Professional Documents

Culture Documents

Design and Development of Hydroelectric Gear Shifter

Uploaded by

IJARTETOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Development of Hydroelectric Gear Shifter

Uploaded by

IJARTETCopyright:

Available Formats

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 3, Issue 4, April 2016

Design and Development of Hydroelectric

Gear Shifter

S. Biju, R.Byju, A.Bergin, A.Binish Mon

Student, Mechanical Department, Bethlahem Institute of Engg, Karungal, Tamilnadu

Student, Mechanical Department, Bethlahem Institute of Engg, Karungal, Tamilnadu

Student, Mechanical Department, Bethlahem Institute of Engg, Karungal, Tamilnadu

Student, Mechanical Department, Bethlahem Institute of Engg, Karungal, Tamilnadu

Abstract: Main objective of this project is to provide an improved hydro-electric gear shifting mechanism which will

overcome the shortcomings of conventional gear changing mechanism. In conventional gear shifting mechanism, cables

and mechanical linkages are used. In the proposed project, we are using solenoid valves and hydraulic cylinders so

jamming and slipping is not possible. This proposed method is specially designed for rear engine vehicles or in vehicles in

which gear box is placed a bit away from the driver. The arrangement of switches in the gear shifting switch panel is as

follows: R (Reverse) N (Neutral) 1 2 3 4 5(Top). This mechanism shifts the gear in straight manner i.e. to

increase gear make the lever one step reverse and for decreasing one step forward. Neutral is placed before the first gear

and reverse is placed before neutral. In this method, the three shafts that control the synchronizer unit are coupled with

piston rods of three hydraulic cylinders. Each one of these hydraulic cylinders are connected with their respective solenoid

valves and these solenoid valves are connected with gear shifting switch panel.

Keyword: Gearshifter, Hydroelectric, Hydraulic cylinder, Reverse motion linkage, Solenoid valves.

I. INTRODUCTION

In modern world vehicles have become important

machine in humans daily life because it saves the time of travel

by reaching the target place very faster. Since the invention of

automobiles many new feature are introduced in order to

improve the user satisfaction. This project is designed in order

to overcome the shortcomings in the conventional gear

transmission system. Here conventional gear transmission

system is replaced by a hydroelectric gear transmission. The

name of this project is HYDROELECTRIC GEAR SHIFTER.

Nowadays each family has their own automobiles to make

transportation easier and faster. Gear transmission is one of the

major mechanisms present in the automobiles but there are lots

of shortcomings available in the conventional gear transmission

system that is used in most of the automobiles today. Todays

conventional system uses mostly mechanical linkages and

cables to transmit the motion from leaves to the gear shifting

shafts. But these systems have many shortcomings. When using

cables shipping in the gear transmission is possible and also

frequent application of lubricant is required and when using

mechanical linkages jamming during the gear transmission is

possible and periodic replacement of bush is required .Also both

of these methods are noisy . In order to overcome the

shortcoming in these methods hydroelectric gear shifter is

designed.

II. LITERATURE REVIEW

A. P.MasoomBasha, P.Nithesh Reddy (2014) Fabrication of

Pneumatic Gear Changer

According to suggested gear shifting method the

control unit chooses optimum gear shifting ratio for an

automobile without operating it manually using relays.

The two solenoid valves are connected to a compressor

with the help of hoses of 6mm from which pressurized air is

extracted. The solenoid valves are followed by two pneumatic

cylinders with the help of air hoses. The cylinders are followed

by a clutch pedal. Next to the clutch pedal gear box and a motor

arrangement is present. The construction also includes a

proximity sensor which senses the speed of the wheel. The

precise signals are sent to the solenoid valves by the control unit

through the relays. Therefore the input is speed of the wheel

sensed by a sensor and the output is shifting of gear accordingly.

The power to the control unit is supplied from the 12V battery.

On the other hand the shifting of gear can be monitored on an

LCD. It also consists of DC motor, ATMEGA Development

board, speed regulator (accelerator), transformer etc.

The compressor sends the pressurized air to the

solenoid valves through the hoses of 6mm diameter whereas the

solenoid valve acts as temporary storage of air and acts as

passage. The air from the solenoid valves passes to the

pneumatic cylinders which act as working medium for actuating

cylinders. When air enter into the cylinders the pistons starts

All Rights Reserved 2016 IJARTET

64

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 3, Issue 4, April 2016

reciprocating that is extraction and retraction. The retraction is

done manually by operating switches on the solenoid valves by

closing the air inlet. On the other hand the relays send the

precise signals to the solenoid valves. The input for these relays

is the speed of the wheel or vehicle which is sensed by sensor

proximate to the wheel. The shifting of gear is done by altering

the speeds by rotating the rotor in the speed regulating board

i.e., accelerator in case of automobile.

B. Tadashi Ichida, Akira Tsumiyama (2006) Hydraulic Gear

Shift Mechanism

A hydraulic gear shift mechanism for a bicycle having

a positioning mechanism for controlling the motion of the piston

of a master cylinder assembly is disclosed, wherein in the

master cylinder assembly is in communication with a slave

cylinder for operation of derailleur. The positioning mechanism

preferably includes a pivot soft spaced apart from the handle

bar, a rotating member rotatable about the pivot shaft, a push

mechanism for rotating the rotating member in a first direction

and a return mechanism for rotating the rotating member in a

second direction point in a more preferred embodiment of the

invention, an adjuster piston is threading the engaged with the

master cylinder assembly for adjusting the initial position of the

slave cylinder.

C. Ken Gilbert (2003) Electrohydraulic control system

The electrohydraulic control system for the

transmission and transfer consists of various sensors and

switches, a transmission control module (TCM) and the

hydraulic controlling units including solenoid valves. The

system controls the automatic transmission operation, including

gear shifting, lockup clutch operation, line pressure, automatic

control pattern selection (Base and Power), and gear-shift

timing. It also controls the operation of the transfer clutch. The

TCM determines vehicle operating conditions from various

input signals and controls a total of eight solenoids by sending

appropriate signals to them.

III. EXISTING METHOD

Since the invention of automobiles many changers and

new features are introduce in order to make them more efficient

and user friendly. Gear transmission system is one of those

systems that will periodically undergo changes to improve the

drivers satisfaction. Shifting the gears manually is the common

method available in the automobiles. But nowadays automatic

gear transmission systems, semi-automatic gear transmission

systems and electronically controlled gear transmission systems

are introduced in the automobiles to improve the gear shift

quality. Commonly in gear transmission systems the following

two methods are used to carry motion from lever to gear box.

Cables

Rod Linkages

But there are many disadvantages are present in both of these

methods that are making them difficult to use.

A. Cables

These cables are designed to replace the maintenance

prone rod linkages commonly used in cab over trucks and rear

engine buses. Cables in manual transmission is introduced to

make the gear shifting easier for both the vehicle builder and

operator. This system provides cost effective and less

maintenance manual transmission shifting. This system is

commonly used in tractors, loaders, agricultural sprayers. But

this system also have some shortcomings.

B. Rod Linkages

There are two types of shift linkages used on manual

transmissions. They are the external rod and the internal shift

rails. They both perform the same function. They connect the

shift lever with the shift fork mechanism. The transmission shift

lever assembly can be moved to cause movement of the shift

linkage, shift forks, and synchronizers. The shift lever may be

either floor mounted or column mounted, depending upon the

manufacturer. Floor-mounted shift levers are generally used

with an internal shift rail linkage, whereas column-mounted

shift levers are generally used with an external rod linkage.

IV. CURRENT PROJECT

In our project we have introduced combined electronic

and hydraulic system for gear transmission instead of

mechanical linkages and cables. This decreases the wear and

tear produced by the linkages and hence the life of the system

gets increased.

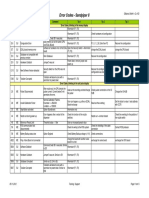

a) Hydraulic circuit

In the hydraulic system, the hydraulic flow starts with

reservoir and ends with hydraulic cylinder. In the reservoir noncompressible hydraulic fluid is stored at atmospheric pressure.

The pump sucks the fluid from the reservoir. The fluid from the

reservoir is filtered before it is entered into the pump through

filter. The pump increases the pressure of the fluid to 150 bar.

The variable Pressure relief valve send back the fluid to the

reservoir when the pressure of the fluid goes beyond 150 bar.

The function of splitter is, it gets a single input and produce

multiple outputs. These outputs are with same pressure and it is

given as the input for DC solenoid valves.The 4/3 DC solenoid

valve controls the flow direction of the fluid to the cylinder. The

DC solenoid valve consists of four ports and three directions. To

All Rights Reserved 2016 IJARTET

65

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 3, Issue 4, April 2016

bring back the piston to normal position, a spring is welded

inside the cylinder and it will retard automatically to make the

neutral gear.

b) Electric circuit

In the electric circuit 240v ac power source is used in

this system to run the motor. A step down transformer is used to

convert the 240v ac to 110v ac current. This 110v power source

is given to the switch. Each solenoid valves are controlled by the

output from the switch. The switch is controlled by gear lever.

V. CALCULATION

1. Calculation of load and pressure

Load due to gear lever and fork=3 kg

Load given to the spring to deflect 2 cm =15 kg

Total load= 15+3=18 kg

=189.81

=176.58 N

Pressure=

Area of cylinder= 2

4

= (5 102 )2

4

Area of cylinder= 1.963103 2

176.58

Pressure=

1.96103

= 89931.45 N/2

= 0.89931 105 N/2

= 0.899 bar

Take factor of safety as 20

Maximum pressure = 0.89920

= 17.98 bar

2. Design of spring

Load P = 15 kg

= 147.15 N

Deflection = 20 mm

Material = High carbon steel

Working stress = 430 N/2

Modulus of elasticity E = 2.0 105 N/2

Modulus of rigidity G = 0.85105 N/2

Spring index C = 15

8

Stress =

2

2=

d(

)1/2

K Wahls shear stress factor

41 0.615

K=

+

44

4151

0.615

K=

+

4154

15

K = 1.0902

81.091515

d(

)

430

d 1.458 mm

The standard diameter above 1.458 mm is d= 1.63

Standard wire gauge number is SWG16

C= 15 =

D= 151.63

D= 24.45 mm

Mean diameter of coil= 24.45 mm

Outer diameter of coil= D + d

= 24.45+1.63= 26.08 mm

Inner diameter of coil = D d

=24.45 1.63 = 22.82 mm

Deflection =

n=

8 3

8 3

200.83105 1.63

n=

815153

n = 6.84

n = 7 turns

Free length of spring = n d + (n-1) gap btw adj coil

Assuming gap between adjacent coil = 5

= 7 1.63 + (7-1) 5

= 41.41 mm

Pitch =

41.41

=

71

Pitch = 6.96 mm

Type: open coil helical spring

Wire diameter d = 1.63 mm

Wire gauge number = SWG16

Diameter of coil = 24.45 mm

Number of turns = 7 nos

Free length = 41.41 mm

Pitch = 6.96 mm

3. Design of hydraulic cylinder

Free length of spring = 41.41 mm

Number of spring = 2

Total length of spring = 41.41 2

= 82.82 mm

Length of cylinder = 100 mm

Piston thickness = 30 mm

Stroke length = length of cylinder piston thickness

= 100 30

All Rights Reserved 2016 IJARTET

66

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 3, Issue 4, April 2016

Reservoir (LP

fluid)

Stroke length = 70 mm

Maximum pressure = 0.899 bar

Load = 18 kg = 176.58 N

Pressure =

176.58

Area =

0.899105

= 1.957 103

2 = 1.957 103

4

Pump

1.957 103 4

2 =

2 = 2.492 103

d = 0.0499 = 49.9 m

Diameter of cylinder = 49.9 mm

Stroke length of cylinder = 70 mm

Splitter (HP

fluid)

Pressure

relief valve

4. Frame calculation

Length of frame = length of (cylinder+ valves+ pump+

gearbox+ clearance)

Length of cylinder with piston rod = 25 cm

Length of valve 20 cm

Length of pump = 20 cm

Length of gearbox = 35 cm

(+ + + )

Clearance =

25+20+20+35

4/3 DC

Solenoid

valve 1

4/3 DC

Solenoid

valve 2

4/3 DC

Solenoid

valve 3

Cylinder 1

Cylinder 2

Cylinder 3

=

2

Length of frame = 25+20+20+35+50

=150 cm = 1.5 m

Width of frame = width of 3 cylinder + clearance

= 103+15

= 45 cm

VI. WORKING

The working of hydroelectric gear shifter is given

through the flowchart below. A 240v AC current is given to the

motor which runs the pump. Pump converts the uncompressed

fluid that stored in the reservoir to the highly compressed liquid.

These compressed liquid is transmitted towards the three

solenoid valves by using splitter. These solenoid valves are

operated at the power range of 110v ac current. For using

solenoid valve 240v ac should be converted into 110v dc, for

this purpose step down transformer is used. These solenoid

valves are controlled by switches placed in the switching panel.

Switching panel consists of 7 switches, each solenoid valves are

controlled by two switches and one is for neutral.

Exten

d (1st

gear)

Retard

(Reverse gear)

All Rights Reserved 2016 IJARTET

Exten

d (2nd

gear)

Retar

d (3rd

gear)

Exten

d (4th

gear)

Retar

d (5th

gear)

Center position

(Neutral gear)

67

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 3, Issue 4, April 2016

Solenoid valve consists of four ports, they are

1)

2)

3)

4)

Pressure port

Tank port

Cylinder port A

Cylinder port B

The pressure port is connected to the splitter; tank port

is connected to the reservoir. Both the cylinder ports are

connected to the respective positions in the cylinder. Gear box

consists of four gear shifting shafts to change the gear. 2 nd and

3rd gears are controlled by one shaft and 4th and 5th gears are

controlled by another shaft. Both the first and the reverse gears

have independent shafts and share the same hydraulic cylinder.

The 2D and the3D design of project is given below.

VII.

CONCLUSION

Thus the design and assembling of Hydroelectric gear

shifter is successfully done. This project is particularly

implemented for rear engine vehicles and the result was found to

be positive. This proposed method is capable of shifting the gear

in straight manner thus increases the quality of gear shift and

operator satisfaction. In conventional gear shifting method many

shortcomings are present due to the use of cables and rod

linkages. In this proposed system we are not using rod linkages

or cables. So the gear shifting process can be performed much

smoother. Also this project can be implemented without the

presence of mechanical linkages in case of commercial usage,

thereby avoiding friction that occurs due to mechanical linkages.

This proposed method is complex when comparing with

conventional methods that uses cables and rod linkages. But this

proposed system produces significant amount of advantages

such as no slipping, no jamming over the conventional gear

shifting methods.

REFERENCE

[1]. Frank Owen (2008) Electronic Transmission Control

[2]. Mustafa, Rashad (2010) Modelling and Analysis of the Electrohydraulic

and Driveline Control of a Dual Clutch Transmission

[3]. Roshan.S.Hubly (2009) Development of Push Button Operated Shifting

Lever Mechanism

[4]. P.Masoom Basha, P.Nithesh Reddy (2014) Fabrication of Pneumatic Gear

Changer

[5]. M.S.Kumbhar (2014) A Literature Review on Automated Manual

Transmission

[6]. Kei-Lin Kuo (2011) Simulation and Analysis of the Shift Process for an

Automatic Transmission

[7]. James.E.Erickson (2006) Hydraulically Assisted Gear Shift Mechanism

for a Marine Propulsion Device

[8]. Tadashi Ichida, Akira Tsumiyama (2006) Hydraulic Gear Shift

Mechanism

[9]. Ken Gilbert (2003) Electrohydraulic control system

[10]. Maurizio Uberti (2010) Electro-hydraulic control system for a motorvehicle dual-clutch transmission

[11]. Michinobu Suzuki, Masahiko Hayashi (2003) Gear Change Device

[12]. Yong Zheng, Xinghui Lian (2011) Gear Shifting Mechanism for the

Vehicle Automatic Transmission

[13]. Yasushi Yamamoto (2004) Gear Change Device

[14]. Robert A Dejonge, Stephen D Wexall (2001) External electronic

transmission shift system

[15]. Norbert Esly, Jens Benndorf (2003) Motor vehicle with gearbox

All Rights Reserved 2016 IJARTET

68

You might also like

- Tech Vivasayi Mobile ApplicationDocument3 pagesTech Vivasayi Mobile ApplicationIJARTETNo ratings yet

- Complaint Box Mobile ApplicationDocument4 pagesComplaint Box Mobile ApplicationIJARTETNo ratings yet

- Smart Water Management System Using IoTDocument4 pagesSmart Water Management System Using IoTIJARTETNo ratings yet

- Wireless Notice Board With Wide RangeDocument5 pagesWireless Notice Board With Wide RangeIJARTETNo ratings yet

- Comparative Harmonics Analysis of ThreeDocument8 pagesComparative Harmonics Analysis of ThreeIJARTETNo ratings yet

- Non Invasive Blood Glucose Monitoring ForDocument4 pagesNon Invasive Blood Glucose Monitoring ForIJARTETNo ratings yet

- Ready To Travel ApplicationsDocument4 pagesReady To Travel ApplicationsIJARTETNo ratings yet

- Smart Farm Management System For PrecisionDocument5 pagesSmart Farm Management System For PrecisionIJARTETNo ratings yet

- Real Time Dynamic Measurements andDocument6 pagesReal Time Dynamic Measurements andIJARTETNo ratings yet

- Makeover Features Base Human IdentificationDocument7 pagesMakeover Features Base Human IdentificationIJARTETNo ratings yet

- Optimized Design and Manufacturing of WasteDocument5 pagesOptimized Design and Manufacturing of WasteIJARTETNo ratings yet

- Behaviour of Concrete by Using DifferentDocument3 pagesBehaviour of Concrete by Using DifferentIJARTETNo ratings yet

- Privacy Preservation of Fraud DocumentDocument4 pagesPrivacy Preservation of Fraud DocumentIJARTETNo ratings yet

- Object Detection and Alerting System inDocument4 pagesObject Detection and Alerting System inIJARTETNo ratings yet

- Hygienic and Quantity Based WaterDocument10 pagesHygienic and Quantity Based WaterIJARTETNo ratings yet

- Experimental Investigation On Concrete WithDocument18 pagesExperimental Investigation On Concrete WithIJARTETNo ratings yet

- A High-Availability Algorithm For HypercubeDocument8 pagesA High-Availability Algorithm For HypercubeIJARTETNo ratings yet

- Exam Seating ArrangementDocument3 pagesExam Seating ArrangementIJARTETNo ratings yet

- Study of Hypotenuse Slope of Chandrayaan-2 While Landing On The Moon SurfaceDocument3 pagesStudy of Hypotenuse Slope of Chandrayaan-2 While Landing On The Moon SurfaceIJARTETNo ratings yet

- Wireless Cardiac Patient Monitoring SystemDocument6 pagesWireless Cardiac Patient Monitoring SystemIJARTETNo ratings yet

- A Novel Artificial Neural Network and 2dPCABasedDocument9 pagesA Novel Artificial Neural Network and 2dPCABasedIJARTETNo ratings yet

- Application of Computer Vision in HumanDocument6 pagesApplication of Computer Vision in HumanIJARTETNo ratings yet

- A Non Threshold Based Cluster Head RotationDocument7 pagesA Non Threshold Based Cluster Head RotationIJARTETNo ratings yet

- Review On Field Testing of Protective RelaysDocument4 pagesReview On Field Testing of Protective RelaysIJARTETNo ratings yet

- Smart Door Using Raspberry PiDocument4 pagesSmart Door Using Raspberry PiIJARTETNo ratings yet

- Power Transformer Explained PracticallyDocument4 pagesPower Transformer Explained PracticallyIJARTETNo ratings yet

- Insect Detection Using Image Processing and IoTDocument4 pagesInsect Detection Using Image Processing and IoTIJARTETNo ratings yet

- Face Detection and Recognition Using Eigenvector Approach From Live StreamingDocument5 pagesFace Detection and Recognition Using Eigenvector Approach From Live StreamingIJARTETNo ratings yet

- Fire Detection and Alert System Using Convolutional Neural NetworkDocument6 pagesFire Detection and Alert System Using Convolutional Neural NetworkIJARTETNo ratings yet

- Review On Recycled Aluminium Dross and It's Utility in Hot Weather ConcretingDocument3 pagesReview On Recycled Aluminium Dross and It's Utility in Hot Weather ConcretingIJARTETNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Catalase TestDocument2 pagesCatalase TestsekaralingamNo ratings yet

- 10 STD Specifications - Building - 2018 (A1)Document902 pages10 STD Specifications - Building - 2018 (A1)Logan LiNo ratings yet

- Na-S BatteryDocument12 pagesNa-S Batterymeseret simachewNo ratings yet

- Water Supply Sanitary Eng PDFDocument5 pagesWater Supply Sanitary Eng PDFReddy NaveenNo ratings yet

- Mx37y Technical DescriptionDocument38 pagesMx37y Technical DescriptionVladimir PeshicNo ratings yet

- Parts Crane Hitachi FK600 - PRDocument2 pagesParts Crane Hitachi FK600 - PRDefly Gusti100% (1)

- Wave-Particle Duality FundamentalsDocument7 pagesWave-Particle Duality FundamentalsRahmatullahNo ratings yet

- SUNSLATES™ 6 PV Roof Tile - Award Winning Architectural AppealDocument2 pagesSUNSLATES™ 6 PV Roof Tile - Award Winning Architectural AppealFaeria20No ratings yet

- Training Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IIDocument5 pagesTraining Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IICharlie ShowNo ratings yet

- Quat KrugerDocument52 pagesQuat Krugerruby0808No ratings yet

- 66 KV Design Parameters in GujaratDocument1 page66 KV Design Parameters in GujaratAkhilesh SolankiNo ratings yet

- Screw Compressor 6C1 Series 185S 185SRDocument79 pagesScrew Compressor 6C1 Series 185S 185SRthuan100% (1)

- FCRR19 (6) Kirkwood Matura-ShepherdDocument5 pagesFCRR19 (6) Kirkwood Matura-ShepherdRuslan ZakirovNo ratings yet

- An Impedance Source Multi-Level Three Phase Inverter With Common Mode Voltage Elimination and Dead Time CompensationDocument18 pagesAn Impedance Source Multi-Level Three Phase Inverter With Common Mode Voltage Elimination and Dead Time CompensationRadu GodinaNo ratings yet

- 30 International Cablemakers Federation Schroth PDFDocument25 pages30 International Cablemakers Federation Schroth PDFsajuaanalsaNo ratings yet

- Atomic Nucleus Facts and ConceptsDocument24 pagesAtomic Nucleus Facts and ConceptsKashyap PatelNo ratings yet

- Cooling Tower Research PaperDocument13 pagesCooling Tower Research PaperBhaskar KumarNo ratings yet

- Water Wash Procedure For EconomizerDocument3 pagesWater Wash Procedure For EconomizerRajendra100% (1)

- Igcse Economic Activity Revision PackDocument24 pagesIgcse Economic Activity Revision Packapi-232441790100% (2)

- Altronics DD Annunciator BLLTN 07-1996 PDFDocument4 pagesAltronics DD Annunciator BLLTN 07-1996 PDFSMcNo ratings yet

- F0358 CMM 010Document164 pagesF0358 CMM 010MJI EUWNo ratings yet

- Wires and Cables PDFDocument14 pagesWires and Cables PDFRomel Panis88% (8)

- Power Electronics For Renewable Energy Systems PDFDocument160 pagesPower Electronics For Renewable Energy Systems PDFSUSHITANo ratings yet

- IPL, Briggs, 14B907-0110-B1, 950 Series, EngineDocument25 pagesIPL, Briggs, 14B907-0110-B1, 950 Series, EngineGiacomo DesideriNo ratings yet

- Luminous PDFDocument1 pageLuminous PDFKushal AkbariNo ratings yet

- Nseallcompanies 31122020Document78 pagesNseallcompanies 31122020guy fawkesNo ratings yet

- Exercise 8-Life ScienceDocument2 pagesExercise 8-Life ScienceKarinaNo ratings yet

- Compressor Station MallnowDocument8 pagesCompressor Station MallnowMANIU RADU-GEORGIANNo ratings yet

- AD534Document12 pagesAD534Vaibhav GaurNo ratings yet

- Heat Exchangers of PolypropyleneDocument2 pagesHeat Exchangers of PolypropyleneTan So100% (1)