Professional Documents

Culture Documents

Inside-Out Algo - Boston 1974

Uploaded by

Jeremy HernandezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inside-Out Algo - Boston 1974

Uploaded by

Jeremy HernandezCopyright:

Available Formats

A New Class of Solution Methods for

Multicomponent, Multistage

Separation Processes

J . F . BOSTON

College of Petroleum and Minerals, Dhhran, Saudi Arabia

rmd

S . L. SULLIVAN, JR.

Tulane University, New Orleans, Louisiana, U.S.A.

A new algorithm was developed for the solution of the

equations that describe multicoqponent, multistage separation

processes operating at steady state. The algorithm is based on

the use of newly defined energy and volatility parameters as

the primary successive approximation variables. A third parameter was defined for each stage as a unique combination

of the liquid and vapor phase rates and the temperature, and

the quasi-Newton method of Broyden was employed to iterate

on these parameters. The exceptional stability of the new algorithm in very difficult cases, as well as its efficiency in easy

cases, are demonstrated using a variety of example problems.

he equations that describe a countercurrent, multistage separation process operating a t steady

state, while appearing to be quite simple, are in fact

highly nonlinear and interdependent. Hence, the calculations that are necessary to solve them are intrinsically iterative, complex and large in number. While

the widespread availability of high-speed computers

resulted in a greatly intensified interest in so-called

rigorous methods, i.e., methods of solving the governing equations without introducing simplifying assumptions beyond that of the equilibrium stage, there

are certain deficiencies associated with all such methods that have evolved. Some methods are oriented to

the solution of particular classes of problems, and

cannot be successfully applied to problems of other

classes. Other methods are not directly applicable to

problems involving systems that exhibit nonideal solution behavior.

In the past few years considerable progress has been

made in the area of correlation of thermodynamic

properties, resulting in increased availability and usage of more rigorous and more complex correlations.

Most of the present methods for performing simulation calculations, however, were not designed for the

most efficient utilization of thermodynamic property

evaluations, hence they tend to expend an inordinate

amount of computational effort when complex, composition dependent correlations are used.

A new class of methods which does not possess

On a mis au point un nouvel algorithme pour rksoudre les

Cquations qui dkcrivent les mbthodes de ¶tion de plusieurs

composants en plusieurs Ctages et en rkgime permanent. Lalgorithme est bask SUI lutilisation des parambes dknergie et

de volatibilitk, rCcemment dkfinis comme les principales variables dapproximations successives. On a dkfini, pour chaque

&age, un troisihme paramkre comme une combinaison unique

des taux en phase liquide et en phase de vapeur et de la

tempkrature; on a mployk la m&hode de Broyden, qui se r a p

proche beaucoup de celle de Newton, pour faire une itkration

sur lesdits paramkres. On dkmontre, au moyen dexemples de

problhes variks, la stabilitk exceptionnelle du nouvel algorithme dans des cas t r b difficiles et son efficacitC dans les

cas faciles.

these shortcomings was developed. The methods were

based on the selection of newly defined energy and

volatility parameters as the primary successive approximation variables. A third parameter was defined for

each stage, in order to eliminate certain interactions,

as a unique combination of the liquid and vapor phase

rates and the temperature, and a modification of the

quasi-Newton method of Broyden was employed to

iterate on these parameters. An improved algorithm

for solution of the component mass conservation equations was developed, and has been discussed in a previous paper).

The present paper describes the algorithm as applied

t o distillation only. Subsequent papers will discuss

the application of the new class of methods to absorption, reboiled absorption and extractive distillation,

and a final paper will discuss the treatment of problems involving hydrocarbon-water systems in which a

separate liquid water phase may appear on any of

the stages. A special, very efficient algorithm was

developed to solve the system of component mass balance equations and constraints that arise in this case.

Previous work

For steady state vapor-liquid separation processes,

there

are basically five sets of independent algebraic

aaaaa~aa~~aa~~a~~~~Daaaaaaaaa~~aaaaaaaaaoa~~aaaaaaaoa~aooaaaaaaoaaoaaaaa~c

equations that must be simultaneously satisfied for

Present Address : Scientific Development Department, Bechtel Corpoeach stage : component mass conservation (CMC),

ration, San Francisco, California

52

!

The Canadian Journal of Chemical Engineering, Vol. 52, February, 1974

energy conservation (EC), phase equilibrium (PEQ),

and liquid and vapor mole fraction constitutive

(LMFC and VMFC) equations. In addition, certain

combinations of these sets of equations which are frequently utilized are the total mass conservation

(TMC), bubble-point (BP), and dew-point (DP)

equations.

Since most of these equations are highly nonlinear,

with strong coupling both within each set, and from

cine set to another, all of the previous rigorous methods for solving them are based on successively approximating the exact ~olution*~~.

In previous workc4four

classes of rigorous methods were identified. The

classes are characterized by the choice of the successive approximation (SA) variables, while the variations that have evolved within classes are due primarily to differences in the procedures used to generate

the SAs. Three of the four classes of methods were

concluded to have serious disadvantages which essentially preclude their utility as general purpose methods capable of efficiently solving a wide variety of

problems. The methods of Class B appeared to be

the most promising in this regard, and these are the

methods which have received by f a r the greatest attention of recent investigators.

Clms B methods

The use of the stage temperatures and interstage

phase rates as the SA variables characterizes these

methods. Either the liquid or vapor phase rates are

chosen, and the others are immediately obtained from

the TMC equations. In the case of ideal solution behavior, knowledge of these variables is sufficient to

solve the CMC equations over all the stages simultaneously, one component a t a time. For this purpose,

the CMC equations are modified by substituting the

PEQ equations to eliminate vapor (or liquid) mole

fractions or component flow rates. Following solution

of the CMC equations, the SAs of the stage temperatures and liquid o r vapor interstage phase rates are

calculated from the BP (or DP) and EC equations.

The first use of a class B method was presented by

Thiele and Geddes in 1933, although they did not

propose a definite convergence scheme for the SA

variables. The later methods included in the previous review4 are those of Donne11 and Turbin, Rea

and Hanson, Amundson and Pontinen, Holland, Petryschuck and Johnson, Sullivan, Wang and Henke,

Newman, Boynton, Sujata, McNeese, Friday, Tierney

and Bruno and TomichS*E.More recent papers by

Tierney and Yanosik), Orbach, et al.8*90and Billing~ley~)

have been published on Class B methods.

The general approach of the Class B methods is a

very versatile one. It can be applied with relative case

to complex columns, i.e., columns having multiple feeds

and multiple product streams. With various forms of

the SA procedures, it has been shown to be relatively

efficient for many distillation, absorption and s t r i p

ping and reboiled absorption pr~blerns~.

The more

recent methods of this class appear to be the most

efficient and reliable when applied to those types of

problems for which they are best suited. In particular,

the method of Sullivan for distillation, and Sujatas

method for absorption are citedc4. The recent paper

by Billingsleyl) describes what appears to be the best

Class B method published to date for distillation problems. It is substantially the same as Sullivans method,

with an improved temperature determination procedure for difficult cases, and an efficient means of

handling mildly nonideal systems in which equilibrium

TOP

TERMINAL

STAGE

TYPICAL

INTERNAL

STAGE

BOTTOM

TERMINAL

STAGE

FVN

--T-

*B (LN, WLN)

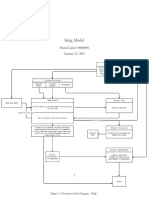

Figure 1 - Schematic diagram of general model column.

ratios and enthalpies are composition dependent. On

the other hand, no Class B method has been demonstrated to be reliable and efficient when applied t o

difficult problems such as distillation problems with

wide boiling feeds, and certain reboiled absorber

problems.

There are a number of disadvantages associated

with the Class B choice of SA variables. One is that

both the CMC and EC equations effectively contain

severe interactions between these variables. Direct

combinations of the phase rates with the temperaturedependent equilibrium ratios appear as the coefficients

of the CMC equations, and the EC equations involve

direct combinations of the phase rates with the temperature-dependent liquid and vapor enthalpies. In

general, the ease of solution of any system of nonlinear equations is enhanced if the independent variables can be chosen in such a way a s to eliminate or

reduce the effects of interactions between them. The

presence of strong interactions means that the offdiagonal elements of the Jacobian matrix which defines the iteration algorithm may be large and may

change markedly from trial to trial. The Jacobian

matrix may also have other undesirable properties,

such a s near-singularities and conditions that represent saddle points. Any adverse effects of interactions

on the iteration algorithm will be more pronounced

when the initial estimates of the variables are very

poor.

Another disadvantage of the Class B choice of SA

variables arises when the equilibrium ratios are composition dependent. The liquid and vapor compositions

are not known a t the point where i t is necessary to

calculate composition-dependent equilibrium ratios,

that is, just before the CMC equations are solved.

Class B methods tend to be inefficient when applied

to such problems, since either the compositions from

a previous trial must be used o r a n extra iteration

loop must be introduced.

If the composition lag approach is adopted, the

convergence properties of the iteration algorithm may

be adversely affected, especially for highly nonideal

systems. The second approach would require iterating

on the equilibrium ratios, solving the CMC and PEQ

equations for each iteration, until the assumed equilibrium ratios matched those calculated using the resulting liquid and vapor compositions. This approach

The Canudiun raurnal of Chemical Engineering, Vol. 52, February, I9F4

53

could obviously be exceedingly costly in terms of expenditure of computational effort.

The new method

The following sections describe the algorithm a s

applied to distillation problems, and results a r e presented to demonstrate its performance on a group of

test problems. Performance results obtained using a

program based on Tomichs algorithm a r e also given

for comparison.

The model equations

The model equations t h a t describe a steady state

distillation process a r e based on the general model

column depicted schematically in Figure 1. Stage 1

is regarded as the condenser and stage N the reboiler,

both of which a r e treated as equilibrium stages. The

condenser and reboiler heat duties a r e Ql and QN,

and Dv

DL is the total distillate rate. I n the case

of a total condenser, i.e., DV = 0, the liquid of stage 1

is assumed to coexist in equilibrium with the vapor

above it. The feed streams FLI,Fvl,FLNand FvN will

usually be zero. It is assumed t h a t a liquid feed mixes

perfectly with the liquid contents of the stage below its

entry point, and that a vapor feed mixes perfectly with

the vapor rising from the stage below its entry point.

The withdrawal streams are assumed to have the same

composition and conditions as the fnterstage streams

from which they are drawn. Perfect mixing is assumed to occur in the liquid phase of each stage, and

the vapor and liquid phases exiting from a stage a r e

therefore related by the condition of equilibrium. No

loss of generality is suffered by virtue of these latter

assumptions, since the departure from equilibrium

can be taken into account by appropriately modifying

the equilibrium ratio expressions2, using either modified vaporization efficiencies, or combinations of

these with modified Murphree efficiencies.

The principal results of the detailed derivations of

the model equations given in Appendix A are summarized below for convenience :

Comfionent mass conservation (CMC):

bi9nli.n

(n=2,3,. . . N-1). . . (1)

Cirnlirn+l = f;,n

Liquid aul vrrpor mole frartion definition (LMFD mad VMFD):

xi,, = li,n/glj,n,.

................................

.(2)

Yi,,, =

ffi,nli,n

/ L: ffj,n lj,n. . . . . . . . . . . . . . . . . . . . . .

..

(3)

Bubble Boint (BP):

KbnT 0% xi,, = 1.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(4)

Energy consewation (EC):

-@-l

54

- a:) L,1

En -

d + 1 MTn

Vn+I =

L,

MTn

(n

1, 2, . . . . N-1).. . . . . . . . . . . .(6)

Selection of the inde@endent variables

The new method to be discussed in the present paper

is based on work previously reported by one author4,

in which the method was found t o be superior to both

Sullivans and T ~ r n i c h s ~methods.

~~

The algorithm

given here (and in later papers), however, contains

substantial improvements over the version reported

earlier.

-lit*&-1

Totd mass conservation (TMC):

GnWLn --

+ (a,

a:+I)L

+ Wvn)

4, (M~n-1

(n = 2, 3, . . . , N-1). . . . . . . . . . . . . . .(5)

A method of determining which variables can be

specified in a multicomponent, multistage process consists of counting the number of independent constraining equations and the total number of variables that

completely describe t h e process. Subtracting t h e former from the latter then gives the number of degrees

of freedom, or the number of variables in any subset t h a t can be specified arbitrarily. I n t h e slightly

different but equivalent approach used here, the constraining equations were f i r s t listed and counted, and

a corresponding set of unspecified variables, equal in

number t o the constraining equations, was listed. All

of t h e remaining variables were then recognized as

those which must be specified in order to have a determinate problem: number of stages; heat duties;

withdrawal stream rates (other than LN and VI) and

locations ; feed rates, conditions, compositions and locations; and all pressures.

In some cases it is expedient to exchange one or

more variables from the unspecified list with the same

number from the list of specified variables. In the

present work, such an exchange was made in order

to permit the condenser and reboiler heat duties (Q1

and Q N ) to be determined. Thus, t h e reflux rate L,

and the bottom product rate LN were treated as specified variables, and Q1and Q N were calculated from the

corresponding EC equations.

Sircressive afiproximation variables

The choice of SA variables on which the new method is based makes i t quite unlike any previous method,

hence it may be regarded as a member of a n entirely

new class of methods. The SA variables a r e referred

to as volatility parameters (m,,,), defined by Equation

(A-7), and energy parameters( QTn, h,,

Om, ,6 and

hEl), f o r which the defining relations are Equations

(A-16),(A-17), (A-18), (A-20) and (A-19), respectively. An important attribute of these variables is

that they a r e very weak functions of variables for

which initial estimates may be very poor, such as

stage temperatures, interstage phase rates, and liquid

and vapor mole fractions. Reasonably good initial estimates of the energy and volatility parameters (EVPs)

can always be obtained by using quite inaccurate initial estimates of t h e temperatures and interstage

phase rates. The procedure t h a t was used to generate

the initial estimates of the EVPs is described in Appendix B. Successive approximations were then obtained by solving the model equations, followed by

updating t h e EVPs using the appropriate physical

property relationships. This procedure was found to

converge rapidly and with exceptional stability, even

when direct iteration was employed (i.e., the updated

EVPs were taken to be the assumed EVPs for the

next trial).

The rapid convergence of the E V P iterations tends

to minimize that portion of the total computational

load associated with the rigorous evaluation of equilibrium ratios and enthalpies, since rigorous evaluations

are required only once per trial. This is especially important for nonideal systems where the correlations

may be very complex, and the associated computational

load is a quite large fraction of t h e total.

T h e Canadian Journal of C h e m i c d Engineering, Vol. 5 2 , February, 1974

The calculations that comprise a single trial of the

EVP method are described by the following stepwise

outline :

Assume values of the EVPs.

Assume values of the S R S , RLS and Rvs (defined in Appendix A).

Solve the CMC Equations (1) for the component

liquid rates.

Calculate the liquid mole fractions from the

L M F D Equations (2).

Calculate the Kbs from the B P Equations (4).

Calculate the temperatures from the Kdemperature relationships.

Calculate the coefficients of the EC Equations

( 5 ) , and solve for the liquid phase rates.

Calculate the vapor phase rates using the TMC

Equations ( 6 ) .

Calculate the SRs,R L s and Rvs from the defining relations (A-11), (A-12) and (A-17). Compare these values with the last assumed values.

If they do not agree within an acceptable tolerance, assume a new set of values and return to

step 13).

Calculate the vapor mole fractions from the

V M F D Equations (3).

Evaluate the equilibrium ratios and enthalpies.

Update the EVPs, using the defining relations

(A-7), (A-161, (A-17), (A-181, (A-19) and

(A-20). Compare these values with the last assumed values. If they do not agree within an

acceptable tolerance, retain the updated values

and return to step (2).

The EVPs are truly independent variables in the

sense that the updated values depend only on the immediately preceding assumed values, even for nonideal

systems. All of the model equations can be solved directly, and there are no lags of compositions, temperatures, phase rates, etc.

I t is also significant that all of the model equations

can be solved without assuming separately values of

the temperatures and phase rates. This is accomplished

by using the relative S-parameters (SR)as the variables of the iterative procedure in steps (2) to (9).

Thus, these quantities may be viewed as unique combinations of temperatures and phase rates which, in

essence, eliminate the very undesirable interactions

between these variables.

Another advantage in the use of the relative S-parameters is the elimination of internal inconsistencies

that can occur in class B methods. In these methods

the solution of the CMC equations results either in

mole fractions that do not sum to unity, or in component flow rates that do not sum to the assumed total

phase rates. Some Class B methods introduce an extra

interation loop to adjust temperatures or phase rates

to attain consistency before proceeding. Others proceed simply by normalizing the mole fractions to sum

to unity, while still others proceed without taking any

measures to eliminate the inconsistencies.

Other notes and observations regarding certain

steps of the EVP method are listed below:

St@

(1)

(2)

The initial estimates of the EVPs, SRS,

RLSand

Rvs were developed by a procedure outlined in A p

pendix B.

S W (3)

The CMC equations for each component form a

tridiagonal system that was solved using a new algorithm developed by the authors. As discussed later,

this step includes the determination of the base Sparameter Sa and the value of S1 for the condenser

(when V1 > 0) to satisfy certain overall material

balance criteria.

Ste@ ( 5 )

and (6)

The temperature determination method used in these

steps is referred to as the bubble-point method. It

is notable that no bubble-point iterations were performed, i.e., i t was not required to iterate on the temperatures to satisfy simultaneously the phase equilibrium and vapor mole fraction constitutive equations.

Rather, these equations were used directly in step (5)

in the form of the BP equations.

step

(6)

The functional form of the Kb temperature dependence relationships, referred to as the Kb models, are

discussed in a later section. A weighting function was

developed by which the Kb temperature dependency

coefficient was related to the temperature sensitivities

of the individual component equilibrium ratios. In a

later paper, the development of a special Kb model

for extractive distillation will be presented.

St@ ( 9 )

A quasi-Newton method was employed to develop

the new set of SHs,RLs and Rvs; this algorithm is

discussed in a later section.

Step (11)

For all cases studied in the present work, the Grayson-Streed2) version of the Chao-Seader correlation, along with the Redlich-Kwong and SchatchardHildebrand equations, were used to calculate equilibrium ratios and enthalpies. In later work other correlations were used.

Step (12)

The Kb model coefficients were also updated in this

step, if necessary. Since, in some cases, moderate

damping of the EVPs prior to returning to step (2)

improved the overall convergence behavior, a simple

damping algorithm that generates a damping factor

lying between 0.5 and 1.0 was developed.

The K,,Model

defined by the relaThe volatility parameters a;,,,,

tionship

Kbn

Ki,,

were used as successive approximation variables because, for a particular stage, the d s for those components that most significantly affect the stage temperature are the least sensitive to variations in that

temperature. This effect was achieved by devising a

Ka temperature dependence model that effectively absorbs the temperature dependence of the most significant component equilibrium ratios. The magnitude of

the temperature dependence of this model is a weighted average of the individual equilibrium ratio dependencies, using the component vapor mole fractions as

the weighting factors. The form of the weighting

function was derived by requiring that the tempera-

The Canadian Iournal of Chemical Engineering, VoZ. 52, February, 1974

55

ture sensitivity of the BP equation in terms of

(with temperature-independent a s )

3 Kbn(Yi,nXirn =

z

Kb

from which the corresponding temperature T, was

determined, match as closely as possible the sensitivity

of the BP equation in terms of the individual component Ks :

This requirement may be shown to lead directly to

the following result :

Since the component vapor mole fractions may vary

markedly from stage to stage, i t was found to be advantageous to generate a unique K b model for each

stage. Further, i t proved to be beneficial to update the

Ks models for some or all of the stages after each trial.

It may be assumed, therefore, that the K b model for

a particular stage would be applied over relatively

small temperature intervals. Thus, the simple exponential form

log Kb,

A , - -.B . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

(8)

was found to be quite adequate to describe the K b

temperature dependence, where the coefficient B was

dtermined by applying Equation (7), using numerical differentiation to calculate the partial derivatives.

Thus, a total of two calculations of the component

equilibrium ratios were required each time the Ka

coefficients were updated. While the value of A is arbitrary, for scaling purposes it was initially evaluated

by :

A, =

L:i Yi,, log Ki.,

B, . . . . . . . . . . . . . . . . . . . .

T

-.

,(9)

The correctness of the final solution requires only

that the a s be updated after each trial based on the

current K b values and updated Ks. I t is not essential

t o update either of the Kb coefficients after the initial

determination. If the Bs are updated a s well as the

as two evaluations of the Ks per stage are obviously

required, whereas if only the as are updated a single

evaluation of the Ks will suffice. However, the best

convergence behavior was achieved when the Bs were

conditionally updated after each trial. When the relative change in any B over any two successive trials

became less than some specified value, that B was not

updated before performing the next trial. When a B

value was updated, the corresponding A value was

determined to satisfy the K b model with K b unchanged

from its current value:

A , = log Kan

2

B

Wzy

N

=-j 2 F,... . . . . . . . . . . . . . . . . . . . . . . . .

n= 1

,(lo)

where

W;,

(RL, - 1)LE

S firn

i

Fn

Assuming that the values of the specified flow rates

L I , W L ,and LN are properly chosen, the overall mass

balance equation

WL,

N

2 F,. . . . . . . . . . . . . . . . . . . . . . . . .

n=l

+ LA, =

.(11)

is also satisfied. No constraint has been imposed, however,

which requires either Wzl = WLI or L i = LN.Thus,the

value of sb was determined to force the latter condition to

be satisfied, the former one being satisfied automatically

by virtue of Equations (10) and (ll),and all results were

thereby consistent with the specified withdrawal rates.

In many cases of practical interest numerical difficulties arise because the sensitivity of L: to changes in sb

is exceedingly small, thereby preventing the accurate

determination of Sb by the above criterion. Yet, the liquid

rate profiles of very light components near the bottom

(and heavy components near the top) stage may be extremely sensitive to changes in Sa, and may strongly influence the values of calculated temperatures and phase

rates. Distillation problems with wide boiling feeds and

extractive distillation problems are examples of such

situations.

This apparently insurmountable difficulty was overcome by algebraic rearrangements of the overall mass

balance equation. The components of the feeds were

first ordered according to the relative magnitudes of

their equilibrium ratios, and all of the least volatile

components for which the combined feed rates constituted an amount equal precisely to the bottom product rate LN were designated as heavy components.

The remaining components were designated as light

components. (This procedure sometimes required the

designation of a fraction of some component as heavy

and the remaining fraction of the same component as

light). An overall mass balance equation, similar to

Equation (10) is satisfied for any component, or any

group of components, and i t is therefore satisfied in

particular for the heavy components :**

WE

+ Lg =

L: F,h...........................

(12)

n= 1

The criterion L: = LN for the determination of Sb may be

written in terms of the lights and heavies as:

T,

L$

Deterniination of Sb

The value of the base S-parameter Sa was determined to satisfy certain mass balance conditions that

would otherwise be satisfied only by the final converged solution. The component liquid flow rates resulting from solution of the C~~ ~~~~~i~~~(1) depend

56

on the value of S b through the coefficients b and c,

defined by Equations (A-10). Regardless of the value

of Sb, these results always satisfy an overall total mass

balance :*

+ L$

L N . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.Assuming, for convenience, a total

(v,

no withdrawal streams other than W,,,and L,.

= s, = ),,

.(13)

and

**The

rates of heavy components are indicated by the superscript

h, flow

and those of light components by the superscript 1.

The Canadian Journal of Chemical Engineering, Vol. 52, February, 1974

Sollving (12) for Lh,",substituting the result into (13), and

F:

using the definition

LN,the final result is:

n=l

Lg

W E .......................................

(14)

This condition, then, is completely equivalent to the previous condition L i = LK. yet its implementation is not

in any way encumbered by numerical difficulties.

For the most general case, in which there may be

liquid and vapor withdrawal streams for each stage,

a general criterion for the determination of S b was

derived by manipulations similar to those just described for the simple case. The result is:

ed, the analogous mean value (LSR,,)'" of the SR'S

must always be precisely unity. This has the effect

of imparting a high degree of inherent stability to

the iterative process by which the SR's are determined.

For scaling purposes, and in order t o avoid estimating a zero or negative SR value, the simple transformation

u = log S R

was employed, making the U's the actual iteration

variables. The problem may then be stated as follows.

Let U be a vector of assumed values, and let ?i be the

corresponding vector of values calculated from the

results of step (9) of the above outline. The problem

is to determine a vector of assumed values such that

some norm of the error function vector defined by:

c=g-v_

A

WZ

+ v:u +

m

n=2

(WE

+ W $ & ). .. . . . . . . . . . .(13l

where

was selected to divide the column into two

segments, each containing approximately the same

number of stages.

A procedure based on rational function approximations was employed to iterate on the value of SI,until

tlhe appropriate criterion was satisfied. Convergence

was generally quite rapid, seldom requiring more than

t w o iterations except during early trials of the SA

variables. As the overall SA procedure converges, the

value of Sb rapidly approaches its final value, so that

frequently in later trials of the SA variables not even

two S b iterations were necessary.

In some problems with wide boiling feeds, a dramatic improvement in the stability of the overall SA

zrlgorithm was experienced after (15) was implemented as the criterion for determining SI,.

The degree of

improvement was more pronounced the more difficult

the problem. Some problems which could not otherwise be solved without resorting to an alternative

temperature determination scheme were quite readily

solved by employing criterion (15).

Since V1 > 0 and S1 > 0 for partial condenser problems, both St and Sb were determined t o satisfy simultaneously the two criteria consisting of (15) and

the following additional one :

E/L? = Vi/Li . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

116)

where V , and L1 are known, and

IterutZve determimtion of the

relative S-parameters

The iteration on the SR's in steps (2) to (9) of the

calculationaI outline above may be considered as the

core of the new algorithm. By virtue of the choice of

the energy and volatility parameters as the main successive approximation (SA) variables, the SR's arise

naturally as the variables which must be determined

iteratively in each trial to satisfy all of the model

equations on the basis of the current estimates of the

SA variables.

It is notable that the Sx's, as defined by Equation

(A-13), depend only on the relative magnitudes of

the S-parameters. Whereas the magnitude of the mean

value Sb of the S-parameters is completely unrestrict-

is reduced to zero (within some specified tolerance).

I n view of the above discussion regardi!g

the mean

S R values, it is obvious that any set of U's based on

the values of the SR's calculated in step (9) will sum

t o zero. Similarly, every set of assumed values must

be adjusted t o insure that the sum is zero.

By virtue of the way in which the problem is formulated, it is amenable to treatment by direct iteration (DI), the simplest of all iteration algorithms.

placement away from the kth vector of assumed values

Let the direction vector 8V k ) be the direction of disU'".

Thus

U(k+') = UP) + p 6 U(h)

-

where the scalar multiplier p is a "distance factor".

In DI the direction vector is taken to be simply the

vector of error functions:

6_u=_G

hence the assumed values for the next iteration are

given by

-UP+') -UW + pG@)

=

The formulation of the problem as a system of nonlinear algebraic equations

-ccy

also makes it amenable to solution by any of a number

of general equation-solving algorithms, such as the

recently proposed quasi-Newton (Q-N) methods"6-'e'.

These methods are based on the Newton-Raphson

method, but do not require explicit re-evaluation of

the Jacobian matrix after each iteration. The Q-N

variation proposed by Broyden"'" was selected for

solution of the above equations. Thus, the ( k + l ) t h

vector of assumed values was obtained as:

-UP+') = -Utk)+ p H(k)G(k)

I

where H is the negative Jacobian inverse, which was

updated directly after each iteration using a formula

provosed by Broyden.

The heuristics employed with the Broyden algorithm

were found to have a significant influence on the success of the method. The strategy that finally evolved

was based on selective use of the Broyden algorithm

along with D I and a variation of the bounded Wegstein method of Kliesch'20). The optimization of the

heuristics was based on a wide variety of test p r o b

lems, including absorption, reboiled absorption and

extractive distillation as well as distillation. The aspects of the heuristics that were found to be important

included the choice of the norm of G by which con-

The Canadian Iournal of Chemical Engineering, Vol. 52, February, 1974

57

vergence progress was monitored, t h e criteria by

which the overall strategy was controlled, the determination of the distance factor p, stepsize limitations

and tolerances.

The formulation of the problem in such a way that

it is amenable to treatment by DI suggests the use of

the identity matrix as the initial H matrix. I n fact,

this is an important feature of the algorithm, since

i t means that not even one explicit evaluation (or inversion) of the Jacobian is required. This is particularly significant in those cases for which convergence

is very rapid, where a single Jacobian evaluation and

inversion would consume much more time than the

entire solution by the method of this paper.

For problems in which there were withdrawal

streams (other than LN,V,, and WLl), the corresponding withdrawal parameters were treated simultaneously with the SRSby the algorithm just described. For

each nonzero liquid withdrawal stream, an additional

variable U was defined by:

u = log (RL -

Hence, any failure of the modified Tomichs methou

implies a failure of Newtons method, as well as any

quasi-Newton method of a similar nature.

In all cases the equilibrium ratios were based on

liquid fugacity coefficients calculated by the ChaoSe~der~

correlation

using the Grayson-Streed(la) coefficients, vapor fugacity coefficients calculated by

the Redlich-K~ong~equation, and liquid activity

coefficients calculated by t h e Scatchard-Hildebrand

eauation. The latter equation was also used to calcnlate the liquid partial molar excess enthalpies. The

Redlich-Kwong equation was used for vapor phase

enthalpy departures, and special correlations of reduced temperature and acentric factor were employed

t o calculate liquid phase enthalpy departures.

For the E V P method the convergence criterion was

based on t h e maximum of the suitably normalized

changes of the EVPs over two successive trials. The

Convergence criterion for Tomichs method was based

on the Euclidean norm of the normalized error functions.

For the E V P method the initial estimates of the

successive approximation variables were obtained by

the procedure outlined in Appendix B. The phase rate

and linear temperature profiles on which these estimates were based were taken as the initial estimates

of the successive approximation variables for Tomichs method.

Table 1 contains certain key information regarding

the example problems. More detailed problem statements have been filed and may be obtained a t a nominal charge. These problem statements include the

1)

Vapor withdrawal parameters were treated analogously.

Example problems

A total of 23 example problems were selected to

illustrate the efficiency and stability of the new energy and volatility parameter ( E V P ) algorithm. For

comparison, Tomi~hs~,~

Class B quasi-Newton method

was also applied to the same problems. Because Tomichs method failed to converge on some of the problems, a slight modification was introduced wherein

t h e Jacobian matrix was recalculated by finite differences at any point where t h e quasi-Newton algorithm was unable to progress towards the solution.

Copies of Tables 1-9 are available. for a nominal charge from the

National Library, National Research Council, Ottawa, Ontario

KIA OS2.

TABLE1

EXAMPLE

PROBLEM

DESCRIPTIONS

-

Example

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

Problem Type

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

4 Component dumbel

4 Component dumbel

4 Component dumbel

4 Component dumbel

4 Component dumbel

Gasoline stabilization

Multiple feeds and sidt:

Multiple feeds and sidt:

Multiple sidestreams

Multiple feeds and sidt:

Debutanizer

Deethanizer

No. of

Components

2

2

2

2

2

2

2

2

2

2

2

4

4

4

4

4

11

6

2

5

5

20

12

~

~

Range of Components

n-butane

n-butane

n-butane

n-butane

n-butane

n-butane

n-butane

n-butane

n-butane

prbpane

ethane

n-butane

n-butane

n-butane

n-butane

n-butane

methane

propylene

n-butane

propane

propane

hydrogen

methane

Number of

Number Withof

drawal

Stages2 Streams3

No.

of

Feeds

- n-rentane

- n-hexane

1

1

1

- n-heptane

- n-octane

- n-nonane

- n-decane

1

1

1

1

1

- n-decane

- n-undecane

- n-dodecane

- n-dodecane

- n-dodecane

- n-decane

1

1

n-decane

- n-decane

- n-decane

- n-decane

- 400 NBP

- n-heptane

- isopentane

- n-hexane

- n-hexane

- 700NBP

- n-octane

1

1

1

1

2

2

1

2

1

1

~

~

19

61

106

154

199

240

233

274

312

415

533

225

225

225

225

225

258

88

9

39

37

-600

137

___

-

7

7

7

7

7

7

7

7

7

7

7

20

20

20

20

20

13

29

7

11

11

25

30

2

2

2

2

2

2

2

3

2

2

2

2

2

2

2

2

2

5

4

4

4

3

2

Zondenser

Type

____

Total

Total

Total

Total

Total

Total

Total

Total

Total

Total

Total

Total

Total

Total

Tot01

Total

Partial

Total

Total

Total

Partial

Partial

Partial

-~

-~

1. Dew point minus bubble point of feed, F; based on comFosite feed for multiple feed cases.

2. Including condenser and reboiler.

3. Including top and bottom product streams.

58

The Canadian journal of Chemical Engineering, Vol. 5 2 , February, 1974

method efficiently solved every problem of this series,

for which the largest ADBvalue was 533F, is a n

illustration of the exceptional stability of the algorithm.

In Examples 12-16 the feed stream is made up of

the two lightest and the two heaviest of the components of Examples 1-6, with a ADBvalue of 225F.

The two intermediate components are present with a

total concentration of only 20 mole per cent, hence

this feed is not markedly different from that of Example 6. While Example 12 requires an even split of

the feed between the two terminal streams, i n Examples 13-16 a split between the two lightest components was specified.

The results obtained using the E V P method f o r

these problems are listed in Table 2. Example 13 was

infeasible because the reflux rate was too small, hence

the section of the column below the feed stage was

essentially dried up by the overwhelming heat content of the feed. T h e E V P method converged very

rapidly to a quasi solution having the minimum allowed vapor rates below the feed stage and a large

feed stage energy balance error. In Example 14 the

feed condition was changed from a dew point vapor t o

a bubble point liquid, and in Examples 15 and 16 a

dew point vapor feed was again used, but the reflux

rate was increased by 40 and 30 moles/unit time, respectively, over that used in Example 13. These three

problems were all feasible, and the E V P method readily obtained the solutions, with very small vapor rates

below the feed stage i n Examples 15 and 16.

Tomichs method performed poorly in all of Exam-

feed compositions and conditions, the total rates of

:ill feed and withdrawal streams, column pressures

and the (calculated) top and bottom temperatures on

which the initial linear profiles were based.

Examples 1 - 11 constitute a series of problems with

single feeds consisting of binary pairs of normal hydrocarbons. The feed streams represent a succession

of increasingly wide-boiling binary dumbbell systems, with ADBvalues ranging from 19 t o 533F.

While these a r e simple problems, they illustrate the

exceptional stability of the EVP method f o r difficult

problems with very wide boiling feeds, t h e efficiency

of the method for very easy problems, and the limitations of Class B methods of the type of Tomichs

method.

Results a r e listed in Table 2, where it may be noted that Tomichs method failed to converge in a rea,sonable number of trials for all t h e problems after

Examples 1 and 2. For Example 1, the easiest of the

series, 7 trials were required after the initial Jacobian

evaluation, as compared with only 3 trials f o r the E V P

method. The solution times for Tomichs method reflect the inordinately large amount of computational

effort required to evaluate the initial Jacobian by

finite difference approximations.

It is notable that the E V P method is essentially a

bubble-point ( B P ) method, in t h a t the BP equation

is used to correct the temperature of each stage. Friday and Smithcz1have indicated t h a t Class B B P

methods with damping do not exhibit asymptotic convergence for systems with ADBvalues greater than

approximately 150F. Thus, the fact that the EVP

2

TABLE

EXAMPLE

PROBLEM

RESULTS

___ El

Examp1e

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

Problem Type

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

Binary dumbell

4 Component dumbell

4 Component dumbell

4 Component dumbell

4 Component dumbell

4 Component dumbell

Gasoline stabilization

Multiple feeds and sidestreams

Multiple feeds and sidestreams

Multiple sidestreams

Multiple feeds and sidestreams

Debutanizer

Deethanizer

Number Total No. Solution

Time,3

of

of S R

Sec.

Trials Iterations

3

5

6

8

9

8

10

9

11

12

14

8

6

5

7

7

6

4

3

5

7

13

16

1

1

2.4

3.4

3.8

Tomichs Method

Number Solution

Maximum Errors

of

Time,3

Energy

Phase

Sec.

Trials2

Balance

Equilibrium

7

13

20

20

20

20

20

20

20

45

17

43

47

15

10

25

15

25

26

20

21

9

6

20

20

20

20

20

20

20

20

9

4

8

7

8.5

13

29

29

31

27

31

40

37

22

26

-

160

155

153

115

156

0.81 x 10-5

0.43 x

0.37 x

0.47 x

0.95 x

0.25 x

0.46 X

0.51 X

0.67 X

0.19 x

0.55 x

0.67

10-5

10-2

10-2

10-2

10-1

lo-?

10-2

10-l

0.84

0.14

0.16

0.43

0.29

0.19

0.59

0.87

0.80

0.30

x

x

0.16 x

0.41 x

0.40 x

0.35 x

0.11 x

0.11 x

0.11 x

0.57 x

0.97 x

0.30

0.36

0.28

10-4

10-4

10-1

10-1

10-1

10-1

10-1

10-1

lo-

10-3

10-1

x 10-1 0.34

x

x

x

x

x

x

x

10-4

10-5

lo-

10-5

10-5

10-3

10-4

0.25

0.30

0.66 x

0.28 x

0.20 x

0.16 x

10-4

10-4

10-4

10-4

0.10 x 10-4

0.35 x 10-1

0.20 x 10-4

.~

____

1. Energy and volatility parameters updated once per trial.

2. Not including calculations required to obtain initial Jacobian iteration matrix. These calculationsare approximately equivalent to 2N

- 2 trials, where N is the number of stages. A maximum of 20 trials was allowed.

3. Total times required for computations in double precision arithmetic using IBM 370/145 computer, including generation of initial

estimates,but not including times required for data input or result output.

4. Maximum of absolute values of normalized errors in the energy balance and phase equilibrium equations when the calculations were

terminated.

The Canadian Journal of Chemical Engineering, Vol. 5 2 , February, 1974

59

ples 12-16. After 20 trials the results were still quite

f a r from the solutions for all the problems of this

series.

Examples 17-23 represent a variety of distillation

problems, with feeds having ADBvalues that range

from 9 t o -600F. Included are problems with partial condensers, multiple feeds, multiple sidestreams,

and feeds containing hydrogen, carbon dioxide and

hydrogen sulphide in addition to a wide range of hydrocarbons. While Tomich's method converged in a

reasonable number of trials for all of these problems

except Example 22, the results shown in Table 2

again demonstrate the superiority of the EVP method

with regard to both stability and computational efficiency.

encircle only single stages. For an internal stage

n ( n = 2, 3 , . .. ,N-l) the CMC equation is:

cmc1usions

A unique algorithm based on newly defined energy

and volatility parameters (EVP's) as the primary

successive approximation (SA) variables has been

shown to be exceptionally stable and efficient. Use

of the volatility parameters as SA variables leads

naturally to the choice of the newly defined relative

S-parameters as the variables of an iterative procedure in which the quasi-Newton method of Broyden

i s very efficiently employed to accelerate convergence.

Use of the S-parameters, which are unique combinations of the liquid and vapor phase rates and the stage

temperatures, avoids the difficulties associated with

interactions between these variables. I n addition, i t

it possible to solve all of the model equations without

any of the internal inconsistencies that arise with

other methods.

The new algorithm is particularly well suited to the

solution of problems in which enthalpies and equilibrium ratios are liquid and/or vapor composition dependent. It has been designed t o minimize the required number of rigorous evaluations of these properties.

The performance of the EVP algorithm has been

illustrated using a variety of example distillation

problems. Its stability was demonstrated by "dumbbell" problems having very wide boiling feeds, and its

requirement of less than 10 evaluations of the physical

properties in most cases, and only 14 in the most

difficult case, is a measure of its efficiency.

APPENDIX A

Derivation of the model equations

The general equation that describes phase equilibrium

(PEQ)is:

Y;,"= Ki,nXi,n,.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

where

The liquid and vapor mole fraction constitutive (LMFC

and VMFC) equations are:

2

i

xi,, =

s Yi,,

V=+I = L,

(A-1)

where

MT"= z ( W L ~ Wix - F L k - F v t )

k= 1

The component mass conservation (CMC) and energy

conservation (EC) equations are based on envelopes that

60

(A-5)

Combining the PEQ and VMFC equations, the bubblepoint ( B P ) equation is obtained:

7 K;,, Xi,,, =

1, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(A-6)

(ZI) The modified model equations

Most of the model equations were not used in precisely

the forms just given. Certain variables were eliminated

by combining equations, and certain new variables were

introduced. The purpose of most of these changes was to

obtain the model equations in terms of the successive approximation variables.

The first modifications involve the PEQ equations

(A-4). The equilibrium ratio, K,,,,was partitioned

-

+ MT,. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...............................

( I ) The basic model equations

The model equations are based on the general model

column shown in Figure 1. For generality, feed and withdrawal rates and a heat duty are included for each stage,

although in most cases only a few of these will be nonzero. Unless indicated otherwise, the equations given are

applicable to any stage n (n = 1, 2 , . ... N ) .

The total mass conservation (TMC) equation is based

on an envelope that encircles stages 1 t o n, inclusive

(72 = 1, 2 , . ... N-1) :

(A-4)

K,, (T,)

(X,,, Yn, T,,P,).. . . . . . . . . . . . .(A-7)

and this relations,hip was taken t o be the defining relat,ion for the new variables

which are referred to as

"volatility parameters". The definition of the new variables K b n and the utility of this transformation are discussed elsewhere in this paper. The transformation was

used t o obtain the B P equation in the alternate form:

Kb.7

Xi,,= 1.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.(A-8)

In order to transform the CMC eqiations (A?) to a tridiagonal

system in terms of the 1's alone, the l's, u's and v's were eliminated

by using the PEQ and other relationships, and several new

variables were introduced. The final result was (for II = 2 , 3 , . . . .

N - 1):

-li,n-~

bi,Ji,=

- ~ i , ~ l i . ~=+f ii, " . . . . . . . . . . . . . . . . .(A-9)

where the coefficients are given by the relations:

The Canadian Journal, of Chemical Engineering, Vol. 52, February, 1974

bi,, = R L -k~ RvnSbSRn(Yi.n

=

Cisn

....................

(A-10)

&SRn+lai,n+l

The defining relations for the new variables are:

+ WLJL

1 + Wvn/Vn

R L ~1

Rvn

SRn

sn/sb..

.........................

................................

Xi,, = Ln/Z ljrn

}. .....................

1irn/Zaj,nlj,n1

(A-13)

.(A-14)

The modification of the EC equations (A-3) was based

on total stream enthalpies that were expressed in terms

of several new variables, some of whioh became the successive approximation variables referred to as energy

parameters. In tihe analysis that follows, the stage index

n was dropped for convenience. The total enthalpy of a

vapor may be expressed as:

4 Y&

@i/@bi

Y,i

= Yi@bi/Z(Yj(P,tj

i

The partial molal enthalpy of a component in the liquid

may be expressed as:

hi

hp +;h$

where hp is the ideal liquid Fartial molal enthalpy a t T and P, and

h$ is the excess partial molal enthalpy. The former is related to

the ideal gas enthalpy in terms of the liquid fugacity coefficient

vi by:

(A-15)

l

h (Pi

abi

(A-12)

The Ss are referred t o as S-parameters, the SRs as

relative S-parameters, and Sa is a base S-parameter.

From the solutions of the CMC equations, the corresponding mole fractions may be calculated using the following liquid and vapor mole fraction definition (LMFD

and VMFD) equations:

Yi,=

Yi(Pbi

@b =

. (A-11)

.(A-18)

T-t T b

(nS,)l/N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

n

Sb

Z Y,i G r i . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

0,.

&,Vn/Ln. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S,

where

zY i f l + A H ( P , T . T)

i

where fl. is the ideal gas enthalyy, and A H is a pressure and

composition correction defined in terms of the vapor fugacity

coefficient qi as:

and hy may be expressed in terms of the liquid phase activity

coefficient yi as:

A new set of variables was introduced, defined as:

4i

(h:

- h,i)/(T- TL)

where hii is the ideal liquid enthalpy evaluated at the reference

temperature Tb. In terms of these variables, the total liquid

enthalpy is given by:

h

+ hB + 2 Xi&

X@

where

f? = 2 Xi4i

This correction function was separated into a composition correction term and a temperature-deFendent term by introducing

new variables @ y and ( P T :

A H ( P , T,?) =

Cpy

@T

( T - T*)

h =

f?

[ A H ( P ,T , Y*F- A H ( P , T*,Y*F/(T- T * ) ., .(A-16)

(Py E

AH*

+ AH(P, T,

- AH(P,

(Hg

6,

T,T*),.

. . . . .(A-17)

ro + av + CpT(r- r*)+

Y~H;~

xri

2 Yi@,

1

The variable 8 was partitioned into two factors:@b,which is strongly dependent on the vapor composition; and @, a very weak

function of both vapor composition and temperature:

=

860,

2 Xi4bi

i

= xi + b i / Z

xj 4 b j

The results just obtained for vapor and liquid enthalpies, together with other equations including the TMC

equation (A-1) and the CMC equations (A-2), were s u b

stituted into the basic E C equations (A$) to obtain the

form of the E C equations employed t o calculate the liquid

phase rates:

-(a.-1

(A-20)

PST-Tb

3

Z X&i.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

4r< = 4v/4b<

where

6b

- H,i)/(T- Tb)

where H{i is the ideal gas enthalpy evaluated a t an arbitrary

reference temperature Tb. Hence, the total vapor enthalpy is,

in terms of these variables and 0,another new variable:

H

6b6r

where

and where A H * = A H ( P , T * , Y * ) , T* is a reference

temperature and F* a reference vapor mole fraction vector. An additional new set of variables was introduced,

defined as:

@i

.(A-19)

The new variable f? was partitioned in the same manner as 0

above:

where

(PT

Xih:. .................................

- Ub)L,-l

+ (a,

- ak,,)L

En - u ~ W L-- d ( M T n - 1 + Wv,,)

+ d + t M ~. ,. . (A-21)

where

an

a:, =

r,&+ hf - X n

r,@,+ aYn+ (r, - rwm

The Canadian /ozcrnnl of Chemicol Engineering, Vol. 52, February, 1974

. . . . . . . . . . . (A-22)

61

H&fi,n... . . . . . . . , . . . . . . . . . . . . . . .(A-23)

En =

QT,

A:,

7 Xi., (Hii - h:&),. . . . . . . . . . . .

. . . . . . . . . . (A-24)

The definitions of the new variables @I+,, @rn, Or,, (Iln and

h,E imply that they are unique for each stage n. They are collectively referred to as "energy parameters": together with the

volatility parameters aitndefined earlier, they become the main

successive approximation variables of the algorithm of this

paper.

three-parameter rational function temperature correlation

was obtained for each stage, using the corresponding

temperature T* as a center point. Thus, it was not necessary to retain the reference vapor compositions y* in

storage.

Acknowledgments

The authors are indebted to the Computer Centers of Tulane

University and the College of Petroleum and Minerals for providing

the computer time requil,ed for this work.

Nomenclature

APPENDIX B

Initial values of the successive

approximation variables

It was required to develop initial estimates of the energy and volatility parameters to be used a s the assumed

values in the initial trial, and of the SR's to be used as

the assumed values for the first SR iteration of the initial

t.rial. The procedure that was employed for this consisted

of two parts, the first of which resulted in preliminary

estimates of the volatility parameters and S R k . In the

second p a r t these estimates were refined and initial estimates of the energy parameters were developed.

= coefficients in energy conservation equations, de-

b, c

= coefficients in component mass conservation equa-

B

D r.

= total molar flow rate of the bottom product

=

(Lx).

total molar flow rate of the liquid top product

total differential-operator.

constant appearig in energy conservation equation.

defined by (A-23).

= feed stream molar flow rate.

= component molar flow rate in a feed stream.

= error functions for relative Sparameter iterations.

= negative inverse of Jacobian matrix for relative Sparameter iterations.

= total enthalpy of a vapor stream.

= partial molal vapor enthalpy.

= total enthalpy of a liquid stream.

= partial molal liquid enthalpy.

= partial molal excess liquid enthalpy.

= vapor-liquid equilibrium ratio for a component, Y / X .

= base vapor-liquid equilibrium ratio function.

= total molar flow rate of a liquid stream.

= comuonent molar flow rate in a liquid stream for

which the total flow rate is L.

= component molar flow rate in a liquid stream for

which the total flow rate is L WL.

= naperian base loqarithm.

= total number of stages, including condenser and reboiler when present.

= total static absolute pressure above the liquid phase

of a stage.

= rate of external heat input to a stage.

= gas constant.

= liquid and vapor withdrawal parameters, defined by

(A-11).

= S-parameter, defined by (A-12).

= base S-parameter, defined by (A-14).

= relative S-parameter, defined by (A-13).

= temperature of a stage, absolute units.

= temuerature used as basis for energy parameter definitions.

= total molar flow rate of a vapor stream.

= comuonent molar flow rate in a vapor stream for

which the total flow rate is V.

= component molar flow rate in a vapor stream for

which the total flow rate is V WV.

= total molar flow rate of a draw-off stream.

= component molar flow rate in a draw-off stream.

= component liquid mole fraction.

= component vapor mole fraction.

=

=

It was assumed that the pressure profile, the liquid reflux rate

composite feed was formed by adding together all the feed

streams, and its bubble point and dew point temperatures a t the

were determined. An initial temmedian pressure P(N+1)/2

perature profile was obtained by linearly interpolating between

two-values related to these bubble and r'ew Foint tmreratures

and their arithmetic average was taken as the base temperature

Tb on which the definitions of the energy parameters were based.

The temperatures of the linear temperature profile became the

reference temperatures denoted as T* in the defining relations

(A-16) and (A-17) for @T and @IT.

An isothermal, single stage equilibrium flash of the

composite feed was performed at the temperature Tb

and the median pressure. Preliminary estimates of the

equilibrium ratios were obtained using the vapor and

liquid compositions from the isothermal flash, the linear

temperature profile and the known pressure profile. These

equilibrium ratios were takn a s the initial estimates of

the volatility parameters, and the initial KL1s were all

taken as unity.

The liquid rates were calculated from a constant molal

overflow liquid phase rate balance around each stage,

and the vapor rates were calculated from analogous vapor

phase rate balances. Finally, the S-parameters, the SR%,

Sb and the liquid and vapor withdrawal parameters were

calculated from the defining relations (A-11) to (A-14).

Refined estimates

62

tions, defined by (A-10).

(WLI).

L1and the total rates of all withdrawal streams were known. A

Since the vapor enthalpy correction A H ( P , T , F * ) is a

function of temperature alone for each stage, a unique

f i e d by (A-22).

= total molar flow rate of the vapor top product ( VI),

Prelimiiutry estimates

Using the preliminary estimates of the volatility parameters,

SR'Sand withdrawal parameters, the CMC equations were solved

to obtain the component molar flow rates. The equations (A-15)

were employed to calculate the liquid and vapor mole fraction

profiles. The latter became the reference vapor compositions

denoted as 5r* in the defining relations for @T and &. Using

these liquid and vapor composition profiles, the linear temperature profile and the known pressures, the equilibrium ratios,

K, model coefficients and liquid and vapor enthalpies were

evaluated. Using Ka's calculated from the Kb model expressio?

and the preliminary estimates of the liquid and vapor phase

rates, refined estimates of the S-parameters, SR'Sand Sb were

obtained from the defining relations (A-12) to (A-14). Finally,

the refined estimates of the volatility and energy parameters

were calculated from the definitions (A-7), and (A-16) to (A-20).

coefficients in Kamodel.

A, B

a, a'

Greek letters

LY

r

ADR

6

(3

Oh

0,

=

=

=

=

=

=

=

=

=

96

er

=

=

@T

=

=

=

?

A;

IT

=

=

=

=

volatility parameter, K/Kh.

temperature difference,defied as T - Ta.

dew point minus bubble point of a feed stream, "F.

finite differenceoperator.

partial differentiation operator.

vapor enthalpy variable.

vapor enthalpy variable.

vapor energy parameter, defined by (A-18).

liquid enthalpy variable.

liquid enthalpy vanable.

liquid energy parameter, defied by (A-20).

vapor enthalpy variable.

vapor energy parameter, defined by (A-16).

vapor energy parameter, defined by (A-17).

liquid enthaluy variable.

enthalpy variable, defined by (A-24).

product ouerator.

summation operator.

The Canadian Journal of Chemical Engineering, Vol. 52, February, 1974

(.7 ,) Tierney. J. W.

component index.

stage index.

pertains to liquil streams.

pertains to vapor streams.

denotes a vector over all stsges.

SivtJerscripts

D

=

=

denotes a quantity obtained by summing over all

components.

Idenotes a vector over all components for a given

stage.

References

( 1 ) Boston, J. F. and Sullivan, S. L., Jr., Can J. Chem. E n s . 50,

663 (1972).

(2) Holland, C. D.,Multicsnponent Distillation, Prentice-Hall, Inc..

Englewood Cliffs, N.J. (1963).

( 3 ) Smith, B. D., Design of Equilibrium Stage Processes, McGrawHill, New York (1963).

( 4 ) Boston. J. F.. Ph.D. Dissertation. Tulane Univ.. New Orleans,

Louisiana (1970).

( 5 ) Tomich, J. F., Paper presented a t joint AIChE-IIQPR meeting,

Tampa, Florida (1968I .

(6) Tomich, J. F.. AIChE Journal, 16, 229 (1970).

and Yanosik, J. L., AIChE Journal,

15. $97

(196911

(8) Orbach, 0.. Ph.D.

Canada (1969).

Thesis. McMaster Univ., Hamilton, Ontario,

(9) Orbaeh, 0.. Crowe, C. M. and Johnson, A. I., Private Communication.

(10) Orbach, 0. and Crowe, C. M., Can. J. Chem. Fhg., 49. 609 (1971).

(11) Bill~ngsley, D. S., AIChE Journal, 16, 441 (1970).

(12) Grayson, H. G. and Streed, C. W., Paper presented a t Sixth

World Petroleum Congress. FrankfoiWMain. J u n e 19-26. 1963.

( 1 3 ) Chao, K. C. a n d Sender, J. D., AIChE Journal, 7, 598 (1961).

(14) Redlich, 0. and Kwong, J. N. S., Chem. Rev., 44, 233 (1949).

(16) Hildebrand, J. H. and Scott, R. L., The Solubility of Non-

electrolytes. 3rd ed., Reinhold, New York (1950).

(16) Barnes, J. G. P., Computer Journal, 8, 66 (1966).

117) Brwden, C. G.. Math. of Computations, 19, 577 (1966).

(18) m e n , E M., Proc. 21at National Conf. Assoe. C ~ m p .Mach., 37

(1966).

(19) Zeleznik, F. J., J. Assoc. Comp. Mach., 15 (2). 265 (1968).

(20) Kliesch, H. C., Ph.D. Dissertation, Tulane University, New Orleans, Louisiana (1967).

( 2 1 ) Friday, J. R. and Smith, B. D., AIChE Journal, 10, 698 (1964).

Manuscript received April 6 ; accepted November 1, 1973.

The Canudiun Journal of Chemical Engineering, Vol. 5 2 , Febrwuy, 1974

* * *

63

You might also like

- Love My LifeDocument5 pagesLove My LifeLinda Veronica0% (1)

- Luo Shu Ancient Chinese Magic Square On Linear AlgDocument12 pagesLuo Shu Ancient Chinese Magic Square On Linear AlgAJAY KUMAR JAINNo ratings yet

- Flash Calc 1flash Calc 185Document18 pagesFlash Calc 1flash Calc 185Mohamed MamdouhNo ratings yet

- ECUST PROII Advanced TrainingDocument118 pagesECUST PROII Advanced Trainingbakhtyar21100% (2)

- Computation of Phase and Chemical Equilibrium IDocument9 pagesComputation of Phase and Chemical Equilibrium IThou KanshieNo ratings yet

- Load CalculationsDocument5 pagesLoad Calculationsarif_rubinNo ratings yet

- A Quasi-Newton Algorithm For Solving Multi Phase Equilibrium Flash ProblemsDocument22 pagesA Quasi-Newton Algorithm For Solving Multi Phase Equilibrium Flash ProblemsDaniel MedeirosNo ratings yet

- Interfacial Heat Transfer Coefficients of Various Vapors in Direct Contact CondensationDocument11 pagesInterfacial Heat Transfer Coefficients of Various Vapors in Direct Contact CondensationJesse Haney IIINo ratings yet

- Phase Equilibria: Basic Principles, Applications, Experimental TechniquesFrom EverandPhase Equilibria: Basic Principles, Applications, Experimental TechniquesNo ratings yet

- Vapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodFrom EverandVapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodNo ratings yet

- Troubleshooting and Rectification of A C3 Splitter TowerDocument25 pagesTroubleshooting and Rectification of A C3 Splitter TowerparykoochakNo ratings yet

- Compressibility Factors for Naturally Occurring Petroleum GasesDocument11 pagesCompressibility Factors for Naturally Occurring Petroleum GasesLawrenceLopezNo ratings yet

- Correlation of entrainment for annular flow in horizontal pipesDocument24 pagesCorrelation of entrainment for annular flow in horizontal pipesJohn Doe100% (1)

- A Continuous Model For C7+ Fraction CharacterizationDocument9 pagesA Continuous Model For C7+ Fraction CharacterizationargirotopNo ratings yet

- Troubleshooting in Distillation ColumnsDocument15 pagesTroubleshooting in Distillation ColumnstalhawasimNo ratings yet

- Getting A Handle On Advanced Cubic Equations of State: Measurement & ControlDocument8 pagesGetting A Handle On Advanced Cubic Equations of State: Measurement & ControlAli_F50No ratings yet

- Calculation of Phase Envelopes and Critical Points For Multicomponent MixturesDocument10 pagesCalculation of Phase Envelopes and Critical Points For Multicomponent Mixturesflavio_cordero_1No ratings yet

- Extension of Peng-Robinson For Complex MixturesDocument18 pagesExtension of Peng-Robinson For Complex MixturesMandy NelsonNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- 1987 - Multiphase Isenthalpic and Isentropic Flash Algorithms - MichelsenDocument15 pages1987 - Multiphase Isenthalpic and Isentropic Flash Algorithms - MichelsenhakeemniyasNo ratings yet

- Design of 10m Span RCC Slab CulvertDocument105 pagesDesign of 10m Span RCC Slab CulvertD.V.Srinivasa Rao100% (4)

- SPE-175877-MS EOS Tuning - Comparison Between Several Valid Approaches and New RecommendationsDocument17 pagesSPE-175877-MS EOS Tuning - Comparison Between Several Valid Approaches and New RecommendationsCamilo Benítez100% (1)

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Effect of On Equation-of-State Predictions: C Prop ErtiesDocument12 pagesEffect of On Equation-of-State Predictions: C Prop ErtiesAllanNo ratings yet

- DYNSIM Best Practices 1 - CompressorDocument21 pagesDYNSIM Best Practices 1 - CompressorJorge Luis Hernández100% (1)

- Binary Interaction Parameters in Cubic e PDFDocument6 pagesBinary Interaction Parameters in Cubic e PDFagarwalashwin32No ratings yet

- A Comparison of The Peng-Robinson and Soave-Redlich-Kwong Equations of StateDocument18 pagesA Comparison of The Peng-Robinson and Soave-Redlich-Kwong Equations of StateVettidog100% (1)

- Journal of Petroleum Science and Engineering: Ehsan Heidaryan, Jamshid Moghadasi, Masoud RahimiDocument6 pagesJournal of Petroleum Science and Engineering: Ehsan Heidaryan, Jamshid Moghadasi, Masoud RahimipeNo ratings yet

- A Improving Predictions of Equation of State by Modifying Its Parameters For Super Critical Components of Hydrocarbon Reservoir FluidsDocument17 pagesA Improving Predictions of Equation of State by Modifying Its Parameters For Super Critical Components of Hydrocarbon Reservoir Fluids13670319No ratings yet

- Phase Oil Equilibria of Oil-Water-Brine - Yaun Kun LiDocument11 pagesPhase Oil Equilibria of Oil-Water-Brine - Yaun Kun LiRonald NgueleNo ratings yet

- Dukler 1980Document10 pagesDukler 1980Vassilios KelessidisNo ratings yet

- Don't Gamble With Physical Properties For SimulationsDocument12 pagesDon't Gamble With Physical Properties For Simulationslaiping_lum100% (1)

- Thermodynamic Modelling of Asphaltene Precipitation and Related Phenomena 2015 Advances in Colloid and Interface ScienceDocument12 pagesThermodynamic Modelling of Asphaltene Precipitation and Related Phenomena 2015 Advances in Colloid and Interface ScienceEzequiel AbrilNo ratings yet

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- Flash Calculation Stability PDFDocument12 pagesFlash Calculation Stability PDFAndre BecNo ratings yet

- Tos Mathematics 8 q2Document1 pageTos Mathematics 8 q2Kenny Ann Grace BatiancilaNo ratings yet

- A Method To Estimate The Patel-Teja Equation of State ConstantsDocument7 pagesA Method To Estimate The Patel-Teja Equation of State Constants1940LaSalleNo ratings yet

- Binary Interaction Parameters in Cubic-ValderramaDocument6 pagesBinary Interaction Parameters in Cubic-Valderramaflavio_cordero_1No ratings yet

- Crisfield M A Vol 2 Non-Linear Finite Element Analysis of Solids and Structures Advanced TopicsDocument509 pagesCrisfield M A Vol 2 Non-Linear Finite Element Analysis of Solids and Structures Advanced TopicsIffat Siddqiue0% (1)

- 1.6a Line Sizing SlidesDocument24 pages1.6a Line Sizing SlidesPhani Raj M100% (1)

- NORSOK Standard For Process DesignDocument27 pagesNORSOK Standard For Process DesignM. Faisal SiddiquiNo ratings yet

- A. Radically Different Formulation and Solution of The Single-Stage Flash ProblemDocument14 pagesA. Radically Different Formulation and Solution of The Single-Stage Flash ProblemPrantik DasNo ratings yet