Professional Documents

Culture Documents

FlowroxHosePumps e Version

Uploaded by

siamak1438Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FlowroxHosePumps e Version

Uploaded by

siamak1438Copyright:

Available Formats

Flowrox Peristaltic Hose Pumps

Flowrox Peristaltic Hose Pumps

for Transferring, Dosing and Metering

The innovative Flowrox peristaltic hose pumps set the industry standard for peristaltic pump

technology. Designed for heavy industrial duties, they are ideal for pumping diverse slurries

and dosing a wide range of abrasive, corrosive, viscous or crystallizing media.

THE OPERATING PRINCIPLE OF

A PERISTALTIC PUMP

The operating principle of the

Flowrox hose pumps is based

on the peristaltic effect. As

the cylindrical rotor rotates

along the hose, the process

medium gets pushed forward

through the hose. At the same time,

the hose behind the compression

point reverts to its original circular

shape creating a suction effect at

the pump inlet port. As a result, the

hose bore gets filled with the

medium. No backward flow can occur

as the hose is squeezed tight by the roller.

ADDITIONAL FEATURES

Incorporating an advanced design,

the Flowrox hose pumps can offer

unbeatable additional features

including:

The worlds biggest

hose pump, maximum

continuous flow being

100m3/h.

360 degree operating cycle

Only one compression per

revolution

Rolling hose contact

In-line pipe connection

Reliable hose connection

Low lubrication need, only 20% of

conventional peristaltic pumps

need

TECHNICAL FEATURES

PROCESS BENEFITS

Equipped with standard technical features of a typical

peristaltic pump such as dry run capability and self

priming, the Flowrox hose pumps provide exact flow

per revolution. As Flowrox pumps are seal less, they

will not get damaged even if they run dry for longer

periods of time.

Flowrox hose pumps

incorporate an

advanced design,

which eliminates

friction, maximizes hose

life time and lowers energy

consumption.

Standard technical features include:

Only the hose is in contact with the medium

No gland water or packing

Full vacuum capability

No backward flow

Positive displacement

Resulting in process benefits such as:

No wear and corrosion

Dry run capability

Selfpriming up to 9,5 metres

Exact flow per revolution

irrespective of the pipeline

pressure

Accurate flow

No mixing or shearing of the

medium

Other remarkable process benefits are:

Extended hose lifetime

High pressure capability

No overheating at high continuous flow rate 24/7

Higher flow with smaller pump

Low energy consumption

Easy maintenance

Low operating costs

Flowrox hose pump is the number one pump for hot

temperatures, as it can run continuously even in

98C degrees.

Flowrox pumps offer:

Superior rolling technology Energy efficiency

Long service intervals Low life cycle costs

LPP-T Pumps for Transfer Duties

LPP-T pumps provide substantial savings through improved process performance and efficiency,

long service intervals and low maintenance costs. They are manufactured using durable

elastomers and advanced materials making them perfect for pumping a wide range of media.

PATENTED ECCENTRIC HOSE ADJUSTMENT

Flowrox LPP-T pumps are equipped with patented,

reliable hose flange and in-line pipe connections;

a hose leak detection unit and a patented adjustment

mechanism that senses hose wear when compression

is readjusted. This helps to maximize hose lifetime

and minimize the risk of over-compression.There is no

need for shimming.

WITH FLOWROX PUMPS THE TOTAL

LIFE TIME COSTS ARE REDUCED

Energy efficiency, long hose life and low maintenance

need lead to substantial savings during the life cycle

of peristaltic pumps. Flowrox pumps hose life time

is more than 4 times longer than with a conventional

pump.

Hose flange

Fastening

bushing

O ring

Seal wings

Connection

flange

CONVENTIONAL DN65

HOSE PUMP

designed flow rate 10 m3/h

pump will run: 10 000 l/h

-------> 25 RPM

Estimated hose life time

518 400 cycles.

--------> 346 hours.

FLOWROX LPP-T65

designed flow rate 10 m3/h

pump will run: 10 000 l/h

-------> 31 RPM

Flowrox estimated hose life time

2 700 000 cycles.

--------> 1452 hours.

LPP-T Pumps in

Mining & Minerals Industry

Products:

12 x LPP-T 65 pumps

Application: Washing liquid circulation pump

Talvivaara open-pit mine has used Flowrox LPP-T 65

pumps since 2008 (5 pcs) and 2009 (7 pcs). The

pumps work with Outotec Larox rubber belt filters

RB-SV in order to recycle water from filter cloth and

rubber belt washings to cake washing. This saves

water and all valuable minerals coming out of the cloth

and rubber belt can be fed again to the cake.

Flowrox hose pumps are ideal in these kinds of

filter applications, as the washing water typically

has very high content of solids. This was one of the

main reasons why the customer chose Flowrox hose

Washing liquid circulation pumps in Talvivaara mine.

pumps for this application. Flowrox pumps also suit

extremely well for viscous, crystallizable, corrosive

or abrasive media.

Flowrox pumps used in Talvivaara:

6 pumps in gypsum precipitate filters

2 pumps in nickel-cobalt sulphide filters

2 pumps in zinc sulphide filters

2 pumps in copper sulphide filters

LPP-D Pumps for Dosing Duties

THE TRAILBLAZING LPP-D DOSING PUMPS

Flowrox LPP-D dosing pumps have a high turndown

ratio making them ideal for dosing and flow control.

They provide accurate dosing in all process conditions

as the pump discharge flow does not depend on the

pipeline pressure.

The advanced design

A simple and reliable hose connection.

Locking, sealing and securing with a

one piece locking bracket.

Operators do not have to worry about overheating

even with high continuous flow rates. The pump

operation is trouble-free and consistent.

16 bar high pressure as well as acid

proof pump heads are also

available.

Locking

bracket

Seal

Hose

Threaded

coupling

LPP-D Pumps in

Construction Industry

Products: 8 x LPP-D25 pumps

23 x LPP-D20 pumps

5 x LPP-D15 pumps

Medium: Paint Oil Based and Paint Pigments +

Coater

Since changing to the Flowrox Pumps James Hardie

Building Products, the market leader in Fiber Cement

Technology in the USA, has been able to remarkably

reduce downtime. Controlled by a variable frequency

drive (VFD) the LPP-D pumps have also significantly

increased flow accuracy.

James Hardie replaced air operated diaphragm pumps

with a first LPP-D20 pump for dosing of paint primer

in 2007. By now they have totally 36 LPP-D pumps in

each of their 6 locations.

According to the engineering manager at James Hardie

the air operated diaphragm pumps were failing every

three weeks, and a decision was made to find a more

reliable pump.

The benefits they achieved with Flowrox pumps are:

Reduced downtime

Increased flow accuracy

Already 36 LPP-D pumps increase accuracy in dosing

duties at James Hardie.

Reduced maintenance labor costs

Reduced spare parts costs as the LPP-D hose is

significantly less cost than diaphragm pump parts

replacement

Reduced cost due to high air consumption of

diaphragm pumps and costs of generating this air

Rolling hose compression of the LPP-D offers a

more reliable uninterrupted flow of the medium to

the process compared to diaphragm pumps

The customer is very pleased with the ease of use and

maintenance as well as low operating costs of the

pumps. They have utilized hose or peristaltic pumps

also in the past but have never been able to achieve

the same level of reliability and reduced costs as now

with the Flowrox pumps.

LPP-M Pumps for Metering Duties

SUPERIOR ACCURACY FOR YOUR PROCESSES

A MULTITUDE OF PROGRAMS

Accuracy of metering in any

application is the most

vital property of a

metering pump. Flow

rate of LPP-M metering

pump is not affected

by variation of the

discharge pressure

condition. Positive

displacement of the

tube bore with zero slip

provides same output volume on every cycle. The

compression point of the tube acts as self-cleaning

check valve without clogging risk providing clear flow

path with no possibility for vapour lock.

LPP-M pumps have wider programmability and

controllability than any other comparable pumps. They

offer excellent connectivity to all possible customer

environments. Inputs can include for example:

Flowrox LPP-M pump has a protection rating of

NEMA 4X/IP66 and is equipped with a unique Tube

Failure Detection, which is designed to stop the pump

if pump tube is ruptured and chemical enters the

pump head.

The non-enclosed version of the pump is designed

especially for OEM purposes.

Manual adjustment

4 to 20 mA

0 to 10 volts DC

Frequency input (Hz)

Remote start / Stop contact closure

Flow verification system (FVS) input

Contact closure input

Control modes make a diversity of dosing functions

possible including

Pulse batch

Manual cycle adjust

Dispensing

Manual dosing

Proportional dosing

Available display languages

are English, German, Spanish

and French.

PVDF adapter fittings allow

easy tube changes.

LPP-M Pumps in

Waste Water Treatment

Products: 4 x LPP-M pumps+ 2 LPP-D pumps

Medium: Sodium Bisulfite and Sodium

Hypochlorite

Nashua New Hampshire is one of many United States

cities and municipalities selecting Flowrox technology

over inferior pumping technologies.

Flowrox pumps offer stable flow and metering

capabilities under varying operating conditions,

and their energy requirement is constant, says the

customer. They can also handle severe variation

in suction line condition in regard to suction lift and

viscosity, and they are also very user friendly, he

continues.

Flowrox engineered peristaltic pumps combine

smart intelligence with superior turndown. Another

remarkable advantage is that peristaltic pumps will not

LPP-M pumping sodium hypochlorite 12.5% at Nashua

New Hampshire.

experience vacuum degassing in summer months like

other designs.

Flowrox was selected for equipment supplier based on

the superior tube pump and control technology of the

LPP-M tube pumps. The engineering consultant, the

city of Nashua New Hampshire elected officials and

contractor all formed a common consensus to order

and approve the use of Flowrox pumps. Flowrox won on

the technical merits, commercial merits and long-term

operational advantages.

These pumps are operating flawlessly without any

downtime since March 2008.

Optimal Hoses and Tubes for Each Media

With decades of experience in developing innovative flow control solutions and elastomer

technology, Flowrox has a wide selection of superior elastomers for diverse media and process

conditions. The correct mechanical hose design and material selection are essential for

optimal hose lifetime.

HOSES FOR LPP-T AND LPP-D PUMPS

The high-grade hose materials include chemical

resistant ethylene propylene (EPDM), oil and fat

resistant nitrile rubber (NBR), which is available

also for food grade mediums (NBRF) and extremely

abrasive natural rubber (NR), which is ideal for heavy

wearing applications. To guarantee the best possible

mechanical characteristics, the hose cover is always

made of natural rubber.

NR

Natural rubber

Medium: extremely abrasive

EPDM

Ethylene propylene

Medium: chemicals

NBR

Nitrile rubber

Medium: oil and fat

NBRF

Nitrile rubber

Medium: fatty foodstuffs

Fulfills FDA requirements

Outer layer

Reinforcement layers

Inner layer

LPP-D hose construction.

The preformed LPP-T hoses

ensure secure, trouble free and fast assembly.

TUBES FOR LPP-M PUMPS

Norprene

Norprene tubing has excellent alkali resistance and

is compatible with numerous oxidizing agents such as

hydrogen peroxide, sodium hypochlorite and ozone.

Norprene tubing fully complies with FDA, 3A Sanitary

Standards, and NSF Standards, which are applicable

to many food contact applications.

It also offers exceptional resistance to oils, greases,

fuels and many chemicals.

Able to withstand rugged daily use, Tygothane tubing

resists weathering. It meets FDA criteria for food and

beverage use.

Norprene tubing exhibits excellent resistance

to ozone and UV light, with little or no signs of

deterioration in laboratory testing equivalent to 10

years of outdoor exposure. Norprene tubing provides

long service life time when exposed to heat, abrasion,

and pressure.

Tygothane

Made of a tough, ester-based polyurethane,

Tygothane tubings clarity, high tear strength and

excellent abrasion resistance makes it ideal for many

applications, including fuel and lubricant lines and

abrasive product transfer.

LPP-M tube materials: Norprene and Tygothane.

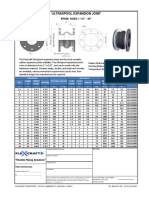

Technical Data of Flowrox LPP Pumps

Technical Data

LPP-T25

LPP-T32

LPP-T40

LPP-T50

LPP-T65

LPP-T80

LPP-T100

Weight

~ 130 kg

~ 300 kg

~ 360 kg

~ 650 kg

~ 960 kg

~ 2450 kg

~ 5300 kg

Flow/revolution

0.28 l

0.65 l

1.25 l

2.75 l

5.4 l

11.6 l

31,6 l

Maximum flow

2.2 m3/h

3.9 m3/h

7.5 m3/h

11.5 m3/h

20 m3/h

40 m3/h

100 m3/h

Maximum pressure

10 bar

10 bar

10 bar

10 bar

10 bar

7.5 bar

Lubricant volume

0.8 l

0.8 l

1l

2.5 l

3l

8l

20 l

Hose bore and

flange connection

25 mm

32 mm

40 mm

50 mm

65 mm

80 mm

100 mm

0.751.5 kW

0.754 kW

1.14.0 kW

1.59.2 kW

Motor power

3.011.0 kW 9.222.0 kW

5590 kW

* contact Flowrox

Technical Data

LPP-D10

LPP-D15

LPP-D20

LPP-D25

Weight

47 kg

47 kg

47 kg

60 kg

Flow/revolution

0.06 l

0.1 l

0.18 l

0.3 l

Maximum flow

0.4 m3/h

0.6 m3/h

1.2 m3/h

2.0 m3/h

Maximum pressure

16 bar

16 bar

16 bar

16 bar

Lubricant volume

0.4 l

0.4 l

0.4 l

0.4 l

Hose bore and

flange connection

10 mm

15 mm

20 mm

25 mm

0.551.1 kW

0.551.1 kW

0.551.1 kW

0.751.5 kW

Motor power

Technical Data

Weight/Shipping weight

LPP-M

12.4 kg/13.5. kg

Maximum flow

126 l/h

Maximum working pressure

8.6 bar

Max fluid temperature

54C

Enclosure

IP66

Plug type

240V AC, CEE

7/VII (Europe)

More technical information available in datasheets.

All stages of the LPP-T and LPP-D pumps and their hose

design and manufacturing are covered by ISO 9001:2000.

They are also ATEX approved.

Proven Performance with Flowrox

Our customers work in some of the most challenging conditions on the planet. They run extremely abrasive or corrosive

processes, often in remote locations. Whether they do business in mining, metallurgy, energy, cement, pulp & paper,

chemical or other heavy duty industries, we are there for them.

And we are glad to help.

Flowrox (former Larox Flowsys) is a privately held family owned company with over 30 years of experience and more

than 100 000 global deliveries. We value long partnerships with our customers, and are inspired by their success. Our

products increase our customers productivity and offer the lowest total costs of ownership. Flowrox is the benchmark

in heavy duty valves and pumps.

Experience with Insight Participating Partner Facilitating Performance

Contact our nearest office or one of our

50+ partners we have all over the world.

02/2012

www.flowrox.com

You might also like

- Power PhrasesDocument20 pagesPower PhrasesUma Maheswari100% (2)

- MEE40004Document8 pagesMEE40004siamak1438No ratings yet

- Fluid Mechanics Exam PaperDocument9 pagesFluid Mechanics Exam Papersiamak1438No ratings yet

- Thermodynamics vs Heat TransferDocument45 pagesThermodynamics vs Heat Transfersiamak1438No ratings yet

- Swinburne Thermofluid Exam GuideDocument12 pagesSwinburne Thermofluid Exam Guidesiamak1438No ratings yet

- 05 NumericalHeatTransfer 1Document35 pages05 NumericalHeatTransfer 1siamak1438No ratings yet

- 02 HeatConductionEquation PDFDocument16 pages02 HeatConductionEquation PDFsiamak1438No ratings yet

- The Normal Heart and How It WorksDocument2 pagesThe Normal Heart and How It Workssiamak1438No ratings yet

- Pumps & MotorsDocument370 pagesPumps & MotorsStefano SquadraniNo ratings yet

- 04 TransientHeatConduction2Document30 pages04 TransientHeatConduction2siamak1438No ratings yet

- CFD PostDocument228 pagesCFD Postyxc11100% (1)

- Heart StructureDocument9 pagesHeart Structuresiamak1438No ratings yet

- Pump Selection GuideDocument12 pagesPump Selection GuideLeok Tang100% (2)

- Useful PhrasesDocument8 pagesUseful PhraseswinnieXDNo ratings yet

- ANSYS Mechanical User's Guide PDFDocument1,858 pagesANSYS Mechanical User's Guide PDFSatadal Dash100% (15)

- Useful PhrasesDocument8 pagesUseful PhraseswinnieXDNo ratings yet

- LeDocument7 pagesLesiamak1438No ratings yet

- Mew IsDocument10 pagesMew Issiamak1438No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 4.1.8.5 - 200917 - 7.0 Clubhouse Foodservice Specifications - BOH 100 PDFDocument176 pages4.1.8.5 - 200917 - 7.0 Clubhouse Foodservice Specifications - BOH 100 PDFSantosgrupo latinoamericaNo ratings yet

- Rocktrans Conveyor Belt Quality ManagementDocument11 pagesRocktrans Conveyor Belt Quality ManagementDedi Sumaha WijayaNo ratings yet

- Internal Scraper ComparisonDocument11 pagesInternal Scraper ComparisonHarshGuptaNo ratings yet

- As ISO 14949-2003 Implants For Surgery - Two-Part Addition-Cure Silicone ElastomersDocument10 pagesAs ISO 14949-2003 Implants For Surgery - Two-Part Addition-Cure Silicone ElastomersSAI Global - APACNo ratings yet

- CAT - Duo Cone Seal InstructionsDocument26 pagesCAT - Duo Cone Seal Instructionsford62b100% (2)

- (Taken From EN ISO 10077-2: 2003) : Thermal Conductivities of MaterialsDocument4 pages(Taken From EN ISO 10077-2: 2003) : Thermal Conductivities of MaterialsCao NguyênNo ratings yet

- Wellmade® HDPC Engineered Vinyl Plank/Tile Installation GuideDocument6 pagesWellmade® HDPC Engineered Vinyl Plank/Tile Installation GuidethomasmegargleNo ratings yet

- Productivity Improvement of Rubber Roller Mixing Process Using Cause and Effect Analysis: A Case StudyDocument8 pagesProductivity Improvement of Rubber Roller Mixing Process Using Cause and Effect Analysis: A Case StudyVibhu JainNo ratings yet

- Material Master Upload TemplateDocument55 pagesMaterial Master Upload TemplateVenkat ChakriNo ratings yet

- 2017 09 29 CV Guido Waser PDFDocument14 pages2017 09 29 CV Guido Waser PDFDak KaizNo ratings yet

- Pahs in Toys and Childcare Products: Survey of Chemical Substances in Consumer Products No. 114 2011Document41 pagesPahs in Toys and Childcare Products: Survey of Chemical Substances in Consumer Products No. 114 2011lthyaguNo ratings yet

- TDS Araldite Standard 2016 enDocument2 pagesTDS Araldite Standard 2016 endantewow1No ratings yet

- Planos Molde para Vulcanizado de LlantasDocument10 pagesPlanos Molde para Vulcanizado de Llantascristobal_tl2277No ratings yet

- Embossing Printing Attaching FullDocument49 pagesEmbossing Printing Attaching FullAzmain IktedarNo ratings yet

- Pall Poly Fine ARD L PDFDocument3 pagesPall Poly Fine ARD L PDFMod KaewdaengNo ratings yet

- CIPL Skechers Vs Inter PacificDocument15 pagesCIPL Skechers Vs Inter PacificRolan Klyde Kho YapNo ratings yet

- Succinic Acid ProductionDocument3 pagesSuccinic Acid ProductionadzhamNo ratings yet

- Buyer DetailsDocument85 pagesBuyer DetailsMahajan VickyNo ratings yet

- AVK Butterfly BrochureDocument44 pagesAVK Butterfly Brochurevinurules20No ratings yet

- 446.PDF - Rubber Air HoseDocument11 pages446.PDF - Rubber Air HoseKaushik SenguptaNo ratings yet

- SECTION 07 53 23 Ethylene-Propylene-Diene-Monomer RoofingDocument29 pagesSECTION 07 53 23 Ethylene-Propylene-Diene-Monomer RoofingJuanPaoloYbañezNo ratings yet

- Hydrite®UF 90: (Μm) 0.2 (Laser) 0.4 Screen ResidueDocument1 pageHydrite®UF 90: (Μm) 0.2 (Laser) 0.4 Screen ResidueDuc NguyenNo ratings yet

- Polysar Limited Case Analysis: NASA Fixed Cost AllocationDocument5 pagesPolysar Limited Case Analysis: NASA Fixed Cost AllocationAlex ThomasNo ratings yet

- Hydraulics hose, fittings, valves and monitoring product guideDocument28 pagesHydraulics hose, fittings, valves and monitoring product guidekuraimundNo ratings yet

- 0006luk 0073 enDocument1 page0006luk 0073 enmsimic57No ratings yet

- Structural Glazing and Acp FacadeDocument16 pagesStructural Glazing and Acp FacadeHriday AgarwalNo ratings yet

- Conectores para CableDocument64 pagesConectores para CablejorgecastleNo ratings yet

- Ultraspool Single ALLDocument8 pagesUltraspool Single ALLAmina TaissaNo ratings yet

- FM Approval 4924Document18 pagesFM Approval 4924Thành Đại GiaNo ratings yet

- Sailun PLT CATALOG 2019Document45 pagesSailun PLT CATALOG 2019cticusorNo ratings yet