Professional Documents

Culture Documents

Nelson Stud Properties - Esr-2856

Uploaded by

ellisblCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nelson Stud Properties - Esr-2856

Uploaded by

ellisblCopyright:

Available Formats

Most Widely Accepted and Trusted

ICC-ES Report

ICC-ES | (800) 423-6587 | (562) 699-0543 | www.icc-es.org

000

ESR-2856

Reissued 10/2015

This report is subject to renewal 10/2016.

DIVISION: 03 00 00CONCRETE

SECTION: 03 15 00CONCRETE ACCESSORIES

REPORT HOLDER:

NELSON STUD WELDING, INC.

7900 WEST RIDGE ROAD

ELYRIA, OHIO 44036

EVALUATION SUBJECT:

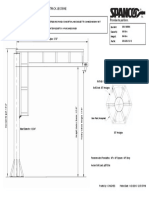

NELSON SHEAR CONNECTOR STUDS

Look for the trusted marks of Conformity!

2014 Recipient of Prestigious Western States Seismic Policy Council

(WSSPC) Award in Excellence

ICC-ES Evaluation Reports are not to be construed as representing aesthetics or any other attributes not

specifically addressed, nor are they to be construed as an endorsement of the subject of the report or a

recommendation for its use. There is no warranty by ICC Evaluation Service, LLC, express or implied, as

to any finding or other matter in this report, or as to any product covered by the report.

Copyright 2015 ICC Evaluation Service, LLC All rights reserved.

A Subsidiary of

ICC-ES Evaluation Report

ESR-2856

Reissued October 2015

This report is subject to renewal October 2016.

www.icc-es.org | (800) 423-6587 | (562) 699-0543

DIVISION: 03 00 00CONCRETE

Section: 03 15 00Concrete Accessories

REPORT HOLDER:

NELSON STUD WELDING, INC.

7900 WEST RIDGE ROAD

ELYRIA, OHIO 44036

(440) 329-0480

www.nelsonstud.com

EVALUATION SUBJECT:

NELSON SHEAR CONNECTOR STUDS

1.0 EVALUATION SCOPE

Compliance with the following codes:

2012, 2009 and 2006 International Building Code (IBC)

Property evaluated:

Structural

2.0 USES

The Nelson shear connector studs are intended for use in

steel and concrete composite construction.

3.0 DESCRIPTION

The Nelson shear connector studs are intended for use in

steel and concrete composite construction and are

manufactured from ASTM A29-12, Grades 1010 through

1020, cold-drawn steel. The studs conform to minimum

physical properties as presented in Table 1. The shear

connector studs are Type B studs conforming to

requirements of the American Welding Societys Structural

Welding CodeSteel, AWS D1.1 -10 and Section A3.6 of

the AISC Specification for Structural Steel Buildings

(AISC 360-10 for the 2012 IBC, or -05 for the 2009 and

2006 IBC). The shear connector studs are provided in

3

/8- 1/2-, 5/8-, 3/4-, 7/8- and 1-inch (9.5, 12.7, 15.9, 19.1, 22

and 25.4 mm) diameters.

4.0 DESIGN AND INSTALLATION

4.1 Design:

The nominal horizontal shear strength of Nelson stud

shear connectors [diameters from 3/8 to inch (9.5 to

19.1 mm)] is given in Table 3-21 of the AISC Steel

th

th

Construction Manual (13 and 14 editions), in accordance

with Specification for Structural Steel Buildings (AISC 360).

Alternatively, the nominal shear strength of one stud shear

A Subsidiary of the International Code Council

connector may be calculated in accordance with Sections

I2.1g and I3.2d(3) of AISC 360-05 (2009 and 2006 IBC), or

Section I8.2a of AISC 360-10 (2012 IBC). The design of

composite members with shear connectors must comply

with the provisions of Sections 2203, 2204, and 2205 of

the IBC and Chapter I of AISC 360.

For studs installed through steel deck, the steel deck

material must be galvanized steel as specified in this

report, unless field qualification tests in accordance with

AWS D1.1-10 are conducted to the satisfaction of the code

official. The following through-steel deck applications are

recognized in this report:

1. Three-quarter-inch-diameter (19.1 mm) stud through

one layer of No. 16 gage or thinner deck with a

maximum 1.25-ounce-per-square-foot (381 g/m2)

galvanization complying with ASTM A525, Class G90.

2. Three-quarter-inch-diameter (19.1 mm) stud through

two layers of No. 20 gage or thinner deck with

a maximum 0.6-ounce-per-square-foot (183 g/m2)

galvanization on each deck layer complying with ASTM

A525, Class G60.

4.2 Installation:

Nelson shear connector studs are automatically endwelded with equipment and procedures recommended by

Nelson Stud Welding, Inc. All welding must comply with

AISC 360 Section M2, item 4, and AWS D1.1-10. Prior to

welding, steel deck surfaces and supporting beams must

be clean, unpainted, and free of heavy rust and mill scale,

dirt, sand, oil, water or other deleterious materials. The

deck material must be tightly secured to the top flange of

beams. No air gaps are permitted at welded areas. The

ambient temperature must be above 0F (18C). Between

0F and 32F (18C and 0C), special welding

instructions in the Nelson stud installation manual must be

followed.

4.3 Special Inspection:

The welding of the shear connectors requires special

inspection in accordance with Sections 1705.2 and 1705.3

of the 2012 IBC, or 1704.3 and 1704.4 and Tables 1704.3

and 1704.4 of the 2009 and 2006 IBC. The special

inspector duties include identification of studs; concrete

mix design; quality of concrete; stud clearances between

edges, base and adjacent studs; stud size; concrete

placement and testing; sampling materials; verifying

welders qualifications; weld-joint preparation; welding

procedure and process; and tolerances.

ICC-ES Evaluation Reports are not to be construed as representing aesthetics or any other attributes not specifically addressed, nor are they to be construed

as an endorsement of the subject of the report or a recommendation for its use. There is no warranty by ICC Evaluation Service, LLC, express or implied, as

to any finding or other matter in this report, or as to any product covered by the report.

1000

Copyright 2015 ICC Evaluation Service, LLC. All rights reserved.

Page 1 of 2

ESR-2856 | Most Widely Accepted and Trusted

5.0 CONDITIONS OF USE

The Nelson Shear Connector Studs described in this report

comply with, or are suitable alternatives to what is

specified in, those codes listed in Section 1.0 of this report,

subject to the following conditions:

5.1 Installation complies with this report and the

manufacturers instructions. In the event of conflict

between this report and the manufacturers

installation instructions, this report governs.

5.2 Nominal shear strength of shear connectors must be

determined in accordance with references given in

Section 4.1 of this report.

5.3 Design of composite beams and concrete slabs on

formed steel deck panels must comply with the

provisions of Section 4.1 of this report.

Page 2 of 2

connected to steel beams is limited to shear

connectors 3/4 inch (19 mm) or less in diameter.

5.5 Special inspection must be in compliance with Section

4.3 of this report.

6.0 EVIDENCE SUBMITTED

Report of tests specified in AWS D1.1; manufacturers

product data; and quality documentation.

7.0 IDENTIFICATION

The Nelson shear connector studs are identified by

the letter N on the head of each stud. The studs are

shipped in containers with a label bearing the name and

address of the manufacturer, stud size, part number, heat

number, manufacturers code and evaluation report

number (ESR-2856).

5.4 Design of composite construction consisting of

concrete slabs on formed steel deck panels

TABLE 1MINIMUM PHYSICAL PROPERTIES OF STUDS

PROPERTY

VALUE

Ultimate tensile strength

65,000 psi (450 MPa)

Yield strength0.2% offset

51,000 psi (350 MPa)

Elongation in 2 inches (51 mm)

20 percent

Reduction of area

50 percent

You might also like

- Catalogo AWSDocument46 pagesCatalogo AWScesarNo ratings yet

- Principles and Practices of Stud Welding: State-Of-The-Art PaperDocument13 pagesPrinciples and Practices of Stud Welding: State-Of-The-Art Paperalbert limantonoNo ratings yet

- AISE Anchor Bolt Details PDFDocument1 pageAISE Anchor Bolt Details PDFYash PaulNo ratings yet

- Structural Bolts, Steel, Heat Treated 830 Mpa Minimum Tensile Strength (Metric)Document8 pagesStructural Bolts, Steel, Heat Treated 830 Mpa Minimum Tensile Strength (Metric)abohassn72No ratings yet

- Mechanical Testing 01B: Part 2 Charpy Impact TestingDocument25 pagesMechanical Testing 01B: Part 2 Charpy Impact Testingsamurai7_77100% (1)

- Ssec - Tip - 56 Cambered Steel Beams PDFDocument4 pagesSsec - Tip - 56 Cambered Steel Beams PDFAdrian Guerra EspinosaNo ratings yet

- AWS Guide To Abbreviations Certified WelderDocument1 pageAWS Guide To Abbreviations Certified Weldersigurdur hannessonNo ratings yet

- AWS D1.1 - Bend PDFDocument1 pageAWS D1.1 - Bend PDFVIVEKNo ratings yet

- SSPC QP 3Document6 pagesSSPC QP 3anoopkumarNo ratings yet

- Certification: Structural Steel and Bolting Special Inspector Exam ID: S1Document2 pagesCertification: Structural Steel and Bolting Special Inspector Exam ID: S1Ammar A. AliNo ratings yet

- Avoidance of Discontinuities in The Joint HardoxDocument10 pagesAvoidance of Discontinuities in The Joint HardoxfsfunbNo ratings yet

- H4L StudDocument1 pageH4L StudisracumaNo ratings yet

- GB-T 232-2010 Metallic Materials-Bend TestDocument14 pagesGB-T 232-2010 Metallic Materials-Bend TestH. Camer E.No ratings yet

- Wrought Austenitic Stainless Steel Piping Fittings: Standard Specification ForDocument8 pagesWrought Austenitic Stainless Steel Piping Fittings: Standard Specification FormilecsaNo ratings yet

- Aws B5.5 Specification For The Qualification of Welding Educators PDFDocument27 pagesAws B5.5 Specification For The Qualification of Welding Educators PDFYago MendozaNo ratings yet

- Totten CatalogDocument19 pagesTotten CatalogxpertsteelNo ratings yet

- Errata D1.1 D1.1M 2020Document6 pagesErrata D1.1 D1.1M 2020Darwin EnriqueNo ratings yet

- Care & Cleaning - Stainless Steel PDFDocument7 pagesCare & Cleaning - Stainless Steel PDFpsp710No ratings yet

- Astm A380-17Document13 pagesAstm A380-17EmekaNo ratings yet

- OPSS 906 - Nov12Document20 pagesOPSS 906 - Nov12umerfr2No ratings yet

- Aws C 5.4 Stud Welding PracticesDocument7 pagesAws C 5.4 Stud Welding PracticesJose Aciano Hernandez0% (1)

- Advanced Gas Metal Arc Welding ProcDocument20 pagesAdvanced Gas Metal Arc Welding ProcjavadmohammadiNo ratings yet

- Norma CWB Cambios en W47.1-2009Document6 pagesNorma CWB Cambios en W47.1-2009Jose ManuelNo ratings yet

- Steelwise AISCDocument6 pagesSteelwise AISCAruna Kumari GNo ratings yet

- STUD WELDING REQUIREMENTS From AWS D1.1-D 1.1M-2015Document10 pagesSTUD WELDING REQUIREMENTS From AWS D1.1-D 1.1M-2015Mark Darrel AranasNo ratings yet

- Aws B1.11Document36 pagesAws B1.11Gary TeongNo ratings yet

- E140 32302 PDFDocument25 pagesE140 32302 PDFTony HerreraNo ratings yet

- Astm A1011Document1 pageAstm A1011otaviossNo ratings yet

- Astm17 0303Document5 pagesAstm17 0303Edgardo Emilio CantillanoNo ratings yet

- Star Core 6Document2 pagesStar Core 6jmur10No ratings yet

- TACOM Weld Code - Alumn (12472301A)Document123 pagesTACOM Weld Code - Alumn (12472301A)mtcengineeringNo ratings yet

- Esr 1308Document21 pagesEsr 1308dkimNo ratings yet

- Table 6 1 AWS D1 1 D1 1M 2010 PDFDocument1 pageTable 6 1 AWS D1 1 D1 1M 2010 PDFFu AdNo ratings yet

- The Death of Welding InspectorDocument1 pageThe Death of Welding Inspectormekag94100% (1)

- d10 12m-d10 12PVDocument6 pagesd10 12m-d10 12PVkhairy20130% (1)

- Specification For Automotive Weld Quality-Arc Welding of SteelDocument6 pagesSpecification For Automotive Weld Quality-Arc Welding of Steelromanosky11No ratings yet

- Astm A500 A500m-21Document6 pagesAstm A500 A500m-21alvin duey100% (1)

- TDS005-Grade 2 and ASTM A307 BoltingDocument2 pagesTDS005-Grade 2 and ASTM A307 BoltingKrish DoodnauthNo ratings yet

- 471 Dif 0Document2 pages471 Dif 0Shyam ParsanaNo ratings yet

- Specification For The Certification of Radiographic InterpretersDocument20 pagesSpecification For The Certification of Radiographic Interpreterscharles46No ratings yet

- Weld Joints TypeDocument6 pagesWeld Joints TypeJerry ZhangNo ratings yet

- Traduccion Parte BDocument7 pagesTraduccion Parte Bkill100% (1)

- Iso 1011Document58 pagesIso 1011CüneytNo ratings yet

- Sampling Procedure For Impact Testing of Structural SteelDocument5 pagesSampling Procedure For Impact Testing of Structural Steelrodrigo nuñezNo ratings yet

- Chemical RraghavanDocument60 pagesChemical RraghavanjoekaledaNo ratings yet

- Aws B2.5 - B2.5M-2021Document34 pagesAws B2.5 - B2.5M-2021Noe NuñezNo ratings yet

- Basic Welding Filler Metal Technology: Lesson Ii Common Electric Arc Welding ProcessesDocument38 pagesBasic Welding Filler Metal Technology: Lesson Ii Common Electric Arc Welding ProcessesPrabhakar KattulaNo ratings yet

- Standard Test Method For Radioscopic Examination of WeldmentsDocument5 pagesStandard Test Method For Radioscopic Examination of WeldmentsWagner Renato AraújoNo ratings yet

- AWS D1.1:2020 - Changes To Structural Welding Code - SteelDocument1 pageAWS D1.1:2020 - Changes To Structural Welding Code - SteelVuong Tran VanNo ratings yet

- Steel Plates For Pressure Vessels, Produced by Thermo-Mechanical Control Process (TMCP)Document10 pagesSteel Plates For Pressure Vessels, Produced by Thermo-Mechanical Control Process (TMCP)Sama UmateNo ratings yet

- American Welding SocietyDocument56 pagesAmerican Welding Societyasvdsf50% (2)

- Esr 2583Document19 pagesEsr 2583VaniaCuevaSotoNo ratings yet

- Simspon at Epoxy Anchor - ICC ER-0263Document19 pagesSimspon at Epoxy Anchor - ICC ER-0263pandavision76No ratings yet

- Screw Strength DocumentDocument3 pagesScrew Strength Documentmsiddiq1No ratings yet

- Icc-Es Esr-1917Document15 pagesIcc-Es Esr-1917kmccrapmailNo ratings yet

- ps1791s WELD SCREWS PROJECTION WELDINGDocument10 pagesps1791s WELD SCREWS PROJECTION WELDINGWinb SunNo ratings yet

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 pagesAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89No ratings yet

- Specification Requirements For Conveyor Pulleys and ShaftsDocument15 pagesSpecification Requirements For Conveyor Pulleys and Shaftsjonodo8967% (3)

- Steel Tapping Screws For Cold-Formed Steel Framing ConnectionsDocument5 pagesSteel Tapping Screws For Cold-Formed Steel Framing ConnectionsAlvaro Alexis Mendoza PradaNo ratings yet

- Item Specific Guidelines For ZTLF System ProvisionalDocument11 pagesItem Specific Guidelines For ZTLF System ProvisionalPreeti goswamiNo ratings yet

- Hand Chain Hoist YL 1008 0807 OptDocument8 pagesHand Chain Hoist YL 1008 0807 OptellisblNo ratings yet

- DrawingDocument1 pageDrawingellisblNo ratings yet

- Con-Serv BrochureDocument19 pagesCon-Serv BrochureellisblNo ratings yet

- CRSI SplicesDocument6 pagesCRSI SplicesellisblNo ratings yet

- CMU WeigthsDocument1 pageCMU WeigthsAnonymous v9cXHdjNo ratings yet

- DSI Catalog SupportingDocument140 pagesDSI Catalog SupportingZola1stNo ratings yet

- CMU WeigthsDocument1 pageCMU WeigthsAnonymous v9cXHdjNo ratings yet

- EDOC 0129 Rev01Document8 pagesEDOC 0129 Rev01ellisblNo ratings yet

- Hand Chain Hoist YL 1008 0807 OptDocument8 pagesHand Chain Hoist YL 1008 0807 OptellisblNo ratings yet

- Yale Hook Suspension Trolleys CBTP ModelDocument3 pagesYale Hook Suspension Trolleys CBTP ModelellisblNo ratings yet

- Beam Selection Chart For Overhead CranesDocument16 pagesBeam Selection Chart For Overhead Cranesellisbl60% (5)

- RISA-2D Educational TutorialDocument18 pagesRISA-2D Educational TutorialAlfredo FranquezNo ratings yet

- EDOC 0129 Rev01Document8 pagesEDOC 0129 Rev01ellisblNo ratings yet

- PMP HandbookDocument57 pagesPMP HandbookThabet QudahNo ratings yet

- HIT-HY 200 SupplementDocument56 pagesHIT-HY 200 SupplementarnoldistunoNo ratings yet

- Equivalent Static Loads For Random VibrationDocument70 pagesEquivalent Static Loads For Random Vibrationbreaker1999100% (1)

- Harbor Drive WebDocument5 pagesHarbor Drive WebellisblNo ratings yet

- Cybernetic Trading Strategies RuggieroDocument163 pagesCybernetic Trading Strategies Ruggierokesk3267% (3)

- A Guide To Successfully Planning and Implementing A Total Rewards SystemDocument54 pagesA Guide To Successfully Planning and Implementing A Total Rewards SystemSanjeewa HemaratneNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- C-SAS-2012 - Concrete Anchor Bolts Catalogue - SimpsonDocument252 pagesC-SAS-2012 - Concrete Anchor Bolts Catalogue - SimpsonRay CoelloNo ratings yet

- Design File8Document3 pagesDesign File8Inês FerrazNo ratings yet

- A Practical Guide To Swing TradingDocument76 pagesA Practical Guide To Swing TradingHemlata Gupta100% (1)

- Retaining Walls - 2Document27 pagesRetaining Walls - 2ellisblNo ratings yet

- 06-GB Moment ConnectionsDocument16 pages06-GB Moment ConnectionscblerNo ratings yet

- Introduction To Plate BucklinDocument12 pagesIntroduction To Plate BucklinAndré FerreiraNo ratings yet

- Reference List For StructuresDocument6 pagesReference List For StructuresellisblNo ratings yet

- Thermal ExampleDocument1 pageThermal ExampleellisblNo ratings yet

- Reference List For StructuresDocument6 pagesReference List For StructuresellisblNo ratings yet

- IEC 61724-1 - Monitoreo de Sistemas FotovoltaicosDocument62 pagesIEC 61724-1 - Monitoreo de Sistemas FotovoltaicosJhonny Richard Verdugo RodríguezNo ratings yet

- CNT-81 & CNT-81R: Timer/Counter/CalibratorsDocument4 pagesCNT-81 & CNT-81R: Timer/Counter/CalibratorsMichael DixonNo ratings yet

- 800 Series SCBA ManualDocument50 pages800 Series SCBA ManualmecambNo ratings yet

- ILI9488 Data Sheet - 100Document343 pagesILI9488 Data Sheet - 100Zoltán HorvátNo ratings yet

- Sensus 243 Gas ReguladorDocument28 pagesSensus 243 Gas Reguladorlggomezupb100% (1)

- Moi Truong Chromogenic Coliform AgarDocument5 pagesMoi Truong Chromogenic Coliform AgarNgoc Tuan HaNo ratings yet

- Manual EasyTech Full Idro UKDocument12 pagesManual EasyTech Full Idro UKshufuckNo ratings yet

- Practical No 06Document5 pagesPractical No 06Vaibhav BhagwatNo ratings yet

- GS1 System of StandardsDocument32 pagesGS1 System of StandardsJavier RomerolNo ratings yet

- DNS 3GPPDocument54 pagesDNS 3GPPupeshalaNo ratings yet

- Triac Tic206mDocument5 pagesTriac Tic206mKristian Aram Perez RuedaNo ratings yet

- EaziVal SE Software User ManualDocument74 pagesEaziVal SE Software User Manualluroguita-1No ratings yet

- Piping EstimatingDocument23 pagesPiping EstimatingMYGMINo ratings yet

- Vehicle InfotronicsDocument156 pagesVehicle Infotronicssarthak ggargNo ratings yet

- 0116 Mass and Dimension Limits Truck VehiclesDocument10 pages0116 Mass and Dimension Limits Truck VehicleskejspmNo ratings yet

- Serial No.: Machine Type:: 4480 KSR - Sealing HeadDocument58 pagesSerial No.: Machine Type:: 4480 KSR - Sealing HeadMarco VargasNo ratings yet

- BS en 22768-2 1993Document16 pagesBS en 22768-2 1993Hüseyin BuğdaycıNo ratings yet

- Lab Record Final AbinDocument172 pagesLab Record Final AbinAbin PaulNo ratings yet

- Iec62271-203 (Ed1.0) en DDocument8 pagesIec62271-203 (Ed1.0) en Demy118850% (2)

- Proprietati Ulei Specific 504 507Document2 pagesProprietati Ulei Specific 504 507livachefNo ratings yet

- Distributed Objects (ML Liu)Document58 pagesDistributed Objects (ML Liu)sachdevapayal93_8815No ratings yet

- Template - Project Office ChecklistDocument6 pagesTemplate - Project Office ChecklistGryswolfNo ratings yet

- Nepal Industrial Development Perspective Plan Analytical ReportDocument350 pagesNepal Industrial Development Perspective Plan Analytical ReportAman GuptaNo ratings yet

- IBM 4690 User Guide v1998Document40 pagesIBM 4690 User Guide v1998Richard ChuaNo ratings yet

- Solution For Improving Bit Error Rates (BER) in Microwave Long Haul LinksDocument5 pagesSolution For Improving Bit Error Rates (BER) in Microwave Long Haul LinksJournal of Telecommunications100% (2)

- Analog Communication SystemDocument16 pagesAnalog Communication SystemSyed Faisal HassanNo ratings yet

- Specification Sheet: Multi-Stage Seawater (MSS) Pump Model Mss-30 For Reverse Osmosis DesalinationDocument1 pageSpecification Sheet: Multi-Stage Seawater (MSS) Pump Model Mss-30 For Reverse Osmosis DesalinationizaNo ratings yet

- Dreambox 500 For Newbies 5.5Document75 pagesDreambox 500 For Newbies 5.5Izza Noor Laila100% (1)

- OnboardDiagnostics AudiDocument183 pagesOnboardDiagnostics AudiMd Jafri AhmedNo ratings yet

- Optoma X316 XGA Desktop DLP ProjectorDocument2 pagesOptoma X316 XGA Desktop DLP ProjectorWebAntics.com Online Shopping StoreNo ratings yet