Professional Documents

Culture Documents

Experimental Elastic Stress Analysis of Partial Penetration Welded Nozzle

Uploaded by

Andres_Pastor1987Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental Elastic Stress Analysis of Partial Penetration Welded Nozzle

Uploaded by

Andres_Pastor1987Copyright:

Available Formats

NUCLEAR ENGINEERING AND DESIGN 7 (1968) 73-86.

NORTH-HOLLAND PUBLISHING COMPANY, AMSTERDAM

EXPERIMENTAL ELASTIC STRESS ANALYSIS

OF PARTIAL PENETRATION WELDED NOZZLES

IN A SPHERICAL SHELL

E. P R O C T E R

and R. F. F L I N D E R S

Central Electricity Generating Board,

Berkeley Nuclear Laboratories,

Berkeley, Glos., England

Received 12 May 1967

The initial stage of a test programme to investigate, in detail, the behaviour of radial and oblique

nozzle junctions in spherical shells, has been completed. Although this stage was designed to investigate elastic and elastic/plastic behaviour at ambient temperature, this report describes the elastic

analysis only.

Three basic designs of through nozzles were investigated, one of each design mounted radially and

the other at 45 obliquity. Four hundred E.R. strain gauges were fixed on the inner and outer surfaces

of the shell plate and nozzles and optical equipment was set up to measure tilt of the nozzles. For the

purpose of this elastic test the vessel was hydraulically pressurized to 240 psig.

Stress distributions in the form of stress concentration factors (SCF = stress magnitude divided by

the corresponding stress in an unpiereed sphere of the same radius and thickness) are shown for the

individual nozzles. Maximum values of SCF and 'equivalent' stress are shown plotted against the ratio

of nozzle thickness to nozzle internal diameter, for both radial and oblique cases.

Comparisons are made with nozzles designed according to BS.1500 and BS.3915, and the limitations

of elastic design methods allowing limited plasticity are demonstrated and discussed in the report.

1. INTRODUCTION

O p e r a t i o n a l i n f o r m a t i o n of p r e s s u r e c i r c u i t

c o m p o n e n t s on n u c l e a r and m o d e r n high e f f i c i e n c y

conventional plant i s s t i l l e x t r e m e l y l i m i t e d .

E a r l y work at B e r k e l e y N u c l e a r L a b o r a t o r i e s ,

on m o d e l v e s s e l s containing standpipe n o z z l e

c l u s t e r s and cylindrlLcal s u p p o r t s k i r t s , p r o v i d e d

a b a s i c u n d e r s t a n d i n g of g e o m e t r i c a l e f f e c t s on

v e s s e l s s u b j e c t e d to p r e s s u r e alone and p r e s s u r e

and t e m p e r a t u r e combined. H o w e v e r , in o r d e r to

modify e x i s t i n g p a r a m e t e r s to a c h i e v e m o r e

e c o n o m i c a l d e s i g n s ,.and to p r e d i c t m o r e a c c u r a t e l y

the working life of e x i s t i n g n u c l e a r plant, c o m p o nents m u s t be studied in g r e a t e r d e ta il .

Throughout the C e n t r a l E l e c t r i c i t y G e n e r a t i n g

B o a r d much e f f o r t is being e m p l o y e d in t h e o r e t i c a l

s t u d i e s to i m p r o v e the design of p r e s s u r e containing s t r u c t u r e s . The.,~e s t u d i e s take into account

long t e r m c r e e p b e h a v i o u r at e l e v a t e d t e m p e r a t u r e s as well as sho:ct t e r m and c y c l i c e l a s t i c /

plastic considerations. Through these efforts

solutions f o r s y m m e t r i c a l a t t a c h m e n t s a r e b e c o m i n g a v a i l a b l e . It w il l, h o w e v e r , be s o m e t i m e

b e f o r e a s y m m e t r i c p r o b l e m s can be solved.

Detailed experimental results are, therefore,

r e q u i r e d f o r two m a i n r e a s o n s :

1) V e r i f i c a t i o n of t h e o r e t i c a l solutions.

2) P r e d i c t i o n of the b e h a v i o u r of t y p i c a l c o m p o nents which cannot at p r e s e n t be t h e o r e t i c a l l y

an al y sed , a s s i s t i n g both d e s i g n e r s of future

plant and o p e r a t o r s of e x i s t i n g plant.

In o r d e r to obtain a m a x i m u m amount of i n f o r mation with r e s p e c t to t h e s e r e q u i r e m e n t s , a

s e r i e s of t e s t s has been i n i t i a t e d to i n v e s t i g a t e

both s h o r t and long t e r m b e h a v i o u r of t y p i cal

n o z z l e / s h e l l i n t e r s e c t i o n s . Two d e s i g n s r e p r e s e n t a t i v e of e x i s t i n g plant, and a t h i r d design,

n o m i n a l l y p r e s s u r e s t r e n g t h , to p r o v i d e a datum

and an indication of v e r y high s t r a i n b e h a v i o u r

a r e b ei n g t e s t e d . F r o m each design, one n o z z l e

is mounted r a d i a l l y and a second at 45 obliquity.

Although the v e s s e l and n o z z l e s r e p r e s e n t c u r r e n t r e a c t o r v e s s e l s i z e s , the r e s u l t s a r e , of

c o u r s e , applicable to o t h e r t y p e s of v e s s e l s .

The f i r s t t e s t of the s e r i e s was d e s i g n e d

p r i m a r i l y to i n v e s t i g a t e s h o r t t e r m e l a s t i c / p l a s t i c b e h a v i o u r , with p a r t i c u l a r attention being

paid to shakedown e f f e c t s and the e x t e n s i o n of

s t r e s s d i e - a w a y as p l a c t i c i t y p r o c e e d s . A l so ,

74

E. PROCTER and R. F. FLINDERS

since v i r t u a l l y no e x p e r i m e n t a l data is available

for single through n o z z l e s with p a r t i a l p e n e t r a tion welds, a full e l a s t i c s t r e s s a n a l y s i s has

been c a r r i e d out. Special attention was paid to

the d i s t r i b u t i o n of s t r e s s in the shell plate a d j a cent to a r a d i a l l y mounted nozzle. This p a r t of

the work is d e s c r i b e d in this r e p o r t .

2. DESCRIPTION OF TEST VESSEL AND

NOZZLES

2.1. Materials

The behaviour of the v e s s e l beyond y i e l d is

influenced by the p h y s i c a l p r o p e r t i e s of the m a t e r i a l s as well as component g e o m e t r y . If comp a r i s o n s a r e to be made with the full size prototype it is d e s i r a b l e to obtain c o r r e c t r e l a t i o n s h i p

between the v a r i o u s m a t e r i a l s , i . e . , shell plate,

nozzle forgings and deposited weld. In the case

of i n v e s t i g a t i o n s into creep behaviour this r e l a tionship is also d e s i r a b l e , together with the

ability to a c c u m u l a t e c r e e p s t r a i n in r e a s o n a b l y

short test d u r a t i o n s .

The m a t e r i a l chosen for the t e s t p l a t e s was

b o i l e r plate to BS 1501(1958)-161-C and for the

n o z z l e s , forged b a r to BS 1503(1958)-161-B.

Standard t e n s i l e s t r e n g t h r e q u i r e m e n t s for both

these m a t e r i a l s a r e 28 t s i rain., 32 t s i max.

Yield s t r e s s r e q u i r e m e n t s are b a s e d on m i n i m u m

v a l u e s only, 15 t s i for the plate m a t e r i a l and

14 t s i for forged b a r . To obtain s i m i l a r i t y of

p h y s i c a l p r o p e r t i e s in the t e s t v e s s e l an upper

l i m i t of 18 tsi was specified for both plate and

forged m a t e r i a l s .

The m a n u f a c t u r e r s ' a n a l y s i s for the two m a t e r i a l s was as given in table 1.

Table 1

C

Si

S

Ph

Mn

Ni

Cr

Mo

Cu

YP

UTS

Elongation

Reduction

of area

Plate

to BS1501(1958)161-C

Forged bar

to BS1503(1958)161-B

0.22%

0.2%

0.02%

0.024%

0.78%

0.1%

0.08%

0.01%

0.12%

17.7 tsi

31.4 tsi

24% on 8 in.

gauge length

0.21%

0.233%

0.038%

0.028%

0.72%

17.15 tsi

31.9 tsi

35~0 on 4~A

61%

2.2. Nozzle weld procedures

To obtain r e a s o n a b l e r e p r e s e n t a t i o n of the

nozzle welds on the model to those on full size

v e s s e l s , suitable weld p r o c e d u r e s had to be

developed. P r e l i m i n a r y work was c a r r i e d out at

the C . E . G . B . ' s N.W. Region R. & D. Department,

u s i n g flat plates with edge p r e p a r a t i o n s r e p r e sentative of the v a r i o u s weld conditions. As a

r e s u l t of this work, tentative weld p r o c e d u r e s

were suggested to the v e s s e l m a n u f a c t u r e r .

The m a n u f a c t u r e r s s u b m i t t e d s e c t i o n s through

at least one each of the oblique n o z z l e s , to show

that the specified r e q u i r e m e n t s could be met.

P a r t i c u l a r attention was paid to the h a r d n e s s and

width of heat affected zones, the h a r d n e s s of the

deposited weld m a t e r i a l and the a n g u l a r t o l e r ances.

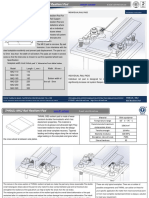

2.3. Manufacture

The n o z z l e s were positioned in the v e s s e l

such that e l a s t i c s t r e s s i n t e r f e r e n c e between

n o z z l e s was nil. Nozzle s e c t i o n s a r e shown in

figs. 1-3.

Fig. 1 shows the thickest p a i r of n o z z l e s fitted

in the v e s s e l . These a r e n o m i n a l l y true to scale

of r e a c t o r v e s s e l standpipe n o z z l e s designed to

BS1500, in which design all r e i n f o r c e m e n t for

the opening in the shell plate is provided by the

nozzle. Fig. 2 shows n o z z l e s r e p r e s e n t a t i v e of

r e a c t o r v e s s e l standpipe a t t a c h m e n t s , designed

to BS1500, but where the whole of the upper p a r t

of the v e s s e l is made in t h i c k e r plate than r e q u i r e d by n o r m a l m e m b r a n e s t r e s s c a l c u l a t i o n s ,

i.e., p a r t r e i n f o r c e m e n t for the openings i s p r o vided by the nozzle and p a r t by the use of thicker

shell plate. Fig. 3 shows the final p a i r of n o z z l e s .

It was d e s i r e d to design these on a p u r e p r e s s u r e

s t r e n g t h b a s i s , i.e., nozzle t h i c k n e s s 0.035 in.

Owing to obvious welding p r o b l e m s the n o z z l e s

were made ~ in. thick. The r a d i a l nozzle is

s l i g h t l y thicker than that r e q u i r e d by BS3915

(t = 0.07 in.) and the oblique nozzle slightly thinn e r (BS3915, t = 0.21 in.).

Care was taken before and d u r i n g m a n u f a c t u r e

to e n s u r e that t o l e r a n c e s would be r e p r e s e n t a t i v e ,

at this scale, of r e a c t o r p r a c t i c e . The development

t e s t s indicated that the angles of the oblique nozzles could be m a i n t a i n e d within +2 . In the t e s t

v e s s e l the m a x i m u m deviation f r o m n o m i n a l was

1. The test plate p r o f i l e was checked by t e m plates. The m a x i m u m deviation f r o m t r u e shape,

m e a s u r e d over a 4 ft chordal length was 0.050 in.,

and over a 1 ft chordal length 0.025 in. These

t o l e r a n c e s a r e well within acceptable l i m i t s ,

even when c o n s i d e r i n g the scale factor. The nozzles were machined to an a c c u r a c y of +0.005 in.

EXPERIMENTAL ELASTIC STRESS ANALYSIS

75

-125~

N O Z Z L E . 2,.

f

"

=oo,,

.328~

&

W

I

,3211"

~]

"687"

/ / ~

2.87

//

NOZZLE

5.

= 0'287

NOZZLE 4,

r",'//i//'///

t/T

~ !:

0-0148

~t=

0,I14

= 0.603

~Di = 0"0148

~"/~i = 0239

Fig. 1. Section through nozzles 1 and 4.

on d i a m e t e r . Two holes, ~ in. d i a m e t e r were

d r i l l e d through each nozzle wall and located b e tween the i n n e r and outer filled welds (see figs.

1-3). These were to f a c i l i t a t e leak t e s t s on the

root r u n s . Any flaw:3 allowing leakage r a t e s

g r e a t e r than 1 cusec', were r e p a i r e d before f u r t h e r welding. After completion, the nozzle welds

were u l t r a s o n i c a l l y e x a m i n e d with the aid of

automatic s c a n n i n g equipment supplied and

o p e r a t e d by p e r s o n n e l f r o m C.E.G.B S.W. Region

R. & D. A t h i c k n e s s s u r v e y on the t e s t plate at

3 in. pitches, indicated t h i c k n e s s v a r i a t i o n s b e tween 1.125 in. and :1.135 in.

Fig. 2. Section through nozzles 2 and 5.

3. INSTRUMENTATION

3.1. Slrain gauges

The s t r a i n gauges used were Budd type HE 121,

having ~ in. gauge length and 120~ n o m i n a l r e s i s t a n c e . L a b o r a t o r y t e s t s d e m o n s t r a t e d these

gauges to be s a t i s f a c t o r y for m e a s u r i n g s t r a i n s

up to at l e a s t 7% when used with Budd type GA 5

adhesive [1].

The total n u m b e r of gauges was r e s t r i c t e d to

400, by the capacity of the r e c o r d i n g equipment.

The m a j o r i t y were fixed on n o z z l e s and s u r rounding plate, in positions chosen to provide

E. PROCTER and R. F. FLINDERS

76

NOZZL__E _3

t/T

- 0"11

L~/D. = 0"0148

~/~( - 0"0434

"125"

"25~

","

Ux

S"

j/

M ~

/ , 4s'~

//

~-~,..~I

NOZZLE 6

~/T

"

%~ =

INSIDE H OOP/CIRC.

X OUTSIDE HOOP/CIRC,

-p

Q O~u'l"SIDE A XlAL/~4EI~I

1 ~

--

"%-/

O'"

0.0,48

2"0

1"O

-I,O

S.C.F.

Fig. 3. Section through n o z z l e s 3 and 6.

LIGHT SOURCE PROJECTING

CROS5 WIRE IMAGE,

OPTICALLY FLAT

MIRROR .~.~ " ~ /

RECTANGULAR SCALE.

Fig. 4. Diagrammaticarrangementof optical lever

system.

Fig. 5. S t r e s s d i s t r i b u t i o n s for radial nozzle (No. 1).

the most economical distribution with due consideration of the information required. Gauges

were provided on both the inner and outer surfaces of the vessel and the nozzles. Since high

strain gradients were expected inside the nozzles, particular care was taken to position

gauges at the expected maximum strain positions. Gauge positions are shown on the stress

plots in figs. 5-7 and 16-18. The gauges were

fixed inside the nozzles by an expanding mandrel

technique [2].

All strain gauges were connected to intermediate junction boxes by light-gauge double

insulated twin core cable. Multi-core cables

were used for the lead outs from these junction

boxes to the permanent strain recording equipment. The multi-core cables from inside the

vessel were brought through rubber packed sealing glands [3] in the end flanges of the two I0 in.

bore branches.

T h e v e s s e l w a s to b e p r e s s u r i z e d

EXPERIMENTAL ELASTIC STRESS ANALYSIS

HOOP/CIRC.

INSIDEHOOP/CIRC,

X OUTSIDEHOOP/CIRC.

e OUTSI

INSIDE

DI.~AXIAL/tVlERID.

AXIAL/MERi D.

77

GAUGE6

~+

,.I-

S.C.F_~_

HOOP /CIRC.

't" AXIAL/MERID.

S.C.F'S.

INSIDE HOOP/CIRC.

X OUTSIDEHOOP/CIRC.

1- IN$10E AXlAL/MERID.

-t

S.C.F.

Fig. 6. Stress distributions for radial nozzle (No. 2).

Fig. 7. Stress distributions for radial nozzle (No. 3).

with w a t e r , thus the i n t e r n a l g a u g e s and junction

b o x e s w e r e w a t e r p r o o f e d with a b i t u m a s t i c c o m pound [4].

Since the s t r a i n g a u g e s w e r e all fixed to a

c o m p a r a t i v e l y s m a l l a r e a of the t e s t v e s s e l ,

which i t s e l f was f i l l e d with w a t e r , one c o m p e n sating gauge only was used. This was attached

to a plate of the s a m e m a t e r i a l as the v e s s e l ,

w a t e r p r o o f e d and p l a c e d in a d r u m of w a t e r

a lo n g s i d e the v e s s e l . To p r o v i d e a check on z e r o

gauge d r i f t one f u r t h e r gauge was a t t a c h e d to a

f r e e plate, w a t e r p r o o f e d and p o s i t i o n e d i n s i d e

the v e s s e l and c o n n e c t e d to the r e c o r d i n g equipm e n t t o g e t h e r with the a c t i v e gauges. The r e c o r d i n g eq u i p m en t e m p l o y s a digital v o l t m e t e r

with v i s u a l display and an a s s o c i a t e d p r i n t - o u t

unit.

of each n o z z l e and, to p r o v i d e a datum, to the

c e n t r e of the t e s t plate. Individual p r o j e c t i o n

l a m p s w e r e u s e d to r e f l e c t a c r o s s - w i r e i m a g e

on to s c a l e s a p p r o x i m a t e l y 8 ft below the m i r r o r s , a s shown in fig. 4. Closed c i r c u i t t e l e v i sion was u s e d to p r o v i d e a v i s u a l link between

the t e s t c e l l and c o n t r o l a r e a , thus enabling

n o z z l e r o t a t i o n s to be r e c o r d e d r e m o t e f r o m the

vessel.

3.2. Nozzle deflections

Nozzle r o t a t i o n s o r t il t, r e l a t i v e to the t e s t

p l a t e , w e r e m e a s u r e d by an o p t ic a l l e v e r s y s t e m .

An o p t i cal l y flat m i r r o r was attached to the end

4. T E S T P R O C E D U R E

At z e r o p r e s s u r e all gauges w e r e individually

b a l a n c e d to indicate z e r o output f r o m the wheatstone b r i d g e c i r c u i t . To e l i m i n a t e the p o s s i b i l i t y

of gauge h y s t e r e s i s the v e s s e l was p r e s s u r e

c y c l e d s e v e r a l t i m e s between z e r o and 250 psig.

Gauge r e a d i n g s and n o z z l e c r o s s - w i r e r e a d i n g s

w e r e then r e c o r d e d at 40 p si i n c r e m e n t s f r o m

z e r o p r e s s u r e to 240 p s i g and r e t u r n e d to z e r o .

V e s s e l p r e s s u r e was i n d i cat ed by a s t a n d a r d

10 in. t e s t gauge.

78

E. PROCTER and R. F. FLINDERS

MEAN STRESS.

x\

x.

...e...- - - f

o

l

i

05

Fig. 8. Stress concentration factors inside radial nozzles.

Maximum hoop SCF's

+ Axial SCF's at maximum hoop positions

Q Maximum axial SCF's

,Io

20

.2Is

Fig. 9. Maximum stress concentration factors for shell

plate (radial nozzles).

Q Inside circumferential

Outside circumferential

Inside and outside meridional

5. R E S U L T S

.05

.IO

-15

"20

-;iS

Fig. 10. Equivalent stress ratios. Radial nozzles.

Equivalent stress ratio at maximum axial positions

in nozzle.

Equivalent stress ratio at maximum hoop positions,

maximum stress in nozzle.

Equivalent stress ratio on outer surface of plate at

toe of weld

5.1. Radial nozzle s

R e c o r d e d s t r a i n r e a d i n g s f o r all gauges w e r e

p l o t t ed ag ai n st p r e s s u r e up to 240 p s i g to v e r i f y

l i n e a r i t y . Strain v a l u e s at this p r e s s u r e w e r e

p l o t t ed ag ai n st r e s p e c t i v e gauge p o s i t i o n s and,

f r o m t h e s e g r a p h s , s t r e s s e s c a l c u l a t e d and ex p r e s s e d as s t r e s s c o n c e n t r a t i o n f a c t o r s (SCF)

b a s e d on an e x p e r i m e n t a l s h e l l m e m b r a n e s t r e s s

of 11000 l b / i n , z. Due to the p h y s i c a l s i z e of the

s t r a i n gauges it was not p o s s i b l e to position the

gauge g r i d c e n t r e s c l o s e r than 0.15 in. to the

w e l d / s h e l l plate i n t e r s e c t i o n , i . e . , the f i l l e t weld

toe. Consequently the c u r v e s for s t r a i n d i s t r i b u tion along the plate w e r e extended to the weld toe

position. The ' e x t r a p o l a t e d ' v a l u e s w e r e u s e d to

c a l c u l a t e s t r e s s e s at t h e s e points.

The c a l c u l a t e d S C F ' s a r e shown p l o t t ed r e l a tive to p o s i t i o n s in f i g s. 5-7. Fig. 8 shows the

m a x i m u m hoop and c o r r e s p o n d i n g axial s t r e s s e s

and m a x i m u m ax i al and c o r r e s p o n d i n g hoop

s t r e s s e s i n s i d e the n o z z l e s , plotted as S C F ' s

ag ai n st the r a t i o of n o z z l e t h i c k n e s s to i n t e r n a l

d i a m e t e r , i . e . , t / d i. The c u r v e showing hoop

s t r e s s e s has b e e n extended on the a s s u m p t i o n of

E X P E R I M E N T A L ELASTIC STRESS ANALYSIS

79

KEY :G&IJGES.

HOOP/CIRC.

AXIAL / MERID.

[] 4 5

s,(;,~s.

x

+

O

~,

[]

INSIDE H O O P / C I R C

OUTSIDE H O O P ] C I I

INSIDE AX/AL~ME

OUTSIDE A X I A L I M |

I NSIDE MAX. PRINq

OUTSIDE MAX. PRIN

INSIDE M I N . PRII~

OUTSIDE M I N . PRIN

O

f

\

2

SC.F.

/J \

i

SECTION

O

S.C.F.

A-A

F i g . 11. S t r e s s d i s t r i b u t i o n s f o r o b l i q u e n o z z l e no. 4.

-I

80

E. P R O C T E R and R. F. F L I N D E R S

.KEY :GAUGES

HOOP/CIRC.

+ AXIAL / MERID.

oi

D 45

S,~.F'S,

INSIDE H O O P I C I R C .

x OUTSIDE HOOP~ClRC.

+ INSIDE AXlALIMERID.

O OUTSIDE A X I A L I MERID.

I NSIDE M A X . PRINCIPAL.

OUTSIDE MAX. PRINCIPAL.

~. INSIDE M I N . PRINCIPAL,

D OUTSIDE MIN. PRINCIPAL.

1k

i

/~ll,

2

-I

S. C.F.

21

0

i

I

SEC TION

A'A

0

S.C.F.

F i g . 12. S t r e s s d i s t r i b u t i o n s f o r o b l i q u e n o z z l e no. 5.

-I

E X P E R I M E N T A L ELASTIC STRESS ANALYSIS

81

KEY:-

~AUGt~S

HOOP / CIRC.

+ AXIAL /MERIDIONAL.

a 45

.s.c.F's.

INSIDE HOOP/CIRC.

x OUTSIDE HOOP/CIRC.

+ I NSIDE A X I A L / M E R I D I O N A L .

O OUTSI[)E A X I A L / M E R I O I O N A L .

INSIDE M A X . PRINCIPAL,

OUTSIDE MAX, PRINCIPAL,

h I N S I D E M t N . PRINCIPAL.

E10UTSIrp E MIN, PRINCIPAL.

I

$ . C . I~

I

S.C. E

U

!

0

S.C.F.

-I

SECTION 'AAI

Fig. 13. S t r e s s d i s t r i b u t i o n s f o r oblique nozzle no. 6.

-I

82

E. PROCTER and R. F. FLINDERS

AXlS'E'

3~:

2.~

I.S

X--AXIS~A * MAX. HOOP S.C,F.IS.

F'I--AXIS'B' MAX. HOOP S.C.F?S.

- - A X I S .~s AXIAL 5.C,F?S. AT MAX. HOOP STRESS POSITIONS.

(~--AXIS ~B* AXIAL S.C,F.~.AT MAX HOOP STRESS POSITIONS.

A --A X IS *C* PRINCIPAL S~'F,~S. HAVING MAX, EOUIVALENT STRESS

VALUE.

"O

IO ' ~ ' t :

.....

"25

"1

Fig. 15a. Maximum c i r c u m f e r e n t i a l and meridional

S C F ' s at toe of welds (oblique nozzles).

(aCA) c i r c u m f e r e n t i a l SCF at A outside vessel

(aCB) c i r c u m f e r e n t i a l SCF at B outside v e s s e l

I.O

" 2 L

(CrMA) m e r i d i o n a l SCF at A outside vessel

+ (OMB) m e r i d i o n a l SCF at B inside vessel

OS

~ "- -

--J'C

'OS

Fig. 14. S t r e s s concentration f a c t o r s inside oblique

nozzles.

x Axis A m a x i m u m hoop S C F ' s

[] Axis B m a x i m u m hoop S C F ' s

Axis A axial SCFTs at m a x i m u m hoop s t r e s s positions

@ Axis B. Axial 8 C F ' s at m a x i m u m hoop s t r e s s p o s i tions

~ Axis C. P r i n c i p a l SCFTs having m a x i m u m equivalent

s t r e s s value

s t r e s s r a t i o s of 2.0 f o r a p l a i n c y l i n d r i c a l o p e n i n g w i t h o u t r e i n f o r c e m e n t , i . e . , t/d i = 0 , a n d 1.0

for full compensation. Similar curves are shown

i n fig. 9 f o r m a x i m u m c i r c u m f e r e n t i a l a n d m e r idional SCF's inside and outside the shell plate.

These curves have also been extended assuming

the mean circumferential and meridional SCF's

to b e 2.0 a n d 0 r e s p e c t i v e l y , f o r a p l a i n c y l i n d r i c a l o p e n i n g w i t h o u t r e i n f o r c e m e n t , i . e . , t/d i =0.

Nozzle thicknesses have been calculated for the

t e s t c a s e a c c o r d i n g to B S 1 5 0 0 a n d B S 3 9 1 5 r e spectively. The thickness/diameter

ratio for

e a c h c a s e i s s h o w n on t h e p l o t s i n f i g s . 8 a n d 9

to i n d i c a t e c o m p a r a t i v e s t r e s s r a t i o s .

Since first yield does not necessarily occur at

" IO

"IS

"~O

.25

Fig. 15b. Maximum c i r c u m f e r e n t i a l and m e r i d i o n a l

S C F ' s at toe of welds (oblique nozzles).

y ((rCc) c i r c u m f e r e n t i a l SCF at C outside vessel

[] ((~CD) c i r c u m f e r e n t i a l SCF at D inside v e s s e l

). ((rMc) m e r i d i o n a l SCF at C outside vessel

((YMD) m e r i d i o n a l SCF at D inside v e s s e l

the maximum stress position, equivalent stress

ratios have been calculated, based on Von Mises

criterion and assuming the third principal stress

t o b e z e r o . T h e s e v a l u e s a r e s h o w n i n fig. 10.

5.2. Oblique nozzles

Strain values were plotted and SCF's calculated on the same basis as the radial nozzles. However, in this case gauge pairs and rosettes could

not be fixed at the same position. Therefore, in

calculating stresses, the strain distributions

w e r e i n t e r p o l a t e d i n o r d e r to o b t a i n t h e s t r a i n

components at the same location.

The calculated SCF's are shown plotted relat i v e t o p o s i t i o n i n f i g s . 1 1 - 1 3 . F i g . 14 s h o w s t h e

EXPERIMENTAL ELASTIC STRESS ANALYSIS

83

IO

INSIDE ~'VI~CI'OR ~ALE

,30

-20

S~:'1.O

Fig. 16. Maximum and minimum SCF's and directions at toe of welds. Oblique nozzles.

O ~PE maximum principal SCF's at : I inside vessel

[] ~PE minimum principal SCF's at

[] (~PF maximum principal SCF's at F t outside vessel

/h ~PF minimum principal SCF's at F

"~"q)

~ B

2

8

0 5

-lO

.I 5

.20

.2S

~;.

Fig. 17. Maxiraum SCF's in shell plate.

ObLique nozzles.

O'PE max.

ffCA y ff CC

ffC B

G ffMA

+ ffM B

~ECrCD see fig. 15

~k a M C

OO-MD

[] (rpE min. see fig. 16

[] (rpF max.

A O'pF rain.

.O5

-IO

-IS

.20

,2S

Fig. 18. Equivalent s t r e s s ratios for oblique nozzles.

X axis A see + position A

[] position E see

see [] position F fig.

G axis B fig. [] position B fig.

axis C 14

position C 15

16

position D

84

E. PROCTER and R. F. FLINDERS

m a x i m u m hoop and c o r r e s p o n d i n g axial S C F ' s

inside the n o z z l e s on axial p l a n e s through the

m a j o r axis of the i n t e r s e c t i o n e l l i p s e , plotted

a ga i n s t t / d i. In addition S C F ' s of m a x i m u m and

m i n i m u m p r i n c i p a l s t r e s s e s on the axis n o r m a l

to the above are shown, t h e s e l a t t e r v a l u e s being

l o c a t e d at the position of m a x i m u m e q u i v a l e n t

s t r e s s . In this c a s e the value f o r the thinnest

n o z z l e t e s t e d is not shown due to the f a i l u r e of a

gauge. F i g s . 15 and 16 show s i m i l a r c u r v e s for

the S C F ' s at the weld t o e s on the i n n e r and o u t e r

s u r f a c e s of the s h e l l plate. In fig. 16 the d i r e c tions of the p r i n c i p a l s t r e s s e s a r e also shown.

To i l l u s t r a t e m o r e c l e a r l y the position of the

absolute m a x i m u m the c u r v e s a r e shown plotted

t o g e t h e r in fig. 17.

The equivalent s t r e s s r a t i o s c a l c u l a t e d f r o m

the above v a l u e s for both n o z z l e s and s h e l l plate

a r e shown in fig. 18.

Nozzle t h i c k n e s s e s have again been c a l c u l a t e d

a c c o r d i n g to BS1500 and BS3915 and t h i c k n e s s

d i a m e t e r r a t i o s shown at the a p p r o p r i a t e v a l u e s

on the above c u r v e s , indicating c o m p a r a t i v e

s t r e s s r a t i o s . In o r d e r to include the value for

BS1500 it was n e c e s s a r y to e x t r a p o l a t e the c u r v e s .

6. DISCUSSION OF R E S U L T S

6.1. Radial n o z z l e s

The m a x i m u m s t r e s s e s o c c u r r i n g at the r a d i a l

n o z z l e s a r e on the o u t e r s u r f a c e of the s h e ll

plate, at the weld toe, in the c i r c u m f e r e n t i a l

d i r e c t i o n . F o r the n o z z l e t e s t e d , the S C F ' s r a n g e

f r o m 1.7 to 1.16 with i n c r e a s i n g n o z z l e t h i c k n e s s .

T h e r e is s o m e bending of the s h e l l plate, howe v e r , which i n c r e a s e s with the r e d u c t i o n in nozzle t h i c k n e s s (fig. 9). M a x i m u m hoop s t r e s s r a tios inside the n o z z l e s r a n g e f r o m 1.61 to 1.03,

i . e . , slightly l o w e r than those in the s h e l l plate

(fig. 8). The m e a n s t r e s s in the plate a p p r o x i m a t e s

to hoop s t r e s s in the n o z z l e at the s m a l l e r t h i c k nesses.

Fig. 5, i l l u s t r a t i n g in s o m e detail the d i s t r i bution of s t r e s s in the s h e l l p l a t e , shows that

the c i r c u m f e r e n t i a l s t r e s s i n c r e a s e s smoothly as

the weld toe is a p p r o a c h e d , while the m e r i d i o n a l

s t r e s s d e c r e a s e s until, at a d i s t a n c e a p p r o x i m ating to nozzle t h i c k n e s s f r o m the weld toe, a

s h a r p i n c r e a s e o c c u r s . Bending s t r e s s in the

m e r i d i o n a l d i r e c t i o n is e l i m i n a t e d at the weld toe.

The S C F ' s shown in figs. 5-7 i l l u s t r a t e that

the m a x i m u m s t r e s s inside each n o z z l e o c c u r s in

the hoop d i r e c t i o n and c o i n c i d e s with the s h e l l

t h i c k n e s s c e n t r e line. The s t r e s s e s die away

r a p i d l y , dependent upon n o z z l e t h i c k n e s s , each

side of the peak. The axial S C F ' s p r o d u c e c u r v e s

peaking at a n u m b e r of points with a m a x i m u m

value which is c o m p r e s s i v e and coincident with

the n o z z l e / w e l d i n t e r f a c e on the outside of the

shell. Whilst the magnitude of m a x i m u m axial

s t r e s s is dependent on both nozzle t h i c k n e s s and

weld p e n e t r a t i o n , i t s position is dependent on

p e n e t r a t i o n only; as the weld a p p r o a c h e s full

p e n e t r a t i o n the m a x i m u m axial s t r e s s will app r o a c h a position coincident with the c e n t r e line

of the plate and m a x i m u m hoop s t r e s s .

The design of n o z z l e s a c c o r d i n g to the two

p r e s s u r e v e s s e l codes w e r e b ased on actual t e s t

plate t h i c k n e s s and ambient t e m p e r a t u r e conditions. The c u r v e s in fig. 9 indicate that the m a x i m u m S C F ' s in the sh el l would be 1.1 for a nozzle d e s i g n e d to BS1500 and 1.86 if d e s i g n e d to

BS3915. Fig. 8 i n d i c a t e s that c o r r e s p o n d i n g

m a x i m u m S C F ' s in the n o z z l e s would be 1.0 and

1.75.

The m a x i m u m SCF v a l u e s for the BS3915 d esign a r e well within the a c c e p t a b l e l i m i t of 2.25

stated in Appendix A of the code. H o w e v e r , f i r s t

y i e l d does not o c c u r at the m a x i m u m s t r e s s position. Fig. 10 c l e a r l y i n d i c a t e s that, b ased on

Von M i s e s c r i t e r i o n , f i r s t y i e l d o c c u r s inside

the nozzle at the m a x i m u m axial s t r e s s position,

i . e . , coincident with the c e n t r e line of the weld

f i l l et .

F o r the BS3915 design the m a x i m u m e q u i v a lent s t r e s s r a t i o is shown, on e x t r a p o l a t i o n , to

be 2.35. Since, in this code, design m e m b r a n e

s t r e s s is b a s e d on 2 uniaxial y i e l d s t r e s s for the

m a t e r i a l the p r e s s u r e to f i r s t y i e l d will be ex c e e d e d 1.57 t i m e s at design p r e s s u r e and 1.96

t i m e s at p r o o f t e s t p r e s s u r e , a s s u m i n g this to

be 1.25 t i m e s the design value. At t e s t p r e s s u r e

the v o l u m e of n o z z l e m a t e r i a l s u b j e c t e d to p l a s t i c

conditions will be l i t t l e m o r e than that contained

within the sh el l p l at e t h i c k n e s s . P l a s t i c s t r e s s e s

in the s h e l l plate will be contained within a c i r c l e ,

i n s c r i b e d f r o m the nozzle c e n t r e of r a d i u s app r o x i m a t i n g to n o z z l e b o r e . The l i m i t i n g f a c t o r

on t h i c k n e s s of r a d i a l n o z z l e s d e s i g n e d to this

code may well be g o v e r n e d by welding t e c h n i q u e s .

F o r i n s t a n c e , at four t i m e s the s i z e of the t e s t

v e s s e l , which c o r r e s p o n d s with e x i s t i n g r e a c t o r

v e s s e l s , a r a d i a l n o z z l e would be of the o r d e r of

0.28 in. thick welded into ~t 4 in. thick sh el l plate.

In the c a s e of BS1500 b a s e d on a design s t r e s s

of U T S / 4 , design p r e s s u r e is of the o r d e r of 0.68

t i m e s p r e s s u r e to f i r s t y i e l d whilst t e s t p r e s s u r e , wMch is 1.5 t i m e s design value, a p p r o x i m a t e s to f i r s t yield.

EXPERIMENTAL ELASTIC STRESS ANALSYSIS

6.2. Oblique nozzles~

In the c a s e of the n o z z l e s mounted at 45

obliquity the m a x i m u m s t r e s s e s o c c u r inside the

n o z z l e s and not on the s h e l l plate, as in the c a s e

of r a d i a l n o z z l e s . T h e s e m a x i m u m s t r e s s e s a r e

in the hoop d i r e c t i o n at p o s i t i o n s coincident with

the c e n t r e of the we].d in the o u t e r obtuse angle.

The S C F ' s ran g e f r o m 2.91 to 2.1 with i n c r e a s i n g

n o z z l e t h i c k n e s s (fi~:. 14). Axial s t r e s s e s in the

n o z z l e s on this and the o th e r axes peak at a n u m b e r of p o s i t i o n s in s i m i l a r m a n n e r to the r a d i a l

c a s e s . The magnitude and position of t h e s e s t r e s s

peaks a r e obviously dependent on n o z z l e t h i c k n e s s

and depth of weld p e n e t r a t i o n .

M a x i m u m s t r e s s e s in the shell plate o c c u r , as

e xpe ct ed , at the weld toes. Fig. 17 i l l u s t r a t e s

that, for v a l u e s of l//di<O.17, t h e s e m a x i m a o c c ur inside the v e s s e l on an axial plane through

the m i n o r axis of the i n t e r s e c t i o n e l l i p s e . F r o m

fig. 16, which shows th e s e p r i n c i p a l s t r e s s r a t i o s

and t h e i r d i r e c t i o n s at t h e s e p o s i ti o n s only, it

can be s e e n that bending in the shell plate is app r e c i a b l e f o r the t h i n n e r n o z z l e s . Since the p r i n c ipa l s t r e s s d i r e c t i o n s change f r o m inside to outside the s h e l l plate, m e a n s t r e s s cannot be dir e c t l y d e t e r m i n e d . H o w e v e r , it is e a s i l y seen

that m e a n s t r e s s will be no g r e a t e r than the c i r c u m f e r e n t i a l s t r e s s e s at the m a j o r axis p o s i t i o n s .

F o r v a l u e s of t / d i > 0 . 1 7 , m a x i m u m S C F ' s o c c u r

in the m e r i d i o n a l d i r e c t i o n at the m a j o r axis posi t i o n s (fig. 17). Fig. 15 shows that the m a x i m u m

s t r e s s d i r e c t i o n s at t h e s e p o s i t i o n s change f r o m

m e r i d i o n a l to c i r c u m f e r e n t i a l for v a l u e s of t / d i <

0.17. Fig. 14 i n d i c a t e s that the absolute m a x i m u m

S C F ' s would be 2.0 f o r a nozzle d e s i g n e d to

BS1500 and 2.7 if d e s i g n e d to BS3915, which is

in e x c e s s of that c o n s i d e r e d as the l i m i t i n g value

in Appendix A of the code, i . e . , 2.25. M a x i m u m

s h e l l plate s t r e s s e s would be 1.4 and 1.89, r e s p e c t i v e l y , as shown in fig. 17.

E q u i v a l e n t s t r e s s r a t i o s inside the n o z z l e s and

on each side of the s h e l l plate, shown in fig. 18

i n d i c a t e s w h e r e f i r s t y i e l d will o c c u r in the v a r ious n o z z l e s . The fact that f i r s t y i e l d does not

n e c e s s a r i l y o c c u r at m a x i m u m s t r e s s p o s i ti o n s

was e n d o r s e d in the l a t e r p l a s t i c t e s t s . F o r a

n o z z l e d e s i g n e d to BS3915 the m a x i m u m e q u i v a lent s t r e s s r a t i o is shown to be a p p r o x i m a t e l y

2.4, thus design and p r o o f t e s t p r e s s u r e s will be

a p p r o x i m a t e l y 1.6 and 2.0 t i m e s the p r e s s u r e to

f i r s t yield, r e s p e c t i v e l y . T h e s e m a x i m u m e q u i v a l e n t s t r e s s e s a r e s i m i l a r to those f o r the r a dial n o z z l e , although in this c a s e the m a x i m u m

SCF is a p p r e c i a b l y l a r g e r . At t e s t p r e s s u r e the

v o l u m e of m a t e r i a l in the nozzle in e x c e s s of

y i e l d point will be th:~t contained within l i n e s

85

drawn, at a d i s t a n c e roughly equal to half the

shell plate t h i c k n e s s , f r o m each side of the sh el l

plate. P l a s t i c i t y in the sh el l plate will 'be contained within a d i s t a n c e a p p r o x i m a t i n g to n o z z l e

r a d i u s f r o m the toe of the weld.

In the c a s e of the BS 1500 design the m a x i m u m

equivalent s t r e s s r a t i o will be of the o r d e r of

2.15, thus design p r e s s u r e will be m a r g i n a l l y in

e x c e s s of f i r s t yield, while proof t e s t p r e s s u r e

will be 1.61 t i m e s that to cause f i r s t yield.

The design of obliquely mounted n o z z l e s is

usually b a s e d on the ' e q u i v a l e n t ' r a d i a l n o z z l e ,

i . e . , oblique nozzle t h i c k n e s s is that c a l c u l a t e d

for a r a d i a l nozzle having a d i a m e t e r equal to

that of the m a j o r axis of the e l l i p s e f o r m e d at

the i n t e r s e c t i o n of the nozzle and sh el l plate.

S t r e s s e s have been cal cu l at ed , by the O ' C o n n e l l

and Chubb [5] method, f o r the r a d i a l n o z z l e

equivalent of the BS3915 oblique design f o r the

t e s t v e s s e l . The m a x i m u m e q u i v a l e n t s t r e s s

r a t i o was shown to be a l m o s t i d e n t i c a l to the

e x p e r i m e n t a l l y obtained value for the oblique

case. This t h e r e f o r e supports the method of

design, by c o n s i d e r i n g the ' e q u i v a l e n t ' r a d i a l

case.

7. CONCLUSIONS

1. Although m a x i m u m s t r e s s e s at r a d i a l nozzle to shell i n t e r s e c t i o n s o c c u r in the s u r r o u n d i n g

sh el l plate, the m a x i m u m equivalent s t r e s s e s ,

b ased on Von M i s e s c r i t e r i o n for yield, o c c u r in

the n o z z l e s at p o si t i o n s coincident with the c e n t r e s

of the weld f i l l e t s . In the oblique n o z z l e to sh el l

i n t e r s e c t i o n s the position of max. s t r e s s and max.

equivalent s t r e s s coincide at t / d i > 0 . ] . This is

on the i n n er s u r f a c e of the nozzle opposite the

outer obtuse weld fillet. F o r thinner n o z z l e s ,

m a x i m u m equivalent s t r e s s o c c u r s on the inner

s u r f a c e of the n o z z l e coincident with the i n n er

obtuse weld f i l l et , although the peak s t r e s s p o s i tion r e m a i n s the s a m e . It has also been d e m o n s t r a t e d that d i f f e r e n t n o z z l e s having si g n i f i can t l y

d i f f er en t S C F ' s can have s i m i l a r m a x i m u m equiv a l e n t s t r e s s r a t i o s . F o r instance in the BS3915

d esi g n s the m a x i m u m equivalent s t r e s s r a t i o s

a r e a p p r o x i m a t e l y 2.4 for both r a d i a l and 45

n o z z l e s while the S C F ' s at the c o r r e s p o n d i n g

p o si t i o n s a r e 1.75 and 2.7 r e s p e c t i v e l y .

These factors provide practical demonstration

of the l i m i t a t i o n s of design methods a c c e p t i n g

p l a s t i c i t y but d e s i g n e d on e l a s t i c a n a l y s i s by

allowing s p e c i f i e d v a l u e s f o r m a x i m u m SCF.

2. F o r both r a d i a l and oblique n o z z l e s d esigned to BS3915 it has been shown that p r o o f

86

E. PROCTER and R. F. FLINDERS

t e s t p r e s s u r e i s of the o r d e r of twice f i r s t yield

p r e s s u r e , although the m a x i m u m S C F ' s a r e app r e c i a b l y different and in the oblique c a s e , the

l i m i t i n g design c o n s i d e r a t i o n is exceeded. Since

the volume of m a t e r i a l subject to p l a s t i c i t y is

c o m p a r a t i v e l y s m a l l , this is quite acceptable by

m o d e r n design s t a n d a r d s for v e s s e l s subjected to

n o r m a l power plant r e q u i r e m e n t s . However,

m o r e c o n s e r v a t i v e design may well be c o n s i d e r e d

n e c e s s a r y for components r e q u i r e d to have long

fatigue life. F u r t h e r , to o v e r c o m e d i s t o r t i o n a l

p r o b l e m s of welding such n o z z l e s into thick shell

plate it may be n e c e s s a r y to i n c r e a s e nozzle

t h i c k n e s s beyond the r e q u i r e m e n t s of BS3915.

3. In view of 1 and 2 above, it is suggested

that the design l i m i t for nozzles should be b a s e d

on a m a x i m u m allowable equivalent s t r e s s , which

o c c u r s inside the nozzle. The acceptable value

may be decided on c o n s i d e r a t i o n of the fatigue

life r e q u i r e m e n t s of the v e s s e l . F o r the avoidance of low cycle fatigue the m a x i m u m allowable

equivalent s t r e s s could be d e t e r m i n e d on the

b a s i s of f i r s t yield p r e s s u r e not exceeding 0.5 x

proof test p r e s s u r e .

Oblique nozzle design, b a s e d on the ' e q u i v a l e n t '

r a d i a l case, a p p e a r s s a t i s f a c t o r y provided it is

b a s e d on m a x i m u m equivalent s t r e s s .

4. At the shell plate s u r f a c e s s u r r o u n d i n g r a dial n o z z l e s , the m e r i d i o n a l s t r e s s e s , which are

n o r m a l l y c o n s i d e r e d to d e c r e a s e as the nozzle

wall is approached, have been shown to i n c r e a s e

n e a r the weld toe to a value approaching the c i r c u m f e r e n t i a l s t r e s s . This c o n f i r m s indications

obtained during r e a c t o r v e s s e l proof t e s t s ,

although it is not shown by s i m p l e thin shell

theories.

5. The m e a s u r e m e n t s of nozzle tilt c o n f i r m

existing i n f o r m a t i o n obtained f r o m e x p e r i m e n t a l

and r e a c t o r v e s s e l s . Although tilt is s m a l l at

design p r e s s u r e s , i.e., l e s s than 10 m i n u t e s of

a r c , its d i r e c t i o n cannot be p r e d i c t e d .

ACKNOWLEDGEMENT

This paper i s published by p e r m i s s i o n of the

C e n t r a l E l e c t r i c i t y G e n e r a t i n g Board.

REFERENCES

[1] A. Grindrod and E. Procter, CEGB Report RD/B/

M.424 (1965).

[2] A. Grindrod and R. P. Fearnley, CEGB Report RD/

B/M.428 (1965).

[3] K. G Mantle and E. Procter, The Engineer 209 (1960)

527.

[4] P. H. R. Lane, The Engineer 204 (1957) 812.

[5] J M. O'Connell and E.J. Chubb, CEGB Report RD/

B/R.585 (1966).

You might also like

- Weld TheoryDocument47 pagesWeld TheoryAndres_Pastor1987No ratings yet

- Leak in Control Rod Drive Mechanism HousingDocument17 pagesLeak in Control Rod Drive Mechanism HousingAndres_Pastor1987No ratings yet

- Experimental Elastic Stress Analysis of Partial Penetration Welded NozzleDocument14 pagesExperimental Elastic Stress Analysis of Partial Penetration Welded NozzleAndres_Pastor1987No ratings yet

- Assessment of Socket Weld Integrity in PipingsDocument30 pagesAssessment of Socket Weld Integrity in PipingsAndres_Pastor1987100% (1)

- BWR Pressure Vessel Cladding Cracking InvestigationDocument18 pagesBWR Pressure Vessel Cladding Cracking InvestigationAndres_Pastor1987No ratings yet

- Weld TheoryDocument47 pagesWeld TheoryAndres_Pastor1987No ratings yet

- WeldingDocument752 pagesWeldingAndres_Pastor1987100% (3)

- Fatigue Testing in Socket WeldsDocument31 pagesFatigue Testing in Socket WeldsAndres_Pastor1987100% (1)

- Effect of Commercial Cladding On The Fracture BehaviorDocument9 pagesEffect of Commercial Cladding On The Fracture BehaviorAndres_Pastor1987No ratings yet

- Thermal and Mechanical Analysis of WeldDocument11 pagesThermal and Mechanical Analysis of WeldAndres_Pastor1987No ratings yet

- Investigations On Partial Penetration Welded NozzleDocument15 pagesInvestigations On Partial Penetration Welded NozzleAndres_Pastor1987No ratings yet

- Reactor Vessel CladdingDocument23 pagesReactor Vessel CladdingAndres_Pastor1987No ratings yet

- BWR Reactor Vessel Bottom Head Failure ModesDocument11 pagesBWR Reactor Vessel Bottom Head Failure ModesAndres_Pastor1987No ratings yet

- Weld DesignDocument2 pagesWeld DesignAndres_Pastor1987No ratings yet

- A Review of Fatigue Failures in LWR Plants in JapanDocument16 pagesA Review of Fatigue Failures in LWR Plants in JapanAndres_Pastor1987No ratings yet

- Manganese Effects 2Document8 pagesManganese Effects 2Andres_Pastor1987No ratings yet

- ASME Code Calculation BMI RepairDocument22 pagesASME Code Calculation BMI RepairAndres_Pastor1987No ratings yet

- BWR Pressure Vessel Cladding Cracking InvestigationDocument18 pagesBWR Pressure Vessel Cladding Cracking InvestigationAndres_Pastor1987No ratings yet

- A Flow-Partitioned Deformation Zone Model For Defect Formation During Friction Stir WeldingDocument5 pagesA Flow-Partitioned Deformation Zone Model For Defect Formation During Friction Stir WeldingAndres_Pastor1987No ratings yet

- Effect of Commercial Cladding On The Fracture BehaviorDocument9 pagesEffect of Commercial Cladding On The Fracture BehaviorAndres_Pastor1987No ratings yet

- Assessment of Socket Weld Integrity in PipingsDocument30 pagesAssessment of Socket Weld Integrity in PipingsAndres_Pastor1987100% (1)

- IAEA 1556 Assessment and Management of Ageing of Major Nuclear Power Plant Components Important To Safety PWR Pressure Vessels 2007 Update PDFDocument215 pagesIAEA 1556 Assessment and Management of Ageing of Major Nuclear Power Plant Components Important To Safety PWR Pressure Vessels 2007 Update PDFAndres_Pastor1987100% (1)

- A Review of Fatigue Failures in LWR Plants in JapanDocument16 pagesA Review of Fatigue Failures in LWR Plants in JapanAndres_Pastor1987No ratings yet

- Manganese EffectsDocument4 pagesManganese EffectsAndres_Pastor1987No ratings yet

- Phase Transformation in MetalDocument492 pagesPhase Transformation in MetalAndres_Pastor1987No ratings yet

- Effects of Manganese in Weld MetalDocument9 pagesEffects of Manganese in Weld MetalAndres_Pastor1987No ratings yet

- IAEA 1556 Assessment and Management of Ageing of Major Nuclear Power Plant Components Important To Safety PWR Pressure Vessels 2007 Update PDFDocument215 pagesIAEA 1556 Assessment and Management of Ageing of Major Nuclear Power Plant Components Important To Safety PWR Pressure Vessels 2007 Update PDFAndres_Pastor1987100% (1)

- Weld Op IDocument110 pagesWeld Op IAndres_Pastor1987No ratings yet

- Welding Inspection - Multiple ChoiseDocument15 pagesWelding Inspection - Multiple ChoiseAndres_Pastor1987No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Struct Bearings and Exp JointsDocument86 pagesStruct Bearings and Exp JointsMongi Ben OuezdouNo ratings yet

- AUC Nov/Dec 2011 & 2012: CE 6702/prestressed Concrete StructuresDocument9 pagesAUC Nov/Dec 2011 & 2012: CE 6702/prestressed Concrete StructuresRashed Bantilan SagkalNo ratings yet

- Hastelloy C-22HS Alloy: Oil & Gas ApplicationsDocument12 pagesHastelloy C-22HS Alloy: Oil & Gas ApplicationsYudha SatriaNo ratings yet

- Bonded Versus Unbonded Strip Fiber Reinforced Elastomeric Isolators Finite Element AnalysisDocument10 pagesBonded Versus Unbonded Strip Fiber Reinforced Elastomeric Isolators Finite Element Analysismtor_scribdNo ratings yet

- Boundary Vlaue Problem Module 4 With Solutions Page 1-20Document20 pagesBoundary Vlaue Problem Module 4 With Solutions Page 1-20maran.suguNo ratings yet

- The Hardening Soil ModelDocument4 pagesThe Hardening Soil Modelmetropodikas100% (2)

- Chpter 4 DesignDocument67 pagesChpter 4 DesignRUPESH VIJAYAKUMARNo ratings yet

- Kirana FinalDocument15 pagesKirana FinalKiran Kumar ShNo ratings yet

- 2012-Fracture Toughness of Friction Hydro-Pillar Processing Welding in C-MN SteelDocument5 pages2012-Fracture Toughness of Friction Hydro-Pillar Processing Welding in C-MN SteelPedro CunhaNo ratings yet

- Design of Machine Elements ME1302 2 Marks QuestionDocument16 pagesDesign of Machine Elements ME1302 2 Marks QuestionPushparaj MariaNo ratings yet

- Concrete Pavement Design Report for VIA FLORIAN RouteDocument3 pagesConcrete Pavement Design Report for VIA FLORIAN RouteDario Solano AngelNo ratings yet

- Crane Rail Pads MK2Document2 pagesCrane Rail Pads MK2Mukty BaktiarNo ratings yet

- Crackwidth (Gergely & Lutz)Document61 pagesCrackwidth (Gergely & Lutz)Medianna Novita100% (1)

- Ch11 TestbankDocument43 pagesCh11 Testbankaylwingolivas132850% (4)

- Transparent Polyamide Product Data BulletinDocument2 pagesTransparent Polyamide Product Data Bulletinrumisethna9135No ratings yet

- Graded Examples in Reinforced Concrete Design DiasDocument118 pagesGraded Examples in Reinforced Concrete Design DiasAmgad Talal92% (13)

- Determination of The Melting Enthalpy of A Pure SubstanceDocument5 pagesDetermination of The Melting Enthalpy of A Pure SubstanceLuis GuevaraNo ratings yet

- Axial Shortening of Columns in Tall BuildingsDocument5 pagesAxial Shortening of Columns in Tall BuildingsAnil kumar RNo ratings yet

- Advanced Transport Phenomena Module 2 Lecture 8Document47 pagesAdvanced Transport Phenomena Module 2 Lecture 8Shiva KumarNo ratings yet

- Properties and Testing of Hardened ConcreteDocument17 pagesProperties and Testing of Hardened ConcreteKannan KandappanNo ratings yet

- LS DYNA Basic CardsDocument30 pagesLS DYNA Basic Cardsmadblaster100% (1)

- Failure MechanismsDocument14 pagesFailure Mechanismsho-faNo ratings yet

- Mechanical and Wear Behavior of AA7075 Aluminum Matrix Composites Reinforced by Al 2 O 3 NanoparticlesDocument9 pagesMechanical and Wear Behavior of AA7075 Aluminum Matrix Composites Reinforced by Al 2 O 3 NanoparticlesARULKUMARSUBRAMANIANNo ratings yet

- CBSE Class 12 Chemistry - Solid State AssignmentDocument13 pagesCBSE Class 12 Chemistry - Solid State AssignmentAbhi RajNo ratings yet

- ITA - AITES WORLD TUNNEL CONGRESS Design Aspects of Fibre Reinforced ShotcreteDocument8 pagesITA - AITES WORLD TUNNEL CONGRESS Design Aspects of Fibre Reinforced ShotcreteJuhász KPNo ratings yet

- Mechanics of SolidsDocument23 pagesMechanics of Solidsarun777999No ratings yet

- Chem Academy: Exercise - IDocument11 pagesChem Academy: Exercise - IHamit RanaNo ratings yet

- Nanoelectromechanical SystemDocument3 pagesNanoelectromechanical SystemelangovanNo ratings yet

- Jian PDFDocument49 pagesJian PDFRicardo Cisneros TamayoNo ratings yet

- ASTM D 4014 3 BearingsDocument7 pagesASTM D 4014 3 Bearingssruthi raniNo ratings yet