Professional Documents

Culture Documents

05-Welder Certification PDF

Uploaded by

Anonymous bfxeE1zvYOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05-Welder Certification PDF

Uploaded by

Anonymous bfxeE1zvYCopyright:

Available Formats

Certified

Welder for Welding

Code AWS D1.1-2010

This document includes:

Certified Welder for Welding Code AWS D1.1-

2010 Protocol

Welder Qualification Paperwork

AWS D1.1 Welder Qualification Test

Procedure [Carbon Steel Plate Test

WQTP#1]

AWS D1.1 Welder Qualification Test

Procedure [Carbon Steel Plate Test

WQTP#2]

Fillet Test Setup

Learn more at http://www.psiusa.com/ and specifically about their

welding testing program by clicking on Mechanical Testing Services and

scroll down to Welding Services.

Contact Mike McCraw for radiographic testing and certification at the

Greensboro PSI office.

North Carolina Agricultural Education Certification Program

Certified Welder for Welding Code AWS D1.1-2010

North Carolina Agricultural Education Courses with content in this certification area are Agricultural Mechanics

I and II.

There are many types of welding certification available. The welding certification for which most of our

students will first want to qualify meets Welding Code AWS D1.1. This is basic structural welding using

shielded arc welding on carbon steel plate or its equivalent. There are initially two certification levels that we

are recommending for our students. Carbon Steel Plate Test (WQTP #1) includes 3G (Vertical Uphill

Progression) and Carbon Steel Plate Test (WQTP #2) 3G (Vertical Uphill Progression) and 4G (Overhead).

Detailed specifications are attached for both tests to assist our Certified Welding Instructors as they prepare

their agricultural mechanics students for certification.

The Company

Although there are many Certified Welding Inspectors who can assist with welding certification we have

teamed up with Professional Service Industries, Inc. to offer a standardized program for all students in our

programs. Professional Service Industries, Inc. is the nation's largest firm which provides engineering,

scientific, technical, and management solutions to public and private sector clients. PSI provides a variety of

specialty engineering and testing services to business and industry. One can learn more about PSI at

http://www.psiusa.com/ and specifically about their welding testing program by clicking on Mechanical

Testing Services and then scrolling down to Welding Services.

The Process

Our

Certified

Welding

Instructors

will

use

the

AWS

D1.1

Welder

Qualification

Test

Procedures

provided

to

assist

their

students

in

preparing

for

certification.

Students

will

prepare

test

welds

according

to

the

attached

AWS

D1.1

Welder

Qualification

Test

Procedures

leaving

the

test

weld

in

the

3G

or

4G

position

until

the

instructor

has

acknowledged

with

the

student

that

the

weld

is

complete.

Our

Certified

Welding

Instructors

will

visually

inspect

the

each

test

plate

for

cracks,

craters,

weld

reinforcement,

and

undercut

size.

Once

the

weld

test

plate

has

passed

the

visual

inspection,

it

will

be

subject

to

the

bend

test

by

our

certified

welding

instructors.

If

the

weld

passes

the

bend

test,

the

plate

along

with

accompanying

Welder

Qualification

Paperwork

will

be

submitted

to

Mike

McCraw

for

radiographic

testing

and

certification.

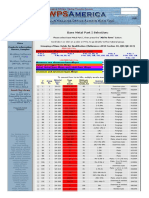

WELDER QUALIFICATION PAPERWORK

School and School District

Date of Qualification Test

Welding Code AWS D1.1-2010

Instructor / Student Name

Instructor / Student ID xxx-xxProcess Shielded Metal Arc

Base Metal A36 (Carbon Steel)

Pipe Diameter N/A

Material Thickness 3/8

Position 3G / 4G

Weld Progression Uphill / N/A

Filler Metal

Specification # A5.1

Classification E7018

Diameter 3/32 / 1/8

F# 4

Trade Name

Backing 1/4 or 3/8 Plate

Shielding N/A

Witnessed By

Required Test(s) Radiographic Inspection per AWS D1.1

$65.00 / plate (includes Paperwork); $105.00 / 2 plates (3G & 4G) from

same welder submitted at the same time. Submit this form and test plates to

Cost of Radiographic Testing

the below address (Attn: Mike McCraw). Please call Mike McCraw of PSI

with any questions at (336)669-1457.

PROFESSIONAL SERVICE INDUSTRIES, INC.

5319 West Market Street Greensboro, NC 27409

Phone (336)294-0522 Fax (336)292-2508

AWS D1.1 Welder Qualification Test Procedure

Carbon Steel Plate Test (WQTP #1) (Revision 0)

Welding Process: Shielded Metal Arc Welding (SMAW)

Base Metal: A36 or equivalent

Plate Thickness: 0.375 with 22.5 Bevel

Backing Plate: 0.250 or 0.375 x 3 Wide Minimum

Welding Electrode: E7018 (3/32 or 1/8)

Test Position: 3G (Vertical Uphill Progression)

Pre-Heat: 50F, Minimum

Testing Witness: To Be Determined

Plate Details:

Bevel: 45 (Included Angle)

Root Gap: 1/4

Page 1

AWS D1.1 Welder Qualification Test Procedure

Carbon Steel Plate Test (WQTP #1) (Revision 0)

Weld Position Details:

3G (Vertical) Weld Progression: Uphill

Welding Variables:

Filler Metal

Weld

Pass(es)

Process

Classification

1n

SMAW

E7018

Diameter

3/32

1/8

Current

Type and

Polarity

DCRP

DCRP

Amps

(Range)

70 110

90 160

Volts

(Range)

19 22

20 23

Travel Speed

(Range)

2 7 IPM

2 8 IPM

Other (e.g.,

Remarks,

Comments, Hot

Wire Addition,

Technique, Torch

Angle, etc.)

Welding Notes:

Once test weld is placed in the 3G or 4G position, the test weld shall not be removed until

completion of the weld

At the completion of the test welds, the coupons shall be visually examined in accordance with AWS D1.1,

Clause 4.9.1.1 Visual Inspection of Groove Welds.

Any crack shall be unacceptable

All craters shall be filled to the full cross section of the weld

Weld reinforcement shall not exceed 0.125

Undercut shall not exceed 0.031 (1/32)

If the test welds meets the visual requirements of AWS D1.1, the test weld will be subjected to mechanical

testing (bend testing) or radiographic testing in accordance with AWS D1.1.

Page 2

AWS D1.1 Welder Qualification Test Procedure

Carbon Steel Plate Test (WQTP #1) (Revision 0)

Failure of Test Weld If the test weld fails either the visual or mechanical/radiographic testing, the welder

will not be permitted to retest for 30 days.

Successful Completion of Test Weld Successful completion of the above described tests weld will allow the

welder to weld on the Covidien jobsite with the following limitations:

Welding Process: Shielded Metal Arc Welding

Welding Electrode F- Number: F1 thru F4

Welding Positions: Flat, Horizontal, Vertical

Backing: With backing, backgouging, or both

Base Metals: AWS D1.1 Base Metals

Base Metal Thickness Range:

Groove Welds: 0.125 to 0.750

Fillet Welds: 0.125 to Unlimited

Diameter Range (Structural Piping):

Groove Welds: 24 diameter & over with backing, backgouging, or both

Fillet Welds: All Diameters

Page 3

AWS D1.1 Welder Qualification Test Procedure

Carbon Steel Plate Test (WQTP #2) (Revision 0)

Welding Process: Shielded Metal Arc Welding (SMAW)

Base Metal: A36 or equivalent

Plate Thickness: 0.375 with 22.5 Bevel

Backing Plate: 0.250 or 0.375 x 3 Wide Minimum

Welding Electrode: E7018 (3/32 or 1/8)

Test Position: 3G (Vertical Uphill Progression) & 4G (Overhead)

Pre-Heat: 50F, Minimum

Testing Witness: To Be Determined

Plate Details:

Bevel: 45 (Included Angle)

Root Gap: 1/4

Page 1

AWS D1.1 Welder Qualification Test Procedure

Carbon Steel Plate Test (WQTP #2) (Revision 0)

Weld Position Details:

3G (Vertical) Weld Progression: Uphill

4G Overhead

Welding Variables:

Filler Metal

Weld

Pass(es)

Process

Classification

1n

SMAW

E7018

Diameter

3/32

1/8

Current

Type and

Polarity

DCRP

DCRP

Amps

(Range)

70 110

90 160

Page 2

Volts

(Range)

19 22

20 23

Travel Speed

(Range)

2 7 IPM

2 8 IPM

Other (e.g.,

Remarks,

Comments, Hot

Wire Addition,

Technique, Torch

Angle, etc.)

AWS D1.1 Welder Qualification Test Procedure

Carbon Steel Plate Test (WQTP #2) (Revision 0)

Welding Notes:

Once test weld is placed in the 3G or 4G position, the test weld shall not be removed until

completion of the weld

At the completion of the test welds, the coupons shall be visually examined in accordance with AWS D1.1,

Clause 4.9.1.1 Visual Inspection of Groove Welds.

Any crack shall be unacceptable

All craters shall be filled to the full cross section of the weld

Weld reinforcement shall not exceed 0.125

Undercut shall not exceed 0.031 (1/32)

If the test welds meets the visual requirements of AWS D1.1, the test weld will be subjected to mechanical

testing (bend testing) or radiographic testing in accordance with AWS D1.1.

Failure of Test Weld If the test weld fails either the visual or mechanical/radiographic testing, the welder

will not be permitted to retest for 30 days.

Successful Completion of Test Weld Successful completion of the above described tests weld will allow the

welder to weld on the Covidien jobsite with the following limitations:

Welding Process: Shielded Metal Arc Welding

Welding Electrode F- Number: F1 thru F4

Welding Positions: All Positions

Backing: With backing, backgouging, or both

Base Metals: AWS D1.1 Base Metals

Base Metal Thickness Range:

Groove Welds: 0.125 to 0.750

Fillet Welds: 0.125 to Unlimited

Diameter Range (Structural Piping):

Groove Welds: 24 diameter & over with backing, backgouging, or both

Fillet Welds: All Diameters

Page 3

You might also like

- Welder Qualification Test For GMAW STT FCAWDocument2 pagesWelder Qualification Test For GMAW STT FCAWSyed Mahmud Habibur RahmanNo ratings yet

- Pocket Welding Guide PDFDocument186 pagesPocket Welding Guide PDFJairo Contreras100% (2)

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocument1 pagePQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraNo ratings yet

- WPS, PQR, WQT, WPQ: BBW30103 Teknologi Kimpalan BerautomasiDocument12 pagesWPS, PQR, WQT, WPQ: BBW30103 Teknologi Kimpalan BerautomasiNazrin GLNo ratings yet

- WPSDocument25 pagesWPSWaqas WaqasNo ratings yet

- Specification For Welding of Duplex Stainless Steel Pipelines AmendmentsSupplements To API STD 1104Document54 pagesSpecification For Welding of Duplex Stainless Steel Pipelines AmendmentsSupplements To API STD 1104Ajesh Kumar Muraleedharan100% (1)

- Asme Section IxDocument260 pagesAsme Section IxHassan Aziz100% (3)

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- 6GR RequirementsDocument1 page6GR Requirementswalitedison100% (1)

- Preguntas Al Comite API 1104Document12 pagesPreguntas Al Comite API 1104alefeli26No ratings yet

- Dep 30.10.60.32 - Welding of Metals, Based On Iso StandardsDocument76 pagesDep 30.10.60.32 - Welding of Metals, Based On Iso StandardsPablo PazNo ratings yet

- API 6A RadiographyDocument4 pagesAPI 6A RadiographyminakshissawantNo ratings yet

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- Shortcut To A WPSDocument18 pagesShortcut To A WPSCepi Sindang Kamulan100% (1)

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDocument2 pagesThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungNo ratings yet

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- SAIC-W-2XXX-11 Control of Welding ConsumablesDocument5 pagesSAIC-W-2XXX-11 Control of Welding ConsumablesAnsuman KalidasNo ratings yet

- Norma CWB Cambios en W47.1-2009Document6 pagesNorma CWB Cambios en W47.1-2009Jose ManuelNo ratings yet

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 pagesNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNo ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument43 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesDinesh SinghNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- QW-403.2 InterpretationDocument1 pageQW-403.2 Interpretationlaz_kNo ratings yet

- Catalogo AWSDocument46 pagesCatalogo AWScesarNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Welding TechDocument348 pagesWelding Techniteenkardi100% (2)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Welding SectionsDocument184 pagesWelding SectionsvmgobinathNo ratings yet

- p999999 100zd11 000 zd0001 - 0 Welding StandardDocument25 pagesp999999 100zd11 000 zd0001 - 0 Welding StandardJennyNo ratings yet

- 127.study The Effect of Welding Parameters of Tig Welding of PlateDocument43 pages127.study The Effect of Welding Parameters of Tig Welding of PlatemoorthikumarNo ratings yet

- Ra-253-Ma DB Us en PDFDocument12 pagesRa-253-Ma DB Us en PDFbadesharamkNo ratings yet

- Welding Procedure QualificationDocument23 pagesWelding Procedure QualificationHosam AhmedNo ratings yet

- Wps Guides 2006Document25 pagesWps Guides 2006BE GNo ratings yet

- WPS PQR WPQRDocument1 pageWPS PQR WPQRFazeel Rick MohammedNo ratings yet

- Welding Procedure Specification (WPS) : Supporting PQR 01Document2 pagesWelding Procedure Specification (WPS) : Supporting PQR 01duyanhNo ratings yet

- Aws d1.5 PQRDocument2 pagesAws d1.5 PQRjacquesmayolNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Document16 pagesNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVNo ratings yet

- GB 50128-2005-EnDocument52 pagesGB 50128-2005-En柳德米拉100% (2)

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDocument1 pagePDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينNo ratings yet

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 pagesCSM-QR-02-2, Medical Gas BPS TablesaadmaadmNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- 625 CRO - SAW Study - Final Report PDFDocument21 pages625 CRO - SAW Study - Final Report PDFAnouar AbdelmoulaNo ratings yet

- ASME 9 Multi Process Welding Procedures QW200Document2 pagesASME 9 Multi Process Welding Procedures QW200Teodor EzaruNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument7 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCTrường Tùng LýNo ratings yet

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocument3 pagesSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNo ratings yet

- Prosedur Vacum Box TestDocument5 pagesProsedur Vacum Box TestIkhsan Dalimunthe100% (2)

- Weld Matrix Format 1Document7 pagesWeld Matrix Format 1Arslan WaheedNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Tube To Tubesheet WeldsDocument1 pageTube To Tubesheet Weldsramzi5ben5ahmedNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNo ratings yet

- Repair WpsDocument2 pagesRepair WpsyogacruiseNo ratings yet

- Quality Plan For Vessel Structural ModificationDocument9 pagesQuality Plan For Vessel Structural ModificationEbuka NwankwoNo ratings yet

- Painting Inspector CVDocument2 pagesPainting Inspector CVGodwin A.udo-akanNo ratings yet

- WPS (1) 1Document5 pagesWPS (1) 1Pedro José PadillaNo ratings yet

- Welding of Pipelines and Related Facilities: Api Standard 1104 Nineteenth Edition, September 1999Document62 pagesWelding of Pipelines and Related Facilities: Api Standard 1104 Nineteenth Edition, September 1999Riki AkbarNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportgst ajah100% (1)

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- Ut ProcedureDocument7 pagesUt Procedurearavindan100% (1)

- W Ps AmericaDocument2 pagesW Ps AmericaAla Reguii100% (1)

- 1a Arc Weld ProcessesDocument45 pages1a Arc Weld ProcessesskgcNo ratings yet

- P235GH Engl PDFDocument4 pagesP235GH Engl PDFraduonoNo ratings yet

- Field Welding Section 12.1Document23 pagesField Welding Section 12.1parmindersinNo ratings yet

- Experimental Investigation of SS 316 by Using TIG-MAG WeldingDocument3 pagesExperimental Investigation of SS 316 by Using TIG-MAG WeldingKaushik Sengupta100% (1)

- Diversity of Welding ProcessesDocument24 pagesDiversity of Welding ProcessesAnonymous cgcKzFtXNo ratings yet

- Scholarship InquiryDocument16 pagesScholarship InquiryHannaNo ratings yet

- MRTS71 SupersededDocument13 pagesMRTS71 SupersededbradrimmNo ratings yet

- Two Marks-Manufacturing Technology-I University Questions and AnswersDocument47 pagesTwo Marks-Manufacturing Technology-I University Questions and AnswersrahmaNo ratings yet

- Chapter 5 WeldingDocument16 pagesChapter 5 Weldingchoriya007No ratings yet

- Welder Management Spreadsheet (Metric)Document4 pagesWelder Management Spreadsheet (Metric)Goutham RathinamNo ratings yet

- CladdingDocument16 pagesCladdingMuhammed SulfeekNo ratings yet

- Gas Comparison ChartDocument1 pageGas Comparison ChartAllen RosonNo ratings yet

- Apm Et13e Chapter 22 Welding and CuttingDocument30 pagesApm Et13e Chapter 22 Welding and CuttingBhakti SagarNo ratings yet

- Handbook R M XA00086820Document130 pagesHandbook R M XA00086820Dan VitkinNo ratings yet

- Liburdi J Weld Head ManualDocument74 pagesLiburdi J Weld Head ManualfelipouseNo ratings yet

- Presentation On: Applications of and Welding in ManufacturingDocument27 pagesPresentation On: Applications of and Welding in ManufacturingHope ThemNo ratings yet

- LPP-013-MEC-VP-042-V - WELDING MAP DEMIN WATER TANK 10GCL10BB001 Eng ReviewDocument13 pagesLPP-013-MEC-VP-042-V - WELDING MAP DEMIN WATER TANK 10GCL10BB001 Eng ReviewabdiNo ratings yet

- Lincoln Electric MIG WelderDocument36 pagesLincoln Electric MIG WelderLiz CNo ratings yet

- Migatronic AccessoriesDocument28 pagesMigatronic AccessoriesImre KathiNo ratings yet

- Kurji Coniglio 2014Document18 pagesKurji Coniglio 2014xaxafagaNo ratings yet

- Asme Wps DemoDocument3 pagesAsme Wps DemoArupendranarayan ThakurNo ratings yet