Professional Documents

Culture Documents

For Coalescence

Uploaded by

Abhijeet H ThakerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

For Coalescence

Uploaded by

Abhijeet H ThakerCopyright:

Available Formats

Chemfcol Engineering Scknce,

Printed in Great Britain.

Vol. 41, No.

I, pp. 65-72,

1986.

0

BREAKAGE

OF VISCOUS

AND NON-NEWTONIAN

IN STIRRED

DISPERSIONS

ocQ9-2509/86

s3.00 + 0.00

1986. Pergamon Press Ltd.

DROPS

J. S. LAGISETTY,

P. K. DAS and R. KUMAR

Department of Chemical Engineering, Indian Institute of Science, Bangalore 560012, India

and

K. S. GANDHI

Department of Chemical Engineering, Indian Institute of Technology.

Kanpur 208016, India

(Received 15 February 1985)

Abstract-A

model of breakage of drops in a stirred vessel has been proposed to account for the effect of

rheology of the dispersed phase. The deformation of the drop is represented by a Voigt element. A realistic

description of the role of interracial tension is incorporated by treating it as a restoring force which passes

through a maximum as the drop deforms and eventually reaching a zero value at the break point. It is

considered that the drop will break when the strain of the drop has reached a value equal to its diameter. An

expression for maximum stable drop diameter, d,.

is derived from the model and found to be applicable

over a wide range of variables, as well as to data already existing in literature. The model could be naturally

when the dispersed phase is a power law fluid or a Bingham

extended to predict observed values of d,,

plastic.

two phases. The viscosity of the dispersed phase has,

INTRODUCTION

however, been found to have a significant influence on

the drop size (Arai et al., 1977; Konno et al., 1982). The

viscous stress resists the flow inside the drop, leading to

its breakage, and sometimes this stress has the same

order of magnitude as the inertial stress due to pressure

fluctuation. There exists very limited information (Arai

et al., 1977; Konno et al., 1982) on the prediction of

maximum stable drop size taking into account the

effect of dispersed phase viscosity. Konno et al. (1977)

were the first to propose a model for predicting the

maximum stable drop diameter incorporating the

effect of dispersed phase viscosity. They considered

that the deformation of a drop under external stress

can be described by the Voigt model which simultaneously takes both interfacial tension (restoring

force) and viscous dissipation (due to resistance to flow

inside the drop) into account. In deriving the model

equations, they assumed that the pressure fluctuation

across a distance due to turbulent flow is periodic and

the break-up of a drop occurs when the deformation

strain (0) reaches a critical value, 13~~. They have

obtained a semi-empirical correlation for the maximum stable drop diameter in terms of two dimensionless groups, Weber number and viscous number.

Although their semi-empirical expression predicts

their experimental results reasonably well, the model is

open to criticism on several grounds. The Voigt model

has a maximum equilibrium deformation and it is

reversible. As such, it is hard to visualize the breaking

of a drop through a classical Voigt model. Arai ef al.

(1977) overcame this problem through the artifice of

associating drop breakage with a maximum deformation, Qr, which is left as an arbitrary parameter.

Further, the regular and periodic pattern assigned by

them to the turbulent flow around the drop does not

dispersions requires knowledge of the sizes of the drops

existing in the vessel. To estimate the drop sizes, it is

essential to know the break-up mechanism of a drop in

a turbulent dispersion. Hinze (1955) suggested a model

for predicting maximum stable drop diameter by

comparing the restoring elastic stress in the drop due

to interfacial tension with the inertial stress across the

drop diameter. He proposed that break-up of a drop

occurs when the ratio of the inertial stress to the elastic

The analysis

of rate processes

in liquid-liquid

exceeds a critical value.

stress, i.e. PCu* (4 40,

Assuming that turbulence is isotropic and that the

diameter d + 1 (Kolmogoroff length), the mean square

velocity fluctuation across distance, d, is given by

UZ(4) cc (.

(1)

If the Reynolds number is sufficiently large, then for a

fully baffled vessel, the power dissipation per unit

mass, E, can be expressed as

E a N3D2.

(2)

Substituting eqs (1) and (2) in Hinzes proposed

criterion, Shinnar (1961) derived the following equation for the maximum stable drop diameter, d,,,:

d

-225

D

= constant (We)-o.6

(3)

where We is the Weber number.

Equation (3) has been used by a number of investigators. Coulaloglou and Tavlarides (1976) have discussed exhaustively all the correlations available to

predict d,

in a turbulent dispersion.

Equation (3) is based on the assumption that there is

hardly any difference in densities and viscosities of the

CES

41:1-E

65

J. S. LAGISEITY et al.

66

appear realistic, especially on the length scale of drop

size being dealt with. Apart from this, their model does

not give rise to the low viscosity limit of the maximum

stable drop size naturally and had to be introduced in

an ad hoc manner. Finally, their model does not yield a

final expression which can be used directly for evaluating the two constants contained in the model. Instead,

the final expression is assumed and the two constants

involved in it are evaluated from their own experimental data. Such a procedure does not allow extension of

their model to other rheologically complex fluids.

The present work aims at proposing a new phenomenological model which accounts for the effect of

viscosity of the dispersed phase in a more rational way.

It also tests the validity of the model against experimental results.

drawn from the vessel and the particle sizes measured

with an optical microscope. At least 150 drop diameters were measured to obtain the value of d,.

To

avoid coalescence of drops during sampling and

subsequent size measurements, polyvinyl alcohol

(PVA) was added immediately before drawing the

sample. This was done when the aqueous phase was

continuous_ When the aqueous phase was dispersed,

PVA was added to it at the beginning itself.

The liquids used together with their properties and

experimental conditions are listed in Tables 1 and 2,

respectively. Interfacial tensions were determined by

the pendant drop method. Viscosities were measured

with a coaxial cylinder viscometer.

DEVELOPMENT

EXPERIMENTAL

The experimental apparatus consisted of a glass

vessel of 14.5 cm i-d. and 20 cm height. The impeller

used was a six-bladed disk turbine, placed centrally in

the mixing vessel through a stainless-steel shaft, which

in turn was connected to a motor, the speed of which

could be regulated. A set of four, equally spaced

stainless-steel balIles, arranged vertically at the wall of

the vessel, was used. The width of each baffle was equal

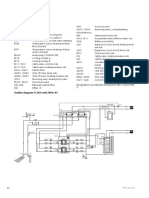

to one-tenth of the diameter of the vessel. A schematic

diagram of the equipment is shown in Fig. 1.

The continuous phase was taken in the stirred vessel

and the stirrer speed raised to the desired value. The

dispersed phase was then added to the vessel. The

dispersed phase volume fraction was kept at less than

0.02 to minimize coalescence. The equipment was run

for 1 h to achieve steady state. Samples were then

Table

D.14.5

Fig. 1. Diagram of the stirredvessel.

cm

OF THE MODEL

When a viscous droplet becomes deformed in a

turbulent flow field, the viscous stress due to the

internal flow will act simultaneously with the interfacial tension force to resist the deformation of the drop

against the external inertial stress arising from the

turbulent pressure fluctuations. If the inertial stress is

sufficiently large and sustained over a long enough

time interval, the drop will deform and a thin column

of liquid will appear somewhere in its bulk. The

column will break due to instability producing two

daughter droplets. This has been assumed to occur

when the magnitude of deformation is of the order of a

drop diameter. As the interfacial tension restoring

force is absent both at zero deformation and at the

breakage point, this restoring force should pass

through a maximum as deformation proceeds. In this

connection, it is interesting to note that based on

calculations for low Reynolds numbers, Rallison

(1984) states that for globular drops, surface tension

acts as a restoring force but that surface tension may

even promote breakage once the drop becomes

elongated. As the interfacial tension and viscous stress

simultaneously oppose the inertial stress, the Voigt

model offers a suitable description of drop deformation. However, the elastic stress due to interfacial

tension needs to be represented in a more realistic

fashion. The Voigt model corresponding to the process

of deformation is presented in Fig. 2.

In accordance with the Voigt. model, the applied

stress (T) must be equal to the opposing elastic stress

due to interfacial tension (rJ plus the viscous stress (7,).

The governing equation therefore has the following

form

7 =

7, + 7.

(4)

1. Experimental conditions

Impeller speed

Reynolds number of the

continuous phase

Dispersed phase volume

fraction

Temperature

3.33-iOrev/s

1.5 x l@-5

0.02

26C

x 104

67

Breakage of drops in a stirred suspension

Table 2. Properties of the $ontinuous and dispersed phases for the systems studied

Dispersed phase

Continuous phase

Description

c1

(Poise)

Description

Water

0.01

1.0

Kerosene

0.021

0.78

CT

13/(cn=2-)

(Mn3)

Polystyrene

in styrene

lO-30% by

wt

lOOm1 of

CMC in water

(2.5 %I +

60ml of 2%

PVA

CaCO, aqueous

suspension

(59.5 % Caco3 +

2.00 y0 polyvinyl

alcohol)

(dynes/cm)

(g/&3)

0X8-0.92

0.4337.50

20

14.5

2/3

50

45.2

1.47

0.137

The condition that 7, is zero for 0, > 1 explicates the

essential feature of the model, i.e. the drop has reached

its break point when the dimensionless strain has

reached the value of unity and surface tension can no

longer bring it back to its original state. Thus the Voigt

model proposed in the present work cannot retract to

its original state, once 0, & 1, even when the applied

stress is withdrawn.

Constitutive

equation for TV

For the fluids considered in this work, the constitutive equation for viscous stress can be written in a

generalized form as

7v =

Fig. 2. Voigt model for the deformation of a drop.

Constitutive

equation for T,

When the drop suffers a small but finite strain, the

interfacial tension force generates a restoring stress

proportional to the strain. However, as the drop

undergoes further deformation and approaches the

breaking point, its structure will be more like that of a

dumb bell: two yet to be born daughter droplets

connected by a thin filament of liquid. The filament will

break because of its inherent instability. Thus near the

break point,- surface tension has no restoring effect.

Hence a more realistic description of the role of surface

tension must be to assign to it a retractive force that

increases for small deformations of the drop but

decreases afterwards and eventually reaches zero at the

break point. Assuming that the total deformation

undergone by the drop up to the point of breakage is of

the order of magnitude of d, the following simple

functional relationship between 5, and 0, has been

assumed.

TS= $ es (1 -e,>

= 0

e, c 1

e, 3 I.

(5)

TV +

(de,/dtY.

(6)

Equation (6) simplifies to the case of Newtonian,

Bingham plastic and power law models when appropriate simplifications are made.

Model equation

For a Voigt element, the total strain 8 = 8, = 0,.

Noting this and substituting eqs (5) and (6), respectively, in eq. (4), we obtain

r-=,--ae(l-e8)+K

d

e c

1.

(7)

The flow inside the drop during breakage will be quite

complex. In the present model, however, it has been

assumed to be a simple shear flow.

Description

of z

In eq. (4), T represents the dynamic pressure difference across the drop diameter. In a turbulent flow

field the pressure difference normally associated with

the arrival of eddies is a quantity which fluctuates with

time and distance over which it operates. However,

exact knowledge of the fluctuations is not yet available.

Therefore, it is assumed that the deformation takes

place under the influence of a mean stress which

remains constant over the average life time of an eddy.

68

J. S. Llsorszrrv et al.

for average values of 7 and T

Let the average values of 7 be + and the average life

time of an eddy beF The expressions for these average

values given by Hinze (1955) and Coulaloglou and

Tavlarides (1977) have been used in the present

investigation. They are

Expressions

7 ~PcU2W

cannot show any instantaneous deformation on the

application of the stress. Hence

8=0

(17)

By separating the variables, eq. (15) can be written as

(18)

where

(9)

=&*

mass, E, and u2 (d)

Tavlarides (1977) are

a = C We (d/D)s3

given

by

Coulaloglou

and

E = 0.407 IV= D2

(10)

u2 (d) = 1.88 s23 d23.

(11)

and

Therefore + can be expressed as:

+ -_ C pc N2 D4/= d2j3

(12)

where C is a constant dependent only on the geometry

of the tank and agitator. The average life time is given

by

(13)

The drop experiences no stress prior to its coming

under the influence of an eddy and from then onwards,

a constant stress equal to + for a time interval of T

Thus

r=O

=p

$213 _

(T,,

d/u) -

l/4.

(19)

solution of eq. (18) with the initial condition

depends on the constant a in eq. (19). There are two

possible solutions corresponding to a < 0 or a > 0. If

a -Z 0, it can be shown that when t -B co, 8 --r [l/2

tto

o<tgT.

- fi]_

Thus, Bean never reach a value of unity, and

breakage is not possible in the finite time interval ofT_

But tI can reach unity in a finite time period when a

> 0, and therefore to predict the maximum drop

diameter, only values of a greater than zero need to be

considered.

Our main concern is to know the maximum size of a

drop that can exist in the stirred vessel. All drops above

such a size will break. As stated earliei, the drop has

been assumed to deform under the influence of T for a

period of?? The maximum stable drop size therefore is

the maximum threshold drop size which reaches a

deformation of unity when exposed to a constant stress

F during the time interval F. Such a drop size can be

calculated as follows.

Equation (18) is integrated to find rl at 8 = 1. If rl at

8 = 1, the dimensionless time required to reach deformation corresponding to breakage, is more than the

nondimensional life time of the eddy, breakage would

not occur. Thus for breakage to occur, the following

condition must be satisfied:

q (0 = 1) < (u/dIQ1Z

Substituting these into eq. (7), we obtain

D413

The

It is necessary to express u2 (d) in terms of the

parameters associated with the stirred vessel. The

expressions for the rate of energy dissipation per unit

Tg +1

-e)e+K

de

-&

(14)

(>

(dlJ/dt# = C We (d/D)/

- (q,d/o)

- (0 - 02)

(15)

where rl is the nondimensional time given by

q = (o/dK)

t.

(16)

stable drop size

The drop is exposed to a stress of i only for a time

period T After this time, the eddy would have dissipated its energy and the external stress on the drop

becomes zero once again. If at the end of the time

interval T the value of B -Z 1, then the surface tension

spring would still have a finite retractive stress and the

drop would return to its original state. Thus for the

drop to break it is not only necessary that 8 = 1 is

reached but also that it should be attained at some

point during the time intervalT. The time required to

reach 0 = 1 can be obtained by integrating eq. (15); an

initial condition is needed to do so. The dashpot

(20)

As the applied stress increases with diameter, q (0 = 1)

decreases with increasing diameter. The maximum

stable drop size is that for which

Equation (14) is more conveniently represented in

dimensionless form as

Maximum

q=O_

(8)

and

C PcN2

at

q (0 = 1) = (a/d_,

K)T.

(21)

Thus eq. (18) can be integrated up to rl(0 = 1)

= (a/d_K)T

to find the maximum stable drop

size. Using the expression for T in eq. (9), ~(0 = 1) can

be written as

r.t(e = 1) = (Re/We)

(d/D)23-n

where

Re

D (NoI2 - nP,

2-(3+l/nrK

(23)

Forr,=Oandn=

1,1/3,1/2and2/3,eq.(18)canbe

integrated analytically; the solutions are listed in

Table 3. It should be noted that C = 8.0 has been used

in these results for both Newtonian and nonNewtonian fluids. This will be discussed further in the

Results and Discussion.

It should be noted that the model developed in the

Breakage of drops in a stirred suspension

69

Table 3. Solution of eq. (18) for non-Newtonian fluids

Solution of the model equation

[32 We (d_/D)s3

= (RejWe) (d-/D)-

- I]* tanm

Ii3

>I=

(Re/We)3/2 (d-/D)-

u2

We (d_/D)

x tan-

13

1.6

(32 We (d_/D)513

c32 We(d_;D)

51.2

- 1) + [32 We (d_/D)53

1,~,2

cRe/~~

2.66(44We(d_/D)53

-1)

[(32We(d_/D)

-l)* Wez(d_/D)o]

x tan-

[32 We (d_;D)=

- l]*

- l]3/2

%axP-43

+ (32 We(d,,,f/$

=

56

[Re/ We] (d-/D)

- 1)5f*

- j3

present work involves a single parameter whereas

the model proposed by Arai et al. (1977) requires the

knowledge of two parameters to be evaluated from

experimental data. A positive test that can be applied to

the present model is that the constant C involved in eq.

(12), which relates the turbulent pressure fluctuations

to d, N and D, should not depend on the rheological

properties of the dispersed phase. If this is satisfied,

then clearly the present model offers a distinct advantage over the model of Arai et al. (1977) which

requires the evaluation of two parameters.

RESULTS

AND

DISCUSSION

Newtonian fluids

and inviscid limit

One of the interesting aspects of the model is that as

the dispersed phase viscosity becomes very small, i.e.

,ud+ 0, the solution of the model equation reduces to

the well-known and widely tested equation given by

Shinnar (1961). For example, looking at the equation

for a Newtonian fluid (n = 1) presented in Table 3, the

only solution that is possible as pd - 0 or Re -+ co is

-+ constant. This result is identical

that We (d_/D)53

to eq. (3) reported by Shinnar (1961).

Using the data of drop diameters against dispersed

phase viscosity for different speeds, the value of

constant C in eq. (12) has been determined. The value

of the constant worked out to be 8.0. Figures 3 and 4

show the experimental drop diameter, d,,

against

dispersed phase viscosity, pd. and impeller speed. The

results predicted by the model are shown as lines

whereas the points are experimental results. The

theoretical predictions are in good agreement with the

observations. From this, it can be seen that C is

dependent only on the geometry of the vessel and

agitator, and not on cl,,. Further, it is worth noting that

the effect of dispersed phase viscosity on d,

becomes

significant only after about 20 cP.

The predictions of the present model and the

numerical value of constant C can be further tested

using the experimental observations of other workers.

Fig. 3. Comparison of experimentalresultswith the present

model (effectof Jo)_

When the dispersed phase viscosity becomes small, i.e.

p, -V 0, the model predicts that

(d-/D)

= 0.125 (We)-*6.

Sprow (1967) has given the following empirical relationship when the dispersed phase viscosity is small:

(d-/D)

= a1 (We)-.6.

The value of a 1 lies between 0.126 and 0.15, which is in

agreement with the value found in the present work.

The present value of 0.125 is somewhat better because

it fits a large amount of other experimental data. For

instance, the experimental results of Arai et al. (1977)

also agree with the present model. This is shown in

Fig. 5.

The present model can be easily modified to incorporate the effect of the dispersed phase hold-up.

The value of the mean square velocity, u* (d), changes

with the change in the dispersed phase hold-up. The

J. S. LAGISETN

70

et al.

(1976) indicate that d,

= 1.5 dS2. Therefore

d

2

= 0.083 (1 + a2#).

D

0.

0.

0.

0

I

Loo

300

Impcllsr

speed

N (r.p.m

pd c 3

CP

o-

z 20

dyneslcm

= 4.5

cm

Fig. 4. Effect of impeller speed on the maximum stable drop

diameter.

0.5

B

i L-0

Non-Newtonian&ids

Figure 7 presents the experimental results of maximum stable drop diameter with change in impeller

speed for a power law fluid (2.5 0A CMC in water

+ PVA, n = 2/3). The grade of CMC used was the

same as that employed by Kumar and Saradhy (1972).

These authors used a test attributed to Philipoff to

ensure the absence of viscoelasticity in CMC solutions

up to a concentration of 4% by weight. The other

component of the solution used in the present work

was PVA, with a molecular weight of about 70,000. At

this molecular weight and low concentrations, PVA

will also not impart an elastic character to the solutions. Therefore the solution employed in this work

can be safely considered to be inelastic. The drop

diameter decreases with impeller speed in a nonlinear

fashion. As mentioned earlier, according to the model,

IJA

I

1.5

(26)

It is found that for a2 = 4.0, the model predictions

given by eq. (26) fit the experimental data of

Coulaloglou and Tavlarides (1976) on continuous

systems reasonably well. This is shown in Fig. 6.

It can be concluded that the value of 8.0 assigned to

constant C is related only to the geometry of the vessel

and agitator, and arises from the nature of the

turbulent fluctuations. It is not affected by the properties of the dispersed phase, which have been varied

over a wide range. The model itself can then be seen to

account for the variation of the viscosity of the

dispersed phase. This can be tested further by examining non-Newtonian fluids.

(We)-o.6.

I/ /

d/

/)/

A;./

_--,_A=

___--b-

Theoretical

Experimental

l3.P.M

xl0

400

0

0

a-

-.=

20

dyneslcm

600

j

D=

6.,5

cm

Fig. 5. Comparison of experimental results (Arai

the present model.

value of m

changes

Tavlarides, 1977)

m+=+

with

et al.)

4 as (Coulaloglou

= (1 +a2+)-2.0[uz(d)]+o.

with

and

(24)

Using the modified expression for u2 (d), the equation

for maximum drop size for Newtonian fluids in the

limit of small viscosity becomes

+

= 0.125

(1 + r~~+)~ (We)-.6.

c-w

The data available in the literature is in terms of dx2.

Sprow (1967) and Coulaloglou and Tavlarides (1976)

indicate that da2 is linearly related to d,.

For

continuous systems, Coulaloglou

and Tavlarides

0

*

.

0

a2

0.15

0.Y)

0 05

0.025

z 4.0

Fig. 6. Comparison of Coulaloglou and Tavlarides experimental values (effect of 4) with those predicted by the present

model.

Breakage of drops in a stirred suspension

71

numbers, i.e. at high values of p,, all the curves merge,

indicating that interfacial tension does not play a

significant role in the breakage of drops. This result is

expected, since when the drop is sufficiently viscous,

the applied force essentially overcomes

the mean

viscous resistance, compared to which the restoring

surface tension force is insignificant. On the other

hand, at high Reynolds numbers, the restoring force

due to interfacial tension is predominant compared to

the viscous forces and the applied force essentially has

to overcome the restoring interfacial tension forces.

That is why at high Reynolds numbers different lines

are obtained for different Weber numbers.

Impeller

speed

ti (r.p.m

Fig. 7. Comparison of experimental results with those predicted by the present model for a power law fluid.

constant C must be independent of the rheology of the

dispersed phase. The solid line represents the results

calculated from the model using constant C evaluated

with the experimental results of Newtonian fluids, i.e.

calculated from the second equation of Table 3. It was

found that the model predicts the results reasonably

well. This lends further credence to the model.

Generalized representation

The model predictions can be represented in generalized graphs by plotting (d-/D)

against the Reynolds

number, Re (defined on the basis of the viscosity of the

dispersed phase) with the Weber number, We, as a

parameter. Figure 8 shows plots of d-/D

against Re,

with We as a parameter for the values of n equal to I,

2j3 and 1j3. The plots show that at low Reynolds

Bin&am plastics

For Bingham plastic fluids the theoretical equations

can be easily developed by replacing 7 in the differential

equations for purely viscous fluids with (7 - 70)_ It is

easily shown that this corresponds to replacing

[32 We (d_jD)s3

- l]

by

[32 We (d_jD)5/3

- 4

(7,, d-/a)

- l]

in equations of Table 3. This implies the usage of the

same value of C determined from Newtonian fluids.

Figure 9 presents the experimental results of the

maximum stable drop diameter with change in the

impeller speeds for a Bingham plastic fluid (aqueous

CaCOS suspension with PVA, c = 45.2 dynes/cm T,,

= 75 dynes/cm, n = 1, p,, = 13.7 cP). It is found that

the drop diameter decreases with increase in the

impeller speed in a nonlinear fashion. The solid line

represents the theoretical results calculated from the

first equation of Table 3 with the modification

described above. The dashed line represents the drop

diameters that would have been observed if the fluid

had been Newtonian,

i.e. 7. = 0. The experimental

results are higher than those for a Newtonian fluid

since the effective applied stress is now lower. The

model reflects this and predicts the d,

values quite

well, thus accruing more evidence in its favour.

Fig. 8. Effect of the Reynolds number on d,,, /D with the Weber number as a parameter.

72

J. S. LAGISETN

0.8

et al.

1

z

Re

0.5

t

T

u= (d)

We

1

0.31

300

400

lmprllrr

speed

N(r.,mm)

Fig. 9. Effect of impeller speed on the maximum stable drop

diameter for a Bingham plastic fluid.

Kolmogoroff length scale, cm

power law index

impeller speed, rev/s

D (ND)- pJ(2- (3 + l/n) K), Reynolds

number

time, s

average life time of eddy, s

mean square velocity fluctuation across distance d, cm2/s2

N2 D p,/a, Weber number

Greek letters

energy dissipation rate/mass, cm2/s3

&

dimensionless time

dispersed phase hold up

2

density of the continuous phase, g/cm

PC

viscosity of the dispersed phase, poise

c(d

a

constant

dimensionless strain; subscripts s and v refer

8

to spring and viscous parts

dynamic pressure difference across the dis

ameter of the drop, dynes/cm2

average value of t, dynes/cm

7

yield stress, dynes/cm

70

resistive stresses due to spring and viscous

=.,*,

dashpot, respectively, dynes/cm2

t7

interfacial tension, dynes/cm

CONCLUSIONS

A model of breakage of drops which accounts for

the effect of interfacial tension in a realistic way has

been used to predict the maximum size of a stable drop

in a turbulent stirred dispersion. Separation of the

rheology of the dispersed phase and representation of

the turbulence characteristics of the stirred vessel by a

constant, dependent only on the geometry of the vessel

and agitator, are the essential features of the model.

Measurements on Newtonian fluids, power law fluids

and Bingham plastics show the efficacy of the predictions of the model and confirm its main features.

REFERENCES

Arai, K.,Konno,

M., Matunga, Y. and Saito, S., 1977, Effect of

dispersed phase viscosity on the maximum stable drop size

for break-up in turbulent flow. .I. them. Engng Jap. IO,

325-330.

Coulaloglou, C. A. and Tavlarides. L. L., 1976. Drop size

distributions and coalescence frequencies of liquid-liquid

dispersions in flow vessels. A.1.Ch.E. J. 22, 289-297.

Coulaloglou, C. A. and Tavlarides, L. L., 1977, Description of

interaction processes in agitated liquid-liquid dispersions.

Chem. Engng Sci. 32, 1289-1297.

Hinze, J. O., 1955, Fundamentals of the hydrodynamic

mechanism of splitting up in dispersion process. A.I.Ch.E.

J. 1, 289-295.

Konno, M., Arai, K. and Saito, S., 1982, The effect of stabilizer

NOTATION

01,

d

42

LX

D

K

02

constants

constant dependent only on the geometry of

vessel and agitator

drop diameter, cm

Sauter mean diameter, c nid:/C n,df,cm

maximum drop diameter, cm

impeller diameter, cm

power law constant, g/(cm s*-)

on coalescence of dispersed drops in suspension polymerization of styrene. J. &em. Engng Jap. 15, 131-135.

Kumar, R. and Saradhy, Y. P., 1972, Drop formation in nonNewtonian fluids. I.E.C. (Fund.) 11, 307-311.

Rallison, J. M., 1984, The deformation of small viscous drops

and bubbles in shear flow. Ann. Reu. Fiuid Mech. 16,4%X

Shinnar, R., 1961, On the behaviour of liquid-dispersions in

mixing vessels. J. Fluid Mech. 10, 259-275.

Sprow, F. B., 1967, Distribution of drop sizes produced in

turbulent liquid-liquid dispersion. Chem. Engng Sci. 22,

435-442.

You might also like

- A Output File 4 5 2016Document5,000 pagesA Output File 4 5 2016Abhijeet H ThakerNo ratings yet

- A Binary Interfacial Conditions 4 5 2016Document1 pageA Binary Interfacial Conditions 4 5 2016Abhijeet H ThakerNo ratings yet

- La 304138 ZDocument8 pagesLa 304138 ZAbhijeet H ThakerNo ratings yet

- Ol0362820 PDFDocument4 pagesOl0362820 PDFAbhijeet H ThakerNo ratings yet

- 120 RPM (40s) (Batch Settling Experiment) DSD by Sampling MethodDocument1 page120 RPM (40s) (Batch Settling Experiment) DSD by Sampling MethodAbhijeet H ThakerNo ratings yet

- Experimental Data For Batch SettlingDocument6 pagesExperimental Data For Batch SettlingAbhijeet H ThakerNo ratings yet

- DATA ModifiedDocument1 pageDATA ModifiedAbhijeet H ThakerNo ratings yet

- Particle Size Model for Suspension PolymerizationDocument15 pagesParticle Size Model for Suspension PolymerizationCamelia MoiseNo ratings yet

- Merry ChristmasDocument1 pageMerry Christmasastrid_johnson03No ratings yet

- Good Paper For ReadingDocument7 pagesGood Paper For ReadingAbhijeet H ThakerNo ratings yet

- I 360041 A 007Document8 pagesI 360041 A 007Abhijeet H ThakerNo ratings yet

- Mesi art:10.1007/BF00905951Document8 pagesMesi art:10.1007/BF00905951Abhijeet H ThakerNo ratings yet

- Dealumination 1-S2.0-S1387181100001475-MainDocument8 pagesDealumination 1-S2.0-S1387181100001475-MainAbhijeet H ThakerNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Gasifier DesignDocument6 pagesGasifier DesignPetrosky RocksonNo ratings yet

- 6.2020-3015 Dolphin Wake StructureDocument9 pages6.2020-3015 Dolphin Wake StructureHua Hidari YangNo ratings yet

- DX0 Conversion KitDocument1 pageDX0 Conversion KitWili Nur RahmanNo ratings yet

- EOS01204Document1 pageEOS01204Lesley-Anne RowandNo ratings yet

- CREII-Module-I - Lecture 1 PDFDocument36 pagesCREII-Module-I - Lecture 1 PDFshubhamNo ratings yet

- Wall Thickness CalDocument6 pagesWall Thickness CalNorazlan Shah MahadiNo ratings yet

- Petrochemicals Plants From Commissioning To Normal Op. - Vol.1-March 2017-1Document229 pagesPetrochemicals Plants From Commissioning To Normal Op. - Vol.1-March 2017-1Mohamed S HelmyNo ratings yet

- Deaerators: Technical BackgroundDocument8 pagesDeaerators: Technical Backgroundกี๋ แต่งงามNo ratings yet

- SPPPL - Profile (Shree Pinak Processing PVT LTD.)Document4 pagesSPPPL - Profile (Shree Pinak Processing PVT LTD.)Amit KaleNo ratings yet

- Measurements and Modeling of Water Adsorption Isotherms of Zeolite Linde-Type A CrystalsDocument11 pagesMeasurements and Modeling of Water Adsorption Isotherms of Zeolite Linde-Type A CrystalsRoger David Melendez GuevaraNo ratings yet

- Department of Chemical Engineering Manipal University JaipurDocument26 pagesDepartment of Chemical Engineering Manipal University JaipurHarshit JoshiNo ratings yet

- DynasetDocument64 pagesDynasetAlexis Peña0% (1)

- Plumber Practice Test 1Document8 pagesPlumber Practice Test 1docino1417100% (2)

- Water Hammer Tutorials Attempt The Tutorials and Check Your Answers Against The Solutions GivenDocument3 pagesWater Hammer Tutorials Attempt The Tutorials and Check Your Answers Against The Solutions GivenNickson KomsNo ratings yet

- Shop Drawings: LegendDocument1 pageShop Drawings: LegendSadev Mini VlogsNo ratings yet

- Hydrodynamic Design of Planing Hulls SavitskyDocument25 pagesHydrodynamic Design of Planing Hulls SavitskyMarcelo CaliNo ratings yet

- GDT - MEP Equipment WeightDocument10 pagesGDT - MEP Equipment WeightsovannchhoemNo ratings yet

- Catalysis Reaction Rates GuideDocument104 pagesCatalysis Reaction Rates GuideMandla Rebirth0% (1)

- Sly Venturi ScrubberDocument2 pagesSly Venturi Scrubberzguy360No ratings yet

- Schema NIBE F1345 Cu HPAC45Document1 pageSchema NIBE F1345 Cu HPAC45Istvan MadacsyNo ratings yet

- Paquete Condensado Por Agua Hasta 5 TRDocument142 pagesPaquete Condensado Por Agua Hasta 5 TREder Yousetf Pacocha RuizNo ratings yet

- Spillway DesignDocument6 pagesSpillway DesignguildkeyNo ratings yet

- Engine Characteristics: UEC33LSE-Eco-C2 Technical Data 1.4 Eco-Engine SystemDocument6 pagesEngine Characteristics: UEC33LSE-Eco-C2 Technical Data 1.4 Eco-Engine Systembritties69No ratings yet

- Mineral Water Plant ProjectDocument14 pagesMineral Water Plant ProjectSourav OjhaNo ratings yet

- PetroSync - Oil Gas Petrochemical and Power Technical Training Career Development - Version 1 (2) 30 Maret 2017Document2 pagesPetroSync - Oil Gas Petrochemical and Power Technical Training Career Development - Version 1 (2) 30 Maret 2017kimikononNo ratings yet

- Mass Transfer Operations 1: Brief Discussion of Unit Processes Involved in NIRMA LTD., MandaliDocument15 pagesMass Transfer Operations 1: Brief Discussion of Unit Processes Involved in NIRMA LTD., MandaliZaid MansuriNo ratings yet

- DEAERATORDocument26 pagesDEAERATORSai Swaroop100% (2)

- Questions and AnswersDocument2 pagesQuestions and AnswerslguetaNo ratings yet

- WPC-21-0851 Field Scale Polymer Flooding of Heavy Oil The Pelican Lake Story - Heavy Oil - GoodDocument29 pagesWPC-21-0851 Field Scale Polymer Flooding of Heavy Oil The Pelican Lake Story - Heavy Oil - GoodGilbert OmittaNo ratings yet

- Internship PresentationDocument26 pagesInternship PresentationKarthik NayakNo ratings yet