Professional Documents

Culture Documents

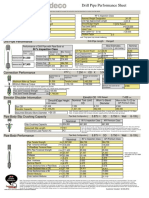

Drill Pipe Performance Sheet

Uploaded by

Garcia C L AlbertoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drill Pipe Performance Sheet

Uploaded by

Garcia C L AlbertoCopyright:

Available Formats

Drill Pipe Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Note: Connection torsional strength is less than 80% pipe body torsional strength.

Drill Pipe Configuration

Pipe Body OD

Pipe Body Wall Thickness

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

Box Tong

(in)

(in)

(in)

(in)

(in)

(in)

80 % Inspection Class

Nominal Weight Designation

28.70

(ft) 31.8

Drill Pipe Approximate Length

(in) 3/32 Raised

SmoothEdge Height

(psi) 120,000

Tool Joint SMYS

Upset Type

IEU

(in) 6.000

Max Upset OD (DTE)

Friction Factor

1.0

5.875

0.500

S-135

Range2

XT57

7.000

4.250

10

15

Note: Tong space may include hardfacing.

Drill-Pipe Length

Drill Pipe Performance

Best Estimates

Performance of Drill Pipe with Pipe Body at

(without Coating)

80 % Inspection Class

Applied Make-up

Torque

Max Tension

Operational

Torque (ft-lbs)

(lbs)

(ft-lbs)

Maximum MUT

56,500

Minimum MUT

47,200

Tension Only

Combined Loading

Tension Only

Combined Loading

0

45,300

894,900

809,200

0

35,500

894,900

843,200

Drill Pipe Adjusted Weight

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

34.52

0.53

(Bbls/ft) 0.0126

(gal/ft) 0.93

(Bbls/ft) 0.0221

(in) 4.125

XT57

7.000

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

56,500

47,200

(ft-lbs)

(lbs)

Tensile Limited

Tensile Limited

SmoothEdge Height

(in)

(lbs)

3/32 Raised

7.188

1,223,100

Assumed Elevator Bore Diameter

33.24

0.51

0.0121

0.95

0.0226

(lbs/ft)

0.92

0.0220

(lbs)

OD X

(in)

4.250

Tension at Connection

Yield

(lbs)

959,500

1,196,200

ID

(in)

120,000

(psi)

Tool Joint Dimensions

Balanced OD

(in)

Minimum Tool Joint OD for API

(in)

Premium Class

Minimum Tool Joint OD for

Counterbore

(in)

6.930

6.780

6.566

94,200

1,200,500

Elevator Shoulder Information

Box OD

Elevator Capacity

(least accurate)

(gal/ft)

Note: The maximum make-up torque should be applied when possible.

Note: To maximize connection operational tensile, a MUT (T4) = 47,000 (ft-lbs) should be applied.

Tool Joint Torsional Strength

Tool Joint Tensile Strength

Nominal

(with Coating)

Note: Oil field barrel equals 42 US gallons.

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

Connection Performance

Maximum Make-up Torque

Minimum Make-up Torque

Range2

(in)

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

Worn to Min TJ OD for

API Premium Class

7.000

993,000

6.780

730,900

Pipe Body Slip Crushing Capacity

Pipe Body Configuration

Nominal

Assumed Slip Length

Transverse Load Factor (K)

(lbs)

(in)

Pipe Body Performance

750,400

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

(in^2)

(in^2)

(in^2)

(in^3)

(in^3)

5.875 (in) OD

80 % Inspection Class

597,300

Pipe Body Configuration

(lbs)

0.500 (in) Wall

S-135 )

API Premium Class

597,300

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

16.5

4.2

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

Cross Sectional Area of Pipe Body

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

(in)

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

6.125

Slip Crushing Capacity

6.721

662,000

7.188

1,139,800

135,900

0.69

108,700

20,106

21,023

5.875

0.500

4.875

8.443

27.109

18.665

10.470

20.939

5.875 (in) OD

80 % Inspection Class

894,900

106,100

0.89

84,900

18,383

14,824

5.675

0.400

4.875

6.629

25.294

18.665

8.172

16.344

0.500 (in) Wall

S-135 )

API Premium Class

894,900

106,100

0.89

84,900

18,383

14,824

5.675

0.400

4.875

6.629

25.294

18.665

8.172

16.344

Note: Nominal Burst

calculated at 87.5% RBW

per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear

conditions (remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance

ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to

the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 02-03-2014

Operational Limits of Drill Pipe

Connection

Pipe Body

XT57

80 % Inspection Class

Tool Joint OD

(in)

7.000

Tool Joint ID

Pipe Body OD

(in)

5.875

Wall Thickness (in) 0.500

(in)

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 56,500

Operational Assembly

Torque

Max Tension

(ft-lbs)

0

2,400

4,800

7,200

9,500

11,900

14,300

16,700

19,100

21,500

23,800

26,200

28,600

31,000

33,400

35,800

38,100

40,500

42,900

45,300

(lbs)

894,900

894,700

894,000

892,800

891,300

889,200

886,700

883,700

880,300

876,300

872,100

867,200

861,800

855,800

849,400

842,400

835,200

827,100

818,500

809,200

Pipe Body Grade

S-135

Combined Loading for Drill Pipe at

Minimum Make-up Torque = 47,200

(ft-lbs)

Connection Max

Pipe Body

Max Tension Tension

(lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

4.250

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(lbs)

(ft-lbs)

Connection

Max Tension

(lbs)

894,900

894,900

1,196,200

894,900

959,500

894,700

959,500

1,900

894,700

894,700

1,196,200

959,500

3,700

894,300

894,300

1,196,200

1,196,200

894,000

892,800

959,500

5,600

893,600

893,600

891,300

959,500

7,500

892,600

892,600

1,196,200

889,200

959,500

9,300

891,400

891,400

1,196,200

886,700

959,500

11,200

889,900

889,900

1,196,200

959,500

13,100

888,000

888,000

1,196,200

959,500

15,000

885,900

885,900

1,196,200

959,500

16,800

883,600

883,600

1,196,200

1,196,200

883,700

880,300

876,300

872,100

959,500

18,700

880,900

880,900

867,200

959,500

20,600

877,900

877,900

1,196,200

861,800

959,500

22,400

874,700

874,700

1,196,200

855,800

959,500

24,300

871,100

871,100

1,196,200

959,500

26,200

867,200

867,200

1,196,200

959,500

28,000

863,200

863,200

1,196,200

858,600

858,600

1,196,200

1,196,200

849,400

842,400

835,200

29,900

959,500

827,100

959,500

31,800

853,700

853,700

818,500

959,500

33,700

848,500

848,500

1,196,200

809,200

959,500

35,500

843,200

843,200

1,196,200

Operational drilling torque is limited by the Make-up Torque.

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

47,200

48,200

49,300

50,300

51,300

52,400

53,400

54,400

55,500

56,500

Connection Max

Tension

(lbs)

1,196,200

1,170,800

1,142,800

1,117,300

1,091,900

1,063,900

1,038,400

1,013,000

985,000

959,500

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

Connection Wear Table

Connection

XT57

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

7

6.961

6.921

6.882

6.842

6.803

6.763

6.724

6.684

6.645

6.605

6.566

Worn OD

(in)

7.000

Tool Joint ID

(in)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

4.250

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

94,200

94,200

93,600

91,200

88,700

86,300

83,900

81,500

79,100

76,800

74,400

72,100

56,500

56,500

56,200

54,700

53,200

51,800

50,300

48,900

47,500

46,100

44,600

43,300

(ft-lbs)

Connection Max

Tension

Min MUT

(lbs)

(lbs)

(ft-lbs)

959,500

955,500

958,500

990,700

1,022,400

1,051,300

1,082,100

1,110,200

1,137,700

1,134,800

1,113,300

1,054,200

47,100

1,198,800

47,100

1,193,700

46,800

1,195,700

45,600

1,180,900

44,400

1,156,500

43,200

1,131,900

41,900

1,104,600

40,700

1,079,800

39,500

1,055,000

38,400

1,006,000

37,200

939,700

36,100

878,900

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

Pipe Body OD

80 % Inspection Class

Pipe Body Torque

(in)

5.875

Wall Thickness (in) 0.500

Pipe Body Grade

S-135

9,600

19,300

28,900

38,600

48,200

57,900

67,500

77,200

86,800

96,500

106,000

891,200

880,000

861,000

833,600

797,200

749,900

690,400

613,900

514,600

371,900

38,200

(ft-lbs)

Pipe Body Max

894,900

Tension

(lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

You might also like

- Asme B56.1Document88 pagesAsme B56.1Ana María FernándezNo ratings yet

- Chartek 7 Application Manual (Rev10) 2017-05-19Document64 pagesChartek 7 Application Manual (Rev10) 2017-05-19suriya100% (6)

- Arrow Set Ficha TecnicaDocument3 pagesArrow Set Ficha TecnicaOscar GuaricalloNo ratings yet

- 2M Tek Torq Tek ZIIDocument1 page2M Tek Torq Tek ZIIamghardjillali_449230% (1)

- Bit Release Tool (BRT)Document2 pagesBit Release Tool (BRT)Evgeny100% (1)

- Questionnaire PMDocument97 pagesQuestionnaire PMapi-3781101100% (7)

- Starbucks CaseDocument50 pagesStarbucks CasePhoebe De la RosaNo ratings yet

- Gigabyte GA-Z270-Gaming-K3 Rev 1.02 BoardView PDFDocument3 pagesGigabyte GA-Z270-Gaming-K3 Rev 1.02 BoardView PDFsraft2000No ratings yet

- Drill Pipe Performance Data SheetDocument3 pagesDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- Rotating Control Device: SperrydrillingservicesDocument4 pagesRotating Control Device: SperrydrillingservicesSlim.B100% (1)

- Varel Mining CatalogDocument24 pagesVarel Mining CatalogEmerson Phocco Yauli100% (1)

- 14P220 Triplex Mud Pump Spec SheetDocument1 page14P220 Triplex Mud Pump Spec SheetWHWENNo ratings yet

- Stuck Point WorksheetDocument5 pagesStuck Point Worksheetjose perozoNo ratings yet

- IV-0794-20 CROSS OVER Pin-Box 05807HDocument1 pageIV-0794-20 CROSS OVER Pin-Box 05807Hivan dario benavides bonillaNo ratings yet

- Drilling Spool SpecsDocument2 pagesDrilling Spool SpecsCarlos Sarmiento CalderónNo ratings yet

- Cup Type TesterDocument1 pageCup Type TesterJohnsNo ratings yet

- 575 Venturi Jet Basket Mini Tech Brief Ver 3 PDFDocument8 pages575 Venturi Jet Basket Mini Tech Brief Ver 3 PDFJhonathan MirandaNo ratings yet

- Check List For SOBM Take On BoardDocument5 pagesCheck List For SOBM Take On BoardVimal SinghNo ratings yet

- Drill Collar SlipsDocument10 pagesDrill Collar SlipsAdrian CantaragiuNo ratings yet

- Rotary Slips "RDL" "RD" "RDS": Side Door Elevator 150 TON 250 TON 350 TONDocument11 pagesRotary Slips "RDL" "RD" "RDS": Side Door Elevator 150 TON 250 TON 350 TONShaikh Sabir HussainNo ratings yet

- FKQ50-2 Use R ManualDocument56 pagesFKQ50-2 Use R ManualMuthia AstriNo ratings yet

- 8-P-80 Mud Pump BrochureDocument2 pages8-P-80 Mud Pump Brochuredavorp1402No ratings yet

- 4.0 S-135 Drill Pipe W Xt39Document1 page4.0 S-135 Drill Pipe W Xt39rdos14No ratings yet

- Tenaris Running Manual 01Document20 pagesTenaris Running Manual 01advantage025No ratings yet

- D392005428-MKT-001 6012 Bop PDFDocument2 pagesD392005428-MKT-001 6012 Bop PDFMitul PatelNo ratings yet

- Surface BOP Kill Sheet - Vertical Well (Metric/BarDocument2 pagesSurface BOP Kill Sheet - Vertical Well (Metric/BarMelnapsterDsouzaNo ratings yet

- PZ-9 FlyerDocument2 pagesPZ-9 FlyerChris KNo ratings yet

- Handing Tools CPMCDocument32 pagesHanding Tools CPMCcristinelb100% (1)

- Daily Mechanical Inspection ChecklistDocument1 pageDaily Mechanical Inspection ChecklistAgil Wahyu PamungkasNo ratings yet

- Wedge 563 Brochure OKDocument32 pagesWedge 563 Brochure OKNico Pan100% (1)

- Volant Crti and CrteDocument4 pagesVolant Crti and CrteSudish Bhat100% (2)

- TDS 93 1 Pib PDFDocument6 pagesTDS 93 1 Pib PDFMohamed HashemNo ratings yet

- 21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Document28 pages21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Mehdi SoltaniNo ratings yet

- 05 02 18 Saturn Specifications 5.8Document1 page05 02 18 Saturn Specifications 5.8Jose FavaNo ratings yet

- CF Diverter Product Line: Diverter Solutions For Jackups and FloatersDocument4 pagesCF Diverter Product Line: Diverter Solutions For Jackups and FloatersiswantmachooNo ratings yet

- Lot 8 Dafora Appendix B Standards and Specifications DaforaDocument81 pagesLot 8 Dafora Appendix B Standards and Specifications DaforaZamfirMarianNo ratings yet

- Drilltech Services (USA) Inc: Spiro-TorqDocument10 pagesDrilltech Services (USA) Inc: Spiro-TorqDante Cabrera GuzmanNo ratings yet

- Drill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUDocument9 pagesDrill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUFernando Ruiz ArroyoNo ratings yet

- Top-Co - AutoFill - BV & HF ValvesDocument4 pagesTop-Co - AutoFill - BV & HF ValvesJuan LacorteNo ratings yet

- Cobra Kcobra MCDocument2 pagesCobra Kcobra MCEd CalheNo ratings yet

- 21 2000 Shaffer Bolted Annular Bop Spec SheetDocument1 page21 2000 Shaffer Bolted Annular Bop Spec SheetJoel SNo ratings yet

- Wenzel Motors Manual 2007Document102 pagesWenzel Motors Manual 2007Kevin MuellerNo ratings yet

- CDT Drill StringDocument19 pagesCDT Drill StringSohaib RashidNo ratings yet

- B2 Anchor Catcher Technical DatasheetDocument3 pagesB2 Anchor Catcher Technical DatasheetEvolution Oil ToolsNo ratings yet

- Casing Cup TesterDocument3 pagesCasing Cup TesterWei ShangNo ratings yet

- Properly Sizing Mud Gas Separator SystemsDocument2 pagesProperly Sizing Mud Gas Separator SystemsHIPAPNo ratings yet

- MKT 001 Rev 02 Rotary Shoulder Handbook RS PDFDocument116 pagesMKT 001 Rev 02 Rotary Shoulder Handbook RS PDFKarla Hernandez0% (1)

- ABS Fire and Safety Features For MODU - Part5Document40 pagesABS Fire and Safety Features For MODU - Part5Eyoma Etim100% (1)

- Cameron Hydraulic Gate Valves Type F & FCDocument3 pagesCameron Hydraulic Gate Valves Type F & FCJuan Sebastian Diaz CuadrosNo ratings yet

- CLE14000DPcerev9 09 PDFDocument139 pagesCLE14000DPcerev9 09 PDFAdhie WaelacxhNo ratings yet

- 1 - Basic Directional Drilling - PdsiDocument21 pages1 - Basic Directional Drilling - PdsiAgungRizkyNo ratings yet

- Drilling Levels 3 and 4 Syllabus PDFDocument35 pagesDrilling Levels 3 and 4 Syllabus PDFGOKUL PRASADNo ratings yet

- National Oilwell W600S OMEGA OPERATION MAINTENANCE MANUALDocument37 pagesNational Oilwell W600S OMEGA OPERATION MAINTENANCE MANUALariel feNo ratings yet

- Catálogo en Inglés PDFDocument76 pagesCatálogo en Inglés PDFBlue FairylandNo ratings yet

- 11"-5000psi Double Ram BOP ManualDocument64 pages11"-5000psi Double Ram BOP ManualDavid EskarousNo ratings yet

- Pipe Data Sheet with Dimensions and SpecificationsDocument1 pagePipe Data Sheet with Dimensions and Specifications087825550697No ratings yet

- Safety Clamp: Operation ManualDocument21 pagesSafety Clamp: Operation ManualDavid Venegas AndradeNo ratings yet

- Sprint CTU ContigencyPlanDocument32 pagesSprint CTU ContigencyPlanJawad Khan100% (1)

- 00-24 Proper Clamps Mud HoseDocument2 pages00-24 Proper Clamps Mud Hoseforajistu100% (1)

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- Drill Pipe Performance and SpecificationsDocument3 pagesDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pages5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- DPPSDocument2 pagesDPPSGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFStowartNo ratings yet

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pages5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- WS36-01 DPPSDocument2 pagesWS36-01 DPPSGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Garcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- Cable Fault DetectorDocument25 pagesCable Fault DetectorHarshalNo ratings yet

- GRI 2808-12V Data SheetDocument5 pagesGRI 2808-12V Data SheetJMAC SupplyNo ratings yet

- WTP - Opeation Engineer - GulfDocument2 pagesWTP - Opeation Engineer - GulfmaniyarasanNo ratings yet

- 8.1.4.7 Packet Tracer - Subnetting Scenario 1 PDFDocument4 pages8.1.4.7 Packet Tracer - Subnetting Scenario 1 PDFSyammirul RashidNo ratings yet

- Enable LDAPS On Windows IISDocument5 pagesEnable LDAPS On Windows IISFahad ShaikhNo ratings yet

- Ebook 042 Tutorial Spss Hierarchical Cluster AnalysisDocument17 pagesEbook 042 Tutorial Spss Hierarchical Cluster AnalysissnehaNo ratings yet

- 151819111846E17A-TSfor48V VRLA BatteryandBatteryCharger - 12042019 PDFDocument40 pages151819111846E17A-TSfor48V VRLA BatteryandBatteryCharger - 12042019 PDFakhilNo ratings yet

- Grago Instructions - Parts ListDocument36 pagesGrago Instructions - Parts ListAkram FerchichiNo ratings yet

- Seat Back PetitionDocument24 pagesSeat Back PetitionCBS Austin WebteamNo ratings yet

- Configure DHCP Option 43Document15 pagesConfigure DHCP Option 43Herbert Leon PascualNo ratings yet

- Data Link LayerDocument43 pagesData Link LayerVenkatakrishnan SubramaniyanNo ratings yet

- Astm A 956Document7 pagesAstm A 956Joshua Surbakti100% (1)

- tl082 Op Amp DatasheetDocument23 pagestl082 Op Amp DatasheetnurburgNo ratings yet

- Moc3061 MDocument8 pagesMoc3061 MFatih ArabacıNo ratings yet

- C AUDSEC 731 PDF Questions and AnswersDocument5 pagesC AUDSEC 731 PDF Questions and Answersflaviolink2466No ratings yet

- Sound Sources Used For Testing Open Office Components and SystemsDocument2 pagesSound Sources Used For Testing Open Office Components and SystemsNada KhlifNo ratings yet

- Pdvsa: Engineering Design ManualDocument7 pagesPdvsa: Engineering Design ManualRafael GarciaNo ratings yet

- Object Oriented Programming (OOP) - CS304 Power Point Slides Lecture 12Document35 pagesObject Oriented Programming (OOP) - CS304 Power Point Slides Lecture 12Sameer HaneNo ratings yet

- SmartCare SEQ Analyst V200R002C01 Web Service Quality Assessment and Optimization GuideDocument39 pagesSmartCare SEQ Analyst V200R002C01 Web Service Quality Assessment and Optimization Guidewangshupeng100% (3)

- December /2014 Addis Ababa: Responsibilities and Organizational Structure of Ethiopian Vital Events Registration AgencyDocument17 pagesDecember /2014 Addis Ababa: Responsibilities and Organizational Structure of Ethiopian Vital Events Registration Agencymohammed jemalNo ratings yet

- CV - Edson C Ayuste - Senior Instrument Engineer - March2018Document8 pagesCV - Edson C Ayuste - Senior Instrument Engineer - March2018Edson AyusteNo ratings yet

- Kim Lighting AFL2 Series Architectural Floodlights Brochure 1995Document32 pagesKim Lighting AFL2 Series Architectural Floodlights Brochure 1995Alan MastersNo ratings yet

- ADSL and Flavors in A NutshellDocument39 pagesADSL and Flavors in A Nutshellvsakthi1985100% (1)

- Telenor (Introduction)Document22 pagesTelenor (Introduction)Bilal SayalNo ratings yet

- 9 InsulatorDocument39 pages9 InsulatorLeo KhkNo ratings yet