Professional Documents

Culture Documents

Pressure Vessel Inspection Record: in Accordance With API 510, 10th Edition

Uploaded by

bgonzalez1981Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Vessel Inspection Record: in Accordance With API 510, 10th Edition

Uploaded by

bgonzalez1981Copyright:

Available Formats

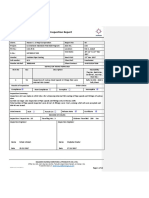

PRESSURE VESSEL INSPECTION RECORD

In accordance with API 510, 10th Edition

DATE INSPECTED CERT EXP DATE

MM / DD / YY

MM / DD / YY

11 /

2 / 15 11 /

2 / 15

OWNER

CERTIFICATE POSTED

Yes

No

NATURE OF BUSINESS

EP PETROCUADOR

2

OWNER no.

E-1305

(Inspector Initials)

BT-EPP-E-1305

(Form no.)

JURISDICTION no.

National Board no.

N.A.

Other

SCOPE OF INSPECTION

Oil & Gas Production

Internal

External

CERTIFICATE INSPECTION

Yes

No

ADDRESS / CITY / PROVINCE / COUNTRY / ZIP

Alpallana E8-86 y Avenida 6 de Diciembre, Quito, Pichincha, Ecuador.

USER'S NAME / LOCATION OF INSTALLATION

EP PETROECUADOR, PLANTA DE LICUEFACCION DE GAS

BAJO ALTO

3

ADDRESS / CITY / PROVINCE / COUNTRY / ZIP

SPECIFIC LOCATION

Planta de Licuefaccin de Gas Bajo Alto. Machala, Ecuador.

Machala, Ecuador. Sector Bajo Alto, Parroquia Tendales, Canton El Guabo, Provincia del Oro

ITEM TYPE

4

YEAR BUILT NAME OF ORIGINAL MANUFACTURER

EXPOSED TUBE BUNDLE

USE

Storage

5

Air Cooler

Process

Tower

2009

Heat Exchanger

Other

CNLP 3X4X3500S. GAS EVAPORATOR PART.

PRESSURE ALLOWED

Current Inspection

6

Cryonorm

SIZE

Diameter

N.A.

Lenght S/S:

N.A.

Int.

in.

PRESSURE GAGE TESTED

Yes

No

Ext.

in.

SAFETY RELIEF VALVES

Setting Pressure

Previous Inspection

580

psi

@ 122

580

psi

@ 122

---

psi

@---

---

psi

@---

---

Explain:

psi

Total Capacity

IS CONDITION OF THE ITEM SUCH THAT A CERTIFICATE MAY BE ISSUED?

Yes

No

(If NO, explain fully under conditions)

PRESSURE CHANGED

-----

PRESSURE TEST

Yes

Hydrostatic

Pneumatic

250

psi

Date

No

Other

11/2/2015

CONDITIONS:

With respect to the internal surface, describe and state location of any scale, oil or other deposits. Give location and extent of any

corrosion and state whether active or inactive. State location and extent of any erosion, grooving, bulging, warping, cracking or

similar condition. Report on any defective rivets, bowed, loose or broken stays. State condition of all tubes, tube ends, coils,

nipples, etc. Describe any adverse conditions with respect to pressure gage, water column, gage glass, gage cocks, safety

valves, etc. Report condition of setting, linings, baffles, supports, etc. Describe any major changes or repairs made since last

8

No indication for repair was detected.

REQUIREMENTS: LIST CODE VIOLATIONS OR ANY NCR

None.

NAME AND TITLE OF PERSON TO WHOM REQUIREMENTS WERE EXPLAINED: Fredy Ramirez

Jefe de Control de Calidad B&T

I HEREBY CERTIFY THIS IS A TRUE REPORT OF MY INSPECTION

IDENT NO.

EMPLOYED BY

IDENT NO.

10

BOLIVAR GONZLEZ

NAME AND SIGNATURE OF INSPECTOR

API 510 Cert.

59308

Date

BEITE B&T CIA. LTDA.

N.A.

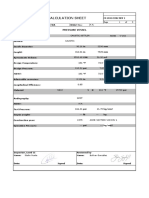

PRESSURE VESSEL INSPECTION RECORD

In accordance with API 510, 10th Edition

(EXTENSION SHEET)

DATE INSPECTED OWNER

MM / DD / YY

11 /

2 / 15

OWNER

no.

E-1305

JURISDICTION

no.

N.A.

(Inspector Initials)

BT-EPP-E-1305

(Form no.)

USER'S NAME / LOCATION OF INSTALLATION

EP PETROCUADOR

EP PETROECUADOR, PLANTA DE LICUEFACCION DE GAS BAJO ALTO

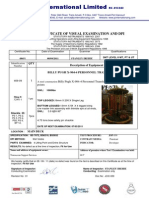

API, ASME or Inspection Certificate

Item /

YEAR

STANDARD Id.

valid

Equipment

Int Ext

BUILT

/ Object

No.

years*

API 510 10th

Edition

CNLP

3X4X3500S.

GAS

EVAPORATO

R PART.

2009

MAWP TEMP.

MANUFACTURER

Cryonorm

psi

580

PRV

Pressure

Setting

@ 122

N.A.

* In this column show the number of years for which the inspector authorizes the issuance of the certificate.

You might also like

- API 510 Corr. Rate & Rem Life Cal.Document1 pageAPI 510 Corr. Rate & Rem Life Cal.Ejaz Ahmed RanaNo ratings yet

- DOE Std.1090 07 Forklift TrucksDocument35 pagesDOE Std.1090 07 Forklift TrucksjoseritoNo ratings yet

- RM 1ehsapprovedcosforliftingequippressvessels250914Document9 pagesRM 1ehsapprovedcosforliftingequippressvessels250914wholenumberNo ratings yet

- Table 5: Requirements For Drill Pipe Inspection ReportingDocument1 pageTable 5: Requirements For Drill Pipe Inspection ReportingJosue FishNo ratings yet

- Summary TER of 13 Unit 20FT ISO Dry ContainerDocument219 pagesSummary TER of 13 Unit 20FT ISO Dry ContainerGhilman0529No ratings yet

- Mobile Crane Test Procedure.Document4 pagesMobile Crane Test Procedure.Deepak GehlotNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- EX - 12.7MM - PLATE 01 PAUT Report TrainingDocument4 pagesEX - 12.7MM - PLATE 01 PAUT Report Trainingagung akbarNo ratings yet

- Procedure For UtDocument12 pagesProcedure For UtMohammad SyeduzzamanNo ratings yet

- BT Lifter HPT Brochure 0614Document12 pagesBT Lifter HPT Brochure 0614Ram ReddyNo ratings yet

- CA-40-02 Rev.03E UT Procedure Fer AWS D1.1-2015Document24 pagesCA-40-02 Rev.03E UT Procedure Fer AWS D1.1-2015hoangdiep phanNo ratings yet

- Piping Thickness Measurement ReportDocument1 pagePiping Thickness Measurement ReportTevriyudha MardikaNo ratings yet

- Joining Instruction - Rigger Level-3 TrainingDocument2 pagesJoining Instruction - Rigger Level-3 TrainingahmadNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Rigging Platform 25-05-2022-1Document1 pageRigging Platform 25-05-2022-1dele jimohNo ratings yet

- Ultrasonic Examination Report: Dac DetailsDocument2 pagesUltrasonic Examination Report: Dac DetailsBalkishan DyavanapellyNo ratings yet

- Info Sheet Iris Inspection of TubesDocument2 pagesInfo Sheet Iris Inspection of TubesCepi Sindang KamulanNo ratings yet

- SRINIVASAN CHANDRAN's ResumeDocument4 pagesSRINIVASAN CHANDRAN's ResumePaul PhiliphsNo ratings yet

- Inspection Capabilities - 2016Document4 pagesInspection Capabilities - 2016muhamadrafie1975No ratings yet

- NullDocument9 pagesNullMichael OkwuwaNo ratings yet

- API 653 General InformationDocument1 pageAPI 653 General InformationBashMohandesssNo ratings yet

- Mobile Crane Checklist EssentialsDocument6 pagesMobile Crane Checklist EssentialsBanesco TemplarisNo ratings yet

- API-653 ASTI In-service Exam TrainingDocument2 pagesAPI-653 ASTI In-service Exam TrainingalgoreNo ratings yet

- Sicc Ac CP 01 Snttc1aDocument15 pagesSicc Ac CP 01 Snttc1aEnrique Campos CannavaroNo ratings yet

- Techno NDT Services: Ultrasonic Flaw Detection ReportDocument1 pageTechno NDT Services: Ultrasonic Flaw Detection Reportram dreamsNo ratings yet

- Coflexip Hose (Tr1-031851clm301)Document1 pageCoflexip Hose (Tr1-031851clm301)RonniNo ratings yet

- Classification of Drilling EquipmentDocument32 pagesClassification of Drilling EquipmentJose BarreroNo ratings yet

- Obite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureDocument22 pagesObite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureeetuaNo ratings yet

- Crane Inspection Check List HSE. STDDocument1 pageCrane Inspection Check List HSE. STDEdy ElfianNo ratings yet

- Wheel Loader Forklift Thorough Exam ReportDocument2 pagesWheel Loader Forklift Thorough Exam ReportRanjithNo ratings yet

- TCR Arabia Company Magnetic Particle Testing ReportDocument1 pageTCR Arabia Company Magnetic Particle Testing ReportRonel John Rodriguez CustodioNo ratings yet

- MPI Reports for ROMFOR Oilfield EquipmentDocument21 pagesMPI Reports for ROMFOR Oilfield EquipmentMehmet SoysalNo ratings yet

- AITIS Company ProfileDocument7 pagesAITIS Company ProfileassurendranNo ratings yet

- Derrick Sample Report PDFDocument11 pagesDerrick Sample Report PDFRajesh ThorweNo ratings yet

- APL-C7!22!109 Ultrasonic Flow Detector Quality InspectorsDocument2 pagesAPL-C7!22!109 Ultrasonic Flow Detector Quality InspectorsSTEPHEN MIGWINo ratings yet

- 2018 Sea Cswip Course Exam FeeDocument4 pages2018 Sea Cswip Course Exam FeeAmar MohammedNo ratings yet

- Audit NDT Basics PDFDocument41 pagesAudit NDT Basics PDFJindarat KasemsooksakulNo ratings yet

- 3576 Erbil MergedDocument4 pages3576 Erbil MergedAli AlahmaNo ratings yet

- Si EvertDocument4 pagesSi EvertLaxmikant TiwariNo ratings yet

- Reporting: Report Manager Generator (P11)Document31 pagesReporting: Report Manager Generator (P11)PrakashNo ratings yet

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNo ratings yet

- Mobile Crane Certification and Inspection ReportDocument2 pagesMobile Crane Certification and Inspection ReportRafael LecuNo ratings yet

- Daily Lrut Report: Lrut Instrument Lrut Probe TechniqueDocument1 pageDaily Lrut Report: Lrut Instrument Lrut Probe TechniqueSang Nguyen QuangNo ratings yet

- E570-97 Flux Leakage Ferro TubularDocument6 pagesE570-97 Flux Leakage Ferro TubularAsif HameedNo ratings yet

- Asa-146 NSH Apco Ir 040Document10 pagesAsa-146 NSH Apco Ir 040Fahad AhmadNo ratings yet

- (Vol I), 2012 Rules For Stowage and Lashing of Containers, 2012Document50 pages(Vol I), 2012 Rules For Stowage and Lashing of Containers, 2012Ardiansyah GassingNo ratings yet

- 01 SY CRT 0001 0A-General Requirements For Welding and NDT PDFDocument42 pages01 SY CRT 0001 0A-General Requirements For Welding and NDT PDFSanjeev Sahota100% (1)

- API 510 2014 Mumbai PDFDocument2 pagesAPI 510 2014 Mumbai PDFBurapha Malutphanth33% (3)

- Roundness Shell #1 - 1-Tank -012 BEFORE WELDDocument2 pagesRoundness Shell #1 - 1-Tank -012 BEFORE WELDyuwantoniNo ratings yet

- CN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1 PDFDocument18 pagesCN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1 PDFTĩnh Hồ TrungNo ratings yet

- Cswip 3 2 Presentations PDFDocument42 pagesCswip 3 2 Presentations PDFJlkKumarNo ratings yet

- Near Bit Stabilizer PDS 6716 ...Document1 pageNear Bit Stabilizer PDS 6716 ...khalilNo ratings yet

- INSPECTION RESULTS AND RECOMMENDATIONSDocument5 pagesINSPECTION RESULTS AND RECOMMENDATIONSBayu Aringga putra100% (1)

- Oil India Tender for Supply of Drill PipesDocument13 pagesOil India Tender for Supply of Drill Pipesifebrian100% (1)

- Hertz Inspection Service PVT LTD Irc1Document18 pagesHertz Inspection Service PVT LTD Irc1Rahul N PatelNo ratings yet

- Procedure for Working at HeightsDocument41 pagesProcedure for Working at HeightsShahla100% (1)

- Certificate of Visual Examination and Dpi: Description of Equipment Billy Pugh X-904-4 Personnel Transfer DeviceDocument3 pagesCertificate of Visual Examination and Dpi: Description of Equipment Billy Pugh X-904-4 Personnel Transfer DeviceMichael OkwuwaNo ratings yet

- Chapter 9: Tank Settlement: Settlement in New ConstructionDocument10 pagesChapter 9: Tank Settlement: Settlement in New ConstructionppatrickkkNo ratings yet

- API 510 Bajo Alto E-1410aDocument2 pagesAPI 510 Bajo Alto E-1410abgonzalez1981No ratings yet

- Cangzhou Spiral Pipe InspectionDocument1 pageCangzhou Spiral Pipe Inspectionbgonzalez1981No ratings yet

- Informe Inspección V202 Rev 1Document11 pagesInforme Inspección V202 Rev 1bgonzalez1981No ratings yet

- Crane Hand Signals Guide 1Document1 pageCrane Hand Signals Guide 1bgonzalez1981No ratings yet

- Cangzhou Spiral Pipe InspectionDocument1 pageCangzhou Spiral Pipe Inspectionbgonzalez1981No ratings yet

- Sketch V 5600Document1 pageSketch V 5600bgonzalez1981No ratings yet

- Cangzhou Spiral Pipe InspectionDocument1 pageCangzhou Spiral Pipe Inspectionbgonzalez1981No ratings yet

- Cangzhou Spiral Pipe InspectionDocument1 pageCangzhou Spiral Pipe Inspectionbgonzalez1981No ratings yet

- Cangzhou Spiral Pipe InspectionDocument1 pageCangzhou Spiral Pipe Inspectionbgonzalez1981No ratings yet

- Cangzhou Spiral Pipe InspectionDocument1 pageCangzhou Spiral Pipe Inspectionbgonzalez1981No ratings yet

- Cangzhou Spiral Pipe InspectionDocument1 pageCangzhou Spiral Pipe Inspectionbgonzalez1981No ratings yet

- Cangzhou Spiral Pipe InspectionDocument1 pageCangzhou Spiral Pipe Inspectionbgonzalez1981No ratings yet

- Informe Inspección v-5500 Rev1Document8 pagesInforme Inspección v-5500 Rev1bgonzalez1981No ratings yet

- Cangzhou Spiral Pipe InspectionDocument1 pageCangzhou Spiral Pipe Inspectionbgonzalez1981No ratings yet

- Cangzhou Spiral Pipe InspectionDocument1 pageCangzhou Spiral Pipe Inspectionbgonzalez1981No ratings yet

- Cangzhou Spiral Pipe InspectionDocument1 pageCangzhou Spiral Pipe Inspectionbgonzalez1981No ratings yet

- WPS-PQR Gmaw LtiDocument2 pagesWPS-PQR Gmaw Ltibgonzalez198150% (2)

- Informe Inspección H - 1110 Rev1Document6 pagesInforme Inspección H - 1110 Rev1bgonzalez1981No ratings yet

- Informe Inspección v-5200 Rev1Document8 pagesInforme Inspección v-5200 Rev1bgonzalez1981No ratings yet

- Informe Inspección H - 1110 Rev1Document6 pagesInforme Inspección H - 1110 Rev1bgonzalez1981No ratings yet

- Sketch H-1172-73-74Document1 pageSketch H-1172-73-74bgonzalez1981No ratings yet

- Pressure Vessel Inspection Record SummaryDocument2 pagesPressure Vessel Inspection Record Summarybgonzalez1981No ratings yet

- Ultrasonic Inspection Report for Vessel V-8000Document8 pagesUltrasonic Inspection Report for Vessel V-8000bgonzalez1981No ratings yet

- Informe Inspección A-1125 Rev1Document8 pagesInforme Inspección A-1125 Rev1bgonzalez1981No ratings yet

- Pressure Vessel Inspection Record SummaryDocument2 pagesPressure Vessel Inspection Record Summarybgonzalez1981No ratings yet

- Pressure Vessel Inspection Record: in Accordance With API 510, 10th EditionDocument2 pagesPressure Vessel Inspection Record: in Accordance With API 510, 10th Editionbgonzalez1981No ratings yet

- Pressure Vessel Inspection Record SummaryDocument2 pagesPressure Vessel Inspection Record Summarybgonzalez1981No ratings yet

- API 510 Bajo Alto E-1410aDocument2 pagesAPI 510 Bajo Alto E-1410abgonzalez1981No ratings yet

- Sketch A 1125Document1 pageSketch A 1125bgonzalez1981No ratings yet

- Scorpion Tank Shell InspectionDocument4 pagesScorpion Tank Shell Inspectionநந்த குமார் சம்பத் நாகராஜன்No ratings yet

- IonosondeDocument3 pagesIonosondeFaizan GoharNo ratings yet

- YSUUSYs NiCd Battery RepairDocument6 pagesYSUUSYs NiCd Battery Repairrwesseldyk50% (2)

- Preparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimDocument9 pagesPreparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimslightlyguiltyNo ratings yet

- FED - Summer Term 2021Document18 pagesFED - Summer Term 2021nani chowdaryNo ratings yet

- T Cells & Autoimmunity, s3Document21 pagesT Cells & Autoimmunity, s3LiaAriestaNo ratings yet

- IntuitionDocument10 pagesIntuitionmailsonNo ratings yet

- SAP SD Course Content PDFDocument4 pagesSAP SD Course Content PDFshuku03No ratings yet

- Book3 79 111000 0000100120 DAH MPL RPT 000005 - ADocument101 pagesBook3 79 111000 0000100120 DAH MPL RPT 000005 - ANassif Abi AbdallahNo ratings yet

- OM - Rieter - UNIMix A76Document321 pagesOM - Rieter - UNIMix A76Phineas FerbNo ratings yet

- Product Manual 82434 (Revision C) : Generator Loading ControlDocument26 pagesProduct Manual 82434 (Revision C) : Generator Loading ControlAUGUSTA WIBI ARDIKTANo ratings yet

- Rock Type Identification Flow Chart: Sedimentary SedimentaryDocument8 pagesRock Type Identification Flow Chart: Sedimentary Sedimentarymeletiou stamatiosNo ratings yet

- Echt Er Nacht 2014Document8 pagesEcht Er Nacht 2014JamesNo ratings yet

- GSMA Moile Money Philippines Case Study V X21 21Document23 pagesGSMA Moile Money Philippines Case Study V X21 21davidcloud99No ratings yet

- Intelligent Transportation System SolutionsDocument38 pagesIntelligent Transportation System SolutionsWisnu AjiNo ratings yet

- BBRC4103 - Research MethodologyDocument14 pagesBBRC4103 - Research MethodologySimon RajNo ratings yet

- Soft StarterDocument6 pagesSoft StarterEric Maglinte TolosaNo ratings yet

- Trishasti Shalaka Purusa Caritra 4 PDFDocument448 pagesTrishasti Shalaka Purusa Caritra 4 PDFPratik ChhedaNo ratings yet

- 6470b0e5f337ed00180c05a4 - ## - Atomic Structure - DPP-01 (Of Lec-03) - Arjuna NEET 2024Document3 pages6470b0e5f337ed00180c05a4 - ## - Atomic Structure - DPP-01 (Of Lec-03) - Arjuna NEET 2024Lalit SinghNo ratings yet

- Ownership and Governance of State Owned Enterprises A Compendium of National Practices 2021Document104 pagesOwnership and Governance of State Owned Enterprises A Compendium of National Practices 2021Ary Surya PurnamaNo ratings yet

- Project Report On Discontinuous Puf Panels Using Cyclopentane As A Blowing AgentDocument6 pagesProject Report On Discontinuous Puf Panels Using Cyclopentane As A Blowing AgentEIRI Board of Consultants and PublishersNo ratings yet

- Neural Network For PLC PDFDocument7 pagesNeural Network For PLC PDFMarcelo Moya CajasNo ratings yet

- Judges - God's War Against HumanismDocument347 pagesJudges - God's War Against HumanismgypsylanternNo ratings yet

- Frequently Asked Questions: Wiring RulesDocument21 pagesFrequently Asked Questions: Wiring RulesRashdan HarunNo ratings yet

- 2.7.3 Lab Use Steganography To Hide Data Answer KeyDocument3 pages2.7.3 Lab Use Steganography To Hide Data Answer KeyVivek GaonkarNo ratings yet

- Organizing and Delivering A Memorized SpeechDocument9 pagesOrganizing and Delivering A Memorized SpeechJanice L. Langit100% (4)

- Health Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4Document7 pagesHealth Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4John Wilfred PegranNo ratings yet

- Clustering Social Network GraphsDocument12 pagesClustering Social Network GraphsRáhùl SréédhãrNo ratings yet

- Reading in Philippine History (Chapter 3)Document14 pagesReading in Philippine History (Chapter 3)AKIO HIROKINo ratings yet

- Simulated Robot Football Team Uses Neural Networks to LearnDocument8 pagesSimulated Robot Football Team Uses Neural Networks to LearnKishore MuthukulathuNo ratings yet

- Self Healing Challenge - March 2023 Workshop ThreeDocument16 pagesSelf Healing Challenge - March 2023 Workshop ThreeDeena DSNo ratings yet