Professional Documents

Culture Documents

X25 XXX 01 SP E-1

Uploaded by

Richard ZerpaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

X25 XXX 01 SP E-1

Uploaded by

Richard ZerpaCopyright:

Available Formats

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

M-S Motor X25

Description

Features

The Miniature Stepper Motor M-S X25 series was

developed primarily as an indicator drive for

dashboard instrumentation and other indicator

equipment. The inherent properties of torque, current

consumption, robust construction, etc. extend its use

also to a number of other applications. The motor can

operate directly from a numerical, i.e. digital, driving

signal to move and position a pointer to visualise any

parameter required. A fine analogue representation of

its value and its changes is made without the need for

a digital to analogue conversion.

The miniature stepper motor consists of a motor and

gear train with a reduction ratio of 1/180. It is

produced with the advanced wide range technologies

of the SWATCH GROUP. These technologies assure

a high quality product as proven by the success of the

famous SWATCH watch. The motor is robust and

simple in construction without concessions to

versatility or longevity.

Each half revolution of the rotor, defined as a full step,

is converted to a one degree rotation of the pointer

shaft. The full step itself again is divided into three

partial steps, i.e. a 360 degree rotation of the pointer

shaft consists of 1080 partial steps. Full steps can be

carried out up to 600 Hz resulting in a 600 /s angular

speed. Such characteristics allow a large dynamic

range for indicator applications.

- 1/3 resolution per step

- low current consumption

- small dimensions: 30 x 9 mm

- can be directly driven by a -controller

- large temperature range: -40C 105C

- high speed: >600 /s

- qualified for automotive applications

Motor versions

This specification applies only to the following motor

versions.

Without stop : X25.156, X25.158, X25.278, X25.559,

X25.579, X25.679

With stop :

X25.166, X25.168, X25.288, X25.569,

X25.589, X25.689

For more details on the differences between those

motors, please refer to the buyer's guide.

Typical Application

SystemMICROPROCESSOR

Microprocessor

SYSTEM

M-S QUAD

DUAL DRIVER

M-S

DRIVER

M-SStd

Motor

M-SStd

Motor

RPM

FUEL

M-SStd

Motor

OIL

M-S CLOCK DRIVER

M-SStd

Motor

Std

ACC

M-S

SPEED

CLOCK

LCD

LCD Driver

DRIVER

s w it e c M-S Products

Analogue/Digital Instrument Cluster Concept

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

Fig. 1

1 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Pin Connection

Schematic

Front contacts

Rear contacts

Fig. 2

Absolute Maximum Ratings

Parameter

Driving voltage

ESD tolerance (MIL 883)

EMI tolerance (1 kHz;

AM 80%; 100 kHz - 2 GHz)

Storage temperature

Solder temperature (10 sec)

(5 sec)

Symbol

Conditions

Ub

UESD

E

10 V

10'000 V

80 V/m

Tstg

Ts

95 C

260 C

270 C

Stresses beyond these listed maximum ratings may

cause permanent damage to the M-S X25. Exposure

to conditions beyond specified operating conditions

may affect the M-S X25 reliability or cause

malfunction.

Table 1

Electrical and Mechanical Characteristics

Tamb = 25C and Ub = 5 V; unless otherwise specified.

Parameter

Symbol Test Conditions

Operating temperature

Coil resistance

Operating current

Magnetic saturation voltage

Start-Stop Frequency

Maximum driving frequency

Dynamic torque

Static torque

Gear play

Forces allowed on the pointer shaft :

Axial push on force

Axial pull off force (refer to part drawing)

Perpendicular force

Imposed acceleration

Noise level

Angle of rotation of motors with internal stop

Ta

Rb

im

Ubs

fss

fm

M200

M600

Ms

Min.

-40

260

@ fz = 200 Hz

Type

290

15

9

@ JL = 0,2x10-6kgm2

@ JL = 0,2x10-6kgm2

@ fz = 200 Hz

@ fz = 600 Hz

@ Ub = 5V

Units

105

320

20

mA

V

Hz

200

1.0

3.5

1.3

0.35

4.0

0.5

FA

FQ

p

SPL

Max.

see p. 5

(conditions : see p. 11)

MS w/o stop: Unlimited rotation

45

600

Hz

mNm

mNm

mNm

Degree

150

12

1'000

50

315

N

rad/s2

dBA

Degree

Table 2

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

2 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Typical Performance Characteristics

Dynamic Torque Md = f(

)

Dynamic Torque in mNm

2.0

Ub = 5V

1.5

1.0

0.5

0.0

0

50

100

150

200

250

300

350

Angular Speed in /s

400

450

500

550

600

Fig. 3a

Dynamic Torque Md = f(Ub)

Dynamic Torque in mNm

2.0

1.5

200/s

1.0

0.5

0.0

2.0

3.0

4.0

5.0

6.0

Coil Voltage in V

7.0

8.0

9.0

10.0

Fig. 3b

Dynamic Torque Md = f(Ta)

Dynamic Torque in mNm

2.0

1.5

50/s

1.0

200/s

600/s

0.5

0.0

-40

-30

-20

-10

10

20

30

40

Temperature in C

50

60

70

80

90

Fig. 3c

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

3 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Product Identification

Coding for production date

Coding for prototypes

Each motor is marked with the product number and its

manufacturing date.

The coding for prototypes and special motor types is

printed above or below the production date.

Hour Day

00

|

23

1

|

7

Manufact. place

Week . Year

Line 1 - Zhuhai

> = Normal prod.

\ = Special trace.

< = Special trace.

01

|

52

0

|

9

Sample

|

A

|

Z

Variant

|

1

|

9

Example:

Line 2 - Zhuhai

} = Normal prod.

# = Special trace.

{ = Special trace.

A1

145>10.6

A-sample, variant 1

14th hour (14:00 - 14:59), Friday,

Line 1 Zhuhai, normal production,

week 10, 2006

Line 3 - Zhuhai

[ = Normal prod.

; = Special trace.

] = Special trace.

Patents

Example:

145>10.6

14th hour (14:00 - 14:59), Friday,

Line 1 Zhuhai, normal production,

week 10, 2006

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

US PAT 4371821

OTHER PATENTS IN:

DE, GB, FR, JP, CH, HK

4 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Installation and Dimensions

Motor Mounting

The Miniature Stepper Motors can be secured in place

by a variety of methods. For all automotive

applications even when the motor is exposed to very

strong vibrations, the soldering of the contact pins is

sufficient provided the versions with mounting pegs

are used. The mounting pegs have been developed to

allow screw-free fixing in ALL applications.

As a general rule, screws are unnecessary and should

be avoided as much as possible, both for cost and

process capability reasons. The motor has a robust

design but normal care should be taken that

excessive forces do not deform the housing.

For further details, refer to the application note

Mounting the M-S/ACC Motor X15.002.02.AN.E.

Examples for Motor Mounting

M-S with rear contacts

M-S with front contacts

Copper pads

Bend contacts for

surface mounting

PT 2.2

Self threading screw for

hot melt plastics

Fig. 4

Mounting Load on Pointer Shaft

The load mounting on the pointer shaft, such as a

pointer, gear, etc. is usually done in a pressing

operation. When using this technique, care should be

taken that the forces (FA and FQ) do not exceed those

given in the specifications (table 2).

Forces on the Pointer Shaft

FQ

FA

p

Caution

Care should be taken not to impose excessive

acceleration onto the pointer shaft. A kick on the

mounted pointer might damage the gear and cause

permanent damage to the M-S motor!

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

Fig. 5

5 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Functional Description

General

The M-S series consist of a "Lavet" type stepper

motor and a gear train. The integrated two step gear

train reduces the rotation by a factor of 180 whereby a

full step driving pulse results in a one degree rotation

of the pointer shaft.

As mentioned earlier, the motor rotor makes one half

revolution for each full step with each full step again

divided into three partial steps. The steps are carried

out according to the applied pulse sequence and

driving diagram shown in fig. 8 and 9 respectively.

The bit map (fig. 8) shows the logic levels at the

contacts 14 (fig. 7) and the corresponding coil

voltage pulses.

The direction of rotation is determined by the bit map

sequence chosen. The rotation can immediately and

at any point be reversed up to the maximum start-stop

frequency fss without loosing a step. The frequency

fss is dependent on the mechanical load applied and

can be calculated using the formulae given below.

The driving diagram (fig. 9) shows how the M-S can

be driven using standard logic components capable of

supplying 20 mA output current at Vdd of 5 volts.

For applications where very little current is available,

such as for battery powered devices, the motors can

be supplied with an optional current less static torque

(see p.4). Here the full step positions 1 and 4 provide

a static torque even in the absence of the coil current

Ib.

Schematic Layout

Rotor Shaft

Gear Reduction

(1:180)

Contacts

Pointer Shaft

Coil

Fig. 6

Pin Configuration

Front contacts

Rear contacts

Fig. 7

Rotor Positions

Rotor Position:

Pulse Sequence:

1 2 3 4 5 6 1 2 3 4 5

+ +

Coil Voltage Ub1

Coil Voltage Ub2

Bit Map:

Contact 1

Contact 2,3

Contact 4

counterclockwise

+ +

-

- -

+ +

- -

1

0

1

0

1

0

clockwise

clockwise

1

6

300

full step

Rotor position

partial step

2

60

120

3

240

5

180

4

counterclockwise

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

Fig. 8

6 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Driving Diagram

im

Ub

1

1 ib

VDD

Ub

ib

ib

Ub

Ub

3

4

GND

ib

Fig. 9

Start-Stop-Frequency FSS

As is normally the case for stepper motors, a shift

register type driver supplies the clock frequency which

determines the rotational speed of the motor. Up to

the start-stop frequency fss a reverse rotation and a

full stop is possible without missing, i.e. failing to carry

out a driving step. The dynamic behaviour of the

system (i.e. fss) is influenced by the inertia of the load.

The fss of the M-S X25 loaded with an inertial mass of

200 gmm2 is approximately 200 Hz.

The following example shows how the fss of a motor

can be calculated.

The parameters needed are:

torque M is equal to the effective dynamic torque Md

at this angular velocity:

3)

M = Md

The value of Md as a function of the full step

frequency fz is determined by measurements directly

on the motor. The acceleration torque M must also

be determined as a function of fz. The angular

acceleration is:

= fz

t

4)

5)

M = J f

- dependence of torque on the frequency (fig. 3)

- motor gear inertia JM-S

- load inertia JL

- number of steps z in 360

- full step frequency fz

The angular velocity is :

1)

= fz

= fz

z

180

The acceleration torque M needed to move the sum

of the inertial masses JM-S + JL = J with the angular

acceleration is:

2)

M = J

Also for acceleration from zero to the applied velocity,

i.e. the applied full step frequency fz, the acceleration

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

z 2 180

(J = JM-S + JL)

The start-stop frequency fss is given by the

intersection of the plot of these two curves as shown

in fig. 10.

The calculation of fss using the indicator norm mass

results:

480 10-9

200 10-9

kgm2

kgm2

680 10-9

kgm2

0.118

0.475

1.068

mNm

mNm

mNm

JM-S

JL

J

M100 =

M200 =

M300 =

Then, from fig. 10 => fss = 235 Hz

7 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Graphic Determination of fss

M 300

1.0

.75

.25

750

700

650

600

550

500

450

400

350

300

250

200

150

100

M 100

50

0.0

1/2 Torque Md= f ( fz )

M 200

.50

1/2 Torque Md

(mNm)

Full step frequency fz

(Hz)

fss

Fig. 10

Acceleration to Frequencies > fss

In order to determine the maximum acceleration step

f, the same type of calculation can be made as for

fss. The difference is that instead of the angular

velocity , the change in the angular velocity is

used in the calculation. The intersection of the two

curves is again used to determine the next higher step

frequency fi.

6)

8)

t =

( fi fi 1) fi

=

t

180

the acceleration torque M needed to accelerate J to

fi can be calculated.

( f f ) fi

= i i 1 = i i 1

=

180

180

9)

Using the acceleration time

7)

and the angular acceleration

M = J =

J ( fi fi 1) fi J fi fi

=

180

180

The intersection of the curves gives the maximum

driving frequency or the shortest period which is

needed to drive the motor with a maximum

acceleration.

1

fi

Determination of the Acceleration Steps

M 300

1.0

.75

1/2 Torque Md= f ( fz )

M 200

.50

fss

fZ1

750

700

650

600

550

500

450

400

350

300

250

200

150

100

0.0

M 100

50

.25

1/2 Torque Md

(mNm)

fZ5

fZ2 fZ3 fZ4 fZ6

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

Full step frequency fz

(Hz)

Fig. 11

8 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Control Circuits

M-S Quad Driver X12.017

M-S Dual Driver X12.014

The M-S Quad Driver X12.017 is a monolithic CMOS

device intended to be used as an interface circuit to

ease the use of the Miniature Stepping Motors X25.

The circuit allows the user to drive four motors as it

contains four identical drivers on the same chip.

Manufactured with the same technologies and using

the identical drivers as the M-S Quad Driver X12.017,

the M-S Dual Driver X12.014 allows the user to drive

two motors which require a smooth and appealing

movement of the pointer (i.e major gauges such as

speed and RPM). Minor gauges such as fuel or

temperature which move only from time to time may

be driven in the partial steps mode directly by the

micro-processor (refer to example fig. 13b).

System -processor

System -processor

M-S

RESET

OUT

M-S

CW/CCW A-B

B

OUT

M-S

C

OUT

X12.014

f(scx) A-B

OUT

M-S Dual Driver

Control Bus

CW/CCW A-B/D

X12.017

f(scx) A-B/D

OUT

M-S Quad Driver

Control Bus

RESET

M-S

Speed

OUT

M-S

RPM

M-S

Fuel

M-S

Fig. 13a

M-S

Temp

Fig. 13b

Microstepping Mode of Operation

The M-S Quad/Dual Driver converts a pulse train into

a current level sequence sent to the two motor coils of

the M-S. This sequence of 24 current levels per rotor

revolution is used to produce the microstepping

movement of the rotor.

A microstep is an angular rotation of 1/12 of the M-S

shaft or 15 on the rotor shaft.

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

A partial step is an angular rotation of 1/3 of the M-S

shaft or 60 on the rotor shaft.

The microstepping allows for a continuous smooth

movement of a pointer if the M-S is used as pointer

drive. It is not intended as a precise positioning. The

precision of the angular position is given by the

resolution of the partial step.

9 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

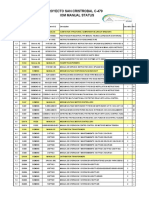

174 PCS

Tests Description and

Conditions

INITIAL

CHARACTERISTICS

EVALUATION

START

30 PCS

Noise, VJ, coil

resistance, Torque,

static and dynamic

detent

(Without print)

MECHANISM

ATTACHEMENT

TEST LEG G

MOTORS

CHARACTERISATION

(Hand soldering)

FIRST INTERMEDIATE

CHARACTERISTICS

EVALUATION

(On print)

Noise, VJ, coil

resistance, kick back

INDICATOR MANUAL

INSERTION

Coil resistance, Noise (16 speeds),

VJ, Torque dynamic (16 speeds),

-static, -detent and friction, pointer

movement (3 speeds), angular

play, kick back, coupling flux, axial

& radial load

Validation Plan Overview

24 PCS

24 PCS

24 PCS

24 PCS

24 PCS

24 PCS

TEST LEG A

TEST LEG B

TEST LEG C

TEST LEG D

TEST LEG E

TEST LEG F

AMBIANT TEMP.

LIFE

EVALUATION

POWER

THERMAL

SHOCKS

(1000 h)

(500 h)

THERMAL

SHOCK

CONDITIONING

STORAGE LIFE

EVALUATION

(100 h)

POWER

TEMPERATURE

CYCLING

(1000 h)

CYCLE

TEMPERATURE

AND HUMIDITY

OPERATING

LIFE

MECHANICAL

SHOCKS

(1000 h)

(1000 h)

VIBRATIONS

- RAMDOM (12 PCS)

- SINUS (12 PCS)

Noise, VJ, Torque,

Analysis + photos

FINAL

CHARACTERISTICS

EVALUATION

(Without print)

INTERMEDIATE

CHARACTERISTICS

EVALUATION

FINAL REPORT

(On print at 48, 250, 500, 750 &

1000h; Leg F 48, 160, 320 & 500h)

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

Noise, VJ, coil

resistance, kick back

10 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

General Conditions

Driving cycles

360

300

Initial preconditioning

180

120

60

FQ

High sp. B

27

24

21

18

15

High sp. A

200/s

100/s

600/s

300/s

1) Driving from 0 to 60 at 1 and wait 1 s.

2) Five cycles consisting each of a driving from

60 to 120 at 1 and back to 60 at 2,

Waiting during 2 s after each cycle.

3) Back to 0 at 1.

4) Variant A: The motor is driven freely without

hitting the stop. Driven at 2 to reach 300

(360 for motors w/o stop) and back again to 0

at 2.

Variant B: The motor is driven against the stop

on versions so fitted in order to increase the

shocks and stresses. They drive at 2 to reach

360 and back again of 360 at 2.

The motor is driven about 25% of the time with

driving cycle at high speed and 40% at low speed.

During the waiting period, the recommended

voltage is applied on both coils.

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

Power Temperature

Cycling

Defect free functioning after passing 1000 h in

Temperature Cycling Test.

The temperature cycle consists of h at 105C, h

to cool down to -40C, h at -40C and h to return

to 105C. The time of each cycle is 2 h.

The motors drive during the first 500 h in variant A

and during the last 500 h in variant B.

2h00

1h45

1h30

1h15

1h00

0h45

0h30

0h15

Tim e

0h00

The Driving Cycle consists of the following sequential

movements in loop for the M-S Motors.

Before the first cycle, the motors with internal stop are

driven continually in the same direction to hit the stop

at 150/s and then return 5. The motor is zeroing at

this position.

Test Leg A:

Temperature

2.5 g

0.2 10-6 kgm2

0.01 mNm

Driving Cycles

Driving cycle at high speed:

Driving cycle at low speed:

Low sp. B

Specific Test Conditions

Indicator Norm Load

Type of driving speed used:

Low sp. A

For the ACC-Motor the driving cycle consist of one

minute step each 0.5 s.

0.5 mm

m :

JL :

Mu :

12

Tim e (s)

FA

- mass

- inertia

- unbalance

0

0

After the initial characteristics evaluation, the M-S

Motors are mounted on a board and soldered with a

gap of 0.5 mm.

When soldered, an axial force (FA) of 150 N and a

radial force (FQ) of 12 N must be applied on the

shaft of all the tested M-S motors. The radial force is

applied at 8.5 mm of the top of the cover.

Angle

240

120

100

80

60

40

20

0

-20

-40

-60

Test Leg B:

Storage and operating

life evaluation

Defect free functioning after passing 100 h in Storage

Life Evaluation and after 1000 h in Operating Life.

The storage life evaluation consists to place the

motors without rotation at -40C during 100 h. After

this time all the motors must start correctly without

step loss.

The operating life consists of a permanent

temperature at 105C during which the motors drive.

The motors drive during the first 500 h in variant A

and during the last 500 h in variant B.

11 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Test Leg C:

Cycle Temperature and

Humidity

Defect free functioning after passing 1000 h in Cycle

Temperature and Humidity Test.

The cycle temperature and humidity test consists of

2 h to ascend the temperature from 25C to 65C and

the relative humidity from 50% to 95%. The

temperature and the humidity are maintained during

4 h then they are descending to the start values 25C

and 50% of relative humidity. The time of each cycle

is 8 h.

Random vibrations

Previously subjected to thermal/mechanical

shocks, of the motors are subjected to the

random vibrations test in each 3 axes.

Vibrations are applied for 10 minutes at a level of

1.8 grms between 10 and 1000 Hz during which no

step loss shall be evident. Then the motors are

vibrated 20 h at a level of 4.5 grms without

mechanical damage and then, they are again

vibrated 10 minutes at the level of 1.8 grms. During

this last step, no step loss shall be evident. The

motors drive in variant A during this test.

Temperature

8h

6h

4h

2h

0h

Tim e

100

100%

90

90%

80

70

80%

70%

60

60%

50

50%

40

40%

30

20

30%

20%

10

10%

0%

Temperature

Humidity

Sinus vibrations

Previously subjected to thermal/mechanical

shocks, of the motors are subjected to the sinus

vibrations test in each 3 axes.

Vibrations are applied for 8 h with an acceleration

of 6 gp-p, but maximum 10 mm of amplitude in the

frequency range of 5 to 250 Hz with a sweep of

1 octave / minute.

The motors drive in variant A during this test.

Test Leg E:

The motors drive during the first 500 h in variant A

and during the last 500 h in variant B.

Test Leg D:

Shocks and Vibrations

Test

Defect free functioning after being subjected Shocks

and Vibrations Tests.

Ambient Temperature

Life Evaluation

Defect free functioning after passing 1000 h in

Ambient Temperature Life Evaluation.

The motors drive during the first 500 h in variant A

and during the last 500 h in variant B.

Comparison is then made between motors subjected

to this test, and those of the other legs in order to

evaluate the evolution of the motors under different

conditions.

Thermal shock conditioning

First, the motors are placed without rotation to be

conditioned in a thermal shock test which consists

of 16 thermal shocks between 85C and -40C in

10 s. The extreme temperatures are maintained

h. The time of each cycle is 1 h.

Mechanical shocks

The motors are subjected to shocks 5 times in 3

axes on the vibration machine. Each shock

consists of a half-sine waveform pulse with an

acceleration peak of 20 g during 11 ms. The

motors drive in variant A during this test.

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

Test Leg F:

Power Thermal Shocks

Defect free functioning after passing the test.

The Power Thermal Shocks test consists of

continuous sequential thermal shocks between 110C

and -50C every 15 min during 500 h.

During this test, the motors drive like the CCP test

(see doc no : CCP-002-e-A M-S Motors CCP Plan).

That means 300 at high speed (600/s), then 60 at a

speed under the start stop frequency (150/s) to

assure a kick back and the same to the another

direction.

12 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Acoustic Measurements

Test Configuration

1

2

4cm

1. reflection free room

2. microphone 1/2" omni-directional Larson-Davis,

Typ. 2541

3. sonometer Larson-Davis Typ. 800B

4. motor under test

5. reflection free cube

6. M-S control unit in -stepping mode (1/12 / step)

Test Conditions

- temperature

- measurement distance

- measurement range

- measurement time

- angular speed max

- ambient noise max

- motor without load.

Tamb :

25

Lm :

4

: 20 20k

tm

:

4

:

600

:

20

C

cm

Hz

s

/s

dBA

Instrument Parameters

The noise level SPL was determined using the

instrument settings (Larson-Davis Typ. 800B):

- weighting :

- integration time :

- detection :

"A"

" Slow "

" RMS "

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

13 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Parameter Definitions

Parameter

Description

E

FA

FQ

fAM

fm

fss

fz

Gnd

Ib

im

J

EMI tolerance

axial force on the pointer shaft

perpendicular force on the pointer shaft

amplitude modulated carrier frequency

maximum driving frequency

start-stop frequency

full step frequency

ground

coil current

M-S ac-current

total inertia = JM-S + JL

kgm2

JL

inertia of the load

kgm2

JM-S

Lm

m

M

M200

Md

M0

Ms

Mu

Rb

SPL

Ta

Tamb

Ts

Tstg

t

tm

Ub

Ubs

UESD

Vdd

z

inertia of the M-S

noise measurement distance

mass of the driven load

acceleration torque

dynamic torque at 200 Hz full step frequency

dynamic torque

static torque at Ub = 0 V

static torque at Ub > 0 V

unbalance of the load

coil resistance

noise level of the motor (sound pressure level)

temperature

ambient temperature

solder temperature

storage temperature

acceleration time

noise measurement time

coil voltage

magnetic saturation voltage

Electro Static Discharge tolerance

operating voltage

number of full steps per revolution (=360)

angular acceleration (= M/J)

kgm2

cm

g

mNm

mNm

mNm

mNm

mNm

mNm

dB

C

C

C

C

s

s

V

V

V

V

rad/s2

angular acceleration imposed to the pointer shaft

possible angle of rotation of the internal stop version

angular speed

random vibration unit

sinus vibration unit (g peak to peak)

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

Unit

V/m

N

N

Hz

Hz

Hz

Hz

A

A

rad/s2

degrees

/s (rad/s)

grms

gp-p

14 / 16

| www.microcomponents.ch

X25 Specification

X25.xxx.01.SP.E

A COMPANY OF THE

Table of Contents

Description ......................................................... 1

Tests Description and Conditions .................. 10

Features.............................................................. 1

Validation Plan Overview........................................ 10

Motor versions ................................................... 1

General Conditions.......................................... 11

Typical Application ............................................ 1

Initial preconditioning.............................................. 11

Pin Connection................................................... 2

Indicator Norm Load ............................................... 11

Absolute Maximum Ratings .............................. 2

Driving Cycles......................................................... 11

Electrical and Mechanical Characteristics ....... 2

Specific Test Conditions ................................. 11

Typical Performance Characteristics ............... 3

Test Leg A: Power Temperature Cycling .............. 11

Product Identification ........................................ 4

Test Leg B: Storage and operating life evaluation 11

Patents

Test Leg C: Cycle Temperature and Humidity ...... 12

Installation and Dimensions.............................. 5

Test Leg D: Shocks and Vibrations Test ............... 12

Motor Mounting......................................................... 5

Thermal shock conditioning .......................... 12

Mounting Load on Pointer Shaft............................... 5

Mechanical shocks.......................................... 12

Functional Description ...................................... 6

Random vibrations .......................................... 12

General

.6

Sinus vibrations............................................... 12

Driving Diagram ........................................................ 7

Test Leg E: Ambient Temperature Life Evaluation 12

Start-Stop-Frequency FSS......................................... 7

Test Leg F: Power Thermal Shocks...................... 12

Acceleration to Frequencies > fss ............................ 8

Acoustic Measurements ......................................... 13

Control Circuits.................................................. 9

Parameter Definitions ...................................... 14

M-S Quad Driver X12.017 ........................................ 9

Table of Contents............................................. 15

M-S Dual Driver X12.014.......................................... 9

Revisions

..16

Microstepping Mode of Operation ............................ 9

The information and specifications given here are correct and valid to the best of our knowledge. However

switec assumes no liability for damages which may arise through the incorrect use of this information or for

switec

eventual damages to existing patents or to the rights of third parties. The general purchase conditions for

electrical and mechanical products of switec

switec apply to all commercial transactions.

switec

switec reserves the right to make changes in the products contained in this document in order to improve

design or performance and to supply the best possible products.

switec

switec is a trade mark of the Swatch Group Management Services AG.

switec a division of Micro-Components SA2001

SR-13/11/2002

Microcomponents SA

Maienstrasse 11 | CH-2540 Grenchen

Phone +41 / 32 655 25 25 | e-mail info@microcomponents.ch

15 / 16

| www.microcomponents.ch

You might also like

- ES-M V0.0.1d PDFDocument11 pagesES-M V0.0.1d PDFDeepak RainaNo ratings yet

- NPM SCR 75 SpecsheetDocument2 pagesNPM SCR 75 SpecsheetElectromateNo ratings yet

- WEG Soft StartersDocument36 pagesWEG Soft StartersgamasistemNo ratings yet

- Axem Disc DC Servo Motor ManualDocument12 pagesAxem Disc DC Servo Motor ManualjohnysonycumNo ratings yet

- USDigital SM23 Data 5pDocument5 pagesUSDigital SM23 Data 5pHayk MartirosianNo ratings yet

- Addendum To The Catalog: Synchronous Servo GearmotorsDocument0 pagesAddendum To The Catalog: Synchronous Servo GearmotorsVictor FriasNo ratings yet

- Yaskawa Manuals 212Document31 pagesYaskawa Manuals 212Pham LongNo ratings yet

- LM 2070-02 MinDocument4 pagesLM 2070-02 Minsanthan1986No ratings yet

- M060 DatasheetDocument2 pagesM060 DatasheetspamlistNo ratings yet

- Micro Pneumatics Rotary ActuatorsDocument4 pagesMicro Pneumatics Rotary ActuatorsFerBotelloNo ratings yet

- Torque Systems Linear Actuator Product GuideDocument5 pagesTorque Systems Linear Actuator Product GuideElectromateNo ratings yet

- 8MT195 and 8MT295Document2 pages8MT195 and 8MT295srinivasNo ratings yet

- RE 50 50 MM, Graphite Brushes, 200 Watt: IndustrialDocument1 pageRE 50 50 MM, Graphite Brushes, 200 Watt: IndustrialIan NishibayaskiNo ratings yet

- Electrical preparation for body control keypadDocument5 pagesElectrical preparation for body control keypadKibtirul Arma FirmansyahNo ratings yet

- Stepper Motor ControlDocument5 pagesStepper Motor ControlKumar R Ranjan86% (7)

- Kenwood Kvt-819 - 829 - 839 Monitor With DVD ReceiverDocument80 pagesKenwood Kvt-819 - 829 - 839 Monitor With DVD ReceiverpromexbrailaNo ratings yet

- Amt 20 Modular Absolute EncoderDocument10 pagesAmt 20 Modular Absolute EncodersthollanderNo ratings yet

- Sensorless Field Oriented Control (FOC) of An AC Inductive MotorDocument34 pagesSensorless Field Oriented Control (FOC) of An AC Inductive MotorpaaraibNo ratings yet

- If StepDocument23 pagesIf Stepkrishna_cad28No ratings yet

- 23 Cb2000 Ls Varmeca enDocument10 pages23 Cb2000 Ls Varmeca enFlying2eagleNo ratings yet

- Dyadic Mechatronics Cylinder CatalogDocument16 pagesDyadic Mechatronics Cylinder CatalogElectromateNo ratings yet

- Stepper Motor OverviewDocument13 pagesStepper Motor OverviewThuan Bui ThanhNo ratings yet

- Three Phase LocomotiveDocument138 pagesThree Phase LocomotiveManas Moharana67% (3)

- Standards For AC MotorsDocument37 pagesStandards For AC MotorsPandaGendut100% (1)

- FCPL asynchronous brake motors technical selection guideDocument10 pagesFCPL asynchronous brake motors technical selection guideehab8320014413No ratings yet

- Re 15228 Radial Piston Hydraulic Motor With A Fixed DisplacementDocument36 pagesRe 15228 Radial Piston Hydraulic Motor With A Fixed Displacementraj8378100% (1)

- 1FL5 Motor Technical Specifications and DimensionsDocument1 page1FL5 Motor Technical Specifications and DimensionsSam eagle goodNo ratings yet

- AMK DT ServomotorsDocument30 pagesAMK DT ServomotorsPaolo GiorgianniNo ratings yet

- SteeringSensor RevA7Document6 pagesSteeringSensor RevA7eng_moh04No ratings yet

- Engineering Document: 757-4002-097 CAD #D8478Document29 pagesEngineering Document: 757-4002-097 CAD #D8478Vasi ValiNo ratings yet

- f3n2c PDFDocument6 pagesf3n2c PDFEduardo HuaytaNo ratings yet

- Siemens manuals for San Cristobal substation project C-479Document18 pagesSiemens manuals for San Cristobal substation project C-479Allen Marcelo Ballesteros LópezNo ratings yet

- Caracteristicas Motores PDFDocument60 pagesCaracteristicas Motores PDF0ZKRCITHONo ratings yet

- 05-06 YFM250 Bruin 07-09 BigBear 2WDDocument444 pages05-06 YFM250 Bruin 07-09 BigBear 2WDTim Burkett100% (2)

- X15 XXX 02 SP E PDFDocument13 pagesX15 XXX 02 SP E PDFIsos CellNo ratings yet

- ED Lab Manual Original - Exp 6 To Exp 10Document33 pagesED Lab Manual Original - Exp 6 To Exp 10Umang MewaraNo ratings yet

- Brochure - 14.458 DC Spring Apllied BrakesDocument2 pagesBrochure - 14.458 DC Spring Apllied Brakeskpr_02161371No ratings yet

- PM-0002-0011 Manual de Chancado - 419 - 501Document83 pagesPM-0002-0011 Manual de Chancado - 419 - 501Christian SantillanNo ratings yet

- ZF Tiratron Catalog Rev 0 PDFDocument28 pagesZF Tiratron Catalog Rev 0 PDFNaracu FabianNo ratings yet

- Sensors: Systems OperationDocument3 pagesSensors: Systems OperationSam SungNo ratings yet

- Motores de Passo NMB PDFDocument20 pagesMotores de Passo NMB PDFErick Dos SantosNo ratings yet

- An Introduction To Stepping Motors: FeaturesDocument41 pagesAn Introduction To Stepping Motors: FeaturesAaron FultonNo ratings yet

- Mitsubishi Manuals 1053Document188 pagesMitsubishi Manuals 1053mrtansNo ratings yet

- Final Drive - Install: Shutdown SISDocument3 pagesFinal Drive - Install: Shutdown SISRajan MullappillyNo ratings yet

- Gen 12MW PDFDocument11 pagesGen 12MW PDFTesta Bonaventura Vincenzo100% (1)

- Fuel Injection Control Linkage - InstallDocument5 pagesFuel Injection Control Linkage - InstallPutra JawaNo ratings yet

- Armado de Valvula de Salida Del ConvertidorDocument2 pagesArmado de Valvula de Salida Del ConvertidorKerbin Enrique NuñezNo ratings yet

- Torque Systems Bnr3000 SpecsheetDocument4 pagesTorque Systems Bnr3000 SpecsheetElectromateNo ratings yet

- M 380Document36 pagesM 380Ajie PrasetyaNo ratings yet

- Electrical Component LocationDocument5 pagesElectrical Component LocationNova kurniawan 34No ratings yet

- Mecanismo de ValvulasDocument7 pagesMecanismo de ValvulasAlaina SousaNo ratings yet

- Eurotech BV SeriesDocument8 pagesEurotech BV SeriesCNC SYSTEMSNo ratings yet

- Sevcon SC2000 Manual - With Calibrator Section PDFDocument58 pagesSevcon SC2000 Manual - With Calibrator Section PDFRicardo Marquez ValenciaNo ratings yet

- Circle Drive - Install Installation Procedure: Desarmado y ArmadoDocument5 pagesCircle Drive - Install Installation Procedure: Desarmado y ArmadoTaller HeavytechNo ratings yet

- Direct Drive Torque Motors Improve Machine Tool PerformanceDocument10 pagesDirect Drive Torque Motors Improve Machine Tool PerformanceHüseyin Murat PolaterNo ratings yet

- The Voltech Handbook of PWM Motor DrivesDocument53 pagesThe Voltech Handbook of PWM Motor DrivesPovaS100% (1)

- Maxon RE Max CatalogDocument22 pagesMaxon RE Max CatalogLCDias1968No ratings yet

- BMW Airbag Reset Tool GuideDocument6 pagesBMW Airbag Reset Tool Guidejpedroblasco14No ratings yet

- Irf2110 AplicationDocument30 pagesIrf2110 Aplicationanand100% (1)

- QN902x Datasheet v0.98 Nov 2013Document38 pagesQN902x Datasheet v0.98 Nov 2013Richard ZerpaNo ratings yet

- Verb PrepositionsDocument22 pagesVerb Prepositionssaiteja1234No ratings yet

- Iso122sensor de TensionDocument15 pagesIso122sensor de TensionRichard ZerpaNo ratings yet

- LED-driver-IC-solutionDocument1 pageLED-driver-IC-solutionRichard ZerpaNo ratings yet

- X12 017Document8 pagesX12 017Richard ZerpaNo ratings yet

- Adjectives PrepositionsDocument1 pageAdjectives Prepositionsshark777No ratings yet

- How To Design LED Signage and LED Matrix Displays Part 1Document9 pagesHow To Design LED Signage and LED Matrix Displays Part 1Richard ZerpaNo ratings yet

- Irf2110 AplicationDocument30 pagesIrf2110 Aplicationanand100% (1)

- (Brief) The Illumination Design and Challenges of High Power and Long Distance Data TransmissionDocument1 page(Brief) The Illumination Design and Challenges of High Power and Long Distance Data TransmissionRichard ZerpaNo ratings yet

- LG Fallas TV PLASMA TrainingDocument74 pagesLG Fallas TV PLASMA Trainingdesonline86% (7)

- Up Rwa1232 e 0810Document2 pagesUp Rwa1232 e 0810Richard ZerpaNo ratings yet

- FADOS9F1 English Datasheet Long PDFDocument8 pagesFADOS9F1 English Datasheet Long PDFRichard ZerpaNo ratings yet

- Byv29fx 600 PDFDocument11 pagesByv29fx 600 PDFRichard ZerpaNo ratings yet

- 2003jun29 HBM An PDFDocument4 pages2003jun29 HBM An PDFRichard ZerpaNo ratings yet

- Hitachi Microcomputer H8/300H Series Application Notes For CPUDocument204 pagesHitachi Microcomputer H8/300H Series Application Notes For CPURichard ZerpaNo ratings yet

- Hitachi Microcomputer H8/300H Series Application Notes For CPUDocument204 pagesHitachi Microcomputer H8/300H Series Application Notes For CPURichard ZerpaNo ratings yet

- LTspiceGettingStartedGuide PDFDocument53 pagesLTspiceGettingStartedGuide PDFRichard ZerpaNo ratings yet

- 101 English Words Youll Never Learn in School 1Document55 pages101 English Words Youll Never Learn in School 1Luiza Sorice100% (2)

- Cep MPPTDocument21 pagesCep MPPTRichard ZerpaNo ratings yet

- Computaris - Top Testing Suite (Quick Demonstration)Document10 pagesComputaris - Top Testing Suite (Quick Demonstration)ioana_diaNo ratings yet

- G. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFDocument2 pagesG. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFinitbashNo ratings yet

- Java Topics To Cover in InterviewsDocument5 pagesJava Topics To Cover in InterviewsHemanth KumarNo ratings yet

- Ceramic Terminal BlocksDocument1 pageCeramic Terminal BlockselijbbNo ratings yet

- Pull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLineDocument7 pagesPull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLinecnuneza4No ratings yet

- WPD Flotationdrying PDFDocument19 pagesWPD Flotationdrying PDFVvbjNo ratings yet

- Wacker Neuson-Dpu - 25 KNDocument3 pagesWacker Neuson-Dpu - 25 KNMilutin BožovićNo ratings yet

- Excellent Hex Key Wrench: English VersionDocument54 pagesExcellent Hex Key Wrench: English Versionmg pyaeNo ratings yet

- FH400 73158464 Pca-6.140Document431 pagesFH400 73158464 Pca-6.140IgorGorduz100% (1)

- INTERCOMP Pt300 Users Manual Rev GDocument44 pagesINTERCOMP Pt300 Users Manual Rev GCTN2010No ratings yet

- Account Manager Business Development in San Jose CA Resume Mark WestonDocument2 pagesAccount Manager Business Development in San Jose CA Resume Mark WestonMarkWeston2No ratings yet

- Setting vpn1Document10 pagesSetting vpn1Unink AanNo ratings yet

- Chapter-6 IscaDocument1 pageChapter-6 IscakishorejiNo ratings yet

- Network What To ReadDocument2 pagesNetwork What To ReadTauseef AhmadNo ratings yet

- Foxpro For O LevelDocument3 pagesFoxpro For O LevelShiv PathakNo ratings yet

- Ornl 2465Document101 pagesOrnl 2465jesusNo ratings yet

- Zener DataDocument2 pagesZener Dataapi-27149887No ratings yet

- PDVSA Engineering Design Manual Volume 9–I Process AnalyzersDocument25 pagesPDVSA Engineering Design Manual Volume 9–I Process AnalyzersAlberto Enrique De Santa Anna CampderáNo ratings yet

- 6GK52160BA002AA3 Datasheet en PDFDocument6 pages6GK52160BA002AA3 Datasheet en PDFgrace lordiNo ratings yet

- Diffraction of Laser Beam Using Wire Mesh, Cross Wire and GratingDocument2 pagesDiffraction of Laser Beam Using Wire Mesh, Cross Wire and GratingPriyesh PandeyNo ratings yet

- 2 CAD Connecting Rod ForgingDocument56 pages2 CAD Connecting Rod ForgingIsrar EqubalNo ratings yet

- YCMOU-6th Semester Question Papers-7Document5 pagesYCMOU-6th Semester Question Papers-7phase_shekhar21No ratings yet

- AASHTO T283-22 Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced DamageDocument11 pagesAASHTO T283-22 Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced DamageErnesto Oscar VidelaNo ratings yet

- Internet Controlled Multifunctional UGV For SurvellianceDocument74 pagesInternet Controlled Multifunctional UGV For SurvellianceMd Khaled NoorNo ratings yet

- Hard Disk DriveDocument4 pagesHard Disk DriveAbhishek AbhiNo ratings yet

- Galvanize Galvanize Business Unit: Trust Us To GalvanizeDocument6 pagesGalvanize Galvanize Business Unit: Trust Us To GalvanizeAdet WildanNo ratings yet

- 2009 Energy Storage-U.S. Department of EnergyDocument380 pages2009 Energy Storage-U.S. Department of EnergydiwhiteNo ratings yet

- Epc of Well Pad D For Sorik Marapi Geothermal Project Recovery ScheduleDocument1 pageEpc of Well Pad D For Sorik Marapi Geothermal Project Recovery ScheduleGema SuryaNo ratings yet

- NTP35N15 Power MOSFET Features and SpecificationsDocument7 pagesNTP35N15 Power MOSFET Features and SpecificationsChristine GomezNo ratings yet

- DMD Documentation Error - Freetronics ForumDocument3 pagesDMD Documentation Error - Freetronics ForumapofviewNo ratings yet