Professional Documents

Culture Documents

Motor Cat 3406-E

Uploaded by

carlucido247970Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Motor Cat 3406-E

Uploaded by

carlucido247970Copyright:

Available Formats

Underground

3406E

Mining

ATAAC

360-500 hp

Equipment

CATERPILLAR ENGINE SPECIFICATIONS

In-Line 6 Cylinder, 4-Stroke-Cycle Diesel

Bore in (mm) . . . . . . . . . . . . . . . . . . . . . . 5.4 (137)

Stroke in (mm). . . . . . . . . . . . . . . . . . . . 6.5 (165)

Displacement cu in (L) . . . . . . . . . . . . 893 (14.6)

Aspiration . . . . . . . . . . Turbocharged for ATAAC1

Compression Ratio . . . . . . . . . . . . . . . . . . . . 16.25:1

Rotation (from flywheel end) . . Counterclockwise

Capacity for Liquids U.S. gal (L)

Cooling System2 . . . . . . . . . . . . . . . . . . . 5.5 (20.8)

Lube Oil System (refill). . . . . . . . . . . . . 9.0 (34.1)

Weight, Net Dry (approx) lb (kg)

Including Flywheel . . . . . . . . . . . . . . 2867 (1303)

1

2

Air-to-Air Aftercooling

Engine only. Capacity will vary with radiator size and use of cab

heater.

Shown with

Optional Equipment

FEATURES

FUEL ECONOMY

Consistent performance, variable-timed fuel

injection, broad rpm turbocharger match,

excellent fuel economy over entire

operating range.

High torque rise, big displacement,

convenient installation, more performance

for your money.

WORLDWIDE PRODUCT SUPPORT

AND PARTS AVAILABILITY

ELECTRONICALLY CONTROLLED

RELIABILITY AND DIESEL DURABILITY

Diesel tough components, precise balance,

and conservative speed for smooth

operation and long engine life.

FLEXIBLE APPLICATION RANGE

Provides superior performance, emission

and smoke control; allows system

integration and data management.

STANDARD EQUIPMENT

STANDARD ELECTRONIC FEATURES

Cooling

gear-driven jacket water pump crank pulley

(2 groove V-belt)

Crankcase breather

Flywheel & housing SAE No. 1 (dry)

Fuel

spin-on, high efficiency filter

priming and transfer pumps

Governor

full-range electronic

isochronous PTO mode governing

Lubricating

full flow cooler

right-hand oil filter

left-hand filler and gauge group

gear-driven pump

front sump oil pan

Turbocharger

Vibration damper and pulley

Automatic altitude compensation

Automatic fuel temp power compensation

Electronic data link, ATA/SAE

Electronically controlled unit injector fuel system

Engine diagnostics

Engine monitoring system off, warning, derate,

shutdown

Engine mounted sensors

Fuel cooled Electronic Control Module (ECM)

Programmable low idle & max rpm limit

Service tool interface

(SAE J1708/J1587)

3406E

UNDERGROUND MINING EQUIPMENT 360-500 hp

PERFORMANCE CURVES

Lube system

rear sump

RH & LH gauge and

filler gps

remote mounted oil

filter (SL)

Power take-offs

crank pulley

rear enclosed clutch

Protection system

air shutoff

Starting system

air starting motor

jacket water heater

24V electric starters

Transmission oil

cooler

Rating Curve 500 hp @ 2100 rpm

500

Power

bhp

Air compressors

gear driven 16 or

31 cfm

Alternators and

mounting gps

12V; 115A

24V; 45A, 60A,

100A

Cooling system

coolant conditioner

coolant level sensor

Flywheel and SAE

No.1 or 0

housing

Instrumentation

Engine Monitoring

System (EMS)

digital tach

magnetic pick-up

450

400

350

1300 1400 1500 1600 1700 1800 1900

2000 2100

Engine Speed rpm

Fuel Curve

25

Fuel Rate

gal/hr

ACCESSORY EQUIPMENT

24

23

22

21

20

19

1300 1400 1500 1600 1700 1800 1900

2000 2100

Engine Speed rpm

MSHA CERTIFIED RATINGS

hp

kW

Vent Rate

rpm

500

373

2100

24 000

48

500

373

2100

12 500

25

490

365

2000

22 000

45

490

365

2000

10 500

21

cfm

cfm/hp

hp

kW

Particulate Index

rpm

cfm

cfm/hp

475

354

2100

22 000

46

475

354

2100

13 000

27

450

336

2100

21 000

47

450

336

2100

12 000

27

425

317

2100

20 000

47

425

317

2100

12 000

28

400

298

2100

18 500

46

400

298

2100

13 000

33

360

268

2100

17 000

47

360

268

2100

14 000

39

Emissions information: MSHA Cert. # 7E-B018-0

Smoke: less than 4% opacity at all operating conditions

RATING & APPLICATION INFORMATION

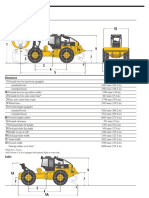

DIMENSIONS

49.75 in.

1264 mm

32.76 in.

832 mm

40 in.

1016 mm

18.83 in.

402 mm

Aftercooler Type . . . . . . . . . . . . . . . . . . . . Air-To-Air

Altitude, Max Operating . . . . . . . . . . . . . . . . 7000 ft

Application, Engine . . . . . . . . . . . . . . . . UG Mining

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TA

Smoke Opacity . . . . . . . . . . . . . . . . . . . . . . . . . < 4%*

Combustion Sys. Type. . . . . . . . . . . . . . . . . . . . . . DI

Duty Type . . . . . . . . . . . . . . . . . . . . . Mining Vehicle

Exhaust Manifold Type . . . . . . . . . . . . . . . . . . . . Dry

Governor Type . . . . . . . . . . . . . . . . . . . . . Electronic

* Smoke less than 4% opacity under all operating conditions.

RATING DEFINITIONS AND CONDITIONS

Ratings are based on SAE J1349 standard

conditions of 29.61 in Hg (100 kPa) and 77 F

(25 C). These ratings also apply at DIN6270

standard conditions of 28.97 in Hg (97.8 kPa)

and 68 F (20 C).

Fuel rates are based on power requirements

of fuel oil having an HHV of 19 590 Btu/Ib

(45 570 kJ/kg) and weighing 7.076 Ib/U.S. gal

(848 g/liter).

Materials and specifications are subject to change without notice.

LEHH8422-02

Printed in U.S.A.

The International System of Units (SI) is used in this publication.

1998 Caterpillar Inc.

All rights reserved.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Service Manual Cummins Mercruiser QSD 2.8 4.2 47 SM 08390Document839 pagesService Manual Cummins Mercruiser QSD 2.8 4.2 47 SM 08390Per Østbø100% (3)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Renault Midlum Truck Engine Workshop ManualDocument15 pagesRenault Midlum Truck Engine Workshop Manualsen til57% (7)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Om444la Spec Sheet AbbyDocument4 pagesOm444la Spec Sheet Abbysxturbo60% (5)

- Motor Cat C7-AcertDocument2 pagesMotor Cat C7-Acertcarlucido247970100% (2)

- Competence 8 Oic-Ew ReviewerDocument16 pagesCompetence 8 Oic-Ew ReviewerCristine Ann Javier100% (1)

- DW 10 TDDocument152 pagesDW 10 TDAgustin SanchezNo ratings yet

- 793B V.S. 793CDocument6 pages793B V.S. 793Ccarlucido247970100% (1)

- Neumáticos Michelin 44-80r57Document4 pagesNeumáticos Michelin 44-80r57carlucido247970No ratings yet

- Garlock Blue Gard 3000 Data SheetDocument1 pageGarlock Blue Gard 3000 Data SheetMatheus TorresNo ratings yet

- Dimensions: GrappleDocument3 pagesDimensions: Grapplecarlucido247970No ratings yet

- Neumáticos Michelin XDRDocument2 pagesNeumáticos Michelin XDRcarlucido247970No ratings yet

- Luces de Camiones CatDocument6 pagesLuces de Camiones Catcarlucido247970No ratings yet

- Dimensions: GrappleDocument3 pagesDimensions: Grapplecarlucido247970No ratings yet

- Salesgram: New Caterpillar 793C Modular Front EndDocument2 pagesSalesgram: New Caterpillar 793C Modular Front Endcarlucido247970No ratings yet

- G3304Document8 pagesG3304carlucido247970No ratings yet

- Motor Cat C9-AcertDocument4 pagesMotor Cat C9-Acertcarlucido247970100% (1)

- Cat DEO: Caterpillar. The Difference CountsDocument2 pagesCat DEO: Caterpillar. The Difference CountsMinaSaeedNo ratings yet

- G3306Document4 pagesG3306carlucido247970100% (1)

- G3304BDocument2 pagesG3304Bcarlucido247970No ratings yet

- Generador Cat 3512bDocument4 pagesGenerador Cat 3512bcarlucido247970No ratings yet

- CuadrosDocument1 pageCuadroscarlucido247970No ratings yet

- IT14GDocument20 pagesIT14GBilal VURALNo ratings yet

- Gas Engines PortfolioDocument41 pagesGas Engines PortfolioAnonymous alQXB11EgQ100% (1)

- All Papers of Thermodyanmics and Heat TransferDocument19 pagesAll Papers of Thermodyanmics and Heat TransfervismayluhadiyaNo ratings yet

- Lea Dardanos Efi-Controller eDocument6 pagesLea Dardanos Efi-Controller eadfumegaNo ratings yet

- 4008tag2a Tsl4184e PDFDocument59 pages4008tag2a Tsl4184e PDFMd Sh100% (1)

- Marine Diesel Engine Lubricating Oil SystemDocument8 pagesMarine Diesel Engine Lubricating Oil SystemAhmed SalemNo ratings yet

- Mitsubishi Selfjector Hercules Series Oil Purifier Locations and SpecsDocument8 pagesMitsubishi Selfjector Hercules Series Oil Purifier Locations and SpecsPutra SeptiadyNo ratings yet

- Condition Based MaintenanceDocument62 pagesCondition Based Maintenanceanurag dimriNo ratings yet

- CPS 185 KD IT4 Compressor Flyer 71414 - HirezDocument2 pagesCPS 185 KD IT4 Compressor Flyer 71414 - HirezmoisesNo ratings yet

- BB. Docking Indent (Repair) Pioneer. 13th Feb.20Document11 pagesBB. Docking Indent (Repair) Pioneer. 13th Feb.20Thiet PhamNo ratings yet

- JCB Forklift 940Document8 pagesJCB Forklift 940MARK NelsonNo ratings yet

- Catalogo AstronicDocument20 pagesCatalogo Astronichapem4No ratings yet

- 20 C32 1000 KW 480VDocument6 pages20 C32 1000 KW 480VDIEGO PEÑALOZANo ratings yet

- Engine Diesel PerfomanceDocument32 pagesEngine Diesel PerfomancerizalNo ratings yet

- Touran Brochure PDFDocument31 pagesTouran Brochure PDFJohn MarkNo ratings yet

- DPF BMW InfoDocument3 pagesDPF BMW Infor0my81No ratings yet

- Tds Navigo MCL enDocument2 pagesTds Navigo MCL enjbaquerizo31No ratings yet

- TCS PTG Savings With Extra PowerDocument9 pagesTCS PTG Savings With Extra PowerAnastas YangyozovNo ratings yet

- Model Boats September 2013Document84 pagesModel Boats September 2013Eng_201491% (11)

- Diesel Generator Sets Inventory ListingDocument4 pagesDiesel Generator Sets Inventory ListingIvan DumontNo ratings yet

- ABBREVIATIONSDocument27 pagesABBREVIATIONSTiago CarrilhoNo ratings yet

- 4BTAA3.3-G12: EPA Tier 3 CertifiedDocument3 pages4BTAA3.3-G12: EPA Tier 3 CertifiedLawternay Stevaneli BritoNo ratings yet

- Factory Acceptance Test and Shipboard Trials of I.C. EnginesDocument5 pagesFactory Acceptance Test and Shipboard Trials of I.C. Enginessaeed ghafooriNo ratings yet

- B9R RangeDocument9 pagesB9R RangePhilippine Bus Enthusiasts SocietyNo ratings yet

- Duty Template June 2016Document87 pagesDuty Template June 2016debo araromNo ratings yet