Professional Documents

Culture Documents

Principles 3 Visual Management

Uploaded by

Anonymous CoGUaJCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Principles 3 Visual Management

Uploaded by

Anonymous CoGUaJCopyright:

Available Formats

P3 VISUAL MANAGEMENT

INTRODUCTION

1. Provide real-time information on work

place status by a combination of simple,

effective visual information aids that allow

employees to understand their influence

on the organization overall performance

hence allowing the employees to improve

their performance.

P3 VISUAL MANAGEMENT

OBJECTIVE

1. Expose waste so that it can be eliminated and prevented from recurring

making the workplace more efficient.

2. Make abnormalities in the 4Ms (Man, Machine, Material, Method) process

inputs visible to everyone for prompt corrective action.

3. Enable trends in QCDMS & abnormalities to be visible for timely preventive

action to be taken.

4. Motivates everybody to improve by clarifying key performance targets.

5. Makes operation standards quicker and easier to understand by all

employees so they can follow them.

6. Builds participation through shared information.

7. Creates flow in the value stream and allows pull to the voice of the

customer.

P3 VISUAL MANAGEMENT

9 VISUAL MANAGEMENT AREAS

Quality

Delivery

Cost

S.H.E

MAN

VISUAL

MANAGEMENT

KPIs

MACHINE

MATERIAL

METHODS

MAKE ABNORMALITIES &

STATUS VISIBLE

P3 VISUAL MANAGEMENT

PRINCIPLES OF VISUAL MANAGEMENT

SAFETY

SAFETY

VISUAL

FACTORY

PRODUCTIVITY

PRODUCTIVITY

QUALITY

QUALITY

Hazards Visual Recognition

Safe Areas Visual Display

5S Eliminates Workplace Clutter

Awareness of Safety Measures

Associates Works Progress

Production Rate

Progress Towards Goals

Production Status

Efficient Operators

Operator Prompts for Error Proofing

Clearly Marked Tools Reduce Errors

Visible Calls to Support Personnel for Parts

Shortage / Problems

Reduce Rework

Immediate Indication of Out of Tolerance

Variables

P3 VISUAL MANAGEMENT

VISUAL MANAGEMENT INITIATIVES

1. Visual Control Boards.

2. Andon

3. Footprints

4. Signage

5. Obeya

4. Hansei

P3 VISUAL MANAGEMENT

VISUAL BOARD

What is Visual Control Board

1. A color-coded , physical visual control system used for monitoring of shop-floor activities

and KPIs.

Use of Visual Control Board

1.

2.

3.

4.

Visual boards are used as activators and data communication centre.

The visual board area is used for shop-floor meetings.

A centre of periodical progress reviews and updates.

Used to drive the business processes from the boardroom to the shop floor.

Benefits of Visual Control Board

1. It quickly gives visibility to the progress of each tasks for further action.

2. Identifies the resources and activities being undertaken.

P2 VISUAL MANAGEMENT

VISUAL BOARD

Red zone indicates

the supplier is on the

verge of not satisfying

their customer. Very

low level of goods

maintained.

Yellow zone indicates

customer

requirements

are

being met. Low level

of finished goods

maintained.

Green zone indicates

the customers needs

are being fulfilled.

Supplier is building

more

than

the

customer is requiring

and it may be time to

stop production until

demand is more in

line with supply.

Other pertinent information

(e.g.. Quality performance)

would be contained in the

information section.

The cards hanging on

the hooks in the

colored zones reflect

the

part

number

identified

in

the

section,

a

given

quantity of material in

one container. When a

card is on the hook it

indicates an empty

container.

This

This is

is an

an example

example of

of aa pull

pull board

board that

that could

could be

be used

used with

with internal

internal operations,

operations, as

as shown,

shown, or

or even

even

with

with external

external customers.

customers.

P3 VISUAL MANAGEMENT

ANDON

What is Andon

1. Andon (Japanese for lantern) is a tool for visual

management and refers to a system of signals

used to indicate the operational status (at a

glance) of a machine or work center.

2. It can be used manually or automatically.

3. It also one of the principle elements of the Jidoka

quality-control method.

P3 VISUAL MANAGEMENT

ANDON

Use of Andon

1. Alerts management and other workers to quality or

process problem.

2. Gives the worker the ability to stop production when a

defect is found, and immediately call for assistance.

3. Indicates where the alert was generated, and may also

provide a description of the trouble whether shortage of

material or maintenance call or supervisor call.

.

P3 VISUAL MANAGEMENT

ANDON

Defect created or found

Common reasons

for manual

activation of the

Andon

Part shortage

Equipment/Tool malfunction

A safety problem exists

P3 VISUAL MANAGEMENT

ANDON

Benefits of Andon

1. Reduces operation & maintenance costs by identifying problems before they become

major issues.

2. Increases equipment availability by making downtime issues more visible, thus

prompting immediate rectification to the issues.

3. Supports Jidoka implementation by making the problem status visual.

Mechanism of Andon

Abnormality

Andon Indicator

Response from

support team

P3 VISUAL MANAGEMENT

Types of Andon

ANDON

Visual Andon

Graphics

Text

Coded signal lights

Green - no problems

Ideal for STOP /

WAIT / GO signaling

in busy factories

Boost health and

safety.

Display production data in

real time.

Calculate shift efficiencies

and production targets.

Yellow - situation requires

attention, production flow at risk

Red - PRODUCTION STOPPAGE:

IMMEDIATE ASSISTANCE

REQUIRED

Audio Andon

Coded

Tones

Coded

Tunes

Buzzers /

Alarms

Prerecorded

Messages

P3 VISUAL MANAGEMENT

FOOTPRINT

What is Footprint

1. Markings on the floor or work area outlining specifically where items should be placed.

Benefit

1. To ease employees during storage or retrieval.

2. It avoids employees wasting time looking for things or pondering their next move.

3. The workplace becomes clean and better organized.

4. Operation on the shop floor and office become easier and safer

.

5. Visible location of parts or equipment for easy traceability and save time of searching

P3 VISUAL MANAGEMENT

FOOTPRINT

CREATING FOOTPRINT

1. A footprint is an outline of the items required at work areas indicating where the items

should be placed.

2. Rules about footprints or floor borders

a) Mark from the floor up to workbenches etc

b) Start with plastic tape to test out, then move to paint

c) Use colours to code footprints as shown in the following example, as a guideline :

Light Blue - Raw parts/material

Black - Finished good/parts

Red - Non-conforming/KIV parts/material

White - Other than parts/material

Yellow Border of work area

P3 VISUAL MANAGEMENT

FOOTPRINT

Yellow for work area border

Black for finished part

Light blue for raw material

LINE

SOZAI

5S CORNER

KANSEI

TOOL CABINET

NG

QC CORNER

Red for non-conforming part

White for equipment

VISUAL BOARD

P3 VISUAL MANAGEMENT

SIGNAGE

Signage is any kind of graphics created to display information.

Two types of signage

1. Displays

A visual display relates information and data to employees in the area. For example, charts showing

the monthly revenues of the company or a graphic depicting a certain type of quality issue that group

members should be aware of.

2. Controls

A visual control is intended to actually control or guide the action of the group members. Examples of

controls are: stop signs at intersections, handicap parking signs, or no smoking signs.

P3 VISUAL MANAGEMENT

SIGNAGE

Signage must be used appropriately for

providing pertinent information on:

hazardous and risky areas & installation

materials

safety measures

emergency exits, etc.

Signage shall be:

in accordance with international

standards, code of practice

maintained

up-to-date

be well known to, and easily understood

by employees, visitors and the general

public as appropriate

visible from at least 1.5m and easily seen

by forklift driver

AMS 9 PRINCIPLES

WASTE

WASTEELIMINATION

ELIMINATION

FLEXIBILITY

FLEXIBILITY

PRODUCTION

PRODUCTIONLEVELLING

LEVELLING

STANDARDISATION

STANDARDISATION

VISUALMANAGEMENT

MANAGEMENT

3 VISUAL

TOTALEMPLOYEE

EMPLOYEEINVOLVEMENT

INVOLVEMENT&&DEVELOPMENT

DEVELOPMENT

2 TOTAL

LONGTERM

TERMBUSINESS

BUSINESSTHINKING

THINKING

LONG

SH

SH

ST

QUALITY

QUALITYRIGHT

RIGHT11STTIME

TIMEEVERY

EVERY

TIME

TIME

PULL

PULLSYSTEM

SYSTEM

BESTQUALITY

QUALITY

LOWESTCOST

COST

BEST

LOWEST

BESTENVIRONMENT

ENVIRONMENT&&SAFETY

SAFETY

--BEST

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Michigan Property Assessment FormDocument2 pagesMichigan Property Assessment FormIsabelle PasciollaNo ratings yet

- How To Design Your Own InnovationDocument6 pagesHow To Design Your Own InnovationAshit AgarwalNo ratings yet

- Sample Complaint Against California Insurance Company For Bad FaithDocument3 pagesSample Complaint Against California Insurance Company For Bad FaithStan Burman80% (5)

- NASA Probabilistic Risk Assessment Procedures GuideDocument431 pagesNASA Probabilistic Risk Assessment Procedures GuideAnonymous CoGUaJNo ratings yet

- Supplier Quality Manual: SQA 2104 - Rev. 10.1Document35 pagesSupplier Quality Manual: SQA 2104 - Rev. 10.1Anonymous CoGUaJ100% (1)

- Financial Reporting and Management Reporting Systems ReviewerDocument7 pagesFinancial Reporting and Management Reporting Systems ReviewerSohfia Jesse Vergara100% (1)

- NASA Risk MNGT HBKDocument256 pagesNASA Risk MNGT HBKAnonymous CoGUaJNo ratings yet

- VDA 4958-3 Langzeitarchivierung 1.0Document107 pagesVDA 4958-3 Langzeitarchivierung 1.0Anonymous CoGUaJNo ratings yet

- Jakki Mohr, Sanjit Sengupta, Stanley Slater Marketing of High-Technology Products and InnovationsDocument569 pagesJakki Mohr, Sanjit Sengupta, Stanley Slater Marketing of High-Technology Products and InnovationsArshed Rosales100% (3)

- When A MSA Should Be Updated - Shawn Rogers - Pulse - LinkedInDocument4 pagesWhen A MSA Should Be Updated - Shawn Rogers - Pulse - LinkedInAnonymous CoGUaJNo ratings yet

- The New TPM - Total Predictive Maintenance - Shawn Rogers - Pulse - LinkedInDocument3 pagesThe New TPM - Total Predictive Maintenance - Shawn Rogers - Pulse - LinkedInAnonymous CoGUaJNo ratings yet

- Delta-Analysis. IATF 16949 - 2016 VsDocument5 pagesDelta-Analysis. IATF 16949 - 2016 VsAnonymous CoGUaJNo ratings yet

- Fault Tree Analysis (FTA)Document194 pagesFault Tree Analysis (FTA)LaciNo ratings yet

- VDA 4956 1 Product Data Management 1.0Document26 pagesVDA 4956 1 Product Data Management 1.0Anonymous CoGUaJNo ratings yet

- Fault Tree Analysis (FTA)Document194 pagesFault Tree Analysis (FTA)LaciNo ratings yet

- Irca 2245 - Qms A - LaDocument14 pagesIrca 2245 - Qms A - LaNagamuthu PandianNo ratings yet

- FX 850p ManualDocument419 pagesFX 850p ManualTopografia Artur FidalgoNo ratings yet

- Method ValidationDocument8 pagesMethod ValidationAnonymous CoGUaJNo ratings yet

- AISE Guidelines For The Safe Handling of Enzymes in Detergent ManufacturingDocument130 pagesAISE Guidelines For The Safe Handling of Enzymes in Detergent ManufacturingAnonymous CoGUaJNo ratings yet

- 10 - Chapter 3 Security in M CommerceDocument39 pages10 - Chapter 3 Security in M CommercehariharankalyanNo ratings yet

- Chari Boru Bariso's Econ GuidsesDocument19 pagesChari Boru Bariso's Econ GuidsesSabboona Gujii GirjaaNo ratings yet

- Alfred Marshall 3Document7 pagesAlfred Marshall 3agapitodimagiba021No ratings yet

- MSS SP 6-2017Document10 pagesMSS SP 6-2017elciolbezerraNo ratings yet

- Starbucks Confirms Rapid Growth StrategyDocument2 pagesStarbucks Confirms Rapid Growth StrategyAlexandros PetronikolosNo ratings yet

- Commercial Lease Jan 2022Document12 pagesCommercial Lease Jan 2022Aniella94No ratings yet

- PhilipsVsMatsushit Case AnalysisDocument7 pagesPhilipsVsMatsushit Case AnalysisGaurav RanjanNo ratings yet

- Curriculum Vitae: Dr. Bidhu Kanti DasDocument22 pagesCurriculum Vitae: Dr. Bidhu Kanti DasTanuj DeyNo ratings yet

- Class Test-1: Manpreet Singh 2K19/DMBA/48 Ans 1)Document2 pagesClass Test-1: Manpreet Singh 2K19/DMBA/48 Ans 1)Roronoa ZoldyckNo ratings yet

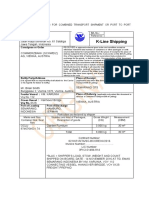

- Bill of Lading AustriaDocument2 pagesBill of Lading AustriaTitik KurniyatiNo ratings yet

- SS - 9 - Forfeiture of SharesDocument3 pagesSS - 9 - Forfeiture of SharesMihir MehtaNo ratings yet

- QuickBooks Chapter 1 QuestionsDocument1 pageQuickBooks Chapter 1 QuestionsibaNo ratings yet

- Navistar Capacity Verification: Supplier / Part InformationDocument4 pagesNavistar Capacity Verification: Supplier / Part InformationAnurag TiwariNo ratings yet

- 1.1. PNC PRE FO 66 Proposed Student Research Topics 2.1Document9 pages1.1. PNC PRE FO 66 Proposed Student Research Topics 2.1ALWINA CATINDOYNo ratings yet

- Farming Question 1Document2 pagesFarming Question 1Tawanda Tatenda HerbertNo ratings yet

- Competitive Intelligence On The InternetDocument4 pagesCompetitive Intelligence On The Internetprofthadaskew4433No ratings yet

- Sr. Acc Suroor ResumeDocument2 pagesSr. Acc Suroor ResumeVaibhav VermaNo ratings yet

- Hotel Resevation System - Database ProjectDocument9 pagesHotel Resevation System - Database ProjectMero Hmd100% (1)

- Parate EksekusiDocument15 pagesParate EksekusiWanda WandaNo ratings yet

- Class-Xii Accountancy (2020-2021) General InstructionsDocument10 pagesClass-Xii Accountancy (2020-2021) General InstructionsSaad AhmadNo ratings yet

- ACCA Membership To ICPAPDocument4 pagesACCA Membership To ICPAPMian Muhammad Talha MehmoodNo ratings yet

- 1.2 Introduction To Cash ManagementDocument8 pages1.2 Introduction To Cash Managementasmamatha23No ratings yet

- Customer Persona and Value PropositionDocument24 pagesCustomer Persona and Value PropositionVishnu KompellaNo ratings yet

- ROFIT RATES - SAVINGS ACCOUNT Historical Rates Remained Applicable On Savings Account From1st January, 2000 To OnwardsDocument3 pagesROFIT RATES - SAVINGS ACCOUNT Historical Rates Remained Applicable On Savings Account From1st January, 2000 To OnwardsShahid Majeed ChaudhryNo ratings yet

- How To Write A Salt Room Business PlanDocument15 pagesHow To Write A Salt Room Business Planwaleed saeedNo ratings yet