Professional Documents

Culture Documents

Pehp0002 02

Uploaded by

Manuel Moreno GalarzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pehp0002 02

Uploaded by

Manuel Moreno GalarzaCopyright:

Available Formats

Cat Advanced 3Moly Grease

For grease fittings and lubrication points in medium-load and medium-speed applications.

Recommended Use

Cat Advanced 3Moly Grease is recommended for grease fittings and lubrication points

in medium-load and medium-speed applications with ambient temperatures ranging

from 20 to 40 C (4 to 104 F).

Discover the Difference

Cat Advanced 3Moly Grease is developed, tested and approved by Caterpillar to meet

the same high standards as Genuine Cat Parts.

Factory-FillUsed as standard factory-fill for most Cat machines.

Long LifeLithium based and enhanced with 3% molybdenum disulfide (moly),

Cat Advanced 3Moly Grease is an excellent grease for Cat applications where

speed, load and temperature are moderate and moisture is low.

Reduced Component WearResists softening and protects parts from wear.

Corrosion ProtectionResists oxidation and protects metal against rust. Will not

corrode or damage steel, copper bearing alloys or conventional seal materials.

NLGI Grade 2

Cat Advanced 3Moly Grease

Grease Selection Guide*

Cat Ultra 5Moly Grease

NLGI 1

(-35 to 40C / -31 to 104F)

Cat Desert Gold Grease

NLGI 2

(Temp up to 60C / 140F)

With 5% moly

With 5% moly

Cat Ultra 5Moly Grease

NLGI 2

(-30 to 50C / -22 to 122F)

High Load

Low Temp

Without moly

Cat Multipurpose Grease

NLGI 2

(-30 to 40C / -22 to 104F)

With 5% moly

High Temp

Cat High Speed Ball Bearing Grease

NLGI 2

(Temp above -20C / -4F)

With 3% moly

Cat Arctic Platinum Grease

NLGI 0

(Temp down to -50C / -58F)

With 5% moly

Working

Environment

Cat Advanced 3Moly Grease

NLGI 2

(-20 to 40C / -4 to 104F)

Without moly

Medium Load

Low Load

Low Load

And High Speed

*All temperatures are ambient.

Typical Characteristics*

NLGI #

Ambient Range

Operating Range

Base Fluid Type

Thickener Type

Color

% Molybdenum disulfide

Worked Penetration (mm)

% Change/100,000 stroke

Roll Stability w/H2O, % change

Viscosity Index, Min

Viscosity @ 100 C, cSt

Viscosity @ 40 C, cSt

4 Ball Wear (mm) Max, Typ.

4 Ball E.P. Weld Point (kg) Min.

Timken E.P. Test OK load (lb) Typ.

Oxidation psi drop/500 hr Max

Rust Test

Salt Fog Test, hours

Copper Corrosion

Dropping Point

2

20 to +40 C/4 to +104 F

21 to +149 C/5 to +300 F

Petroleum

Lithium Complex

Gray

3

265-295

10 Max

N/A

N/A

22

320

0.55

315

55*

N/A

Pass

N/A

1b

+260 C (+500 F)

*The values shown are typical values and should not be used as quality control parameters to either

accept or reject product. Specifications are subject to change without notice.

CAT DEALERS DEFINE WORLDCLASS PRODUCT SUPPORT.

We offer you the right parts and service

solutions, when and where you need them.

The Cat Dealer network of highly trained

experts keeps your entire fleet up and running

to maximize your equipment investment.

PEHP0002-02

www.cat.com

2007 Caterpillar All Rights Reserved Printed in USA

CAT, CATERPILLAR, their respective logos, Caterpillar Yellow and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

Health and Safety

For information on proper use for

health, safety, and environment,

please refer to the Material Safety

Data Sheet (MSDS). Read and

understand the MSDS before using

this product. Always observe good

hygiene measures. For a copy of the

MSDS, contact us or visit the web

at www.catmsds.com.

You might also like

- Site Preparation and Earth WorkDocument31 pagesSite Preparation and Earth WorkGerobak Gaya100% (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Exploratory ResearchDocument13 pagesExploratory ResearchisrazargarNo ratings yet

- Grasa Multiproposito CatDocument2 pagesGrasa Multiproposito Catrolex21No ratings yet

- Cat Desert Gold GreaseDocument2 pagesCat Desert Gold GreaseAnibal RiosNo ratings yet

- Cat Ulrta 5moly GreaseDocument2 pagesCat Ulrta 5moly GreaseYvan Vidal Calapuja MachacaNo ratings yet

- Arctic PlatinumDocument2 pagesArctic PlatinumAndresan507100% (1)

- Cat Grease 5% MolyDocument2 pagesCat Grease 5% MolycatoeraleifNo ratings yet

- (Grade 1.5) GR181-EN-Timken-Spec-SheetDocument2 pages(Grade 1.5) GR181-EN-Timken-Spec-SheetnacerNo ratings yet

- Cat Extreme Application Grease DesertDocument2 pagesCat Extreme Application Grease DesertAnibal Rios50% (2)

- GR180 EN Timken Spec SheetDocument2 pagesGR180 EN Timken Spec SheetThe WorshipperNo ratings yet

- TDTO 10W Ulei Transmisie CaterpillarDocument2 pagesTDTO 10W Ulei Transmisie CaterpillarCorina Stanculescu0% (1)

- Valvoline Heavy Duty TDL PRO 75W-90-PI SheetDocument2 pagesValvoline Heavy Duty TDL PRO 75W-90-PI SheetJUAN BAUTISTANo ratings yet

- Grease 082504referenceDocument6 pagesGrease 082504referencesmhea123No ratings yet

- Grasa Cat Advanced 3moly PDFDocument1 pageGrasa Cat Advanced 3moly PDFJorgeLuisRodriguezAguilarNo ratings yet

- Oil DatasheetDocument2 pagesOil DatasheetF.Nicolas LanciaultNo ratings yet

- She Tds TherbDocument2 pagesShe Tds TherbNhu Kien PhamNo ratings yet

- TDS MHT GreaseDocument2 pagesTDS MHT GreaseAntonio DávilaNo ratings yet

- Torlon Processing and PostprocessingDocument26 pagesTorlon Processing and Postprocessingfrox123No ratings yet

- Shell Thermia BDocument2 pagesShell Thermia Bsegunoyes100% (1)

- Heat Transfer OilDocument2 pagesHeat Transfer OilDony LieNo ratings yet

- Statoil LoadWay EP 100Document2 pagesStatoil LoadWay EP 100mstan11No ratings yet

- Statoil LoadWay EP 220Document2 pagesStatoil LoadWay EP 220mstan11No ratings yet

- 76 Grasa Megaplex XD3Document2 pages76 Grasa Megaplex XD3Gustavo De Haro GonzálezNo ratings yet

- 1540 Gulf Superfleet Supreme 15W 40Document1 page1540 Gulf Superfleet Supreme 15W 40RezaNo ratings yet

- Mobiltemp Series Product Data SheetDocument3 pagesMobiltemp Series Product Data SheetRonaldo RossiNo ratings yet

- Castrol Spheerol EPLDocument2 pagesCastrol Spheerol EPLDiego GalvanNo ratings yet

- Eastman 2197 Turbo-Oil TDS - SkySupplyUSADocument2 pagesEastman 2197 Turbo-Oil TDS - SkySupplyUSASkySupplyUSANo ratings yet

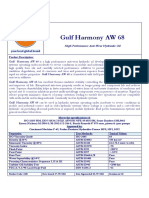

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 DataHitesh MahajanNo ratings yet

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 Datakatty_89No ratings yet

- GL XX Mobiltemp SHC SeriesDocument3 pagesGL XX Mobiltemp SHC Seriestatoddo2017No ratings yet

- Cat TdtoDocument2 pagesCat TdtoAhmed GhonimyNo ratings yet

- Arcanol SPEED2,6: FAG Rolling Bearing GreaseDocument1 pageArcanol SPEED2,6: FAG Rolling Bearing GreaseDwika YanuariNo ratings yet

- AmsoilSyntheticOilProductInfo SheetsDocument2 pagesAmsoilSyntheticOilProductInfo Sheetsapi-19921780No ratings yet

- Texamatic 7045EDocument3 pagesTexamatic 7045EIgor MitrovićNo ratings yet

- Technical Data: Protective Grease For Overhead Line ConductorsDocument3 pagesTechnical Data: Protective Grease For Overhead Line ConductorssreedharNo ratings yet

- Tech Data: Turbonycoil 600 L B A G T FDocument2 pagesTech Data: Turbonycoil 600 L B A G T FJeremias UtreraNo ratings yet

- Mirr T-Cross 4T Api SM CF Sae 15W-40 TDSDocument2 pagesMirr T-Cross 4T Api SM CF Sae 15W-40 TDSAbdul GhafoorNo ratings yet

- Aeroshell Grease 58: Main ApplicationsDocument2 pagesAeroshell Grease 58: Main ApplicationsSophia RoseNo ratings yet

- TorqGear SeriesDocument1 pageTorqGear SeriesSameh RadwanNo ratings yet

- Hilubric Ep 0Document1 pageHilubric Ep 0ANILNo ratings yet

- Pehj0030-03 Cat GoDocument2 pagesPehj0030-03 Cat GoJorge A. Paredes RodriguezNo ratings yet

- 300V Chrono 10W-40: Racing Lubricant For Racing Cars 100% Synthetic - Double Ester TechnologyDocument1 page300V Chrono 10W-40: Racing Lubricant For Racing Cars 100% Synthetic - Double Ester TechnologyGus VergaraNo ratings yet

- Komatsu OilsDocument200 pagesKomatsu OilsBrian Careel100% (1)

- Pds Etro 4plus 2022.01Document1 pagePds Etro 4plus 2022.01Samee84No ratings yet

- Petrotherm Heat Transfer FluidsDocument4 pagesPetrotherm Heat Transfer FluidsderekfisherNo ratings yet

- Mobilgear SHC 3200 6800 PdsDocument2 pagesMobilgear SHC 3200 6800 PdsMohamed SalemNo ratings yet

- High Temperature-Grease-pds-EngDocument3 pagesHigh Temperature-Grease-pds-Engdavide comuzziNo ratings yet

- Shell Turbo Oil T 32 TDSDocument2 pagesShell Turbo Oil T 32 TDSBahim BahimanNo ratings yet

- Oli Energol GR-XPDocument2 pagesOli Energol GR-XPakun leptopNo ratings yet

- Gpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) TdsDocument3 pagesGpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) Tds100impianNo ratings yet

- Gpcdoc Sa Tds ThermiaDocument2 pagesGpcdoc Sa Tds ThermiaAbdelrahman MagdyNo ratings yet

- Lithium Complex Ep GreaseDocument1 pageLithium Complex Ep GreaseRandi Riki AdtiaNo ratings yet

- Castrol Molub-Alloy 243 ArcticDocument2 pagesCastrol Molub-Alloy 243 ArcticMaciejNo ratings yet

- Triton 5005 EXDDocument3 pagesTriton 5005 EXDCarlosNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesFrom EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesRating: 1 out of 5 stars1/5 (1)

- Motor de 10 Cil en V PDFDocument2 pagesMotor de 10 Cil en V PDFManuel Moreno GalarzaNo ratings yet

- Ford WSG1068 Spec Sheet PDFDocument2 pagesFord WSG1068 Spec Sheet PDFManuel Moreno GalarzaNo ratings yet

- Ford WSG1068 Spec Sheet PDFDocument2 pagesFord WSG1068 Spec Sheet PDFManuel Moreno GalarzaNo ratings yet

- Ford WSG1068 Spec Sheet PDFDocument2 pagesFord WSG1068 Spec Sheet PDFManuel Moreno GalarzaNo ratings yet

- Ros Merci To PoeDocument1 pageRos Merci To PoeManuel Moreno GalarzaNo ratings yet

- Instrucciones Distribuidor SB12-LSDocument28 pagesInstrucciones Distribuidor SB12-LSbenjamin100% (1)

- Cs Fet Ee Btech PDFDocument108 pagesCs Fet Ee Btech PDFrakshitNo ratings yet

- Habitat International: Nesru H. Koroso, Monica Lengoiboni, Jaap A. ZevenbergenDocument15 pagesHabitat International: Nesru H. Koroso, Monica Lengoiboni, Jaap A. ZevenbergenSG GhoshNo ratings yet

- Compressive Strength of Mortar CubesDocument10 pagesCompressive Strength of Mortar CubesPablo Gomes0% (1)

- Long-Range Thermal Video Imaging System: Multiple Mission Profiles. One Reliable SolutionDocument3 pagesLong-Range Thermal Video Imaging System: Multiple Mission Profiles. One Reliable Solutionsquad bravoNo ratings yet

- Pipe Earthing 8Document2 pagesPipe Earthing 8raghavendran raghu75% (4)

- Lab Equipment Worksheet: FlameDocument6 pagesLab Equipment Worksheet: FlameSabu LazerNo ratings yet

- Enhancing Institutional Mechanism Forum 1: Changing The Context by Jerolet SahagunDocument2 pagesEnhancing Institutional Mechanism Forum 1: Changing The Context by Jerolet SahagunEJ Henz SahagunNo ratings yet

- Iso 10684 PDFDocument27 pagesIso 10684 PDFAliceNo ratings yet

- Laboratory Exercise in Computer FundamentalsDocument2 pagesLaboratory Exercise in Computer FundamentalsGwenn PosoNo ratings yet

- Condensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDocument8 pagesCondensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajNo ratings yet

- Romi Oop 05 Javadatabase 1mei2011Document78 pagesRomi Oop 05 Javadatabase 1mei2011Nora AsteriaNo ratings yet

- Assam Power Distribution Company LTDDocument7 pagesAssam Power Distribution Company LTDkabuldasNo ratings yet

- Kta19 G3Document2 pagesKta19 G3ryan fernandezNo ratings yet

- Mangesh PatilDocument3 pagesMangesh Patilcrushboy18No ratings yet

- Welcome To OU Training!: Key Event DetailsDocument4 pagesWelcome To OU Training!: Key Event Detailsaercio manuelNo ratings yet

- 06 Earth - Quake - Tips PDFDocument55 pages06 Earth - Quake - Tips PDFMaheshbabu CheetakoruNo ratings yet

- Telephone Dir.Document1 pageTelephone Dir.Sandeep PasumarthiNo ratings yet

- Hyundai ManualDocument25 pagesHyundai ManualDavor Profesor89% (18)

- Suffolk Library Consultation ResponsesDocument3,050 pagesSuffolk Library Consultation ResponsesjehargraveNo ratings yet

- Some Observations and Experience With Pile Integrity Testing at Various Projects For EssarDocument5 pagesSome Observations and Experience With Pile Integrity Testing at Various Projects For EssarKausik DewanNo ratings yet

- Seagate Part21 Family f3Document52 pagesSeagate Part21 Family f3OmegalexNo ratings yet

- SOG F5 PWR Silo Fire FightingDocument9 pagesSOG F5 PWR Silo Fire FightingGothandaraman Muthu ManickamNo ratings yet

- PacketDocument10 pagesPacketapi-248057958No ratings yet

- International MarketingDocument77 pagesInternational MarketingSaki HussainNo ratings yet

- Integrated Management Systems Manual Without Company RefDocument17 pagesIntegrated Management Systems Manual Without Company ReflkjhiuhNo ratings yet

- Rubber TechDocument35 pagesRubber TechThang CaoNo ratings yet