinders away from

sources of heat, highly

combustible materials and all

ignition sources.

Cylinders of oxygen should not

be stored close to cylinders of

acetylene or other fuel gas nor

permitted to come in contact

with oil or grease.

Never use oxygen for cleaning

and purging, use an inert gas,

like nitrogen.

Earth cable to be connected as

close as possible to welding

operation.

Earth cable for welding

machine shall be terminated

properly to avoid arching

during the execution of work.

Ensure

approve

and

appropriate Hot work Permit

with its necessary attachment

(checklist, MS, RA, etc.) is

acquired prior to start the work

Segregate flammable liquids or

material from the source of

ignition.

Contain welding slag by fire

blanket. Cover sewers and

manholes located near the

source of ignition.

Ensure that grounding of equipments and system grounding of portable

electrical machine and tools are correct and in good condition at all

times.

Sub standard earthing materials is strictly prohibited.

Continuity of grounding system must be check prior to start of work.

Barricade and warning signs are provided.

Appropriate fire protection system and firefighting equipment shall be

installed/establish.

Inspection of fire protection system shall be conducted in a monthly

basis.

Have a post welding inspection to ensure that the activity is safely

completed.

Chemicals shall be properly stored on designated area.

Remove all possible combustible materials near the hot work activities.

Always use gases only in areas where adequate ventilation is provided.

Turn off cylinders when not in use for extended period of time, such as

during lunch breaks. Remove all gauges and replace the cylinders caps at

the end of each shift.

Hot work areas shall be free from any combustible and flammable

materials.

Conduct housekeeping before and after work to include proper material

management of cylinder tanks.

Cylinder tanks shall be provided with protective caps and chained to

prevent from rolling.

Barricade and warning signs are provided.

Have a post welding inspection to ensure that the activity is safely

completed.

Chemicals shall be properly stored on designated area.

Remove all possible combustible materials near the hot work activities.

Leak testing for cylinders shall be done prior to pressurize the line.

Pressurized cylinder tanks shall be transported by means of approved

cylinder trolley or by means of certified cylinder cage.

Risk Assessment Title:

Risk Assessment Installation of Electrical Equipment and Panels

JHRA 1760 - 010

JHRA NO. / Revision:

Item

Task (Steps)

Potential Hazard

Existing Control

Current Risk

Prob. Risk

Cons.

Shut-off diesel driven welding

machines

and

remove

electrode from the holder when

not in use.

Provide

fire

extinguisher

located near diesel driven

welding machine and where

hot works are conducted.

Cons.

Final Risk

Prob. Risk

Leak testing for cylinders shall be done prior to pressurize the line.

Pressurized cylinder tanks shall be transported by means of approved

cylinder trolley or by means of certified cylinder cage.

Welding equipments, electrical equipments and cutting outfit accessories

that will be use must be inspected, with updated inspection color code

and in good condition.

Assign competent fire watch for hot works where fire could occur.

Equipment shall be inspected, color coded and in good condition prior to

work.

Appropriate PPEs shall be use in line to the Samsung Standard

requirement for PPEs

Unsafe practices while on heights,

improper use of fall protection system.

Workers/employees/staff to be

assigned in work at heights must be

trained by Samsung C&T HSE

department.

Elevated working platforms shall be

free from bolts, nuts and stockpiled

materials. Provide bolt bags for bolt

and nuts.

Workers assigned on elevated work

area with a height of 1.8 m. (6 ft)

or greater shall be equipped with an

inspected and color coded bull body

harness and 100% tie-off whenever

possible.

Adequate anchorage points shall be

provided for fall protection system.

Only trained personnels for working at heights are allowed to work on

elevated areas.

Responsible supervision must discuss the RA to all involved personnel

prior to job execution.

Make sure work area is free of tools and materials that pose obstruction

or trip hazard.

Involve workers/staff/employees in working at height must have the

training sticker located on the right side of their respective helmet.

Unsecured materials on the elevated

area.

Only workable materials shall be

present in the elevated work area.

Observe proper material

management and maintain good

housekeeping.

All materials must not be stored

near the edges of structure or open

hole.

Secure materials properly, use bolt

bags for small material parts to

prevent from falling.

Use correct type of pulley and rope

hoisting materials and must be

inspected and color coded prior to

use.

Hand tools shall be provided with retaining strings.

Hoisting area must be barricaded with signage and adequate lifting

materials shall be used.

Do not leave tools and other materials unattended on working platforms.

Use proper containment for small materials such as bolt bag.

Working platforms shall be free from unprotected floor opening.

Fall protection system shall be inspected and maintain in good condition

prior for work execution such as: working plat forms, full body harness,

anchorage points, guard rails, barricades, signboards and etc.

Working at Heights.

9

HSE-001 Risk Assessment

7

Additional Control

Risk Assessment Title:

Risk Assessment Installation of Electrical Equipment and Panels

JHRA 1760 - 010

JHRA NO. / Revision:

Item

Task (Steps)

Potential Hazard

Prepared By:

A - Architect (Architect engaged by Samsung C&T)

PM Project Manager

CM Construction Manager

LM Logistics Manager

PLM Plant Manager

HSEM HSE Manager

PS Project Supervisor (Samsung C&T / Subcontractor)

SC Subcontractor

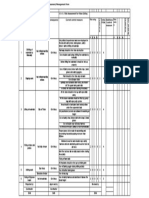

Severity (S)

1

2

3

4

5

Current Risk

Prob. Risk

Existing Control

Minor Injury

Major Single Injury

Major Multiple Injuries

Single Death

Multiple Deaths

Frequency (F)

1

2

3

4

5

Additional Control

Cons.

Risk Rating (RR)

R=SxF

Improbable

Possible

Occasional

Frequent

Regular

Unacceptability Limits

More than 5 is unacceptable re-assess task

and preventative actions.

S = 0 is deemed to be the limit of practicability

of control measures.

Cons.

Very High

15-25

S

5

4

3

2

1

5

25

20

15

10

5

High

8-12

4

20

16

12

8

4

Medium

4-6

3

15

12

9

6

3

Risk assessment complied by:

Risk Assessor

ALLAN G. LAROCO

HSSE ENGR. II

NAME

Designation

PEDRITO A. CERIA

CONSTRUCTION MANAGER

NAME

Designation

Signature

Date

Signature

Date

Signature

Date

Signature

Date

Risk assessment approved by:

Construction

HSE Department

Management

HSE-001 Risk Assessment

8

ALLAN G. LAROCO

HSSE ENGR. II

NAME

Designation

MARIO P. RAYOS DEL SOL

PROJECT MANAGER

NAME

Designation

Final Risk

Prob. Risk

2

10

8

6

4

2

Low

1-3

1

5

4

3

2

1

You might also like

- Risk Assessment - PLCC Cable and GIB Testing 26DEC15 - Rev 0Document7 pagesRisk Assessment - PLCC Cable and GIB Testing 26DEC15 - Rev 0NirmalKumarSelvarajNo ratings yet

- Risk Assessment Form: 1 Biophysical HazardsDocument5 pagesRisk Assessment Form: 1 Biophysical HazardsGajendran Sriram33% (3)

- Man Machine InterfaceDocument22 pagesMan Machine Interfaceamdarrif3723100% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- 4-Cable Laying PDFDocument6 pages4-Cable Laying PDFAhmed ZaiNo ratings yet

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk assessment for night shift activitiesDocument16 pagesRisk assessment for night shift activitiesthomson100% (1)

- Risk Assessment For Back FillingDocument6 pagesRisk Assessment For Back FillingBhargav BbvsNo ratings yet

- Emergency Action ZamilDocument11 pagesEmergency Action ZamilTAUQEER AlamNo ratings yet

- Cable PullingDocument4 pagesCable Pullingtrndem0% (1)

- SWMS Mobilisation of Blocks For MLT TEST RKDocument14 pagesSWMS Mobilisation of Blocks For MLT TEST RKrakeshkhanna78100% (1)

- EFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of SignagesDocument2 pagesEFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of Signagesmohammed ayazNo ratings yet

- AL JOOD TRADING RISK RATINGSDocument5 pagesAL JOOD TRADING RISK RATINGSghada gattouch100% (1)

- Risk Assessment for Electrical WorksDocument3 pagesRisk Assessment for Electrical WorksSaleem Basha50% (2)

- Risks of Working at Height AssessmentsDocument30 pagesRisks of Working at Height AssessmentsSamboy DionisioNo ratings yet

- Temporary Electrical Safety ProcedureDocument9 pagesTemporary Electrical Safety ProcedurejaimonjoyNo ratings yet

- HSE TRA-04 Steel Reinforcement and Shuttering WorksDocument6 pagesHSE TRA-04 Steel Reinforcement and Shuttering WorksQusai Khalil Abu Awad100% (1)

- JSA E&I 4.earthing Bonding InstallationDocument3 pagesJSA E&I 4.earthing Bonding InstallationAmyNo ratings yet

- Expansion Project Risk AssessmentDocument3 pagesExpansion Project Risk AssessmentAftab Qadir100% (1)

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- Company Instrumentation Coring Works Risk AssessmentDocument11 pagesCompany Instrumentation Coring Works Risk AssessmentJayson EscamillanNo ratings yet

- Risk Assessment - Placing of Transformer - TTSDocument6 pagesRisk Assessment - Placing of Transformer - TTSnsadnan100% (2)

- Ehs Risk AssessmentDocument2 pagesEhs Risk AssessmentRohit Singh100% (1)

- Risk Assessment For Snake BiteDocument4 pagesRisk Assessment For Snake BiteVIKASH KUMAR100% (1)

- Safe Work Method Statement - PlumbingDocument4 pagesSafe Work Method Statement - PlumbingJohn KurongNo ratings yet

- Electrical Risk Assessment FormDocument1 pageElectrical Risk Assessment FormGyogi MitsutaNo ratings yet

- Brick/Block Work Hazards AssessmentDocument40 pagesBrick/Block Work Hazards AssessmentGyanendra Srivastava0% (1)

- RA - Electrical WorksDocument9 pagesRA - Electrical WorksShezi Bhatti0% (1)

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- Earth Mat Risk AssessmentDocument1 pageEarth Mat Risk Assessmentakshaf10No ratings yet

- CALACA POWER COMPLEX RISK ASSESSMENTDocument14 pagesCALACA POWER COMPLEX RISK ASSESSMENTJayson Escamillan100% (1)

- Risk Assessment of Cantilever ScaffoldDocument1 pageRisk Assessment of Cantilever ScaffoldGyanendra Srivastava100% (1)

- JSARA - Fire Detection System InstallationDocument13 pagesJSARA - Fire Detection System InstallationUtku Can KılıçNo ratings yet

- CIVIL WORKS SAFETY ANALYSISDocument7 pagesCIVIL WORKS SAFETY ANALYSISMoaatazz Nouisri67% (3)

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDocument3 pagesLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINNo ratings yet

- Risk Assessment For Installation of Automatic Sliding DoorDocument6 pagesRisk Assessment For Installation of Automatic Sliding DoorKalid JmalNo ratings yet

- Risk Assessment For Installation of SMDB&DBDocument15 pagesRisk Assessment For Installation of SMDB&DBAnandu Ashokan78% (9)

- EEEPL - JSA Light Fitting ErectionDocument6 pagesEEEPL - JSA Light Fitting ErectionnishanthNo ratings yet

- Distribution Swms Substation MaintenanceDocument5 pagesDistribution Swms Substation MaintenanceAnonymous mNQq7ojNo ratings yet

- Risk-Assessment Ducts & AccessoriesDocument13 pagesRisk-Assessment Ducts & AccessoriesMohammed Amer PashaNo ratings yet

- Hazard Task Risk Control MeasuresDocument5 pagesHazard Task Risk Control MeasuresIshan DankharaNo ratings yet

- RISK ASESSMENT For SKYLIGHTDocument23 pagesRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- Risk Assessment For GroundingDocument2 pagesRisk Assessment For GroundingUtku Can KılıçNo ratings yet

- Installing Cladding Risk AssessmentDocument3 pagesInstalling Cladding Risk AssessmentAhmed Tarek67% (3)

- Fencing Installation Risk AssessmentDocument6 pagesFencing Installation Risk AssessmentVictorNo ratings yet

- 7 Hand Held Power ToolsDocument4 pages7 Hand Held Power ToolsGilmar MonteiroNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- Risk Assessment For Earthing Work-R1Document3 pagesRisk Assessment For Earthing Work-R1Azhar Mushtaq75% (4)

- Old Cables, Conduits and Cable Trays Dismantling - JSEA FormDocument40 pagesOld Cables, Conduits and Cable Trays Dismantling - JSEA FormJayson Escamillan100% (2)

- False CeilingDocument1 pageFalse CeilingChandru67% (3)

- Ra Testing & Commissioning of Irrigation SystemDocument14 pagesRa Testing & Commissioning of Irrigation Systemamal100% (2)

- HSE PLAN Generic RA PDFDocument5 pagesHSE PLAN Generic RA PDFテレブリコ ジェファーソン100% (1)

- RA Construction For Sub-Base & Road Base WorksDocument17 pagesRA Construction For Sub-Base & Road Base WorksBleep NewsNo ratings yet

- Concrete WorkDocument1 pageConcrete WorkChandruNo ratings yet

- WMS - 230207 - 165537Document10 pagesWMS - 230207 - 165537Arun chaudhariNo ratings yet

- Site Specific Safety OrientationDocument39 pagesSite Specific Safety OrientationBernard AmooNo ratings yet

- Aboveground Piping Installation Works 2016Document7 pagesAboveground Piping Installation Works 2016Aldrin75% (4)

- Keema Report On PD TestDocument1 pageKeema Report On PD TestNirmalKumarSelvarajNo ratings yet

- Hvac - Iec PDFDocument1 pageHvac - Iec PDFNirmalKumarSelvarajNo ratings yet

- Hvac - Iec 60840Document1 pageHvac - Iec 60840NirmalKumarSelvarajNo ratings yet

- Hvac - Iec PDFDocument1 pageHvac - Iec PDFNirmalKumarSelvarajNo ratings yet

- DEWA Sub StationDocument18 pagesDEWA Sub StationVishram Deo86% (7)

- 1 Muhr Non-Conventional PD-Measurements (07004-01)Document44 pages1 Muhr Non-Conventional PD-Measurements (07004-01)NirmalKumarSelvarajNo ratings yet

- SS Load Summary Sheets-R3Document8 pagesSS Load Summary Sheets-R3NirmalKumarSelvarajNo ratings yet

- 220kv Cable Cross Bonding TestDocument7 pages220kv Cable Cross Bonding Testvivek2159No ratings yet

- DEWA Regulations For Elect Insatallations 1997 EditionDocument65 pagesDEWA Regulations For Elect Insatallations 1997 EditionApsi LalNo ratings yet

- Difference Between MCB, MCCB, ELCB, and RCCBDocument6 pagesDifference Between MCB, MCCB, ELCB, and RCCBNirmalKumarSelvarajNo ratings yet

- Brugg Cables User GuideDocument27 pagesBrugg Cables User GuideMehdi_Mashayekhi_172No ratings yet

- 3ph Impedance MSDocument4 pages3ph Impedance MSNirmalKumarSelvarajNo ratings yet

- Partial Discharge Equipment PDFDocument6 pagesPartial Discharge Equipment PDFSellappan MuthusamyNo ratings yet

- Online Partial Discharge Testing ExplainedDocument61 pagesOnline Partial Discharge Testing ExplainedNirmalKumarSelvarajNo ratings yet

- ControllingDocument25 pagesControllingJasmin Jacob86% (7)

- 1 01 SicamSASDocument3 pages1 01 SicamSASNirmalKumarSelvarajNo ratings yet

- Statistical Process Quality Control ChartsDocument46 pagesStatistical Process Quality Control ChartsRavi Kumar G100% (3)

- MarketingDocument1 pageMarketingNirmalKumarSelvarajNo ratings yet

- Vendor Empanelment FormDocument1 pageVendor Empanelment FormNirmalKumarSelvarajNo ratings yet

- Project Report On Total Quality ManagementDocument15 pagesProject Report On Total Quality ManagementNirmalKumarSelvarajNo ratings yet

- Mba Syllabus 2009Document49 pagesMba Syllabus 20091231988No ratings yet

- MEPZDocument1 pageMEPZNirmalKumarSelvarajNo ratings yet

- Gas Turbine EnginesDocument70 pagesGas Turbine EnginesNirmalKumarSelvarajNo ratings yet

- Gas Turbine EnginesDocument70 pagesGas Turbine EnginesNirmalKumarSelvarajNo ratings yet

- Technical Hager PDFDocument32 pagesTechnical Hager PDFjohnvar04No ratings yet

- Filtru HEPA TROX Installation - ManualDocument16 pagesFiltru HEPA TROX Installation - ManualexperthvachomeNo ratings yet

- ATC500 (BMW X5 2003-06) : Revision 07/2013Document2 pagesATC500 (BMW X5 2003-06) : Revision 07/2013JanneLaukkanenNo ratings yet

- SCM Tech2Document7 pagesSCM Tech2Adnan MalekNo ratings yet

- AxialDocument67 pagesAxialAnonymous 6vrljINo ratings yet

- Ahu ControlDocument13 pagesAhu ControleslamNo ratings yet

- Singer 9020 Sewing Machine ManualDocument44 pagesSinger 9020 Sewing Machine ManualLaughgbudh67% (3)

- Firefly Royu Wiring Devices Price List March 2016Document2 pagesFirefly Royu Wiring Devices Price List March 2016Alvin Lagasca100% (1)

- 316 HO Version Coding IC 98-99Document2 pages316 HO Version Coding IC 98-99arkhom1No ratings yet

- 4th Semester Curriculum for Mining Engineering DiplomaDocument18 pages4th Semester Curriculum for Mining Engineering DiplomaPrince SinghNo ratings yet

- 502 Series DC Power System: Netsure™Document8 pages502 Series DC Power System: Netsure™Sahand ArasNo ratings yet

- Cub Cadet Parts Manual For Model 465 4x4 Utility Vehicle Efi SN 1i029z and AfterDocument6 pagesCub Cadet Parts Manual For Model 465 4x4 Utility Vehicle Efi SN 1i029z and Afterenid100% (50)

- Wistron DW50 Winery15 - 48.4et05.0sa 09289-Sa PDFDocument88 pagesWistron DW50 Winery15 - 48.4et05.0sa 09289-Sa PDFWillian AngeloNo ratings yet

- 735, 740 and 740E Electrical System Articulated Truck: Machine Harness Connector and Component LocationsDocument2 pages735, 740 and 740E Electrical System Articulated Truck: Machine Harness Connector and Component LocationsMiguel Bustamante100% (3)

- 17428Document34 pages17428Amit GhadeNo ratings yet

- Pending Call ReportDocument49 pagesPending Call ReportVandana YadavNo ratings yet

- Mazda Protege 1996Document36 pagesMazda Protege 1996ErasmoNieves100% (4)

- Major Aspects of Security & BarriersDocument3 pagesMajor Aspects of Security & BarriersgraciaNo ratings yet

- OM C5613 1 Turismo Veloce 800 Lusso RC SCS 18-20 USA SMLDocument472 pagesOM C5613 1 Turismo Veloce 800 Lusso RC SCS 18-20 USA SMLJulio VizueteNo ratings yet

- STC WV30Document30 pagesSTC WV30ricardoulhoa75No ratings yet

- Tilt Float SwitchDocument1 pageTilt Float Switchdcf67myNo ratings yet

- AKG1212 CNC RouterDocument9 pagesAKG1212 CNC RouterVictor BravoNo ratings yet

- Load Detection On Hoist UnitsDocument4 pagesLoad Detection On Hoist UnitsTh Nattapong100% (3)

- 600/1000V, PVC Insulated Cables According To IEC 60502-1: Kitty@caledonian-Cables - Co.ukDocument11 pages600/1000V, PVC Insulated Cables According To IEC 60502-1: Kitty@caledonian-Cables - Co.ukS.M.Touhidur RahmanNo ratings yet

- Sym Jet4 125 Owners Manual Eng PDFDocument24 pagesSym Jet4 125 Owners Manual Eng PDFJulwen100% (2)

- Nitrogen Gas Generator: 0.1 To 1000 NM /HRDocument2 pagesNitrogen Gas Generator: 0.1 To 1000 NM /HRbarun1977No ratings yet

- Fundamentals of Computers: Reema TharejaDocument39 pagesFundamentals of Computers: Reema TharejaYash SharmaNo ratings yet

- Altec Lansing InMotion (IM310) User ManualDocument10 pagesAltec Lansing InMotion (IM310) User ManualJimmyNo ratings yet

- Electric Submersible Pumps GuideDocument22 pagesElectric Submersible Pumps GuideDanteNo ratings yet

- Drawing List FinalDocument912 pagesDrawing List Finalnaser hasan fauziNo ratings yet